Anomaly Edge Effects in Thermographic Nondestructive

Testing of Polymeric Composite Sandwich Panels

by

Anton F. Thomas

B.S., Mechanical Engineering (1999) Florida Agricultural & Mechanical University Submitted to the Department of Mechanical Engineering in Partial Fulfillment of the Requirements for the Degree of

Master of Science in Mechanical Engineering at the

Massachusetts Institute of Technology June 2002

© 2002 Massachusetts Institute of Technology All rights reserved

Signature of Author Certified by P A 9 K77 MASSACHUSETTS INSTITUTE OF TECHNOLOGY

OCT 25 2002

LIBRARIES

Department of Mechanical Engineering May 8, 2002 James H. Williams, Jr. Professor of Engineering Thesis Supervisor Accepted by Ain A. Sonin Chairman, Department Committee on Graduate Students

Anomaly Edge Effects in Thermographic Nondestructive

Testing of Polymeric Composite Sandwich Panels

by

Anton F. Thomas

Submitted to the Department of Mechanical Engineering

on May 8, 2002 in Partial Fulfillment of the Requirements for the Degree of Master of Science in Mechanical Engineering

ABSTRACT

A two-dimensional thermographic nondestructive testing (NDT) model of a polymeric composite sandwich panel containing a planar anomaly within its core is presented, and its surface temperature distributions in the vicinity of its thermographic transition zone are obtained via the finite element method. A characteristic length of the surface temperature transition zone is defined for anomalies that can be modeled as semi-infinitely long. The effect on the characteristic length of varying the geometrical and thermal anomaly parameters is investigated numerically. Thermographic NDT procedures are devised to characterize the geometrical and thermal parameters of the anomaly.

Thesis Supervisor: James H. Williams, Jr.

ACKNOWLEDGMENTS

First of all, I would like to thank God for a continual renewal of strength, direction, and purpose especially during the dark, discouraging times. Thank you for keeping promises.

To my advisor and mentor, Professor James H. Williams, Jr., whose unwavering support, encouragement, patience, and advice have kept me focused on a promising future, thank-you very much.

To Professor Liang-Wu Cai, whose technical assistance was invaluable in the shaping of this thesis, thank-you.

To Dr. Yapa D. S. Rajapakse of the Office of Naval Research, who supported this research, thank-you.

To the 3M Company and the Graduate Student Office, whose financial support allow me to pursue my educational and professional goals, thank-you.

To my family and friends, whose constant well wishes, words of encouragement, and prayers helped keep me in good spirits, thank-you.

To my daughter, Ayren Joi, whose giggles and smiles of pure love helped me to place stress in its proper place, thank-you. Daddy loves you.

And to my cornerstone, my earth, my joy and indeed my wife, Jocelyn, whose love is my foundation, whose strength is my solid ground and whose beauty is my peace, thank-you for being my partner and complementing my weaknesses. I love you very much.

TABLE OF CONTENTS

Page

A b stract... 2

A cknow ledgm ents... 3

T able of C ontents... 5

N om enclature... 7

L ist of F igures... 9

Introdu ction ... 12

Heat Transfer in Sandwich Panels... 14

Problem D efinition... 14

Nondimensional Parameters... 17

M aterial Properties... 19

Finite Length Anomalies... 20

Semi-Infinitely Long Anomalies... 24

Characteristic Length of Transition Zone... 24

Effects of Biot Numbers on Characteristic Length... 24

Effects of Anomaly Geometry on Characteristic Length... 26

Effects of Fourier Number on the Transient Characteristic Length... 28

Proposed Measurement and Data Processing... 31

C on clu sion s... 3 5 R eferen ces... 36 F ig ures... .... 3 8

TABLE OF CONTENTS (cont.)

Page Table 1

Sandwich panel constituents and anomaly thermal properties at 348'K (167'F)... 49

APPENDIX A Finite Element Equations for the Analysis of Two-Dimensional Heat Transfer... 50

Matrix Notation of Interpolation Functions... 50

Steady-State Heat Transfer Equilibrium... 51

Transient Heat Transfer Equilibrium... 52

Two-Dimensional Four-Node Quadrilateral Elements... 54

Two-Dimensional Nine-Node Quadrilateral Elements... 56

APPENDIX B Verification and Error Analysis of the Finite Element Solution... 61

E xam ple D ata... 61

Finite Element Mesh... 62

Comparison with the One-dimensional Solution... 63

Convergence of Characteristic Length... 64

C onclusions... 66

APPENDIX C Development of Nondimensional Parameters... 76

NOMENCLATURE Latin

Bil Biot number on front surface

BiN Blot number on back surface

da thickness of anomaly

Da depth of anomaly

dc thickness of core

d, thickness of face sheet Fo Fourier number

h, heat transfer coefficient on front surface

hN heat transfer coefficient on back surface

ka thermal conductivity of anomaly kc thermal conductivity of core

k, thermal conductivity of face sheet

La length of anomaly

Lra minimum detectable anomaly length

minimum anomaly length required to approximate the temperature distribution due to an anomaly of infinite length

T temperature

ambient temperature

x axis parallel to thickness of sandwich panel

xi through-thickness locations

y axis parallel to surface of sandwich panel Greek

aa thermal diffusivity of anomaly

ac thermal diffusivity of core a, thermal diffusivity of face sheet $8, thermal resistance of region I

)6, thermal resistance of region II

A,8 deviation of thermal resistance of region II compared to region I S experimental detection resolution

tolerance associated with relative temperature contrast

O temperature distribution throughout sandwich panel (rise above ambient)

OF temperature distribution on front surface OB temperature distribution on back surface

NOMENCLATURE (cont.)

F* normalized temperature distribution on front surface B* normalized temperature distribution on back surface 61 one-dimensional steady-state temperature in region I

E), one-dimensional steady-state temperature in region II A characteristic length of transition zone

TI characteristic time in region I Ti, characteristic time in region 11

LIST OF FIGURES

Figure Page

1 Mathematical model of a portion of a sandwich panel containing an 38 anomaly.

2 (a) Normalized front surface temperature distribution for case one 39 (air void), when the anomaly thickness is 10 mm (0.4 in.), located

at the mid-thickness of the panel, and the normalized anomaly length, La / de, is varied. (b) Based upon the experimental detection resolution, 8, a schematic of limiting anomaly lengths, Lmi and Lo,

are shown.

3 Given the detection resolution 5 = 0.02, the minimum detectable 40 anomaly length, La, normalized by the core thickness, dc, is

plotted as a function of anomaly geometry for cases one and two.

4 Given the detection resolution 5 = 0.02, the minimum anomaly 41 length required to approximate an anomaly of semi-infinite length,

L, normalized by core thickness, dc, is plotted as a function of anomaly geometry for cases one and two.

5 Schematic of the characteristic length, A, of the surface 42 temperature transition zone normalized by the core thickness, dc,

given a tolerance, e = 0.05.

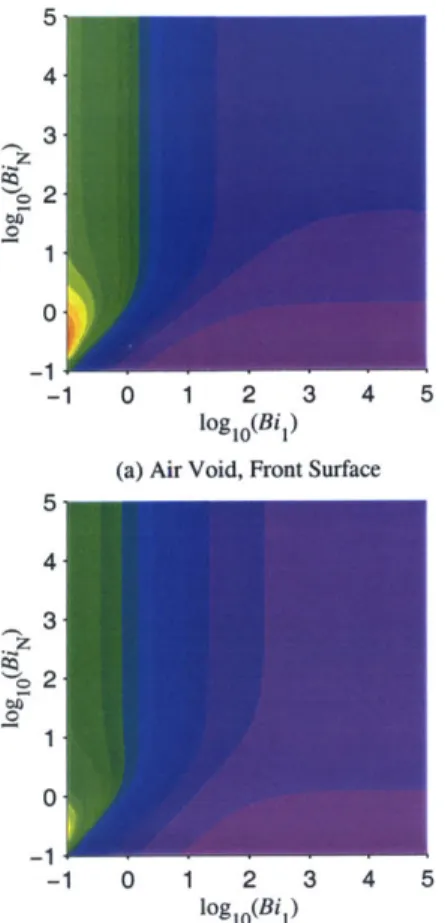

6 Steady-state normalized characteristic length for cases one and two 43 as a function of front and back Biot numbers, Bi, and BiN ,

respectively; where, for both cases the anomaly is 10 mm (0.4 in.) thick and located at the mid-thickness of the core.

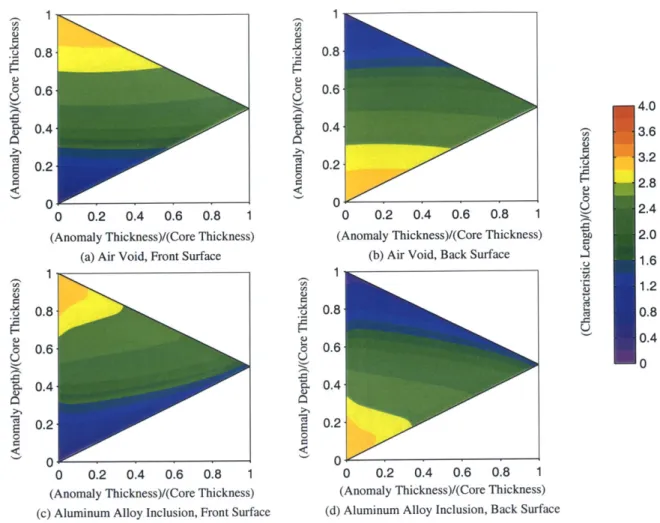

7 Steady-state characteristic length as a function of anomaly 44

geometry for cases one and two.

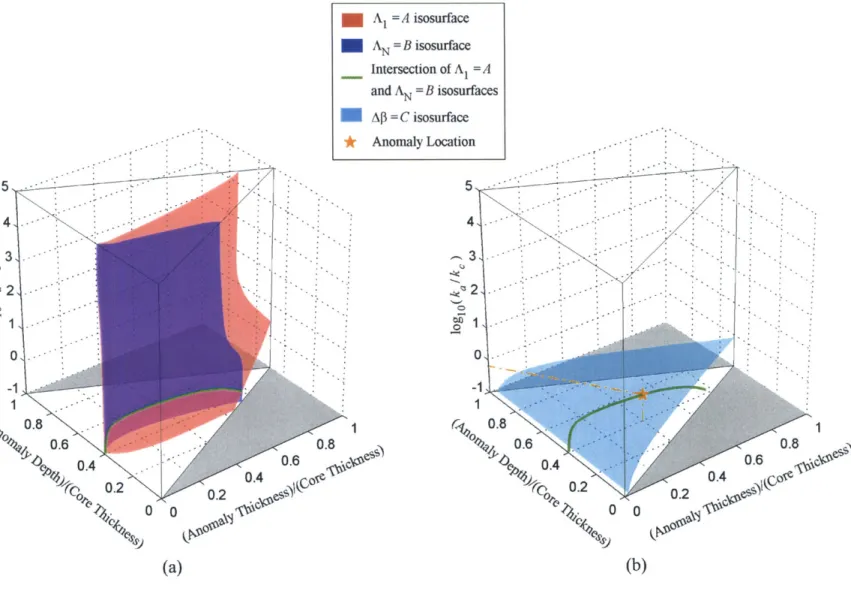

8 (a) Given measurements A1 = A and AN = B for the front and back 45

steady-state characteristic lengths, respectively, the intersection of the corresponding isosurfaces is shown. (b) The intersection of a third isosurface, A/I= C, reveals the anomaly geometry and thermal conductivity.

LIST OF FIGURES (cont.)

Figure Page

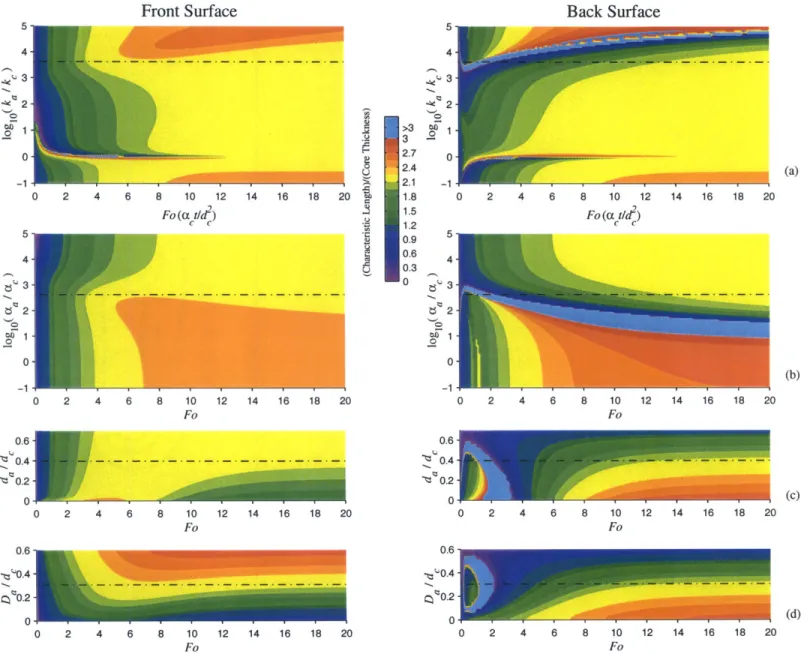

9 Characteristic length histories for case one, where the anomaly is 46 10 mm (0.4 in.) thick and located at the mid-thickness of the panel.

The front surface is heated continuously and one of the anomaly's parameter is varied. (a) Thermal conductivity ka is varied. (b) Thermal diffusivity aa is varied. (c) Thickness da is varied. (d) Depth Da is varied. The dashed black lines represent the characteristic length history of case one with no variation of parameters.

10 Characteristic length histories for case two, where the anomaly is 47 10 mm (0.4 in.) thick and located at the mid-thickness of the panel.

The front surface is heated continuously and one of the anomaly's parameter is varied. (a) Thermal conductivity ka is varied. (b) Thermal diffusivity aa is varied. (c) Thickness da is varied. (d) Depth Da is varied. The dashed black lines represent the characteristic length history of case two with no variation of parameters.

11 Transient-state characteristic length, normalized by core thickness, 48 evaluated at the corresponding region II characteristic time.

A. 1 Schematic of two-dimensional four-node quadrilateral element. 54

A.2 Schematic of two-dimensional nine-node quadrilateral element. 55 B. 1 Steady-state solution of the finite element model of case one using 67

four-node element.

B.2 Steady-state solution of the finite element model of case one using 68 nine-node element.

B.3 Steady-state solution of the finite element model of case two using 69 four-node element.

LIST OF FIGURES (cont.)

Figure

B.4 Steady-state solution of the finite element model of case two using nine-node element.

B.5 Transient solution for the front surface using four-node elements for

case one

B.6 Transient solution for the back surface using four-node elements for

case one.

B.7 Transient solution for the front surface using four-node elements for

case two.

B.8 Transient solution for the back surface using four-node elements for

case two.

B.9 Transient solution for the front surface using nine-node elements

for case one.

B.10 Transient solution for the back surface using nine-node elements for

case one.

B.11 Transient solution for the front surface using nine-node elements

for case two.

B.12 Transient solution for the back surface using nine-node elements for

case two.

B.13 Steady-state characteristic length convergence for case one. B.14 Steady-state characteristic length convergence for case two.

70 71 71 72 72 73 73 74 74 75 75 Page

INTRODUCTION

Sandwich panels comprise a class of engineering structural materials in which the inner core is generally thicker and more flexible than the outer face sheets. By separating the stiffer face sheets with a relatively low density and thicker core, sandwich construction is capable of achieving high structural efficiencies. However, sandwich panels may experience adverse effects such as strength and stiffness deterioration when

anomalies such as delaminations, inclusions or voids exist within the panel. To detect these anomalies, thermographic nondestructive testing (NDT) can be used. Due to the alteration of heat flow by the embedded anomaly, surface temperature variations can be observed. These observations can be used to identify the geometric and thermophysical properties of the anomaly.

Thermographic NDT of sandwich panels have been studied experimentally (Qin and Bao, 1996; d'Ambrosio et. al, 1995; Vickstrum, 1991; Vickstr6m, et. al, 1989) and a few analytical models of multi-layer heat transfer problems have been analyzed (Williams et. al, 1980; Williams, 1981; Williams and Lee, 1982; Williams et. al, 1983; Williams and Nagem, 1983; Mikhalov and Ozisik, 1984; Vavilov and Finkel'shtein, 1986). The one-dimensional transient and steady-state heat transfer through a polymeric sandwich panel containing a planar anomaly was investigated by Cai et. al (2001). A thermographic NDT procedure was proposed to characterize such anomalies; however, access to both front and back surfaces of the sandwich panel was required.

To circumvent the limitations of the NDT procedure proposed in the previous paper, two-dimensional heat transfer is considered. The applicability of the one-dimensional solution to the two-dimensional model is studied. Of primary interest is the surface

temperature transition in the vicinity of the edge of an embedded anomaly, which can be described as a thermographic halo. A measurable length parameter characterizing this surface temperature transition is defined in order to develop alternative NDT procedures.

HEAT TRANSFER IN SANDWICH PANELS

Problem Definition

A sandwich panel containing a planar anomaly is modeled as a multi-layer structure as illustrated in Figure 1. The region of the sandwich panel that is free from damage, denoted as region I, consists of a thicker core bonded between two identical face sheets. The damaged region, denoted as region II, contains an additional planar anomaly, either a void or inclusion, embedded within the core. In this model, the x and y axes define the thickness and length directions, respectively, where x = x defines the front surface of the panel, y = 0 defines the mid-length of the embedded anomaly, and x2 through x6

define other through-thickness locations. Significant thicknesses are denoted by d,, de, and d,; thermal conductivities are denoted by k,, ke, and k,; and thermal diffusivities are denoted by a, a, and a,; where the subscripts s, c, or a, designate the parameters of the face sheet, core, and anomaly, respectively. Additionally, the depth of the anomaly Da is measured from the back of the front face sheet to its mid-thickness; and the length of the anomaly is defined as La Due to symmetry about the anomaly mid-length, y = 0, there is no heat transfer across this symmetry line; hence, only an upper portion of the panel is considered and an adiabatic boundary condition is defined along the symmetry line.

Initially, the temperature throughout the panel, T(x, y, t), is uniform at the ambient temperature T. At time t = 0, a uniform and constant heat flux q" is applied to the front

The heat transfer coefficients on the front and back surfaces are hiand hN respectively.

The governing equation throughout each constituent material is given by (Arpaci, 1966)

D2

0 (x, y,t) 2

0, (x, y,t) _ 1 0, (x, y,t)

x2 ay 2 a

where 01 (x, y, t) is the temperature increase above the ambient temperature, defined by 0, (x, y,t 0 T, (x, y,t 0- T. (2) The initial condition is

01(X, y,O) = 0

(1)

(3) The adiabatic condition at y = 0 is

(4)

D01(x,y,t)

-0

ay Y=Owhere the subscript I in Equations (1) through (4) can represent any of s, c, or a. The boundary conditions on the front and back surfaces are:

at x =x,

q" - h s (xx, y,t)+k a and at x =x6 ,

(

0

(x, y,t)hNOs 6 ,yt+s s

The interlayer continuity equations are: at x = x2

O(x 2, y,t)= 0 (x2, y,t) 0 < y

=0 (5) = 0 < 0O (6) (7) and D0a(x, y,t )

ax

XX2 D0 (x, y, t) ax X=X 0 < y < 00 (8)0, (x3, y,0 = Oa (X3, Y, t)

a0(X, y,t)

3x k a (XYt) xax

Oa(X4 , y,t) = 0,(x4,y,t)

a0(x,Y ,t ) ka ax X=X4 OC(x, y, t) = 0, (x, y, t)

a0,(X,

Y,t)

ax

x=x 5 and, at y = La 2 and a0, (x, y, t) ay 2The solution to the two-dimensional heat transfer problem, O(x, y, t), is obtained using the finite element method. Details about the finite element discretization, solution, and verification of the heat transfer problem are given in Appendices A and B. Although the mathematical model is semi-infinite in the y-direction, the two-dimensional solution needs only to be obtained in the vicinity of the transition zone; that is, the region of the

at x= x3, and La 0 < y < L 2 at x =x , (9) La 2 and (10) at x = x., La 0 < y < " 2 La 2 k (XY,() ax (11) (12) and 0 < y<oo a x y(X,t ) ax (13) 0 < y < oo (14) La 2 ,t) = Oa (X, < x < x4 (15) kaa0, (x, y, t) ay YLa 2 < x < x4 (16) 0, C

panel in which there is significant heat flow in the y-direction. The two-dimensional solution of the surface temperature was validated by comparing appropriate solutions with the corresponding one-dimensional solutions in Cai et. al (2001).

Nondimensional Parameters

The front and back surface temperature distributions are denoted, respectively, as

F (yt) and B(y,t). A normalized temperature distribution is defined as the difference

between the surface distribution of the two-dimensional model and the temperature obtained for region I in the one-dimensional solution divided by the difference in the region II one-dimensional temperature and the region I one-dimensional temperature. For example, for the front surface the normalized temperature is denoted as

o*

(y,t), and defined byF FF

6(,t=OFyF-f~)(7

of'(t)-Of(t)

where O (t) and 0 (t) are the one-dimensional temperature on the front surface of region I and region II, respectively. Accordingly, there are two significant limiting values of a normalized temperature. A normalized temperature equals zero when the surface temperature of the two-dimensional model equals the surface temperature of the one-dimensional solution for region I, and a normalized temperature equals unity when the surface temperature of the two-dimensional model equals the surface temperature of the one-dimensional solution for region II.

The resulting normalized temperature distribution can be written as

These parameters can be divided into the following six groups of nondimensional

parameters (see Appendix C): the normalized surface coordinate, Y ; the Fourier

dc

at

number, Fo -4d2, which is a nondimensional time; the front and back surface Biot

numbers, Bi, h d and BiN h , which are the ratios of the surface heat transfer

resistance to the internal conduction resistance of the core; the presumably known

d k a

geometric and thermal properties of the panel, -i-- and dimensions associated

dc kc ac

d D L k

with the anomaly, -- , - and " ; and the thermal properties of the anomaly, "' and

dc dc dc kc

It is noted that the system is linear with respect to the heat flux; hence, the ac

MATERIAL PROPERTIES

The thermal properties of the panel constituents are listed in Table 1. For the sandwich panel under consideration, the thicknesses of the face sheets and core are 3.8 mm (0.15 in.) and 25.4 mm (1.00 in.), respectively. In the numerical examples that follow, two cases of anomalies are studied. Case one is a void filled with air, and case two is an inclusion of an aluminum alloy. Each case is exposed to a heat flux

q= 0.5 kW/m2 (1.58x 103 BTU/h-ft2). Unless otherwise noted, the heat transfer

FINITE LENGTH ANOMALIES

For various values of anomaly length normalized by the core thickness, La / dc , Figure 2a shows the front surface steady-state normalized temperature distribution for case one when the anomaly is 10 mm (0.4 in.) thick and located at the mid-thickness of the core. For all values of La , the temperature distribution approaches the

one-dimensional region I temperature as y -+ oo. As the anomaly length increases, the

surface temperature above the mid-length of the anomaly, OF

(o),

increasingly closely approximates the one-dimensional region 11 temperature.Figure 2b shows the corresponding normalized temperature above the anomaly mid-length (y = 0) as the anomaly length increases. Two major limiting cases of the anomaly length can be identified.

As La -> 0, the surface temperature distribution above the mid-length of the anomaly also approaches the region I temperature. The experimental relative temperature resolution, denoted by 8, is normally defined as the minimum detectable temperature difference divided by a certain experimental measurement range. It is assumed that the experimental measurement range is tuned to maximize the surface temperature difference resulting from a semi-infinitely long anomaly. At a particular value of La, the normalized temperature above the mid-length of the anomaly is equal to

85. All values of anomaly length that are less than this particular value of anomaly length can not be detected. Subsequently, this value of anomaly length is defined to be the

For example, when the experimental relative temperature resolution is 2% of the overall temperature difference resulting from a semi-infinitely long anomaly, S equals 0.02. Using this value of 6, Figure 3 shows Ls, as a function of anomaly geometry for the front and back surfaces of cases one and two. A few observations are noted.

For case one, when the anomaly depth is held constant, Ls, monotonically increases as the anomaly depth approaches the observation surface. For case two, when the anomaly depth is held constant, L,,, monotonically increases as the anomaly thickness

k

increases. However, because the normalized anomaly conductivity, a , is large for an ke

aluminum inclusion compared to that of an air void, the temperature gradients near the ends of an aluminum inclusion are much larger than the temperature gradients resulting from air inclusion. As La -> L, the surface temperature rise caused by aluminum anomalies are significantly higher than those resulting from an air inclusion. Hence, in general, an aluminum anomaly can be detected at a length down to four orders of magnitude smaller than the core thickness, while an air void can be detected at a length three orders of magnitude smaller than the core thickness.

As La -> O0, the normalized temperature above the mid-length of the anomaly approaches one, which corresponds to the region II steady-state temperature. At a certain value of La, the temperature difference in Figure 2b is equal to a 1-6'. This value of anomaly length is defined to be the minimum anomaly length that results in a temperature distribution that approximates the temperature transition zone of a semi-infinitely long anomaly, L.. All values of anomaly length that are greater than L. have transition regions that are indistinguishable from that of a semi-infinitely long anomaly. The heat

transfer through the mid-length of such anomalies can be modeled as one-dimensional through the thickness.

Figure 4 illustrates L. for case one (air void) and case two (aluminum alloy

inclusion) when 9 = 0.02.

Figures 3 and 4 reveal an interesting symmetry for these panels. An anomaly has a complementary relationship about the mid-plane of the panel, such that if the anomaly were relocated to a mirror-image location about the mid-thickness of the panel, the relative temperature distributions on the front and back surface would be reversed.

Unfortunately, knowledge of the region II one-dimensional temperature, which is needed to compute the normalized temperature, is not normally known a priori, and the luxury of running experiments on anomalies of varying lengths are neither common nor practical. However, to determine whether an anomaly can be considered of semi-inifinite length without knowledge of the region II temperature, a more subtle observation of Figure 2a is necessary. As the anomaly length increases, the temperature distribution becomes increasingly uniform over the mid-length of the anomaly and the curvature approaches zero.

Recall that the curvature, K, of a function of one independent variable , f = f(x), is determined by the first and second derivatives of that function with respect to the independent variable,

f'

andf",

respectively, according to the following equation (Kreyszig, 1993)K(x) (19)

(1+ f2) 3 /

2

According to Equation (19), the curvature of the surface temperature at the position above the mid-length of the anomaly depends only on the absolute value of the second

derivative of temperature relative to the surface coordinate, because according to the adiabatic boundary condition, Equation (4), the first derivative vanishes. For the front surface temperature distribution, for example, the necessary condition that curvature approaches zeros above the anomaly mid-length is expressed as

kcd C [a2O(Y] «1 (20)

q"f ay 2 Y=

Assuming the expression in Equation (20) remains small for finite region near the surface, the governing equation of heat transfer, Equation (1), via an order of magnitude argument, locally reduces to

a20 1

iao

(21)ax2

a at

Recall, that Equation (21) is the governing equation for one-dimensional heat transfer; therefore, for such cases the anomaly can be considered of semi-infinite length.

SEMI-INFINITELY LONG ANOMALIES Characteristic Length of Transition Zone

In the vicinity of the transition zone, consider a surface temperature distribution due to a semi-infinitely long anomaly. To quantify this transition zone, a characteristic length is defined as the length required for the surface temperature to approach, within a certain tolerance e, each temperature asymptote. These asymptotes are predicted by the one-dimensional heat transfer solution in Cai et. al (2001). According to this definition, there is exactly one characteristic length on each surface at each instant. In Figure 5, a schematic of the characteristic length, denoted by A, is shown.

The limits of e are zero and 0.5. Due to the asymptotic nature of the temperature

distributions, as F -> 0 the characteristic length would approach infinity. On the other

hand, as e -> 0.5, the characteristic length would approach zero. This indicates that there is a tradeoff between the sensitivity-higher as c -> 0 and lower as e -> 0.5 -and the

required detection resolution-more demanding as e -+ 0 and less demanding as e -> 0.5. In the numerical examples that follow, e is chosen to be 0.05. Consequently, in

order to resolve A, the minimum resolvable temperature can not be larger than 5 percent of the overall surface temperature difference.

Effects of Biot Numbers on Steady-State Characteristic Length

Figure 6 shows the characteristic length for cases one and two as functions of front and back surface Biot numbers, where the anomaly is 10 mm (0.4 in.) thick and located at the mid-thickness of the core. A few observations are noted.

First, for both case one and case two, there is a symmetric relationship between the front and back contours of characteristic length about the line Bil = BiN ; i.e., for an

anomaly centered at the mid-thickness of the core, a transposition of the front and back Biot numbers results in a corresponding transposition of the front and back characteristic lengths. Thus, when Bil = BiN the characteristic length on both surfaces will be equal for an anomaly located at the mid-thickness of the core. This implies that the normalized temperature distributions on the front and back surfaces for such cases are identical.

Second, there are regions where the characteristic length is a function of only one Biot number. On the front surface of both the air and aluminum inclusions, in the region bounded approximately by logo(BiN )>1.5 and log 0(Bi)<1.5,(that is, conditions such

1

that the front surface heat transfer resistance per unit area, I, is sufficiently low relative

hi d

to the thermal resistance of the core per unit area, - ), the characteristic length is a

kc

function only of Bi1. On the back surface, when logo (Bi )<1 and logo (Bi)>1 for an

air void, or logo(BiN )<2 and log10 (Bi)>2 for an aluminum alloy inclusion,(that is,

conditions such that the back surface heat transfer resistance, , is sufficiently low

hN

relative to the thermal resistance of the core), the characteristic length depends only on

BiN *

Third, in the region bounded by logo(BiN )<O and logo(Bi)<O, the characteristic length is a monotonic function of BiN / Bi which reduces to hNI h1.

For reference, for cases one and two the front and back surface Biot numbers are

Bil= BiN = 5.81, or loglo (Bi)= logo (BiN) =0.76.

Effects of Anomaly Geometry on Steady-State Characteristic Length

The front and back characteristic lengths, normalized by the core thickness, as a function of anomaly geometry are presented in Figure 7.

For both cases, symmetry about the mid-thickness of the core is observed; that is, if the anomaly location is moved to a mirror-image location about the mid-thickness of the panel, the front and back characteristic lengths are transposed.

For case one, the anomaly thickness has very little effect on the characteristic length; as the depth approaches the observation surface, either front or back surface, the corresponding characteristic length decreases. For both cases, the larger the depth of the anomaly is from an observation surface, the larger is the observed steady-state characteristic length.

Figure 7 suggests the following procedure for determining the geometric properties of an anomaly when its thermal properties are known. First, the steady-state front surface temperature of region II, denoted by (61) 11, and a front surface characteristic length, A1,

are measured. The following equations (after Cai et. al, 2001)

= q "(1+ hN II) hi +hN +hhN3II ,=2 ds+ c +d2

can be solved for the thermal resistance of the damaged panel /, and the unknown anomaly thickness d.. The intersection of the contour line for Al with da , in the anomaly thickness-anomaly depth plane, gives the actual depth of the anomaly.

Furthermore, the following graphical procedure can be used for steady-state anomaly characterization when the geometric and thermal properties of the panel are known, but the anomaly depth, anomaly conductivity, and the surface heat transfer coefficients are not known.

First, four steady-state surface temperatures, one for each region on each surface, and two steady state characteristic lengths, one for each surface, are measured. Along with Equation (22), the following equations (after Cai et. al, 2001)

(00 _ q"(1 + hN/1) ( 24) hi + hN + hhN /I (O N+1I q= 25) hN + hN + hlhN ( =EN1I q N+1JIl h + hN + hlhN /3II (26)

can be used to solve for hl, hN, /3, and 6I ;where /, represents the thermal resistance of the undamaged region, given by

d d

,8 = 2 d' + d' (27)

k, kc

Second, after the boundary heat transfer coefficients are found, a series of figures analogous to Figure 7 can be generated for a range of ka. Suppose the value of the characteristic length on the front surface, A,, is equal to A. For each figure generated, a contour line corresponding to A, = A is identified. These contours are combined to form a continuous surface in the anomaly thickness-anomaly depth-anomaly conductivity

space. This surface, which is defined in this triangular prismatic space, can be called an

isosurface for Al=A.

Third, the same procedure can be used to form an isosurface for the characteristic length from the back surface, AN= B. The two isosurfaces are placed in the same triangular prismatic space as shown in Figure 8a. The resulting intersection reveals all possible anomaly parameter coordinates.

Fourth, another parameter, Afl, is computed by subtracting Equation (27) from Equation (23), or

A/ = 8,1 -8, = d. (28)

ka kc

which represents the deviation of the thermal resistance of region II from region I. According to Equation (28), a corresponding isosurface, Af8= C, is generated, where it is noted that A$8 is independent of anomaly depth. As shown in Figure 8b, the coordinates of intersection of this third isosurface with the intersection of Al= A and AN= B determine the values of anomaly thickness, depth, and conductivity.

Effects of Fourier Number on the Transient Characteristic Length

Figure 9 shows colorized maps of front and back surface characteristic length histories for case one, where the anomaly is 10 mm (0.4 in.) thick and located at the mid-thickness of the panel, and when one of the following anomaly parameters is varied: thermal conductivity ka , thermal diffusivity aathickness da, or depth Da . The panel is heated continuously from t = 0 to a time corresponding to a Fourier number of 20,

history of case one with no variations of anomaly parameters. A few observations are noted.

By the definition of the characteristic length, when region I and region II temperatures are equal, the characteristic length is undefined. The discontinuities in otherwise smooth contours of characteristic length distributions represent these times.

According to the front surface characteristic length histories in Figure 9c and 9d, there are certain regions where the characteristic length is not a monotonic function of

Fo. This indicates that the maximum characteristic length in these cases may occur

during a transient state.

There are certain regions where the characteristic length histories show remarkably simple shapes. In Figure 9b on the front surface, in regions where the anomaly diffusivity is larger than that of the core and further when the thermal diffusivity of the anomaly is held constant, the characteristic length is a monotonically increasing function of Fo on both surfaces.

For histories in which there are regions where there has been an equalization of region I and region II temperatures-front and back surfaces of Figure 9a and 9b and the back surfaces of Figures 9c and 9d-the surface characteristic length is a monotonically increasing function of Fo as the anomaly parameters are held constant for all times after the equalization of region I and region II surface temperatures. This indicates that the maximum characteristic length in these cases is reached only when the system approaches the steady-state.

The corresponding series of histories for case two is given in Figure 10. Observations similar to Figure 9 can be made for Figure 10.

In the one-dimensional transient solution (Cai et. al, 2001), the time needed for region I or II to reach 63.2 percent of its steady-state surface temperature is called the

system characteristic time and denoted by 'z for region I and ri for region II. Figure 11 shows the transient characteristic length evaluated at rm as a function of anomaly thickness and anomaly depth for cases one and two. For the air void, the transient characteristic length, is highly dependent upon the depth: as the depth gets closer to the observation surface, the characteristic length decreases. For the aluminum inclusion, (except for thin anomalies), when the thickness is held constant, the characteristic length is observed to monotonically increase as the depth gets farther from the observation surface. For both cases, it is noted that, unlike the steady state results, there is no relationship observed between the front and back surface transient characteristic lengths.

PROPOSED MEASUREMENT AND DATA PROCESSING

Assuming an anomaly is of a length greater than L., based upon the above analysis and the previously proposed procedure based upon the one-dimensional analysis, the following procedures for the thermographic NDT of composite sandwich panels are proposed.

When both the front and back surfaces are accessible:

1. Make seven (7) measurements: one front surface system characteristic time; two steady-state characteristic lengths, one for each surface; four steady-state temperatures, one for each region on each surface.

2. Solve for 83 ,

/3$1 , A$3, h, and hN using the steady-state surface temperatures

measured in the previous step, the known thermal properties of the undamaged core, and Equations (23), (25) ,(26), (27), and (28).

3. A series of color maps, analogous to Figure 7, is generated. For each color map ka is selected so that the entire series covers a range within which the actual k, would likely fall .

4. From the front and back steady-state characteristic lengths measured in step 1, two isosurfaces are created in the anomaly thickness-anomaly depth-anomaly conductivity space. The intersection of the front and back characteristic length isosurfaces is found according to the procedure illustrated in Figure 8a.

5. According to the definition of Alin Equation (28) and its value as found in step

6. Analogous to Figure 8b, the intersection of isosurface A/f with the curve generated from the intersection of the previous isosurfaces is found. This intersection gives the actual values of thermal conductivity, depth, and thickness of the anomaly.

7. Using hl, hN, kal da and Da as calculated in the previous steps, the front surface characteristic time is computed via the one-dimensional solution (Cai et. al, 2002) for a range of anomaly thermal diffusivity, where the thermal diffusivity covers a range within which the actual thermal diffusivity would likely fall.

8. The point where the curve of the previous step equals the front surface characteristic time, as measured in the first step, is the actual value of anomaly thermal diffusivity.

9. Finally, Chart 9 of Ashby (1992) can be used to identify the probable material of the anomaly.

In comparison with the NDT procedure proposed in Cai et. al (2001), the above procedure has distinct advantages and disadvantages. First, the above procedure captures the geometry and thermal conductivity of the anomaly via steady-state measurements, without processing transient information; however, a moderate computational effort is required, particularly in the formation of isosurfaces as illustrated in Figure 8. Second, in order to measure each characteristic length, a more stringent requirement is imposed on the minimum detection resolution. In the numerical cases that have been presented, the minimum resolvable temperature needs to be a fraction of that required for the procedure in Cai et. al (2001).

In our previous paper (Cai et. al, 2001), back surface observations are necessary to characterize an anomaly. By substituting the back surface transient temperature observations with the front surface transient characteristic lengths observations, the above procedure can be modified so that back surface dependence can be eliminated.

When only the front surface is accessible, and the front heat transfer coefficient h, and the thermal resistance of the undamaged panel 8,J, defined in Equation (24), are known, the following procedure is proposed:

1. Make four (4) measurements: one front surface system characteristic time of region II; one front surface characteristic length, at the characteristic time of region II; two steady-state front surface temperatures, one for each region.

2. Solve for hN and A/8 via Equations (23), (24), (25), and (28) using the values

measured in the previous step.

3. According to the definition of Af8 in Equation (28) and its value as found in the previous step, an anomaly thickness versus ka curve is plotted.

4. A series of color maps for the front surface characteristic time versus anomaly thickness and anomaly depth are generated. A series of color maps for the front characteristic length, evaluated at the front characteristic time versus anomaly thickness and anomaly depth, are also generated. For each color map, ka is selected so that the entire series covers a range within which the actual k, would likely fall, and a, is selected such that the a, / k, ratio is constant.

5. For each pair of color maps generated in the previous step (for each selected ka

region II characteristic time and the characteristic length evaluated at the characteristic time are identified. The intersection of overlaying each pair of contours on the same axes is found and anomaly thicknesses and depth are determined.

6. Anomaly thicknesses found in the previous step are plotted as a second anomaly thickness versus ka curve.

7. The two anomaly thickness curves intersect. The intersection of the anomaly thickness curves gives the true values of ka and anomaly thickness.

8. A color map of the front surface characteristic time as a function of anomaly diffusivity and anomaly depth is generated. A color map of the front surface characteristic length at the region II characteristic time as a function of anomaly diffusivity and the anomaly depth is also generated. For each colormap, the now determined values of anomaly thickness and ka are used.

9. The intersection of the contours of the characteristic time and the characteristic length measured at that characteristic time determines a, and the anomaly depth. 10. Finally, Chart 9 of Ashby (1992) can be used to identify the probable material of

CONCLUSIONS

The two-dimensional heat transfer of composite sandwich panels has been modeled and numerical solutions are obtained via the finite element method. Limiting cases of anomaly length were identified and discussed. The characteristic length of the surface temperature transition was defined and, through numerical examples, the effects due to changes in various parameters were observed. In combination with the previous one-dimensional analysis (Cai et. al, 2001), two procedures to characterize anomalies of a well-defined minimum length have been proposed, including cases when the back surface is inaccessible.

REFERENCES

Arpaci, V.S., Conduction Heat Transfer, Reading, Massachusetts, Addison-Wesley Co., 1966.

Ashby, M.F., Materials Selection in Mechanical Design: Materials and Process Selection Charts, Oxford, England, Pergamon Press, 1992.

Cai, L.-W., A.F. Thomas, and J.H. Williams, Jr., "Thermographic Nondestructive Testing of Polymeric Composite Sandwich Panels," Materials Evaluation, Vol. 59, 2001, pp. 1061-1071.

d'Ambrosio, G., R. Massa, M.D Migilore, G. Cavaccini, A Ciliberto and C. Sabatino, "Microwave Excitation for Thermographic NDE: An Experimental Study and Some Theoretical Evaluations," Materials Evaluation, Vol. 53, 1995, pp.5 0 2-5 0 8.

Kreyszig, E., Advanced Engineering Mathematics, 7t Edition, New York, John Wiley & Sons, 1993.

Mikhalov, M.D. and M.N. Ozisik, Unified Analysis and Solutions of Heat Mass Diffusion, New York, John Wiley & Sons, 1984.

Qin, Y.W. and N.K. Bao, "Infared Thermography and its Application in the NDT of Sandwich Structures," Optics and Lasers in Engineering, Vol. 25, 1996, pp. 205-211. Vavilov, V.P. and S.V. Finkel'shtein, "Calculation of the Sensitivity of Active Thermal

Inspection on the Basis of Solving an Unidimensional Problem of Heating a Three-layer Sheet with a Constant Heat Flow," Soviet Journal of Nondestructive Testing (English translation of Defektoskopiya), Vol. 22, 1986, pp. 422-428.

Vickstr6m, M., J. Backlund and K.A. Olsson, "Non-destructive Testing of Sandwich Constructions Using Thermography," Composite Structures, Vol. 13, 1989, pp. 49-65.

Vickstr6m, M., "Thermographic Non-destructive Testing of Sandwich Structures with Simulated Debonds, Sandwich Constructions 2," Proceedings of the Second International Conference on Sandwich Constructions, D. Weissman-Berman and

K.A. Olsson eds., Gainsville, Florida, 1991, pp. 757-775.

Williams, J.H., Jr., S.H. Mansouri and S.S. Lee, "One Dimensional Analysis of Thermal Nondestructive Detection of Delamination and Inclusion Flaws," British Journal of Non-Destructive Testing, Vol. 22, 1980, pp. 113-118.

Williams, J.H., Jr., "Thermal Nondestructive Testing of Fiberglass Using Liquid Crystals," MIT Sea Grant Program Report MITSG 81-16, M.I.T., Cambridge, Massachusetts, 1981.

Williams, J.H., Jr., and S.S. Lee, "Thermal Nondestructive Testing of Fiberglass

Laminate Containing Simulated Flaws Orthogonal to Surface Using Liquid Crystals,"

Journal of Nondestructive Testing, Vol. 24, 1982, pp. 76-81.

Williams, J.H., Jr., B.R. Felenchak and R.J. Nagem, "Quantitative Geometric

Characterization of Two-dimensional Flaws Via Liquid Crystals Thermography,"

Materials Evaluation, Vol. 41, 1983, pp. 190-201.

Williams, J.H., Jr. and R.J. Nagem, "A Liquid Crystals Kit for Structural Integrity Assessment of Fiberglass Watercraft," Materials Evaluation, Vol. 41, 1983, pp. 961-966.

Face Sheet, ks, as

Core,

kc, ac Ladc

K._ I 1 1 X4 X5 X6 Adiabatic BoundaryFigure 1-Mathematical model of a portion of a sandwich panel containing an anomaly. y Orl if

q

hN Region It

Region II Da Anomaly, ka,aa da X1 X2 x E E X3a a) 1 o II 0 -La Id = 16 12 8. 4 .. ... . . -.. . . .. . . . .. . . ... . . .. -. . .. .-. -. . . . . . . . -. . . ... . ..-. . .. . ...-. .. 2 1 0 0. SC > U -UC: o Z y/(Core Thickness) OL . d C (a) 2 L. 4 6 d C

(Anomaly Length)/(Core Thickness)

(b)

Figure 2-(a) Normalized front surface temperature distribution for case one (air void), when the anomaly thickness is 10 mm

(0.4 in.), located at the mid-thickness of the panel, and the normalized anomaly length, La / de, is varied. (b) Based upon the experimental detection resolution, 6, a schematic of limiting anomaly lengths, Lmin and L., are shown.

0.8 0.6 0.4 0.2 0 2 4 6 8 10 12 6 0 8 1 1-8 0.8 0.6 0.4 0.2 0 - - - . - - ... - .

JU 4) 0 44 0 1 0.8 0.6 0.4 0.2 01 0 0.2 0.4 0.6 0.8 1 (Anomaly Thickness)/(Core Thickness)

(a) Air Void, Front Surface 1 0.8 0.6 0.4 0.2 0 0 0.2 0.4 0.6 0.8 1 (Anomaly Thickness)/(Core Thickness) (c) Aluminum Alloy Inclusion, Front Surface

1 0.8 0.6 0.4 0.2 01 0 0.2 0.4 0.6 0.8 1 (Anomaly Thickness)/(Core Thickness)

(b) Air Void, Back Surface 1 0.8 0.6 0.4 0.2 01 0 0.2 0.4 0.6 0.8 1 (Anomaly Thickness)/(Core Thickness) (d) Aluminum Alloy Inclusion, Back Surface

Figure 3-Given the detection resolution S = 0.02, the minimum detectable anomaly length, La , normalized by the core thickness, de, is plotted as a function of anomaly geometry for cases one and two.

0

*1

.2 a 0 x 10-2 5.0 4.5 4.0 3.5 3.0 2.5 2.0 1.5 1.0 0.5 0 0 -0.4 -0.8 -1.2 -1.6 -2.0 -2.4 -2.8 -3.2 -3.6 -4.0rA rA 0 S. 1 0.81 0 0.6 U ' 0.4 E 0.2 O . 0 0.2 0.4 0.6 0.8 1

(Anomaly Thickness)/(Core Thickness) (c) Aluminum Alloy Inclusion, Front Surface

1 4.) U 4.) 0 U 0. 4.) 0 0 0.8 0.6 0.4 0.2 0 . 0 0.2 0.4 0.6 0.8 1

(Anomaly Thickness)/(Core Thickness) (a) Air Void, Front Surface

4.) 0 U 4.) 0 U .0 0. 4.) 0 0 n 0 0.2 0.4 0.6 0.8 1

(Anomaly Thickness)/(Core Thickness) (d) Aluminum Alloy Inclusion, Back Surface

Figure 4-Given the detection resolution S = 0.02, the minimum anomaly length required to approximate an anomaly of semi-infinite length, L., normalized by core thickness, dc, is plotted as a function of anomaly geometry for cases one and two.

0.8 0.6 0.4 0.2 01 0 0.2 0.4 0.6 0.8 1

(Anomaly Thickness)/(Core Thickness) (b) Air Void, Back Surface 1 0.8 0.6 0.4 0.2 O '0 23 8.0 7.2 6.4 5.6 4.8 4.0 3.2 2.4 1.6 0.8 1

-3 -2 -1 0

(y - La /2)/(Core Thickness)

Region II (Flawed) -4 1 Region I (Unflawed)

Figure 5-Schematic of the characteristic length, A, of the surface temperature transition zone normalized by the core thickness, d,, given a tolerance, e = 0.05.

2 3 0x 41) 0d Z. 1 1-E 0.8 0.6 0.4 0.2 A d .... -. -. -- -- . . . . .. - - -. - . - -E 0 -4 1 4

5 4 3 o2 Oz . 2 1 1 0 -1 -1 5 4 3 2 00 0 -1 -1 0 1 2 3 4 5 logl0(Bil)

(c) Aluminum Alloy Inclusion, Front Surface

4 3 z C2 2 0 0 -1 -1 5 4 3 -z '12 2 01 0 0 1 2 3 4 5 logl0(Bil)

(b) Air Void, Back Surface

-1

-1 0 1 2 3 4 5 logl0(Bil)

(d) Aluminum Alloy Inclusion, Back Surface

Figure 6 -Steady-state normalized characteristic length for cases one and two as a function of front and back Biot numbers, Bil and BiN , respectively; where, for both

cases, the anomaly is 10 mm (0.4 in.) thick and located at the mid-thickness of the core.

0 1 2 3 4 5

logl0(Bil) (a) Air Void, Front Surface

0 00 2. U. 10 9 8 7 6 5 4 3 2 1 0 5

1 0.8 0.6 0.4 0.2 0 0.2 0.4 0.6 0.8 1

(Anomaly Thickness)/(Core Thickness) (a) Air Void, Front Surface

0 6 0.6 0.4 0.2 A 0 0.2 0.4 0.6 0.8 1

(Anomaly Thickness)/(Core Thickness) (c) Aluminum Alloy Inclusion, Front Surface

Figure 7-Steady-state characteristic one and two.

C.) C.) C.) 0 U 0. C.) 0 C.) 0 C.) U 0 U .0 0. C.) 1 0.8 0.6 0.41 0.2 0 0.2 0.4 0.6 0.8 1

(Anomaly Thickness)/(Core Thickness) (b) Air Void, Back Surface

1 K-I 0.8 0.6 0.4 C.) 0 4.0 3.6 3.2 2.8 2.4 2.0 1.6 1.2 0.8 0.4 0 0.2 0 0 0.2 0.4 0.6 0.8 1

(Anomaly Thickness)/(Core Thickness) (d) Aluminum Alloy Inclusion, Back Surface

length as a function of anomaly geometry for cases 0.8

5 3 2 0 0.4 0.6

(C

4.2

0 0( > 0 a0 N (a) Anomaly LocFigure 8-(a) Given measurements A1 = A and AN = B for the front and back steady-state characteristic lengths, respectively,

the intersection of the corresponding isosurfaces is shown. (b) The intersection of a third isosurface, AP = C, reveals the anomaly geometry and thermal conductivity.

A =A isosurface M AN =B isosurface Intersection of A, = A and AN = B isosurfaces M AO =C isosurface ation 5 4 3 2-0 1 0. 04 0.0 0.2) (b) 8

Front Surface 5 4 2 001 -1 . 0 2 4 6 8 10 12 14 16 18 20 Fo(x e tid2)C 5 4 S3 d 2 0 0 2 4 6 8 10 12 14 16 18 20 Fo U U S -3 2.7 2.4 2.1 1.8 1.5 1.2 0.9 0.6 0.3 0 5 4 2 0 00 -1 5 4 0 2 0 -1 Back Surface (a) 0 2 4 6 8 10 12 14 16 18 20 Fo (actd2) C~ C (b) 0 2 4 6 8 10 Fo 0 2 4 6 8 10 12 14 16 18 20 Fo 0 2 4 6 8 10 12 14 16 18 20 Fo 0.6 0.4- -0.2 0 0 2 4 6 8 0.6 0.4 0 (c) 10 12 14 16 18 20 Fo 0 2 4 6 8 10 12 14 16 18 20 Fo

Figure 9-Characteristic length histories for case one, where the anomaly is 10 mm (0.4 in.) thick and located at the

0.6 0.4 0.2 0 0.6 0.4 0 S0.2 0 12 14 16 18 20 (d) L --- j

Front Surface 5 3 -d2 0 -1 , . , 0 2 4 6 8 10 12 14 16 18 20 Fo(x tid2) C C 5 ets 0 4 3 2 1 5 0 .0 >3 3 2.7 2.4 2.1 1.8 1.5 1.2 0.9 0.6 0.3 0 3 2 0 0 -1 5 4 S3 0 2 1 C) Back Surface 0 2 4 6 8 10 12 14 16 18 20 Fo(a tidC 2C) 0 0 2 4 6 -1 8 10 12 14 16 18 20 Fo 0 2 4 6 8 10 12 14 16 18 20 Fo 0 2 4 6 8 10 12 14 16 18 20 Fo (b) 0 2 4 6 8 10 12 Fo 06 0.4 0.2 01 0 2 4 6 8 10 Fo 0.6 "t3 0.4 0.2 0 14 16 18 20 (c) 12 14 16 18 20 (d) 0 2 4 6 8 10 12 14 16 18 20 Fo

Figure 10-Characteristic length histories for case two, where the anomaly is 10 mm (0.4 in.) thick and located at the mid-thickness of the panel. The front surface is heated continuously and one of the anomaly's parameter is varied. (a)

0 -1 0.6 0.4 0.2 0 0.6 0.2 0

-1 0.8 1 U U UQ UQ 0 1 0.8 0.6 0.4 0.2 U U U 0 U 0. U S 0 0 0.2 0.4 0.6 0.8 1 (Anomaly Thickness)/(Core Thickness) (c) Aluminum Alloy Inclusion, Front Surface

0.8 0.6 0.4 0.2 0 -0 0.2 0.4 0.6 0.8 1

(Anomaly Thickness)/(Core Thickness) (b) Air Void, Back Surface 1 0.8 0.6 0.4 0.2 A 0 0.2 0.4 0.6 0.8 1

(Anomaly Thickness)/(Core Thickness) (d) Aluminum Alloy Inclusion, Back Surface

Figure 11-Transient-state characteristic length, normalized by core thickness, evaluated at the corresponding region II characteristic time.

0.6 0.4 0.2 01

0 0.2 0.4 0.6 0.8 1

(Anomaly Thickness)/(Core Thickness) (a) Air Void, Front Surface

J U 0 U 3 2.7 2.4 2.1 1.8 1.5 1.2 0.9 0.6 0.3 0

Table 1-Sandwich panel constituents and anomaly thermal properties at 348'K (167'F). Material Thermal Conductivity (k) Thermal Diffusivity (a)

W/(m-K) m2/s (ft2ls)

Face Sheet 0.4250 2.27x10-7 (2.44x10 6)

Core 0.0437 1.69x10~6 (1.82x10-5)

Air 0.0293 0.0272 (0.293)

APPENDIX A: FINITE ELEMENT EQUATIONS FOR THE ANALYSIS OF TWO-DIMENSIONAL HEAT TRANSFER

Matrix Notation of Interpolation Functions

The solution to a two-dimensional heat transfer model is approximated by using the finite element method [A-1]. Consider an analytical model that is discretized into an assemblage of finite elements, with each finite element composed of n number of nodes. The approximate temperature distribution throughout each element can be written as

n

6' (x, y) = g (x, y)O1 (A.1)

where 0' (x,y) is the continuous temperature distribution throughout the m element, 0m

is the temperature of node i, located at position (xi,yi), and gi is a function that satisfies

g (x ,y1) =(S1 1, where 1 i ! n and 15j:! n (A.2) The temperature-gradient distribution is defined by the following equations:

ax x,,y i=1(A3

ao

Mn

a

= g i, (x, y)01a (x,y) i=1

The temperature interpolation for the mth finite element in the assemblage, according to eqn. (A.1), is rewritten in matrix form as

Om(x, y) = H (m) 0(m) (A.4)

where H(m) is a 1 xn row vector called the temperature interpolation matrix, written as H C'" =[g1(x, y) g2(X, y) '--- gn (Xy)] (A.5)

and (m) is an nxI column vector of nodal point temperatures, written as