Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

9th Symposium on High Performance Concrete: Design, Verification & Utilisation [Proceedings], pp. 1-8, 2011-08-12

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=81b61c25-c36e-4fbd-b169-5456ace500bd https://publications-cnrc.canada.ca/fra/voir/objet/?id=81b61c25-c36e-4fbd-b169-5456ace500bd

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Use of porous lightweight aggregate in high performance concrete as a carrier of chemical admixtures and curing water

U se of porous light w e ight a ggre ga t e in high pe rform a nc e c onc re t e a s a c a rrie r of c he m ic a l a dm ix t ure s a nd c uring w a t e r

N R C C - 5 3 9 9 4

C u s s o n , D . ; M a r g e s o n , J . C .

A u g u s t 2 0 1 1

A version of this document is published in / Une version de ce document se trouve dans:

9th Symposium on High Performance Concrete - Design, Verification & Utilisation, Rotorua, New Zealand, August 8-12, 2011 pp. 1-8

http://www.nrc-cnrc.gc.ca/irc

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d'auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d'identifier la source de l'information et, dans certains cas, d'interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

9th Symposium on High-Performance Concrete, Design, Verification & Utilization, Rotorua, New-Zealand, 8-12 August, 2011.

USE OF POROUS LIGHTWEIGHT AGGREGATE IN HIGH

PERFORMANCE CONCRETE AS A CARRIER OF CHEMICAL

ADMIXTURES AND CURING WATER

Daniel Cusson and Jim Margeson

National Research Council Canada, Ottawa, Canada

Abstract

Internal curing of concrete can be achieved by soaking porous lightweight aggregate (LWA) in water before its introduction into the concrete mix as a partial replacement for normal density aggregate. This technique is particularly useful for low water-cement ratio concrete, for which self-desiccation can lead to autogenous shrinkage, tensile stresses and cracking at early ages. A research project has been undertaken to develop low-shrinkage high performance concrete for the design of concrete structures with long service life. One specific objective was to optimize the concrete mix design by introducing selected chemical admixtures into the concrete mix by using porous lightweight aggregate as a carrier. Expanded shale lightweight aggregate sand was soaked in a solution of water and given admixtures, such as a shrinkage-reducing admixture (SRA) and/or a corrosion inhibitor (CI), prior to mixing. Several fresh and hardened concrete properties were measured and compared to those of a similar concrete mix, in which the given chemical admixtures were added directly into the mix according to the manufacturer’s specifications. The results showed that this new admixture delivery method produced no adverse effects on the desired fresh and hardened concrete properties, including compressive strength and autogenous shrinkage. The addition of SRA through LWA mitigated chemical interactions between the air entraining admixture and the SRA, which was previously found to reduce the effectiveness of the air entraining admixture. For instance, when SRA was delivered through LWA, it was found that the target air content of 5% could be achieved with 10 times less air entraining admixture. Keywords: high performance concrete; lightweight aggregate; internal curing; admixtures

9th Symposium on High-Performance Concrete, Design, Verification & Utilization, Christchurch, New-Zealand, 8-12 August, 2011.

Page 2

1 INTRODUCTION

Most departments of transportation in North America specify high performance concrete (HPC) in bridge decks to meet given strength and/or durability requirements [1]; for example, the reduction of permeability to water and chlorides in aggressive environments, and/or the need for superior mechanical performance under demanding load conditions. High performance concrete, however, is prone to early-age cracking when deformations are restrained in concrete structures. Early-age transverse cracking has been observed in more than 100,000 bridges in the USA [2], and is most often due to restrained shrinkage and thermal deformations [3]. This tendency to crack is mainly due to the low water cement ratio (w/c) of HPC used to achieve low permeability and/or high strength. This low w/c often results in self-desiccation of the system, leading to autogenous shrinkage of concrete. Although autogenous shrinkage is practically nonexistent in ordinary concrete, the high water cement ratio often results in undesired performance characteristics, such as high permeability, low strength and high drying shrinkage, thus resulting in structures with short service life. Internal curing (IC) can provide additional moisture in concrete to reduce self-desiccation and improve cement hydration [4, 5]. Internal curing implies the introduction of a curing agent into concrete to provide additional water for a more complete hydration of the cement and to maintain a high relative humidity in the concrete. There are two major methods available for internal curing of concrete. The first method uses saturated porous lightweight aggregate (LWA) [6] to carry and supply the internal source of water. This IC water is naturally drawn from the relatively large pores of the LWA into the smaller pores of the cement paste during hydration as the relative humidity decreases in the paste. The second method uses super-absorbent polymers (SAP) [7], as these particles can absorb a very large quantity of water during concrete mixing and form large inclusions containing free water, thus preventing self-desiccation during hydration. The quantity of IC water required to replace the mix water consumed by chemical shrinkage can be determined as suggested elsewhere [8, 9]. Recent work [10] has demonstrated that the service life of HPC bridge decks in severe corrosive environments can be extended by up to 50% when internal curing with LWA is applied. The use of LWA as an internal curing agent to provide additional curing water to cement-based materials has been extended to pre-soaking porous LWA with liquids other than water. Pioneering work demonstrating this concept was published in 2005 [11], where the pores of LWA sand were filled with a solution of a shrinkage-reducing admixture and tested on mortar specimens. Exploratory work was also conducted in 2007 [12] using LWA filled with the liquid form of a phase change material. Upon the successful demonstration of this concept on laboratory mortar specimens, it was hypothesised that LWA could be engineered to suit several possible applications, such as: (i) reducing the maximum temperature achieved in massive concrete pours; (ii) providing energy conservation via an increased thermal lag in residential wall construction; and (iii) reducing the number of freeze/thaw cycles experienced by concrete structures in cold climates [12]. Recently, pre-soaked LWA was used in mortar specimens to deliver a viscosity-enhancing admixture to the mixture [13]. While viscosity-enhancing admixtures reduce transport rates when added directly to mixing water, a better performance was achieved when a solution of concentrated chemical admixture was used to pre-soak the LWA.

9th Symposium on High-Performance Concrete, Design, Verification & Utilization, Christchurch, New-Zealand, 8-12 August, 2011.

Page 3 An earlier investigation by the authors [14] was undertaken to develop low-shrinkage high performance concrete for the design of concrete structures with longer service life. To that effect, four types of materials for concrete have been investigated and compared, namely: - Supplementary cementing materials, including silica fume and slag, to reduce concrete

permeability and replace some of the cement used in concrete;

- Pre-soaked lightweight aggregate (LWA) sand to provide internal curing (IC) and to reduce early-age autogenous shrinkage cracking;

- Shrinkage-reducing admixture (SRA) to reduce drying shrinkage cracking;

- Corrosion inhibitor (CI) to reduce corrosion of steel reinforcement embedded in concrete. The aim of the study presented in this paper is to assess the feasibility of using porous lightweight aggregate sand not only for internal water curing but also to carry and deliver chemical admixtures within the concrete, since this concept has been proven only on mortars [11]. The admixtures targeted for this study were a shrinkage-reducing admixture and a corrosion inhibitor. The specific objectives were to verify if this new admixture delivery method could: (i) improve shrinkage control and strength development of high performance concrete; (ii) eliminate adverse chemical interactions between different admixtures used in concrete; and (iii) improve fresh concrete properties, or make them more predictable.

2 EXPERIMENTAL PROGRAM

2.1 Materials

For an objective comparison of the above types of materials, a total of six HPC mix formulations were developed, and were based on the same basic proportions:

- effective water-cement ratio of 0.35; - cement/sand/stone mass ratio of 1:2:2; - maximum aggregate size of 10 mm.

Three mix formulations are presented and analysed within the scope of this paper. The mix design features of the selected high performance concrete formulations are:

- HPC-4 (IC/SRA): with internal curing, and shrinkage-reducing admixture;

- HPC-5 (IC/SRA/CI): with internal curing, shrinkage-reducing adm., and corrosion inhibitor; - HPC-6 (control): serving as the reference concrete.

Table 1 presents the three mix formulations analysed in this paper. The difference between Method A and Method B for each of HPC-4 and HPC-5 will be discussed later.

For these mix designs, the effective water-cement ratio was 0.35. The mix water was adjusted to account for the liquid part contained in the chemical admixtures and the water absorbed by the dry normal sand and dry coarse aggregate during mixing. The type of blended cement used in this study was CSA Type GUb-S/SF [15] including 5% silica fume, 20% slag, and 75% of ordinary Portland cement by mass, and a Blaine value of 575 m2/kg. The aggregates used in the concrete were: porous lightweight sand (expanded shale, 5 mm max., 15% water content); normal-density sand (silica/quartz, 5 mm max); and normal-density coarse aggregate (limestone, 10 mm max). It should be noted that the mass of LWA shown in Table 1 corresponds to the saturated surface dry (SSD) state (including mass of IC water).

9th Symposium on High-Performance Concrete, Design, Verification & Utilization, Christchurch, New-Zealand, 8-12 August, 2011.

Page 4 Table 1: Mix designs for HPC-4 (IC/SRA), HPC-5 (IC/SRA/CI) and HPC-6 (control)

Mix constituent (per kg of cement) HPC-4a Method A HPC-4b Method B HPC-5a Method A HPC-5b Method B HPC-6 Control Effective w/c 0.35 0.35 0.35 0.35 0.35 Mix water (kg) 0.34 0.36 0.31 0.32 0.37 SF/slag cement (kg) 1.0 1.0 1.0 1.0 1.0

Dry normal-density sand (kg) 1.0 1.0 1.0 1.0 2.0

SSD lightweight aggregate sand (kg) 0.6 0.6 0.6 0.6 -

Dry 10-mm stone (kg) 2.0 2.0 2.0 2.0 2.0

Water reducer (mL) 2.0 2.0 2.0 2.0 2.0

Superplasticizer (mL) 8.0 9.0 6.0 8.0 9.0

Air entraining admixture (mL) 1.5 0.15 1.5 0.15 0.15

Shrinkage-reducing admixture (mL) 17 17 17 17 -

Corrosion inhibitor (mL) - - 44 44 -

Method A: Conventional method (admixtures added separately in concrete mixer) Method B: New method (SRA/CI pre-absorbed within lightweight aggregate sand)

In HPC-4 and HPC-5, a quantity of 0.6 kg of saturated LWA per kg of cement was used to provide internal curing water to compensate for chemical shrinkage, which is the main factor responsible for the development of autogenous shrinkage in self-desiccating concrete. This quantity of LWA was included in the mix as a partial replacement for 1.0 kg of normal sand per kg of cement to maintain an identical volume of fine aggregates in the concrete. The SRA and CI dosage rates shown in Table 1 corresponded to the respective maximum dosage rates recommended by the manufacturer.

2.2 Test variables

Two admixture delivery methods were compared:

- Method A: Convectional method, in which the admixtures are added separately in the concrete mixer (while the LWA sand only contains internal curing water);

- Method B: New investigated method, in which SRA and/or CI and internal curing water are pre-absorbed within the lightweight aggregate sand prior to concrete mixing.

The first part of this feasibility study focused on the HPC-4 mix formulation with the combined use of internal curing (IC) and a shrinkage-reducing admixture (SRA) as a control measure for shrinkage. The major change in the mix formulations between 4a and HPC-4b, apart from the admixture delivery method, was the dosage rate of the air entraining admixture (AEA) that was required to achieve the 5% target entrained air content. It was found [14] that a dosage rate of 1.5 mL of AEA per kg of cement was required in HPC-4a, while only 0.15 mL/kg was required in the control concrete HPC-6 made without the SRA. This observed reduction in effectiveness of the AEA was attributed to the presence of SRA in HPC-4a. It was therefore hypothesized that a method that could physically isolate the two admixtures from each other during mixing (i.e. AEA in mix water, and SRA within LWA) would solve this problem.

9th Symposium on High-Performance Concrete, Design, Verification & Utilization, Christchurch, New-Zealand, 8-12 August, 2011.

Page 5 The second part of this feasibility study focused on the HPC-5 mix formulation with the use of internal curing (IC), a shrinkage-reducing admixture (SRA) and a corrosion inhibitor (CI). Similarly to HPC-4a described above, the presence of the SRA in HPC-5a affected the effectiveness of the air entraining admixture, thus requiring an AEA dosage rate of 1.5 mL/kg of cement to achieve the 5% target air content. HPC-5b was then tested using both delivery methods. This time, the LWA sand in HPC-5b was soaked in a solution of shrinkage-reducing admixture, corrosion inhibitor, and internal curing water prior to mixing. In order to maintain the same level of internal curing in the LWA of HPC-4a, HPC-4b, HPC-5a and HPC-5b, the amount of internal curing water was reduced based on the added amount of liquid admixture in the LWA of HPC-4b and HPC-5b in order to maintain full saturation of the LWA. This water adjustment resulted in a secondary benefit from the use of Method B over Method A, which is a small increase in the mix water for the same effective w/c (Table 1), making the concrete easier to place.

2.3 Test procedures

The following fresh concrete properties were measured: workability (ASTM C143), density and air content (ASTM C231), and time of setting (ASTM C403).

The free autogenous shrinkage strain of concrete was measured on a set of three sealed concrete prisms (75 × 75 × 300 mm), which were kept at constant room temperature and monitored for a period of 28 days. The test apparatus used for this experiment was similar to that suggested in ASTM C157 for length change measurement. The monitoring started shortly after the casting of concrete.

The concrete compressive strength was determined at 1 day, 7 days, and 28 days on wet-cured 100 × 200 mm cylinders according to ASTM C39.

3 RESULTS AND ANALYSIS

Table 2 presents the fresh and hardened concrete properties measured for the high performance concrete mix formulations. In this section, the effect of the admixture delivery method on a number of concrete properties will be discussed. Consequently, two pairs of concrete mixes will be compared:

- HPC-4a vs. HPC-4b (both with IC & SRA); - HPC-5a vs. HPC-5b (both with IC, SRA & CI);

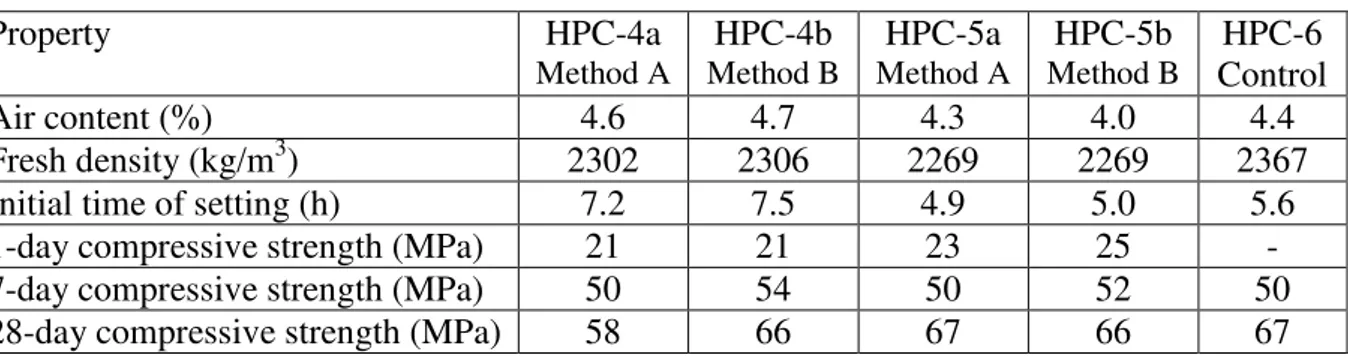

Table 2: Measured properties for HPC-4 (IC/SRA), HPC-5 (IC/SRA/CI) and HPC-6 (control)

Property HPC-4a Method A HPC-4b Method B HPC-5a Method A HPC-5b Method B HPC-6 Control Air content (%) 4.6 4.7 4.3 4.0 4.4 Fresh density (kg/m3) 2302 2306 2269 2269 2367

Initial time of setting (h) 7.2 7.5 4.9 5.0 5.6

1-day compressive strength (MPa) 21 21 23 25 -

7-day compressive strength (MPa) 50 54 50 52 50

9th Symposium on High-Performance Concrete, Design, Verification & Utilization, Christchurch, New-Zealand, 8-12 August, 2011.

Page 6 3.1 Fresh concrete properties

Compared to conventional Method A, the results in Table 2 indicate that the delivery of SRA or SRA/CI solutions from within the LWA resulted in negligible differences in air content, fresh concrete density, and initial time of setting. For HPC-4 and HPC-5, it was found that Method B was able to achieve similar air contents with 10 times less air entraining admixture. 3.2 Compressive strength

Compared to conventional Method A, the results in Table 2 indicate that the delivery of SRA or SRA/CI solutions from within the LWA resulted in small increases in the compressive strength. For instance, the compressive strengths increased by 4% at 1 day, 6% at 7 days, and 6% at 28 days on average. These small strength gains were achieved despite the 5% average increase in the mix water (however with same effective w/c of 0.35). These results suggest that the effective water-cement ratio was not increased by an early release of water from the LWA before the setting of concrete, if any.

The strength results also indicate that the internally-cured high performance concrete mixes made with saturated LWA (HPC-4a,b and HPC-5a,b) developed strengths that were very similar to those of the sealed-cured control mix HPC-6 made with 100% normal-density aggregates at the ages of 7 days and 28 days. This indicates that the possible small strength loss due to the use of lightweight aggregate in concrete is compensated by the improved cement hydration and strength development provided by internal curing.

3.3 Autogenous shrinkage deformation

Figure 1 presents the free autogenous shrinkage deformations measured for the high performance concrete mix formulations, where each curve is an average of three tests. Before discussing the effect of the admixture delivery method, a comparison between any of the internally-cured high performance concretes and the control mix HPC-6, which was sealed to prevent drying shrinkage, reveals a drastic change in the deformation behaviour. HPC-6 starts to contract immediately after the setting of concrete with rapidly developing and significant autogenous shrinkage, reaching –260 µm/m at 28 days. By contrast, HPC-4a,b expanded to +130 µm/m and HPC-5a,b expanded to +260 µm/m in less than 24 hours, providing some pre-stress in concrete against developing tensile stresses. Similar early-age expansions for large-size internally-cured HPC specimens have been observed in previous work [5, 16]. This expansion may be related to ettringite formation and/or swelling of the gel hydration products, as it has been hypothesized earlier [17]. After the peak expansion was reached, a small shrinkage deformation has developed (about –40 µm/m on average over 28 days). The reason for the higher expansion peak observed in HPC-5 compared to HPC-4 is yet to be clarified. With regard to the admixture delivery method, the curves in Figure 1 indicate that both conventional Method A and new Method B resulted in very similar deformation behaviours over 28 days of testing (either before or after the expansion peak). Since the expansion started to develop immediately after the setting of concrete (opposite of HPC-6), it may be said that the release of moisture from the LWA also initiated immediately after the setting of concrete.

9th Symposium on High-Performance Concrete, Design, Verification & Utilization, Christchurch, New-Zealand, 8-12 August, 2011.

Page 7 Figure 1: Autogenous shrinkage strains of HPC-4 (IC/SRA), HPC-5 (IC/SRA/CI)

and HPC-6 (Control)

It is important to note that the shrinkage-reducing admixture used in HPC-4a,b and HPC-5a,b at the time this study was conducted was known to potentially affect the effectiveness of the air entraining admixture, as stated on the manufacturer’s product data sheet. Since then, a new SRA has been formulated by the manufacturer to address this issue.

4. CONCLUSIONS

Based on the results presented in this paper, the following conclusions are drawn:

- Internal curing with saturated lightweight aggregate in a 0.35 w/c high performance concrete can achieve high compressive strengths above 50 MPa in 7 days, which were very similar to those tested on sealed-cured normal-density high performance concrete;

- Internal curing drastically changed the deformation behaviour of HPC from rapidly developing and large shrinkage to high-early expansion followed by negligible shrinkage; - New admixture delivery from pre-soaked LWA produced no adverse effects on fresh concrete

properties, compressive strength and shrinkage deformation;

- New admixture delivery method prevented the loss in effectiveness of the air entraining admixture when used in combination with the SRA. In these mixes, similar entrained air contents between 4% and 5% were achieved with 10 times less air entraining admixture; - New admixture delivery method allowed the use of 5% more mix water for easier

consolidation while achieving 6% higher compressive strengths at 7 days and 28 days. -300 -200 -100 0 100 200 300 0 7 14 21 28 A ut oge nous s hr inka ge s tr ai n ( x10 -6)

Time after setting (days) Sealed specimens (average of 3 tests) HPC-4b (Method B) HPC-4a (Method A) HPC-6 (Control) HPC-5a (Method A) HPC-5b (Method B)

9th Symposium on High-Performance Concrete, Design, Verification & Utilization, Christchurch, New-Zealand, 8-12 August, 2011.

Page 8 ACKNOWLEDGEMENTS

The financial contributions of our project partners are gratefully acknowledged, including: City of Ottawa, Federal Bridge Corporation, National Capital Commission, Transports Québec, and W.R. Grace. The authors would like to thank the following manufacturers for providing the materials used in this project, namely: W.R. Grace (chemical admixtures); Northeast Solite Corporation (LWA); and Lafarge Canada (cement).

REFERENCES

[1] FHWA, Status of the Nation’s Highways, Bridges, and Transit: Conditions & Performance – Report to congress, Federal Highway Administration, 2006.

[2] TRB, Transverse cracking in newly constructed bridge decks, National Co-operative Highway Research Program Report 380, Transportation Research Board, National Academy Press, Washington, 1996.

[3] Cusson, D. and Repette, W.L., Early-age cracking in reconstructed concrete bridge barrier walls, ACI Materials Journal, 97(4), July/August 2000, 438-446.

[4] RILEM TC-196, Internal Curing of Concrete, State-of-the-art Report of RILEM Technical Committee 196-ICC, Edited by K. Kovler and O.M. Jensen, RILEM Publications S.A.R.L., Bagneux, France, 2007, 139 p. [5] Bentz, D. P. and Weiss, W. J., Internal curing: a 2010 State-of-the-Art Review, Report No. NISTIR 7765,

National Institute of Standards and Technology, U.S. Department of Commerce, February 2011, 82 p.

[6] Weber, S. and Reinhardt, H.W., A New Generation of High Performance Concrete: Concrete with Autogenous Curing, Advanced Cement Based Materials, 6(2), 1997, 59-68.

[7] Jensen, O.M. and Hansen, P.F., Water-Entrained Cement-Based Materials: I. Principle and Theoretical Background, Cement and Concrete Research, 31(4), 2001, 647-654.

[8] Zhutovsky, S., Kovler, K. and Bentur, A., Influence of cement paste matrix properties on autogenous curing of high-performance concrete, Cement and Concrete Composites, 26, 2004, 499–507.

[9] Bentz, D.P., Lura, P. and Roberts, J.W., Mixture proportioning for internal curing, Concrete International, February 2005, 1-6.

[10] Cusson, D., Lounis, Z. and Daigle, L., Benefits of internal curing on service life and life-cycle cost of high-performance concrete bridge decks – A case study, Cement and Concrete Composites, 32, 2010, 339-350. [11] Bentz, D., Capitalizing on Self-Desiccation for Autogenous Distribution of Chemical Admixtures in

Concrete. In B. Persson, D. Bentz, & L.-O. Nilsson (Ed.), 4th International Seminar on Self-Desiccation and Its Importance in Concrete Technology, Lund University, Gaithersburg, 2005, 189-196.

[12] Bentz, D. and Turpin, R., Potential Applications of Phase Change Materials in Concrete Technology, Cement and Concrete Composites, 29(7), 2007, 527-532.

[13] Bentz, D., Snyder, K. and Peltz, M., Doubling the Service Life of Concrete Structures. II: Performance of Nanoscale Viscosity Modifiers in Mortars, Cement and Concrete Composites, 32(3), 2010, 187-193.

[14] Cusson, D. and Margeson J., Development of low-shrinkage high-performance concrete with improved durability, 6th International Conference on Concrete under Severe Conditions, Environment and Loading (Consec'10), Mexico, Vol. 2, June 7-9, 2010, 869-878.

[15] CSA A23.1, Concrete Materials and Methods of Concrete Construction / Methods of Test and Standard Practices for Concrete, Canadian Standard Association, Mississauga, Canada, 2004.

[16] Cusson, D. and Hoogeveen, T., Internal curing of high-performance concrete with pre-soaked fine lightweight aggregate for prevention of autogenous shrinkage cracking, Cement and Concrete Research, 38(6), 2008, 757-765.

[17] Bentz, D.P., Sant, G., and Weiss, W.J., Early-age properties of cement-based materials: I. Influence of cement fineness, ASCE Journal of Materials in Civil Engineering, 20(7), 2008, 502-508.