Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Canadian Building Digest, 1964-07

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=1a5c09da-0751-4532-868c-823fb7df7447

https://publications-cnrc.canada.ca/fra/voir/objet/?id=1a5c09da-0751-4532-868c-823fb7df7447

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40000876

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Glazing Design

Canadian Building Digest

Division of Building Research, National Research Council Canada

CBD 55

Glazing Design

Originally published July 1964 G.K. Garden

Please note

This publication is a part of a discontinued series and is archived here as an historical reference. Readers should consult design and regulatory experts for guidance on the applicability of the information to current construction practice.

Glass, clear or tinted, in single or multiple layers, is successful in meeting its requirements as an element in an exterior wall. The joint between the glazing unit and the window sash or frame, however, is vulnerable because of the many requirements it must fulfil. The most common expressions of failure are glass breakage and rain and air leakage. Successful glazing requires an understanding of all the factors that contribute to failures and a knowledge of the properties of the materials to be used. Knowledge of the requirements of each component of the joint detail is also essential. The demands upon each component of the joint can be minimized by good design. Herein lies the secret to successful glazing.

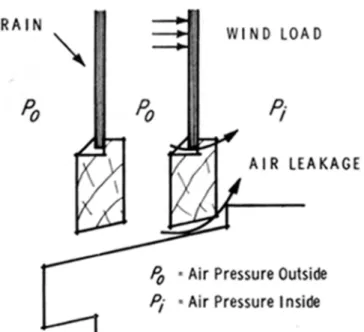

The requirements of the glazing joint and the glazing compounds are related to the properties of the environments being separated. Where a single glass unit is installed in a sash or frame, the joint must meet the requirements of the wall (CBD 48), in particular providing rain and air leakage control and withstanding wind loads. Where two windows (Figure 1) or two sheets of glass in separate rabbets are used the properties of the environments being separated by each can be quite different. With the air pressures on both sides of the outer unit intentionally equalized, the outer pane of glass and its joints will be required to act as a deterrent to rain leakage but not to prevent air leakage or support wind loads other than aerodynamic effects. The inner glazing unit and joints, however, must sustain the wind load and prevent air leakage they are not required to control rain penetration for they should never be wet. Obviously the requirements of the glazing details in this example have been greatly eased. Similar advantages can be gained by proper treatment of a single joint using a double seal.

Figure 1. Requirements divided between two elements to reduce the demands imposed upon each.

Requirements of the Glazing Detail

The glazing detail must provide for holding the glass securely in the wall while preventing direct contact with its surround, despite the differential movements that must be permitted to take place. It must prevent rain and air leakage and yet provide for easy repair in the event of glass breakage. Glazing should be accomplished with materials and workmanship available at a reasonable initial cost and yet perform well with a minimum of maintenance.

The requirements of the glazing detail are met jointly by the surround and the glazing materials used. Differential movements between the glass and its surround can be reduced but not eliminated by increasing the glass or frame stiffness. In determining the amount of glass movement in the surround it should be borne in mind that all the vertical movement will take place at the head, since the glass is supported at its base, unless the glazing materials in the jambs have sufficient hold to support it. Sidewise movements will be relatively equal unless the hold on the glass is greater on one side than on the other.

Warpage of wood from moisture changes is well known, but similar effects occur in metal sash and frames as a result of temperature differences. Unequal temperatures on the two sides of a mullion or transom bar will cause differential thermal strains that result in deflection of the member. This occurs frequently when these members are composed of two or more pieces intermittently fastened to each other. The glass and frame will also move differentially owing to their having different coefficients of thermal expansion. The coefficient of expansion for glass is approximately 5 x 10-6/°F, whereas for aluminum it is 13 x 10-6/°F. In addition to this, their

temperatures under solar radiation will be quite different. The maximum temperature to be expected in a single pane of clear glass is approximately 110°F, whereas aluminum may reach 150°F and, if black, 180°F or more. Other materials will behave in a similar manner in accordance with their respective properties.

The depth of the rabbet in the surround must be sufficient to provide the desired edge cover on the glass and permit differential movements between the glass and its surround without allowing them to come into contact. The seal of factory-fabricated multiple glazing units should be concealed by the edge cover and a continuous air space between the glazing unit and the surround should be maintained at all times.

The edge cover on the glass must maintain sufficient bearing to transmit lateral loads despite withdrawal of the glass as a result of differential movements from thermal contraction and

deflection as well as movements of the surround. Thermal stressing that results in breakage is common when the covered edges of the glass remain cool while the central portion gets warm and expands. If the window sash or frame is cold, further edge cooling occurs to aggravate the condition. If the frame, however, has been designed to be as warm as possible (CBD 44), this condition can be modified. Experience has shown that the smaller the edge cover the less is the likelihood of thermal edge breaking, with an edge cover of about 1 to 1½ inches producing the worst situation.

Requirements of Glazing Materials

Glazing materials must act as a cushion and separator between the glass and its surround, maintain rain and air leakage control allow differential movements to take place, and take up tolerances.

As a cushion separator the glazing materials must dampen vibration and impact loadings, yet be stiff enough to maintain the position of the glass in the rabbet against all normal loadings. As most glazing and sealing materials cannot sustain the lateral loads it is necessary to use resilient spacers that have sufficient bearing stiffness to resist the imposed loads and prevent the extruding or squeezing out of the glazing materials. Glazing materials and spacers must be of sufficient resilience and thickness to permit bending of the glass in the rabbet or torsional defections of the surround without stressing the glass excessively.

Air Leakage

Air leakage is accompanied by dust and odour infiltration, increased heating and cooling loads, and makes the holding of controlled relative humidities in a building very difficult (CBD 23). Air exfiltration in winter through glazing details in humidified buildings is most critical, because it is inevitably accompanied by condensation within the joint. The accumulation of water causes accelerated deterioration of the glazing materials and may cause breakage of the glass if frozen in a confined space. Water from condensation in the joint can run out if drainage to the exterior has been provided. When it is not provided, however, the water may find entry to the interior, causing what appears to be rain penetration.

Rain Penetration

Rain penetration is a major problem with glazing and must be controlled by the glazing materials. Through-wall penetration of rain is a readily recognized nuisance because it always occurs when it is raining and causes flooding of sills, walls and floors, with attendant staining and damage to finishes. Partial rain penetration is seldom recognized, but has various delayed effects and is partially responsible for glazing material deterioration, accelerated failure of factory-sealed multiple glazing units and glass breakage, especially when corrosion of the surround occurs.

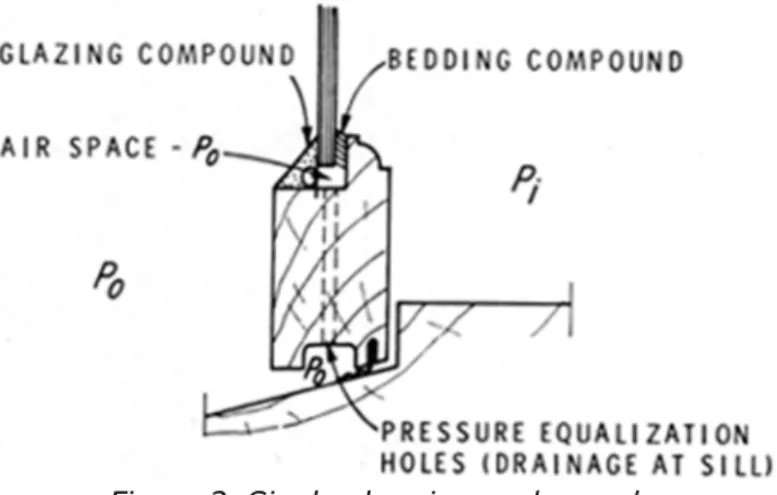

Figure 2. Store front metal glazing detail.

To prevent rain penetration it is necessary to remove one of the three conditions that cause it. There can always be water on the face of the joint and experience has shown that openings inevitably occur; consequently, it is necessary to control the forces acting to move the water inward. It has been shown (CBD 40) that with a deterrent to water entry at the wetted face, an air seal at the dry side of the joint, and the air pressure in the space so created equalized with outside, the forces causing rain penetration can be controlled. The openings from this space can be direct to the exterior, if protected, or from some adjacent dry space wherein the air pressure is permitted to equalize with that on the exterior. The space should, however, always be drained to the exterior, since some water may gain entry from rain penetration or vapour condensation.

Figure 3. Single glass in wooden sash.

Although this principle of rain penetration control has seldom been intentionally applied to glazing details, it is responsible for the good performance of many store-front metal glazing systems (Figure 2). There is only very limited experience to date with its application to small scale details such as single glass in wooden sash (Figure 3). It has been concluded, however, that the intentional air leakage from outside into the space in the joint must be considerably greater than the leakage past the air seal at the inside. A recently developed metal window (Figure 4) does employ air pressure equalization in the space between the sash and frame, and it is quite simple to allow for pressure equalization in the glazing detail if outside glazed. Some problems have yet to be overcome when inside glazing is employed.

Figure 4. Contemporary metal window.

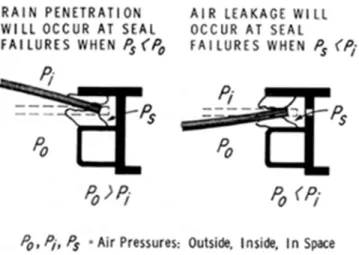

Rain and Air Leakage

Rain penetration normally occurs when there is an inward drop in air pressure. Under this condition the glass is forced against the inside cushion seal, providing improved airtightness (Figure 5), but is moved away from the outer seal. To prevent rain entry a glazing material with good adhesion and extensibility or a compressed material that will maintain intimate contact with both the glass and the surround is required at the exterior. Without pressure equalization across the outer seal any air leakage through even minute failures will be accompanied by rain penetration. With satisfactory pressure equalization, however, rain penetration will not occur unless the openings are over capillary dimensions and located where gravity can draw the water through. With the space drained to outside this small leakage will be no problem, provided that water does not contact the inner seal.

Figure 5. Effects of pressure differentials.

Rain penetration seldom occurs when the air pressure drop is outward, but because the glass is moved outward there is the possibility of opening the inner seal. In this case adhesion and extensibility or a compressed material are required at the interior; with the air space open to the exterior, this is the only plane of air-tightness. As mentioned, air exfiltration in winter can cause condensation within the air spaces and should be minimized.

Differential Movements

In addition to the previous requirements of the glazing materials, differential movements must be permitted to take place. When the material adheres to the glass and surround it must be of sufficient dimension to permit the extension and shear stresses imposed by the movements of

both the glass and its surround. Where compressed gaskets are employed they are relieved of some of the shear stressing through glass slippage. It is important, however, that gaskets be securely attached to the surround to prevent their being worked out of the joint.

In glazing details where tolerances are large, particularly in the surround, the use of a formed in situ gasket or sealant has certain advantages over most gaskets available at this time.

Durability of the Glazing Materials

To determine an acceptable glazing material the designer must know the environmental conditions, the movements to be allowed for and the major mechanisms of deterioration of the materials. Environment in this context is intended to mean the total environment, since such factors as inquisitive fingers have been responsible for glazing failures.

Solar radiation accelerates the breakdown of most organic materials, one prominent effect on glazing materials being the loss of adhesion at the glass surface. A design where adhesion is not essential is an obvious answer to this problem. The glazing materials must retain their desired properties over the range of temperatures to be expected; and in the Canadian climate these can be from -40°F to as high as 200°F. It must not have thixotropic properties (become liquid due to rapidly alternating stress) for working of the seal will occur. Bleeding and sagging of some glazing materials has been found to be partially attributable to this property.

When several glazing and sealing materials are used in the same joint (including that used in a sealed glazing unit) the compatibility of all the materials is of utmost importance. Solvents in one material may have an adverse effect on another, or products from deterioration of one material can be transported to another by water and damage it. Water is a common factor in many of the mechanisms of deterioration of most glazing materials and must be excluded from the glazing detail.

Problem-free glazing can be achieved by proper cushioning of the glass and allowance for differential movements, and by a reduction in the range of requirements imposed on each element in the glazing detail. An air space, satisfactorily opened to the exterior, will relieve the outer seal of air leakage control and the inner seal of rain leakage control. The durability of the glazing materials can also be enhanced by the exclusion of water from the glazing detail.