Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Research Paper (National Research Council of Canada. Division of Building

Research); no. DBR-RP-303, 1967-02-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=e45f7a5e-7e63-4d82-bd01-6707b1cd2c71 https://publications-cnrc.canada.ca/fra/voir/objet/?id=e45f7a5e-7e63-4d82-bd01-6707b1cd2c71

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001491

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Experimental study on moisture and fire endurance

Ser TH1

N2lr2

A M & ~ & ~ Z E Q

no. 303 NATIONAL RESEARCH COUNCIL

c . 2

CANADA

BLDG CONSEIL NATIONAL D E RECHERCHES

Experimental Study on Moisture

and Fire Endurance

I

i . ...

.7 r Repr' ed fromf

:*-J

?Mire

T

chnology $ 1.rt

Vol. 2, No. I February 1966c7-,

4.

52.

-

e5

Research Paper No. 303 of the

OTTAWA February 1967

ETUDE EXPERIMENTALE CONCERNANT L'HUMIDITE E T LA RESISTANCE AU FEU

S O M M A I R E

L'auteur a rdcemment de'crit une me'thode permettant d'kvaluer l'effet de l'hurnidite' sur la re'sistance au feu des ile'ments de construction. Cette me'thode est base'e sur une expe'rimentation approfondie ayant donne' lieu

?I

prks de 50 essais de rdsistance au feu. Dans l'article dont il est question ici, l'auteur dkcrit les me/thodes d9expdrimentation qu'il a ernploydes et il indique les rdsultats obtenus.F I R E TECHNOLOGY

Experimental Study on Moisture

and Fire Endurance

T. Z.

HARMATHYDivision of Building Research

National Research Council (Canada)

The author describes the test procedure for, and the results of, many small-scale fire tests conducted during a recently reported study that was made to provide information for numerically evalu- ating the effect of moisture on fire endurance. H e concludes with an equation for calculating the fie endurance of a building ele- ment at a given moisture content when its fire endurance at some other moisture content is known.

I

T

IS well known that the presence of moisture in building elements is beneficial to their fire endurance, unless it is present in amounts that would produce spalling. The absorption of heat associated with the de- sorption of moisture represses the rise of temperature in a building element during exposure to fire and thus delays the development of certain unde- sirable phenomena that eventually lead to the failure of the element.A comprehensive study, consisting of many small-scale fire tests and computer calculations, was conducted in this laboratory to provide in- formation for the numerical evaluation of the effect of moisture on the fire endurance on certain brick and concrete building elements. The result of this study was recently published in a somewhat condensed form.' As it was not possible to include detailed information concerning the test pro- cedure and the results of the fire tests, the experimental part of the study is re-examined here in a considerably expanded form.

It

is hoped that this informationwiU

be of interest to those concerned with the practical impli- cations of the problem.E X P E R I M E N T A L P R O C E D U R E

The term "small-scale fire test" is generally used to denote tests con- ducted on specimens whose length and breadth are smaller than the mini- mum measurements prescribed by ASTM E119.

It

should be emphasized NOTE: This paper is a contribution from the Division of Building Research, Na- tional Research Council, Canada, and is published with the approval of the Director of the Division. The author wishes to thank E. 0. Porteous for his assistance in con- ducting the experimental work.Copyright 1966 NATIONAL FIRE PROTECTION ASSOCIATION

60 BATTERYMARCH ST., BOSTON, MASS. 02110 Printed in U.S.A.

Moisture and Fire Endurance

Figure 1 . Small-scale fire test assembly.

1 - Electric test furnoce 5 - Multipoint temperature re- 2 - lnconel p l a t e corder

6 - T e m p e r a t u r e c o n t r o l l e r - 3 - Air supply control equipment recorder

4 - O x y g e n analyzer 7 - Saturable core reactor

that the cross-sectional geometry of these small-scale specimens is not scaled down; therefore, from the point of view of heat flow, these tests are actually full-scale tests. Experience over several years has shown that there is no significant difference in thermal fire endurance

*

values obtained in this laboratory by these small-scale tests and by full-scale standard tests.The furnace used in this series of experiments has an opening approxi- mately 30 in. by 30 in. and is heated electrically. Heat input is controlled so that the furnace temperature follows the standard time-temperature curve. Figure 1 shows the testing assembly, which has been described in detail in a previous paper.2

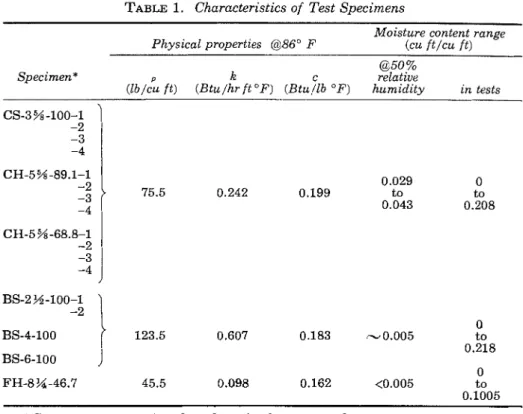

To fit the furnace opening, all specimens were made approximately 32 in. square. They represented three materials of widely different properties and seven different cross-sectional geometries. Table 1 lists the specimens and describes some of their characteristics.

*Thermal fire endurance - the time a t which the average temperature on one side

of a test specimen exceeds its initial value by 250' F when the other side is exposed to a

Fire Technology

TABLE 1. Characteristics of Test Specimens

Moisture content range Physical properties @86' F (CU f t / c u f t )

@50%

Specimen* k relat~ve

(lb/cPu ft ) ( B t u / h r f t ° F ) ( ~ t u ; l b OF) humidity i n tests

0.218 BS-6-100

0

FH-8 ?4-46.7 45.5 0.098 0.162 <0.005 t o

0.1005

* C = concrete, 17.5% hydrated portland cement and 82.5% expanded shale; B = b r o w n clay brick; F = insulating fire biick group 23; S = solid; H = hollow. T h e first n u m b e r is t h e overall thickness o f t h e wall, t h e second is percentage o f specimen v o l u m e t h a t is solid, and t h e third (if used) identifies specimens within a particular group.

Four to five weeks after their construction, all specimens were dried for 6 hrs in a furnace heated to 221" F. The oven-dry weight of each speci- men was recorded immediately after its removal from the furnace. Some were tested in oven-dry condition; others were transferred into poly- ethylene enclosures for storage and conditioning. Before the scheduled fire test, steam was introduced into the enclosure for the length of time necessary to raise the moisture content of the specimen to the desired level. Table 1 shows that prior to the test the moisture content of the speci- mens covered a range much larger than that corresponding to normal atmospheric conditions. Some preliminary calculations, based on nu- merical a n a l y ~ e s , ~ indicated that, if the moisture content were kept strictly within realistic ranges, the gain in fire endurance might be less than, or comparable with, the 'experimental error characteristic of fire endurance tests.

*

To obtain a sufficiently large number of experimental results, twelve of the specimens were subjected to more than one fire test. In the concrete

* T h e reproducibility o f thermal fire endurance values obtained b y small-scale t e s t s i s estimated t o b e f 4.0 per cent.

Moisture and Fire Endurance 55 specimens, some of the nonevaporable water contentt was lost during the first test. No further dehydration was detected during subsequent tests. Since the first test had undoubtedly brought about some permanent changes in the properties of the concrete, once-tested specimens were treated as if made from different material. The weight of a repeatedly tested specimen immediately after each test was considered to be its oven- dry weight for the following test.

The specimens were regarded as representing wall construction; there- fore, they were tested in vertical position.

F I G U R E O F M E R I T O F M O I S T U R E

Previous theoretical studiesGndicated that, for a given material and geometry of construction, the fractional gain in fire endurance in relation to the fire endurance in oven-dry condition, ( 7 , - T ~ ) / T ~ , is proportional

to the volumetric moisture content, 4. Consequently, the dimensionless group

which may be interpreted as the percentage gain in fire endurance due to one per cent moisture (by volume), is approximately constant for a speci- fied construction. The author has previously suggested' that this dimen- sionless group be given the name "figure of merit of moisture.''

The factor, 4, which denotes the volume of moisture present in a unit volume of the porous material, has been called the volumetric moisture content. In everyday practice it is more usual to express the moisture con- tent on a weight basis, i.e., pound of moisture per pound of the porous material in oven-dry condition. If the symbol m is used to denote the moisture content in this latter sense, the volumetric moisture content can be expressed as

By using 4 instead of m in Equation 1, the figure of merit of moisture is defined independently on the density of the building material.

The primary purpose of this experimental study was to learn how the figure of merit of moisture is affected by some characteristics of various building materials and the cross-sectional geometry of building elements.

E X P E R I M E N T A L R E S U L T S

The results of the small-scale fire tests are reported in Table 2.

Concrete specimens yielded 6 to 19 per cent higher fire endurance in the first runs than in subsequent runs. This phenomenon has been attributed

tNonevaporable water is t h a t amount of water t h a t cannot be dislodged by some

standard drying procedure (here, drying in a n oven a t 221' F). For further details see

Fire Technology

TABLE 2 . Results of Small-Scale Fire Tests

Moisture

Nature content, Fire endurance,

Run of Q (hr) Reference

No. Specimen run* (CU ftlcu ft) 7+ 7 runt J

* F R = first run, R R = repeat run.

t

The fire endurance obtained in these runs was taken as the fire endurance in oven- dry condition.Moisture and Fire Endurance 57

to the absorption of latent heat associated with the dehydration reactions taking place in the portland cement paste. The partial dehydration of the cement paste was also reflected by the permanent weight loss following the first runs.

The dehydration of mortar in brick and insulating fire brick specimens was hardly detectable by weighting; therefore, its effect on fire endurance was not taken into consideration.

I n addition to the moisture content prior to the test, the fire endurance of the specimen in oven-dry condition also had to be known to calculate the figure of merit of moisture, fi. As the properties of brick, insulating fire

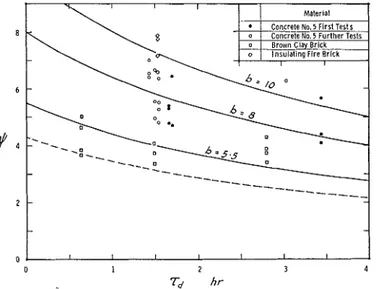

brick, and repeatedly tested concrete specimens were deemed to be un- affected by the fire tests, the fire endurance in oven-dry condition could be obtained from one of a series of tests performed on the same specimen. Of course, to calculate fi for first tested concrete specimens, T~ had to be obtained from a test performed on another specimen belonging to the same group. Computer calculations indicated that fi could be correlated with

Td with a fair degree of success; in other words, fi depended on the material properties and the cross-sectional geometry only through 7d.l

Figure 2 is a plot of fi versus ~d based on the experimental series. The considerable spread of the points may be understood in the light of the following observations:

The reproducibility of the thermal fire endurance values is about f 4.0 per cent.

The accuracy of the weight measurements may be taken as f 100 g, equivalent to a moisture content of f 0.1 to f 0.3 per cent by volume.

Material Concrete No.5 First Tests

o Concrete No.5 Further Tests

o Brown Clay Brick

o Insulating Fire Brick

---__

- -

-

-t I I I I I I

Figure 2. Relationship between figure of merit of moisture and fire endurance i n ouen- d r y condition.

58 Fire Technology There were undoubtedly more than negligible differences in the properties of specimens of supposedly identical materials.

In spite of the considerable spread of the points the experimental re- sults seem to support the following two conclusions, derived earlier1 on theoretical grounds:

e I+L increases with the permeability, v, of the material. e # decreases slightly with the increase of T ~ .

The spread of the points in Figure 2 is somewhat over-emphasized by the selection of the vertical scale. The total range of variation of

+

is, in fact, not very great (from 3.3 to 7.8), thus further experiments to learn more about the*

=*

( ~ d , u) (3) relation would serve little practical purpose.It

is believed that the ac- curacy of the following empirical equation will probably prove sufficient from a n engineering point of view:I n Equation 4, b is a factor dependent on v, and may be taken as 5.5 for brick, dense concretes, and gun-applied concretes; 8.0 for lightweight con- cretes; or 10.0 for cellular concretes.

The curves representing Equation 4 with the recommended values of b are shown as solid lines in Figure 2. The dashed line describes Equation 4 with b = 4.3 which, according to the results of 90 computer calculations, is representative of materials (hypothetical) exhibiting zero permeability in the direction of heat flow.

By combining Equations 1 and 4, the following equation is obtained-

This equation may be utilized to calculate the fire endurance of a building element a t a given moisture content if its fire endurance a t some other moisture content is known. A sample calculation has been presented in Reference 1.

N O M E N C L A T U R E

b = factor, function of v, hr

c = specific heat, Btu/lb

"

Fk = thermal conductivity, Btu/hr f t

"

Fm = moisture content, referred to oven-dry weight, lb/lb

u = permeability, Darcy

Moisture and Fire Endurance

p, = density of water, lb/cu f t

rd = fire endurance in oven-dry condition, hr

T+ = fire endurance a t moisture content

+,

hr4 = volumetric moisture content, cu ft/cu f t

+

= figure of merit of moisture, dimensionlessR E F E R E N C E S

1 "The Effect of Moisture on the Fire Endurance of Building Elements," Tibor Z.

Harmathy, in Moisture of Materials i n Relation to Fire Tests, ASTM Special Technical Publication No. 385 (1965), pp. 74-95.

"Small-Scale Fire Test Facilities of the National Research Council," J. A. Claude Blanchard and Tibor Z. Harmathy, NRC No. 8207, National Research Council, Division of Building Research (1964).

3 "A Treatise on Theoretical Fire Endurance Rating," Tibor Z. Harmathy, in

Symposium on Fire Test Methods, ASTM Special Technical Publication No. 301 (1961), pp. 10-40. Reprinted as NRC 6305.

"Studies of the Physical Properties of Hardened Portland Cement Paste," T . C. Powers and T. L. Brownyard, Portland Cement Association Research Laboratories Bulletin No. 22 (1948), p. 257.