READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Structural design of urban roads

Elhussein H. Mohamed; Nofal, M.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=3dac3df3-3be9-4b73-ac62-caf97cfc96f9 https://publications-cnrc.canada.ca/fra/voir/objet/?id=3dac3df3-3be9-4b73-ac62-caf97cfc96f9

STRUCTURAL DESIGN OF URBAN ROADS

by

Elhussein H. Mohamed1 and Mostafa Nofal2

Institute for Research in Construction, National Research Council Canada 1500 Montreal Road, Ottawa, CANADA K1A 0R6

Summary Résumé

Municipal engineers are faced with the difficult task of managing the urban roadway network. Maintaining this significantly large and expensive infrastructure requires effective planning and design. However, the majority of currently available design tools were developed originally for analyzing highway pavements. Little attention has been given in the past to urban road related issues. The environment under which urban roads operate is uniquely different from highways. Traffic in urban roads is slower and involves braking and turning maneuvers, which introduces critical loading conditions to a pavement surface. Heavy urban buses is another traffic element contributing to the critical loading conditions in urban roads specially at intersections, near loading stations and along Transitways (dedicated bus lanes). Urban road users and businesses are very sensitive to traffic disruptions specially those associated with maintenance operations. The presence of utility pipes and the need to reach them by cutting the road for maintenance purposes or for adding new services, also affect the performance of urban roads. All of these unique characteristics suggest the need for urban pavement analysis beyond that developed for highways.

Review conducted by a multi-disciplinary research team assembled at the National Research Council of Canada, revealed a number of deficiencies in the adopted practices. However, the most significant weakness relates to the theoretical construct that supported earlier developed systems for pavement analysis. Inadequacies of these systems made their use in carrying out road engineering tasks such as material selection, structural design and performance prediction unreliable and less effective. This paper addresses these inadequacies while focusing on critical elements of pavement analysis such as modeling of pavement materials, the road pavement structure and traffic loading. The paper also discusses a new approach to pavement analysis, which benefits from recent developments in material science and engineering mechanics, to demonstrate its effectiveness in addressing urban road engineering requirements. The success of the proposed new approach lies in its ability to accurately determine the state of stress associated with realistic traffic loading conditions, an essential element in producing the information necessary for making correct design decisions. Of particular importance is the ability of the new approach to account for pavement in-service condition while predicting performance, a factor completely ignored in current pavement analysis exercises aimed at selecting the appropriate rehabilitation measure and proceed with its design.

1Research Officer, Institute for Research in Construction, National Research Council of Canada.

He can be reached at mohamed.hussein@nrc-cnrc.gc.ca or at (613) 993-3817.

2Research Officer, Institute for Research in Construction, National Research Council of Canada.

1. Urban Roads

Rehabilitated urban roads rarely last their design life. Rapid rates of deterioration and incidents of premature failure are quite common. Considering the fact that roads and other municipal services are now competing for limited resources, an improved format for management of urban roads is needed. Pavement analysis is one of the tools required to address the perspectives and concerns of municipal engineers related to road rehabilitation planing and design. The following questions need to be answered prior to implementation of any major rehabilitation program:

• When is the right time to introduce a preventative rehabilitation measure to effectively extend the service life of a road?

• What are the parameters needed to carry out the necessary analysis? • How can the structural integrity of an existing road be taken into account? • How are choices made between available rehabilitation techniques?

• Which material or combination of materials will satisfy the requirements of the selected alternative?

• Which technical specifications will guarantee effective implementation of the chosen solution?

Construction cost associated with various rehabilitation options differs substantially. It is important that pavement analysis enables engineers to determine early in the project life whether to seal cracks, overlay the entire road, recycle an existing surface, partially or totally reconstruct one or more of the existing pavement layers prior to constructing a new surface, etc. Unfortunately, none of the above question can be answered with confidence and there is no guarantee that any of the rehabilitation options will survive urban traffic. Cracks in the existing structure may reflect prematurely on to a new overlay, rutting may develop and continue to deepen, construction joints may open and widen and lead to the formation of potholes. While there are a number of factors that may lead to such performance, pavement analysis should enable engineers to predict these trends accurately and to develop counter measures.

2. State-of-the Art

The theoretical construct of existing pavement models is based primarily on Boussinesq’s solutions and multi-layered linear elastic analysis. Simplifying assumptions built into these solutions include (a) homogeneity of the materials of different layers of the pavement structure (b) isotropic layer properties and (c) linear elastic response of asphalt concrete. These assumptions ignore critical elements necessary for conducting effective pavement analysis, as will be demonstrated in the following subsections. The discussion is carried out under three categories, namely: material characterization, traffic loading and in-service conditions. These three elements represent major pavement analysis input requirements for effective damage assessment and consequently performance prediction.

2.1 Material Characterization

The format for analysis provided by current analytical models does not accommodate all of the material properties that may influence the characteristic response of a pavement layer to external loading. For example, the assumption that material properties of the surface layer are homogenous ignores the strong heterogeneous nature of asphalt concrete. The significant differences in mechanical and thermal properties of mineral aggregates and asphalt cement, which forms the mix, have a direct impact on the behavior of asphalt concrete. The absence of a format to account for these differences rendered current systems of analysis ineffective in supporting material selection and mix design tasks. Recent initiatives such as those developed by the Strategic Highway Research Program (SHRP) managed to advance binder characterization substantially but failed to achieve the desired impact because of the absence of a format for structural analysis that may benefit from these advancements. Binder properties such as dynamic shear modulus (G*), phase angle (δ), stiffness and ultimate strain at failure (Bahia and Anderson 1995) are effective measures that can be used to predict damage such as rutting and thermal cracking if incorporated in pavement analysis.

The complexities associated with analyzing asphalt concrete as a composite material involving interactions (chemical and physical) between the binder and mineral aggregates, discouraged researchers from pursuing analysis that may reflect the behavior at the interface (bond strength). However, by assuming homogenous, isotropic and thermally compatible material, current pavement analysis failed to capture the influence of these properties on damage caused by externally applied loads. These assumptions forced the current approach to pavement analysis to rely heavily on characterizing materials using global properties, mainly the elastic modulus and Poisson’s ratio of the asphalt concrete, base and sub-base. The assumption that asphalt concrete may be considered homogenous, continuous and isotropic has been maintained regardless of the theory used to determine the layer response (e.g., elasticity, viscosity, plasticity, and/or fracture mechanics).

It is common knowledge that asphalt concrete is a heterogeneous material composed of coarse aggregates embedded in a matrix made of asphalt cement and fine aggregates populated by many defects (voids, micro-cracks). Asphalt concrete mix designs, such as hot mix asphalt (HMA) and stone mastic asphalt (SMA), involve different material proportions and the compaction process produces different aggregate and void structures within the matrix. Under these circumstances, and considering the fact that thermal and mechanical properties of mineral aggregates and binders are uniquely different, the mix components are expected to respond differently to externally applied loads and consequently contribute differently to damage. Therefore, modeling this composite material must reflect properties of individual components. In current pavement analysis systems, there are no links between material characterization and structural design. Furthermore, road foundation materials are assessed through gradation analysis and indices, such as California Bearing Ratio (CBR). These properties cannot be used to characterize the mechanical response of unbound pavement layers and their contribution (base and sub-grade) to road performance remains a mystery.

2.2 In-Service Condition

Analysis designed to assess/quantify the structural integrity of existing pavements should incorporate all elements that may influence the response of the pavement to external loading. These elements include microstructure features related to the initial state of materials following construction as mentioned in Section 2.1. Other elements may include damage induced during the service life of the structure such as localized cracking associated with exposure to extremely low temperatures (Kim and El Hussein, 1995). Damage may also include rutting associated with the flow

of asphalt cement and/or deformations of the supporting layers of the pavement under the action of heavy trucks. Even if roads are resurfaced, ruts may increase in depth and cracks may continue to propagate under continued traffic loading and exposure to elements of the environment. However, the current system of analysis is not capable of considering these factors for the structural analysis. The theoretical construct does not allow for incorporating these features (voids, cracks, ruts, etc.) in determining the state of stresses associated with external loading, a process necessary for evaluating different rehabilitation techniques that may enhance the structural integrity of pavements. One such critical factor relates to cracks existing throughout or a fraction of the asphalt layer depth.

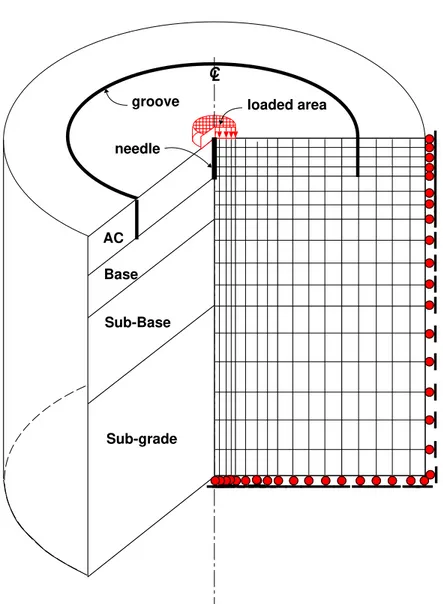

To model existing cracks the method of analysis and the strategy of the adopted solution should recognize their existence and simulate them. A finite element solution based on axisymmetric analysis will not model these cracks because of limitations associated with the geometry of the problem. Based on axisymmetric representation, only vertical cracks in the shape of a tube or a circular groove, as shown in Figure 1, may be modeled under this assumption. However, none of these crack patterns represents the real forms observed in the field. Therefore, the current approach failed to accommodate in-service pavement conditions and proved unsuccessful in designing/evaluating rehabilitation measures. The impact of ignoring a crack on the surface of an existing pavement on the state of stress will be demonstrated after presenting the new approach to pavement analysis.

2.3 Loads

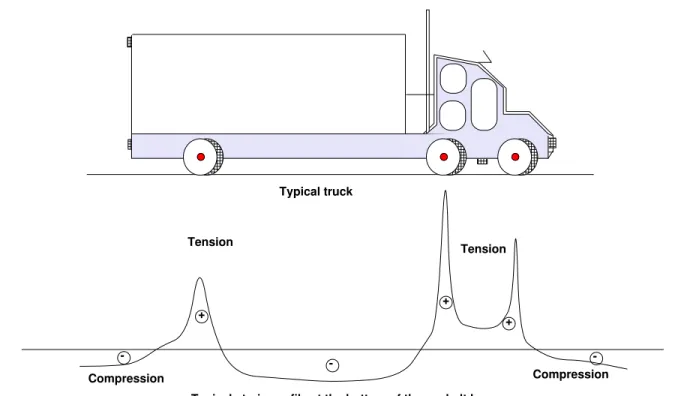

Traffic loading in current practice is applied as an equivalent single-axle load (ESAL) in the form of uniform stress acting over a circular contact area. This choice dictates a solution to the problem based on the assumed axisymmetric stress condition (Duncan et al., 1968; Peattie, 1979). The underlying assumption employs a load at a single location obscuring the impact of multiple loading conditions associated with a group of axles (see Figures 1 and 2). Principles of superposition adopted in the current approach will not capture the actual stress field, a critical element in pavement damage prediction. The concern of the previous attempts to evaluate the impact of vehicles traveling on a pavement has been focused on capturing the combined influence of the entire traffic mix on pavement damage (Fwa et al., 1994; Hajek, 1994; Perdomo and Nokes, 1994). Recently, new concerns arise when a new truck type or urban bus are being designed requiring estimates of potential pavement damage associated with the operation of these vehicles. This step is needed before certifying a vehicle (operating license) or specifying weight limits. Pavement analysis should enable engineers to address these concerns by quantifying damage associated with specific wheel/axle configurations and tire pressures. The current approach based on the use of ESAL does not provide the framework for analysis considering vehicle characteristics different from those adopted as a standard vehicle.

Determination of the true state of stress necessitates that truck loads transferred through individual tires be modeled based on actual tire prints and pressure. This approach will eliminate current inaccuracies associated with analysis based on a uniform circular loaded section followed by another approximation designed to capture the effect of the entire wheel assembly by using the principles of superposition. In general, realistic analysis must consider details such as (i) tire inflation pressure, (ii) axle load, (iii) axle configuration, and (iv) vehicle motion. According to the existing literature, the contact pressure is known to influence the rate of shear flow of asphalt cement, which constitutes a major share of the deformations in asphalt concrete pavements (Pidwerbesky 1994). The result of changing the contact pressure (constant contact area) during a stress-controlled test

suggests a critical tire pressure beyond which the rate of shear deformation increases substantially (El Hussein and Yue 1994). Considering a constant contact pressure, an increase in the axle load will increase the contact area, which will have an impact on the state of stress and the rate of deformation and consequently the rate of pavement damage caused by a given truck (Perdomo and Nokes 1994). Addressing all of these factors will provide road and vehicle designers, through analysis, with the state of stress and strain corresponding to changes in road and vehicle variables. Moreover, the number of axles, their relative position on the chassis of the truck and spacing between the axles will affect the distribution of a truck-load between axles. The combined effect of all axles cannot be evaluated on the basis of the concept of a single-axle wheel load (ESAL), since the method of superposition will miss essential details necessary for determining the state of stress and strain, and accordingly, the type and extent of damage.

Finally, forces acting on the pavement surface are influenced by the actions of a moving vehicle. Pavement response, and hence damage, are affected by dynamic loading conditions. Dynamic loads depend on the vehicle’s suspension mechanisms and the condition of the road surface. Road surfaces are responsible for initiating this dynamic effect, which magnify the applied forces when wheels bounce as a result of traveling over uneven road surfaces. Future efforts should consider this factor while assessing damage induced in pavements.

Other factors related to vehicle motion include the magnitude of the horizontal force acting on a pavement surface and the area of contact between the pavement and the tire. Recent studies showed that horizontal forces exerted by a vehicle wheel increase the tensile strains in the pavement surface by the order of 7 to 12 times those induced when only vertical loads are considered (Perdomo and Nokes 1994). However, the magnitudes of these forces are chosen arbitrarily in current attempts to capture the impact of dynamic loading. Typical vehicle motion includes initial acceleration followed first by steady-state travel, then by deceleration and finally by a full stop. The horizontal force applied on the pavement differs from one state of motion to another, and the magnitude will differ between the braking and acceleration stages. Ignoring these actions in pavement analysis will lead to inaccurate determinations of the state of stress and strain and consequently, incomplete assessment of potential damage. Under these circumstances, prediction of the service life of rehabilitated roads will not be possible. This situation is particularly critical in an urban setting with known traffic stoppage during congestion periods, at traffic control signals and close to bus stops. The impact of a moving vehicle on the state of damage on a given road is under investigation at NRC and the results will be reported elsewhere.

3. Proposed Approach to Pavement Analysis

Current developments in materials science and mechanics have filled gaps in the knowledge base and the next generation of design will rely heavily on mechanistic principles (NCHRP 1997). In this section, a brief description of a proposed process (evolutionary) micro-mechanics damage-based constitutive model for pavement analysis will be discussed. The proposed model includes an improved format for material characterization made possible by the Strategic Highway Research Project (SHRP) initiatives. Furthermore, the proposed model accounts for the strong heterogeneity of asphalt concrete by considering the distinct properties of the mix composition (aggregate, binder and voids). Digital image analysis was used to quantify aggregate shape and size characteristics, particle distribution, and orientation in a compacted asphalt concrete layer (Yue et al. 1994) and the model accounts for these microstructure features in the analysis. This step will provide, for the first time, a

direct link between the nature and quality of an asphalt concrete mix and structural analysis. The proposed model naturally blends the theories of plasticity, damage, fracture and viscosity to determine the overall inelastic response of an asphalt concrete pavement associated with traffic and thermal loading. Therefore, the proposed system of analysis effectively addresses performance evaluation requirements through accurate assessment of the state of stress and strain and proceeds to predict damage.

3.1 Asphalt Concrete Constitutive Model

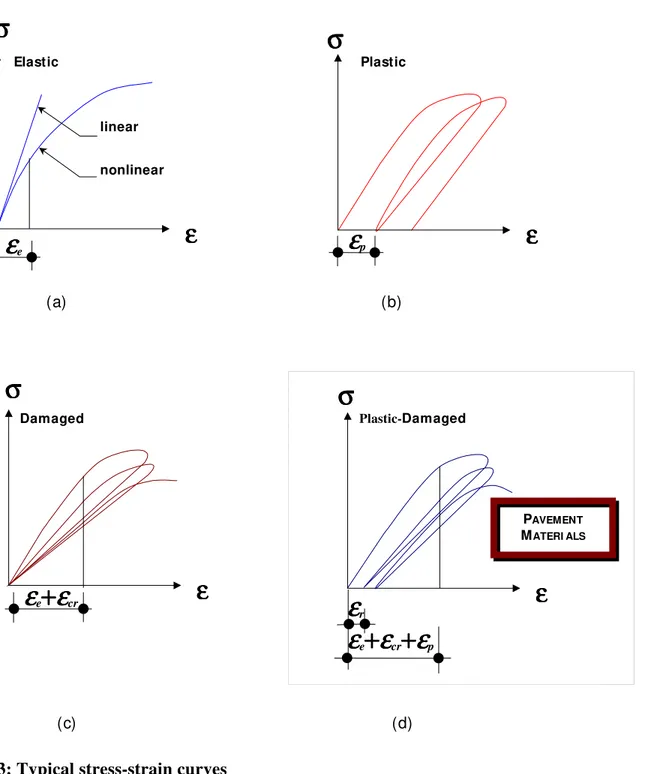

The theoretical construct of the proposed asphalt concrete model described in this paper follows earlier developments incorporated in the finite element program NONLACS (Nofal 1997). These developments include the splitting of deformations into crack, elastic, plastic and viscous strains, i.e.: εεεεij εεεεij εεεε εεεε o ij cr ij p ==== ++++ ++++ (1)

in which εεεεij is the total strain tensor of damaged (cracked) asphalt concrete. The three strain components, εεεεijo , εεεε

ij

o , andεεεε ij

p , are the elastic (recovered), damage and plastic strains, respectively.

It is recognized that other forms of strain decomposition are possible. Furthermore, the crack strain will comprise both reversible and permanent strains. An existing stable crack that opens as a result of an increase in applied loads will close upon unloading and behave in an elastic manner. An existing crack that may propagate and newly formed cracks will both introduce permanent irreversible deformations. Thus identification of crack or damage strains as elastic or permanent in a model may be a matter of reference, but in any case, the proper energy dissipation mechanisms are considered. In the proposed model, the crack strains are combined with the elastic strains for the sake of convenience, but at no point is the assumption made that crack strains are all elastic. Accordingly, damage types (e.g., cracks or ruts) caused by different loading conditions can be isolated and evaluated separately.

The current method assumes that the binder and fines (aggregate passing sieve # 4) forms a matrix that follows a plastic behavior while aggregates are considered embedded elastic inclusions in a binder-fines matrix. Figure 3(a) indicates that in the absence of the damage and plastic strain components the material response will be linear or nonlinear elastic and the material will recover all imposed strains upon removal of the applied load. This behavior indicated that its microstructure would not be affected regardless of the load level and duration. On the other hand, when damage strain is present, the material tends to follow a different load path, as shown in Figure 3(b), because of rearrangement of its microstructure features. When plastic strains are the only source of inelastic response, i.e. in the absence of damage strains, it is clear from Figure 3(c) that the material only gained residual deformation. In asphalt concrete, all of these types of strains are present and accordingly, the material shows different loading and unloading paths because of the evolution of defects reflecting the load history and accumulation of permanent strains associated with plastic deformations. Therefore, constitutive laws developed based on Equation 1 will depict most of the deformation mechanisms associated with asphalt concrete pavements. Details of the developed constitutive relationships are presented in a previous publication (El Hussein and Nofal, 1997).

3.2 Application

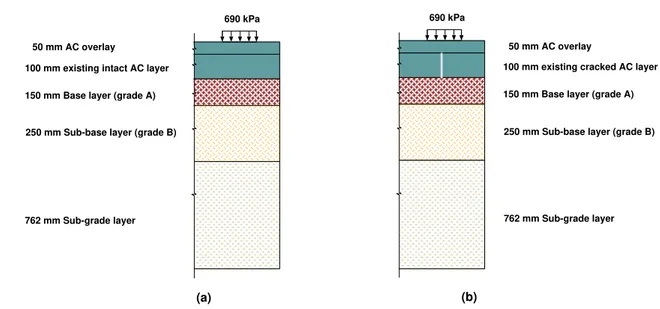

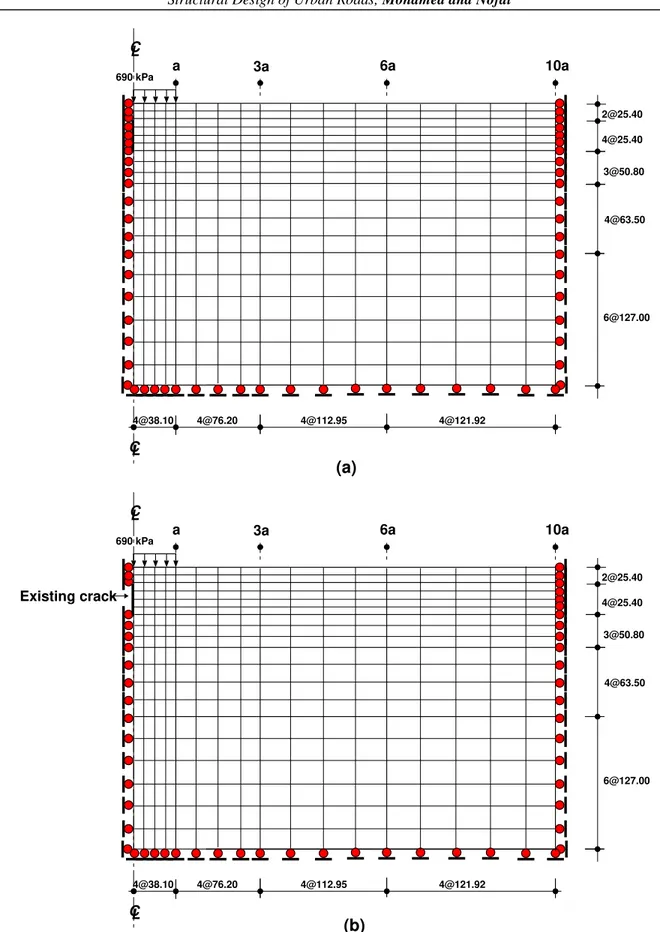

This section discusses the performance of an overlay subjected to loading by a commercial vehicle (truck). The pavement structure is comprised of an existing cracked asphalt concrete layer on top of a granular base A, supported by another granular base B, resting on a cohesive soil (subgrade soil). The general layout and dimensions of the structure are shown in Figure 4. Structural analysis was conducted using the multi-linear elastic analysis approach and the proposed general-purpose finite element program NONLACS. The main difference between the two programs is in the treatment of the asphalt concrete layers. As mentioned earlier, NONLACS traces the inelastic response of the asphalt concrete layers using the proposed micromechanics damage-based model while the multi-linear elastic model assumes a linear elastic response.

The pavement structures shown in Figure 4 were analyzed to simulate two road construction practices. The first configuration simulates construction of an overlay assuming that the existing asphalt layers of the road are intact, i.e., with no cracks. The second structure simulates the same previous configuration; however, the existing asphalt layer sustained a crack that managed to travel the entire depth of that layer. Analysis was conducted using NONLACS to evaluate the performance of an overlay added on top of the cracked asphalt layer. Analysis assumed that the pavement structures were loaded through a tire pressure of 690 kPa (100 psi) distributed over a radius of 152.4 mm. According to current practices, this pressure simulates the medium range of commercial vehicles that may encompass buses, semi-heavy and maintenance trucks.

Table 1: Material Properties

Material Property Asphalt Concrete Granular A Granular B Subgrade Soil

Elastic modulus (psi) 500000 --- ---

---Poisson’s ratio, v 0.40 0.40 0.40 0.45 Ko 3.0 3.0 3.0 2.5 K1(psi) --- 7210 6000 5 K2(psi) --- 0.45 0.38 3020 K3 --- --- --- 1110 K4 --- --- --- 178 Angle of friction --- 20 20 0 Cohesion, c, (psi) --- 0 0 6 Self-weight, w, (lb/cu ft) 150 140 140 115 KI (KII) (ksi/in1/2)* 0.125(0.250) --- ---

---Dmax (Dmin) (in.) *

0.750(0.025) --- ---

---*

Properties used by NONLACS to characterize aggregate and asphalt matrix

Finite element meshes were designed for the two road structures. The first mesh, shown in Figure 5(a), includes no crack representing typical current methods of analysis, which ignore the presence of such a crack. The second structure, shown in Figure 5(b), includes a crack in the existing

asphalt surface layer to represent the type of analysis made possible by the newly introduced developments incorporated in the proposed method of analysis. Material properties for all layers used in this exercise are shown in Table 1. Analysis was limited to a single pavement temperature (-20oC). This choice was made to soften the impact of the assumed elastic response of the asphalt concrete layer adopted by current practices. Accordingly, comparison between the two approaches is limited to the influence of incorporating in-service condition on the accuracy of the model predictions.

3.3 Results and Analysis

Comparison of the two approaches is discussed based on the determined state of stress. The potential performance of the two road structures based on predicted damage is also discussed. The purpose of this examination is to illustrate the impact of considering asphalt concrete macrostructure features, such as cracks, on the predicted structural response associated with the application of vehicle loading.

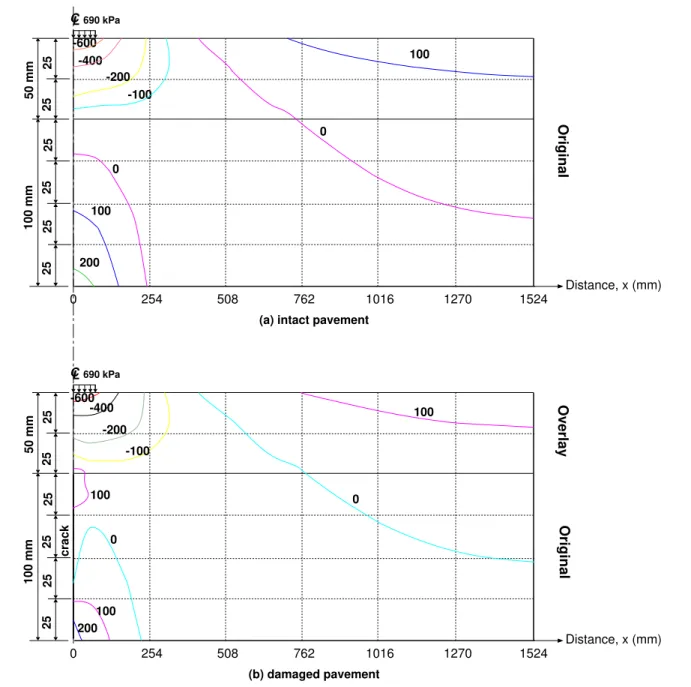

Figures 6(a) show the distribution of horizontal stress in the asphalt concrete layer when no crack exists in the pavement structure. Tensile stresses develop at the bottom of the asphalt layer directly beneath the vehicle tire. Structural analysis conducted while considering a crack in the existing pavement, which was carried out by employing the new approach, is evaluated next. Typical construction practice involves an overlay to cover major macrocracks that may have developed in the original asphalt concrete layer. An asphalt overlay depth of 50 mm is commonly used to upgrade the structural integrity of the road. The NONLACS computer program was employed to analyze the structure represented by the finite element mesh shown earlier in Figure 5(b) where the crack is modeled as a free stress surface. Horizontal stress distribution is shown in Figure 6. Comparison of the stress distributions shown in Figure 6(a) and 6(b) suggests two uniquely different conditions. Tensile stresses increased in the overlay in the presence of the crack. These stresses are critical since they exist above the crack with substantial potential for the crack to propagate to the overlay.

These unique differences eventually influence the performance predictions for the two structures. Current system of pavement analysis can not provide information beyond the determined state of stress without employing approximations related to the endurance of the material to these levels of stresses. Damage analysis conducted using NONLACS, which employs a process micromechanics damage model and fracture mechanics to trace crack propagation, predicted a performance that agrees well with cracking patterns observed in extensive field surveys of newly overlaid pavements. The plot of the damage function, shown as percentage in Figure 7(b), indicated the potential for initiation of a crack at the bottom of the overlay for the structure that includes a crack in the existing asphalt layer. However, for the other structure, shown in Figure 7(a), with no crack present in the overlay, the potential for initiation of such crack is low as indicated by the magnitude of the predicted damage function. No attempt is made to carry analysis beyond this stage, however the program is capable of predicting the state of damage under repetitive loading

4. Conclusion

This paper represents the first attempt to employ a mechanistic approach to analyze a pavement structure including the complexities associated with incorporating pavement in-service conditions. The authors acknowledge the fact that more research is needed to complete the desired format of a model capable of analyzing urban roads. The preliminary results, although not yet fully analyzed,

confirmed the effectiveness of the mechanistic approach in conducting analysis needed for engineering urban roads.

5. References

Bahia H.U., and Anderson, A.D. (1995), “The SHRP binder rehological parameters: Why are they required and how do they compare to conventional properties” The Transportation Research Board, 74th Annual meeting, Washington, D.C., 1995.

Brown, S.F., (1979), “Material characterization for analytical pavement design” Developments in highway pavement engineering-I, ed. P.S. Pell, Applied Science Publisher, London, pp. 41-92. Duncan, J.M., Monismith, C.L., and Wilson, E.L., (1968), “Finite element analysis in pavements”

Highway Research Record, No. 228, pp. 18-32.

El Hussein, H.M., and Yue, Z., (1994), “Criteria for evaluation of rutting potential of asphalt concrete based on repetitive uniaxial compression tests” The Transportation Research Record No. 1454, pp. 74-81.

Fwa, T.F., Ang, B.W., Toh, H.S., and Goh, T.N., (1994), “Estimation of axle loads of heavy vehicles for pavement studies” The Transportation Research Record No. 1388, pp. 70-79.

Hajek, J.J., “General axle load equivalency factors” The Transportation Research Record No. 1482, pp. 67-78, 1994.

Horii, H., and Nemat-Nasser, S. (1983), “Overall moduli of solids with microcracks: load induced anisotropy” J. Mech. of Phys. and solids, 31(2), 155-171.

Kim, Kwang W. and El Hussein Mohamed, (1995), “Effect of Differential Thermal Contraction on Fracture Toughness of Asphalt Materials at Low Temperatures” Asphalt Paving Technology Journal, Vol. 64, pp 474-499.

NCHRP (1997), National Cooperative Highway Research Program (NCHRP), “Development of the 2002 guide for the design and rehabilitated pavement structure” NCHRP Project No. 1-37, Requested for statements of qualification and availability, Washington, DC.

Nofal, M. (1997), Continuum damage mechanics for plain, reinforced, and fibre-reinforced concrete materials and structures, Ph.D. thesis, Department of Civil and Environmental Engineering, Carleton University, Ottawa, Ontario, Canada.

Peattie, K.R., (1979), “Flexible pavement design” Developments in highway pavement engineering-I, ed. P.S. Pell, Applied Science Publisher, London, pp. 1-39.

Perdomo, D., and Nokes, B., (1994), “Theoretical analysis of the effects of wide-base tires on flexible pavement using CIRCLY” The Transportation Research Record No. 1388, pp. 108-119. Pidwerbesky, B.D., (1994), “Strain response and performance of subgrades and flexible pavements

under various loading conditions” The Transportation Research Record, No. 1482, pp. 87-93. Yue, Z., Bekking, W. and Morin, I., (1995), “Application of Digital Image Processing to Quantitative

Study of Asphalt Concrete Microstructure”, The Transportation Research Record, No. 1492, pp 53-60.

CL AC Base Sub-Base Sub-grade needle loaded area groove

-+ + -+

-Typical strain profile at the bottom of the asphalt layer Typical truck

Tension Tension

Compression Compression

εεεε

e++++

εεεε

cr Elastic Plastic Damagedσσσσ

Plastic-Damagedσσσσ

σσσσ

σσσσ

εεεε

εεεε

εεεε

εεεε

εεεε

pεεεε

e nonlinear linearεεεε

e++++

εεεε

cr++++

εεεε

pεεεε

r PAVEMENT MATERI ALS (a) (b) (c) (d)50 mm AC overlay

150 mm Base layer (grade A)

250 mm Sub-base layer (grade B)

762 mm Sub-grade layer

(a) 100 mm existing intact AC layer

150 mm Base layer (grade A)

250 mm Sub-base layer (grade B)

762 mm Sub-grade layer

(b)

100 mm existing cracked AC layer 690 kPa

690 kPa

50 mm AC overlay

4@38.10 4@76.20 4@112.95 4@121.92 CL 3a 6a 10a a CL 690 kPa (a) (b) 4@38.10 4@76.20 4@112.95 4@121.92 CL 3a 6a 10a a CL Existing crack 690 kPa 3@50.80 4@25.40 4@63.50 6@127.00 2@25.40 3@50.80 4@25.40 4@63.50 6@127.00 2@25.40

1270 690 kPa CL Original 25 100 mm 25 25 25 25 50 mm 25 0 254 508 762 1016 1524 Distance, x (mm) (a) intact pavement

200 100 0 -100 -200 -400 -600 0 100 1270 Overlay 690 kPa CL Original crack 25 100 mm 25 25 25 25 50 mm 25 0 254 508 762 1016 1524 (b) damaged pavement 100 0 0 100 200 100 -100 -200 -400 -600 Distance, x (mm)

1270 690 kPa CL Original 25 100 mm 25 25 25 25 50 mm 25 0 254 508 762 1016 1524 Distance, x (mm) (a) intact pavement

12.5% 1270 Overlay 690 kPa CL Original crack 25 100 mm 25 25 25 25 50 mm 25 0 254 508 762 1016 1524 (b) damaged pavement 10% 7.5% 5% 12.5% 10% 7.5% 5% 12.5% 10% 7.5% 5% 50% 20% 30% 40%