Publisher’s version / Version de l'éditeur:

Proceedings of the American Society of Testing and Materials, 57, pp. 1043-1056,

1958-07-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Cement-aggregate reaction in concrete of a canadian bridge

Swenson, E. G.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=cdc36f49-0c1c-4aed-a668-91e76d632ada https://publications-cnrc.canada.ca/fra/voir/objet/?id=cdc36f49-0c1c-4aed-a668-91e76d632adaSer

TH1

N21r

2

no.

59

c. 2

CANADA BLDG DIVISION OF BUILDING R E S E A R C HANALYZED

CEMENT

-

AGGREGATE REACTION IN CONCRETE

OF A CANADIAN BRIDGE

BY

E. G. SWENSON

R E P R I N T E D FROM

PROCEEDINGS O F THE

AMERICAN SOCIETY FOR TESTING MATERIALS VOL. 57. 1957, P. 1043

-

1056 R E S E A R C H P A P E R N O . 59 OF T H E DIVISION OF BUILDING R E S E A R C H O T T A W A JULY 1958 N R C A S 9 2 P R I C E 25 C E N T SThis p u b l i c a t i o n

i s

being d i s t r i b u t e d by

t h e Division of Building Research of t h e National

Research Council a s

a

contribubion towards b e t t e r

b u i l d i n g i n Canada.

It should not be reproduced

i n whole o r i n p a r t , without permission o f t h e o r i -

g i n a l publisher.

The Division would be glad t o be

of a s s i s t a n c e i n o b t a i n i n e such permission.

Publications of t h e Division

of

Building

Research may be obtained by mailing t h e a p p r o p r i a t e

remittance,

( a Bank, Express, o r Post Office Money

Order o r a cheque made payable a t par i n Ottawa,

t o t h e Receiver General of Canada, c r e d f t National

Research council) t o t h e Matioral Research Council,

Ottawa.

Stamps a r e not acceptable.

A

coupon system has been introduced t o

make payments

f o r publications r e l a t i v e l y simple.

Coupons a r e a v a i l a b l e i n denominations of

5,

25,

and

p

cents,

and may be obtained by making a

re-

mittance a s i n d i c a t e d above.

These coupons may be

used f o r t h e purchase of

a l l N a t i o n a 1 Research

Council p u b l i c a t i o n s i n c l u d i n g s p e c i f i c a t i o n s

of

Authorized Reprint from the Copyrighted Proceedings of the AXERICAN SOCIETY FOR TESTING MATERIALS

Philadelphia, Pa. Volume 57, 1957

C E M E N T - A G G R E G A T E R E A C T I O N I N C O N C R E T E O F A

CANADIAN B R I D G E * I

A study was made of a concrete bridge deck which had expanded abnor- mally over a period of more than 25 years. The two deck sections involved, made with different aggregates, were found to have been affected by different types of cement-aggregate reaction. One section had been seriously affected by alkali-aggregate reaction involving mainly a phyllite in the coarse aggre- gate, but the actual expansion and extensive deterioration of the concrete was attributed in large part to freezing and thawing under adverse moisture conditions. A feature of this case was the failure of the mortar bar test to reveal potential reactivity in the source material in spite of other evidence. Some possible explanations are considered. In the second section, abnormal expansion was probably due to the sand component which was shown to be reactive in the Conrow test, ASTM Method C 342.2

An example of abnormal expansion in concrete which has occurred over a

period of 25 years in a bridge deck in

Eastern Canada was brought t o the attention of the Division of Building

Research of the National Research

Council of Canada in 1953. About seven

years after the deck was placed, many * Presented a t the Sixtieth Annual Meeting of the Society, June 16-21, 1957,

t This paper is a contribution from the Division of Building Research, National Re- search Council of Canada, and is published with the approval of the Director.

'

National Research Council of Canada. Division of Building Research, Ottawa. Canada.of the expansion joints had closed and had to be reset. Continuing "growth" of the concrete has necessitated periodic repairs, and nearly all expansion joints have now been reset a t least once.

The bridge itself consists of a steel superstructure placed o n masonry and concrete piers. The concrete deck, which rests on steel stringers, consists of slabs

about 37 f t wide and averaging 80 f t in

length. The 23-in. expailsion joints are, for most of the length, alternated with +-in. "breather joints." The bridge con- sists of two sections, and i t soon became evident t h a t each section represented a Tentative ~ e t h o d of Test for Potential Separate case since each deck Volume Change of Cement-Aggregate Combi-

nations (C 342- 55 T ) , 1955 Book of ASTM had been placed a different 'Ontrac- Standards, Part 3, p. 1244. tor using different sources for aggregates

1043

and cements. Records of mixes were not available.

Preliminary examination had revealed symptoms of cement-aggregate reaction in the south section, but the condition of the concrete in the north section provided no clue as to the probable cause of abnormal expansion. Since the bridge decks are exposed to extremes of weather conditions the possibility of physical as well as chemical causes had to be taken into account. As a result, it

FIG. 1.-Fragment of Concrete from South Section of Bridge Deck, Showing Rims and White Deposits.

was considered necessary to carry out a more extensive series of tests than would have been necessary had there been strong evidence a t the outset that one particular action was involved.

Since one possible cause was cement- aggregate reaction, cases of which have not so far been reported in Canada, i t was considered imperative t h a t expert petrographic evaluation be obtained. Fortunately, it was possible to enlist the aid of recognized authorities a t the

laboratories of the U. S. Bureau of

Reclamation.

The present paper constitutes mainly a description of the problem and the

conclusions drawn from the investiga- tion. Considerable test data have been included, however, in the interests of those concerned with methods of test

for cement-aggregate reaction. T h e

results have certain implicatioils t h a t have made it advisable, for the time being, not to identify the affected structure or the sources of materials involved since these are really of local interest only.

This concrete deck, 6 in. in thickness, had been placed on a floor formed with steel sheets and a paper liner which were left in place. Shortly after the concrete was placed, it tvas covered with a 2-in. layer of "black-top." This topping was completely replaced in 19.52, reportedly as a result of the occurrence of surface depressions where the concrete had dis- integrated.

Two areas were selected for coring, one considered as probably bad because of a surface depression, a n d the secoild considered to be least affected. Six cor-

i n g ~ were made, using 2- a n d 4-in. diam-

eter bits. I n no case was i t possible t o obtain intact cores, the material coming out in broken fragments which indicated an advanced state of disintegration.

Visual examillation of the fragments, broken in many cases along horizontal planes, showed many aggregate particles with the broad, spongy rims usually

associated withalkali-aggregate reaction.

Most of the fragments were clearly fractured. and cracks a n d voids con- tained a n abundance of gel-like deposits. One of the few large fragments is shown

in Fig. 1; Figs. 2 and 3 show enlarged

views of affected particles and gel-like deposits. T h a t these rims were of a iipre-concrete" type was considered unlikely in view of their general appear-

FIG. 2.-~\fiectetl Particle in Concrete iron] South Section, Sholving Rcaclion Rim.

ance and texture. Some of the particles were obviously of a shaley or clayey character and frequent occurrence of voids below larger particles made it probable that a fairly wet mix had been used. The "sealed" environment of the concrete in this section was such that moisture could easily be trapped. Condi- tions were therefore conducive not only to chemical action but also to deteriora- tion through freezing and thawing.

alkali cement. These rock types included phyllites, chalcedonic sandstones, meta- sandstones, and somewhat chalcedonic limestones. The phyllites were soft, laminated, dark gray to black, and slightly chalcedonic. The other rock types present included sandstones, quartzites, limestones, vein quartz, crystalline limestone, schists, siltstones, claystones, and a few other miscellaneous rock types.

Year

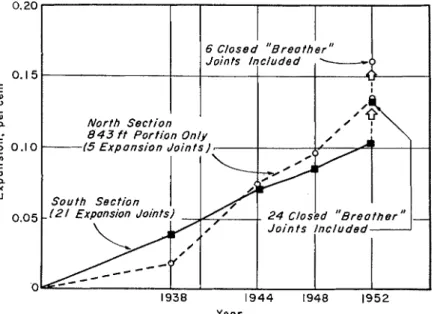

FIG. 4.-Measured Expansion of Concrete Bridge Deck-Sections. The source of the aggregates used in

this concrete was established and s a m ~ l e s were obtained for study. The coarse aggregate had been obtained by crushing large stones and boulders from a deposit probably of fluvio-glacial origin. Much of the material was badly weathered and encrustations occurred on many rocks. A representative sample was later exam- i d d petrographically by the laboratories

A of the U. S. Bureau of Reclamation.

/ A

Almost half of the sample was found to consist of rock types regarded as some- what potentially reactive with high-

The sand obtained from a deposit in the same area, contained the same rock types in its coarse fractions as did the coarse aggregate. The finer fractions were composed chiefly of grains of individual minerals which were not considered deleteriously reactive with high-alkali cement. The sand as well as the stone could be regarded as physically not of first quality.

lVorlh Section:

The concrete deck in this section had been placed in two courses, a 6-in. layer

topped with a 2-in. course, and the wooden formwork removed, leaving both upper and lower concrete surfaces ex- posed. Varying occurrences of random cracking were observed, the most extensive being near the joints.

Six corings were made, two from each of three widely separated areas. In all

cases, the 2- and 4-in. cores were ob-

tained intact, and the concrete appeared to be reasonably sound. The compressive strengths, taken on 4-in. cores but calculated in terms of 6 by 12-in.

were detected, but this aggregate as a whole was considered not deleteriously reactive with high-alkali cement.

The sand used in the concrete on the north section may have been obtained from more than one source. At least a large portion of it was obtained from a source in the vicinity of the limestone quarry. I t was a fluvial sand, the coarse

fractions of which were composed

predominantly of granites, gneisses,

sandstones, quartzites, and other crystal- line types. The finer fractions consisted

TABLE I.-IDENTIFICATION AND SOME PROPERTIES OF AGGREGATES

USED I N TESTS.

Aggregates

AS. . .

Source and Class of Material

Crushed boulders, from source used in south section concrete Crushed limestone, from source used

in north section concrete Crushed limestone, used as unreac-

tive reference material

Natural sand, from source used in south section concrete

Natural sand, from source used in north section concrete

Natural sand, used as unrenctive ref- erence material

Natural gravel and sand, very reac- tive t o high-alkali cements; used as a reference material Bulk Specific Gravity 2.67 2.70 2.61 2.58 2.63 2.47 2.50 Absorption, per cent 1.43 0.42 0.75 0.64 0.12 0.66 0.68 hIgS01 Sound- ness, per cent

loss 13.8 8 . 1 13.4 14.8 6.5 10.0 8.0

cylinders, averaged 5460 psi. Pulse velocities, however, averaged only 12,150 f t per sec. Attempts to detect residual expansion in some of these cores were not successful.

The original source of the limestone coarse aggregate used in this concrete was established, and samples were obtained for study. The quarry is located in the Palaeozoic (Lower Ordo- vician) formation of limestones, dolo- mites, and shales. A sample later exam-

ined by the laboratories of the

U.

S.~ u r e a u of Reclamation was described as

a somewhat carbonaceous and dolomitic limestone. Small amounts of chalcedony

chiefly of individual mineral grains. Potentially deleteriously reactive rock types, mainly phyllites, chalcedonic sandstones, and chalcedonic cherts,

constituted only about 1 per cent of the

sample examined. In these proportions these rock types could be disregarded. Again, both the sand and the limestone could be regarded as not of first quality.

Records of Expansion o f the Bridge Decks:

The actual expansion of the concrete decks had been estimated from the periodic closing and resetting of joints, and these records were made available

for this investigation. These data have

been plotted in Fig. 4 for the complete

south section and for one part of the north section. Despite the apparent difference in the condition of the con- cretes in the two sections, the abnormal movement in the north section has been a t least as great a s that in the south section. Data for the rest of the north section were inconlplete but were in

good agreement with those in Fig. 4.

section, SC (stone) and SS (sand), show relatively high losses in the soundness test, as does the O C reference limestone.

I11 addition, the absorption value for the

SC crushed stone is fairly high; this is considered to have sonle significance i n the light of later results.

T h e allrali contents of the three normal portland cements used in the test mor-

tars and concretes are given in Table 11.

Cement &/I is the current counterpart of

TABLE 11.-ALICALI CONTENTS O F C E J I E N T S .

Source of Data pcr ccnt Total Alkali

M X . . . . Average of nvailable data fro111 102G to 1030 011 cc~llents used in nflectcd area

I\~.~TEI~IALS USED M COMPXR.ATIVE the cements i\IX probably used in the

STUDIES original concretes. T h e low-all< a 1' i cement

The aggregates used for comparative E had a higher specific surface than the

tests are identified in Table I, and some lligll-alltali 'I and

'

celnents.pertiileilt properties are shown. I n addi- PIIYSICAI, TESTS W I T I ~ &~ORTXR BARS

M . . . . .

B . . .

E . . .

tion to the two sands and two coarse aggregates from the original sources used in the bridge deck concretes, several reference materials were included for control purposes. The OC reference limestone coarse aggregate is a fine- grained, somewhat fossilliferous and argillaceous limestone with a satisfac- tory performance record. The AS natu- ral sand, used a s a reference, also has a satisfactory field record. Two alkali- reactive gravels and sands were used as reference materials, the K I material

listed in Table I and a second material

designated as RR. I n addition a gravel-

sand material known to be reactive in the

T h e standard mortar bar test, ASTi\/I

Method C 227 -52 T3 and the Conrow

test," A S T N Method C 342 - 55 T were

the bases for physical tests for cement- aggregate reaction with mortars. I n addition, two non-standard tests on mortar bars were carried out simul- taneously, primarily t o determine their value in connection with the durability of aggregates. One was a wetting-drying test in which inortar bars, after moist

curing for

7

days, were subjected t o 18hr of wetting a t room temperature,

followed b y 6 hr of drying a t 130 f 3

I?.

At the end of 12 months, the procedure

From analyses of cements used in tests

Conrow test2 was used. This material is Tentative i\/Ietllod of T e s t for Potential

designated as KR. Alkali Reactivity of Cement-Aggregate Com- binations (C 227 - 52 T ) , 1955 Book of A S T M

Both the aggregates used in the south Standards, P a r t 3, p. 47.

~ -

0.52

1

0.801

1 . 0 50.5G

was changed to two cycles per day, 6 Duplicate specimens were used and

hr each of wetting and drying. The num- length and weight measurements were

ber of cycles obtained was approximately made periodically a t the end of a wetting

120 in 6 months, 240 in 12 months, 740 or a thawing period. Data on the non-

in 21 nlonths and 900 in 24 months. standard methods are included.

Test C e m e n t

b

EBj - 6 x 2 8 Days-

12 x 2 8 Days 0 - 2 4 x 2 8 Days Note: M - H i g h Alkali Cement E-

Low Alkali Cement L-

Low Woter -Cement R a t i o H- H i g h W a t e r - C e m e n t R a t i o KI-

Alkali-

Reactive R e f e r e n c e Sond AS- Non-

R e a c t i v e R e f e r e n c e Sond SC and S S - M a t e r i a l s Used inSouth Section of Bridge NC ond N S - M o t e r i o l s Used i n

N o r t h Section of Bridge FIG, 5.-Expansion of Mortar Bars under Four Test Conditions.

The second non-standard test con- For purposes of comparison, all inortar

sisted of slow freezing in air and thawing bars were made according to ASTM

in water. The mortar bars were moist- Method C 227 - 52 T with the following

cured for 7 days and then air-dried in modifications: the natural sands, SS,

the laboratory for 21 days before being NS and AS, were separated into six

subjected to 18 hr of freezing in air to sizes (4-8, 8-16, 16-30, 30-50, 50-100,

10 F and 6 hr of thawing in water a t room and pan) and reblended with 19 per cent

5 per cent of the pan size. The stone samples, after crushing, were reblended with 20 per cent of each of the top five fractions, omitting the pan material. The latter proportions were also used for the

reactive K I sand. Two mortar consisten-

cies were used, one based on the original mortar bar test (low water-cement ratio

L) and one based on the revised method

(high water-cement ratio H). The water-

cement ratios for the L specimens aver-

Three significant conclusions may be

drawn from these data: ( a ) the NS

sand, which constituted a t least the major portion of the sand used in the north section concrete, reacted positively

to the Conrow test; (b) the SC stone

and SS sand, which are later shown to

be involved in alkali-aggregate reaction in the south section concrete, reacted negatively in the mortar bar test; and

(c) none of the four test materials, in

0 6 x 2 8 D a y s 1 12 x 2 8 D a y s Note:

K R -Conrow Reactive Reference Sand AS and OC - Non

-

Reactive ReferenceSand ond L i m e s t o n e E - Low A l k a l i C e m e n t M - High A l k a l ~ C e m e n t

FIG. 6.-Repeat of Conrow Test on Second Sample of NS Sand.

aged 0.43 for the natural sand mortars and 0.50 for the crushed stone mortars.

The corresponding values for the H speci-

mens were 0.50 and 0.60. Mechanical mixing was employed and all bars were of nominal 5-in. length.

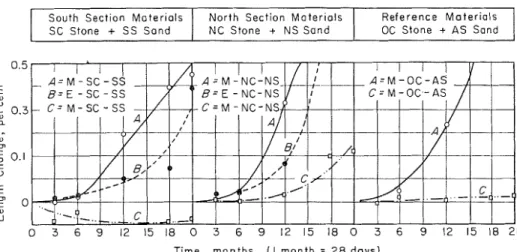

The combined results of the mortar bar tests are shown in Fig. 5. The test conditions are designated as CON for

the Conrow test,

WIB

for the mortar bartest, WD for wetting-drying cycling,

and F T for freezing-thawing cycling. The data shown correspond to periods of 6, 12, and 24 months.

comparison with the reference materials, showed any unusually adverse character- istics in mortar bars subjected to wetting- drying or freezing-thawing conditions.

The Conrow test was repeated on a

different sampling of NS sand. Also

included was the KR reference aggregate

and a pozzolan, California calcined shale. This check was considered necessarv in view of uncertainty as to the nature of this type of cement-aggregate reaction and because of the serious implications concerning the current extensive use of this particular sand. Additional data are shown in Fig. 6 and generally confirm

those from the original series. In Fig. 5, the higher expansion was obtained with

the low-alkali cement E, but the reverse

was the case with the new specimens. A replacement of 25 per cent of the cement by weight with a pozzolan was effective in controlling expansion in the mortars containing NS sand as well as those containing the K R reference sand which was known to be reactive in the Conrow test. These data may be compared with previously reported investigations into

TABLE 111.-COMPOSITION AND

PROPERTIES OF TEST CONCRETES. Mix, 1: 2 3 i : 335

Water-cement ratio, 0.60

' See Tables I and 11.

Composition, Cement- Stone-Sanda . . . M-OC-AS E-OC-AS . . . M-SC-SS . . . E-SC-SS . . . M-NC-NS . . . E-NC-NS . . . M-OC-KI . . . E-KI-AS.. . .

the cement-aggregate reaction for which

this test was developed ( I ) . ~ I t is of

interest to note that aggregates which react positively in the Conrow test show some reactivity in the mortar bar test. The failure of the SC stone and SS sand to produce excessive expansion in the mortar bar test was surprising in the light of other tests which indicated definite alkali reactivity of these mate- rials. A second series of specimens was therefore subjected to this test, in which various proportions of the SC material were combined with the unreactive OC

'

The boldface numbers in parentheses refer to the list of references appended to this paper, see p. 1055. Slump in. 3 3 4 2 625 5 424 335material. This was done on the assump- tion, based on experimental and theoreti-

cal grounds (2), that only a certain range

of proportions of deleterious to innocuous materials will produce excessive expan- sion in this test. In addition to the materials previously used, this series also included a second high-alkali

cement B and a second reference sand

R R , known to be alkali-reactive. In this second series the ASTM method was followed without the minor modifications previously used. After 12 months none of the specimens showed any indication of abnormal expansion except the reac- tive reference materials. The significance of the failure of this test is discussed later in this paper.

Compressive Strength psi

Three non-standard tests were car-

ried out on 3 by 4 by 16-in. concrete

prisms made with materials from the sources originally used in the bridge decks. Control prisms were made with reference materials. Duplicate specimens

from each batch were subjected to: (a)

continuous conditioning a t 130 =t 3 F

and 100 per cent relative humidity, ( b )

wetting-drying cycling similar to the

Scholer method (3); and (c) slow freezing-

thawing cycling.

The composition and general proper- ties of the test concretes are given in

Table 111. The sand fractions were

blended in the same proportions to meet ASTM grading requirements. The coarse aggregate consisted of equal parts of

each of the sizes $ -

+

in., $ -4

in., and- - - ?j in. Aggregates were introduced in the mixes in an air-dried condition.

A number of trial mixes were made in which various proportions, consistencies, and water-cement ratios were used to obtain concretes approximating those which had been used in the bridge decks. A simplified mix was selected, using a

28 days --- 4300 4940 --- 3890 4250 --- 2790 3240

---

. . . . --- . . . . 6 months 5300 5100 3800 3970 3400 3620 . . . . ....water-cement ratio of 0.60, which mas, a t the time, considered a reasonable one. As a result, the differences in absorption and other properties of the aggregates produced differences in consistency and compressive strength shown in Table 111. I t was considered that proper allow- ance could be made for these differences in assessing the results of subsequent tests. Compressive strength data are

accelerate chemical reactivity which could be measured by length change. Each beam was placed in a copper container, over but not in contact with water, then sealed and placed in an oven

maintained a t 130 F. Figure 7 shows the

expansion of specimens over a period of 21 months. The two test specimens M-NC-NS (north section materials) and BI-SC-SS (south section materials)

0 3 6 9 12 15 18 21 T i m e , m o n t h s ( I m o n t h = 2 8 d a y s ) N o t e : Test C o n c r e t e s

-

M - N C - N S ( N o r t h S e c t i o n )-

M - S C - S S ( S o u t h S e c t i o n ) N o n - R e a c t i v e R e f e r e n c e-

M - 0 C - A S R e a c t i v e R e f e r e n c e - M - 0 C - K I a n d M - K I - A SFIG. 7.-Expansion of Concrete Test Beams at 130 F and 100 per cent Relative Humidity.

based on 4 by 8-in. cylinders. The drop

in strength a t 6 months of the concretes

made with the SC and SS aggregates (south section) was not unexpected in the light of other results with this com- bination of materials.

The concrete beams were made with measuring studs countersunk a t each end and progress in deterioration was measured by changes in length, resonant frequency modulus, and pulse velocity. The test involving continuous condi-

tioning a t 130 f 3 F and 100 per cent

relative humidity was designed to

showed more than normal expansion in comparison with the reference specimens M-OC-AS. The alkali-reactive reference specimens showed higher expansions where the reactive constituent was the sand (I\{-OC-KI) than in the case where the reactive component was the stone (M-KI-AS).

The wetting-drying cycling and the freezing-thawing cycling of concrete beams were carried out in the same man- ner as for the mortar bars. The length

change data are shown in Fig. 8. They

cycling, there is no great difference in durability between the reference con- crete and the concretes made with aggregates from the sources used in the bridge decks. The more rapid decrease in durability for all specimens under co~lditions of wetting and drying as compared with freezing and thawing was considered remarkable. This was not observed in the corresponding test with mortar bars, probably because the

CHEMICAL TEST FOR ALKALI REACTIVITY

The quick chemical test, ASTM

Method C 289 - 54 T,6 was carried out

on the four test aggregates SC, SS, NC,

and NS, and on four reference materials.

The data are sho~im in Table IV. Accord-

ing to the generally accepted criterion developed by A4ielenz, Greene, and

Benton (4), the SC stone ivas rated as

deleteriously reactive to cement :llkalis on the basis of this test. This stone mas

Time, months ( I month = 2 8 days) South Section Materials

SC Stone

+

S S SandFIG. 8.-Length Change in Concrete Prisms Subjected to Wetting-Drying and Freezing-Thawing Cycling.

Curves A and 13 - wetting-drying

Curve C - freezing-thawing

Approximately 740 cyclcs in 21 months

smaller specimens showed a progressive loss of water under these conditions; this

~ v a s not the case with the beams. The

North Section Materials NC Stone + NS Sand

signiiicance of the wetting-and-drying method of rating durability of concrete, a modification of the Scholer method

Reference Materials OC Stone + A S Sand

(3), is under continuing study in this laboratory.

The lower durability of the M-NC-NS concrete (north section) compared with the other specimens may be attributed to the lower quality as reflected by a comparison of slumps and compressive strengths (Table 111). The resonant frequency moduli and pulse velocities (not shown here) were in good agreement with the length change data.

TABLE 1V.-DATA ON QUICK CHEMI- CAL TEST FOR ALKALI REACTIVITY.

1tR. . . 98.3 6 3 . 1 35.6

AS . . . 7 0 . 3 19.9 0 . . .

1

::i

1 4 8 . 6 9 . 2S C . . . . . . I 86.1 88.9 42.4

a Modified methyl orange end point.

Not done. SS. . .

N C . . . .

NS . . .

K R . . . .

6 Tentative Method of Test for Potential

Rcactivity of Aggregates (Chemical Method) (C 289

-

54 T ) , 1955 Book of ASTM Standards, Part 3, p. 1206. 39.9 8 . 0 17.3 63.2 7 2 . 1 b 3 4 . 1 34.2 27.2 17.0 -6.7 11.8used as coarse aggregate in the deck concrete on the south section of the bridge. None of the other test materials was shown to be reactive. The K R reference material, which was reactive in the Conrow test but not in the mortar bar test, gave a positive result in the chemical test.

Detailed petrographic examination of fragments of the original concrete from the south section deck by Mr. D. Rama-

ley and Mr. R. C. AiIielenz of the U. S.

~ i r e a u of Reclamation laboratories

revealed that expansion and deteriora- tion were caused primarily by severe alkali-aggregate reaction involving par- ticles of phyllite, chalcedonic sandstone, and chalcedonic limestone. The opinion was expressed that other factors such as freezing and thawing may have con- tributed to the deterioration of the concrete. Considerable amounts of al-

kalic-silica gel were observed in voids and

-

in the numerous fractures as well as quantities of calcium carbonate and calcium sul~hoaluminate. Reaction rims were predominant on phyllite particles. The aggregate in the concrete samples was found to be similar lithologically to those obtained from the original sources. This case was considered to be similar to that which has occurred in the Buck

hydroelectric plant (5) except that the

phyllite in the SC stone was found to be less chalcedonic.

Bryant and Katharine Mather of the

Corps of Engineers, U. S. Army, who

later examined a sample of the affected concrete. concluded that the nature of the exposure and the poorness of quality of the concrete were primarily respon- sible for the deterioration. and that these factors permitted the development of an alkali-aggregate reaction which, under

normal conditions, would probably be mild in degree. In their opinioil chal- cedony was the sole mineral reactant.

The concrete samples from the deck of the north section showed none of the usual symptoms associated with cement- aggregate reaction, and revealed no clue as to the primary cause of abnormal expansion.

Soz~lh Section:

The deteriorated concrete in the south section of the bridge deck was seriously affected by alkali-aggregate reaction involving a phyllite present mainly in the coarse aggregate. The results of the chemical test and a petro- graphic evaluation of the SC stone supported the direct evidence from the petrographic examination of the con- crete. This is believed to be the first case of alkali-aggregate reaction reported in Canada.

The failure of the mortar bar test to indicate potential alkali reactivity for the SC aggregate, in the face of the other evidence, suggests that the method is not entirely reliable in cases such as this, although normally this test is regarded as the most reliable of all those available.

The anomaly in the present case may be

due to one of several possible factors. The porosity of the aggregates, SC and SS, as reflected in part by the absorption data, may have prevented localized accumulation of gel and thereby pre- vented a rapid build-up of internal stresses which accompanies the formation

of gel products ( 6 ) . The reduction in

particle size required by this test may tend to retard the reaction to a greater degree for this particular deleterious

material (2). Another possibility is that

the range of "pessimum" proportions is very limited for this material and is, therefore, easily missed. I t would seem

that the apparently anomalous behavior in this instance will not be explained until the actual constituent in the phyllite responsible for the reaction has been definitely established. In any case i t was evident from the progress of expansion in the bridge deck, and also in the concrete prisms subjected to high-temperature and high-humidity conditions, that the reaction was very slow.

The evidence from petrographic exam- inations and laboratory tests, and from the nature of the expansion observed in this section of the deck which appeared to be increasing in rate, together with the knowledge of an inferior quality stone and a wet mix, lead to the conclu- sion that, under the conditions which existed, freezing and thawing were in large measure responsible for deteriora- tion and expansion. Although an ad- vanced case of alkali-aggregate reaction had occurred over a period of more than 25 years, abnormal expansion attribut- able to this phenomenon could not be reproduced in laboratory samples. I t is interesting to speculate, therefore, to what extent the ultimate disintegration was due to alkali-aggregate reaction. There seems little reason to doubt that it affected indirectly, and in some degree, the observed deterioration and expansion in this section.

advanced as that of the south section concrete, yet the rate and degree of expansion were at least as high. Al- though the wetting-drying and freezing- thawing effects in the concrete prisms indicated a low durability for this com- bination of materials. the slow but con- siderable expansion of samples under high humidity and high temperature conditions indicated that some internal reaction was the major contributing factor. In the latter case, as well as in the bridge deck concrete, expansion had apparently occurred without discernible breakdown throughout the mass of the concrete. I t was concluded, therefore, that the abnormal ex~ansion which had occurred in the north section of the concrete deck was, in all probability, attributable to the NS sand which had proved susceptible to a type of cement- aggregate reaction revealed by the Conrow test.

Acknowledgments:

The author is indebted to Mr. P. L. Pratley, Consulting Engineer, Montreal, for assistance in field studies and the examination of old records. Special thanks are due Mr. W. H. Price, Chief of the Engineering Laboratories, U. S. Bureau of Reclamation, for providing detailed petrographic examinations by Mr. R. C. Mielenz and Mr. D. Ramaley.

North Section: Valuable advice was also received from Actual deterioration of the north several additional sources both in section concrete was not nearly as Canada and the United States.

(1) A. D. Conrow, "Studies of Abnormal ings, Am. Concrete Inst., Vol. 51, pp. 497-

Expansion of Portland Cement Concrete," 785 (1955).

Proceediltgs, Am. Soc. Testing Mats., Vol. (3) C. H. Scholer, "A Wetting and Drying 52, pp. 1205-1227 (1952). Test for Predicting Cement-Aggregate (2) T. C. Powers and H. H. Steinour, "An Reaction," Proceedings, Am. Soc. Testing

Interpretation of Published Researches on Mats., Vol. 49, p. 942 (1949).

Benton, "Chemical Test for Reactivity of Proceedings, Am. Concrete Inst., Vol. 37, Aggregates with Cement Alkalis; Chemical pp. 665-671 (1941).

Processes in Cement-Aggregate Reaction," ( 6 ) D. M ~ c ~ R. C. ~ ~ ~~ ~iI ~,W. y. l ~ ~ ~ ,

Proceeditzgs, Am. Concrete Inst., Val.

a,

Holland, and K. T. Greene, c,Cenlent-pp. 193-221 (1948).

(5) H. A. Kammer and R. IV. Carlson, "Inves- Aggregate Reaction in Concrete," Proceed- tigation of Causes of Delayed Evpansion of i n p , Am. Concrete Inst., Vol. 44, pp. Concrete in Buck Hydro-electric Plant," 93-128 (1948).

![FIG. 2.-~\fiectetl Particle in Concrete iron] South Section, Sholving Rcaclion Rim](https://thumb-eu.123doks.com/thumbv2/123doknet/14497126.527125/6.621.74.526.84.419/fig-fiectetl-particle-concrete-south-section-sholving-rcaclion.webp)