.^

HD28

.M414

no.

WORKING

PAPER

ALFRED

P.SLOAN

SCHOOL

OF

MANAGEMENT

A

Case-based

System

toSupport

Electronic

Circuit

Diagnosis

Thilo

Semmelbauer,

Anantaram

Balakrishnan,

and

Haruhiko

Asada

WP#

3497-92-MSA

October,

1992

MASSACHUSETTS

INSTITUTE

OF

TECHNOLOGY

50

MEMORIAL

DRIVE

CAMBRIDGE,

MASSACHUSETTS

02139

A

Case-based

System

toSupport

Electronic

Circuit

Diagnosis

Thilo

Semmelbauer,

Anantaram

Balakrishnan,

and

Haruhiko

Asada

WP#

3497-92-MSA

October, 1992

A

Case-based

System

to

Support

Electronic

Circuit

Diagnosis

^7/7/70

Semmelbauer

LeadersforManufacturing M. I. T., Cambridge,

MA

Anantaram

Balakrishnan

Sloan Scfiool of

Management

M. I.T., Cambridge,

MA

Haruhiko

Asada

Department of Mechanical Engineering M. I. T.,

Cambndge,

MA

Abstract

Diagnosis

and

repairoperationshave traditionally beenmajor

bottlenecksin electronicscircuit

assembly

operations because they arelabor intensive and highly vanable.Rapid

technological advances, shrinking product lifecycles, and increasingcompetition inthe

electronics industry have

made

quickand

efficientdiagnosis critical forcostcontroland qualityimprovement,

while simultaneously increasing the difficulty ofthe diagnosis task.This paperdescribes acase-baseddiagnosis support system to

improve

the effectivenessand

efficiencyofcircuitdiagnosis by automatically updatingthe setof candidatedefects,and

prioritizingtestsduring thesequential testing process.The

case-basedsystem

storesindividual diagnostic instancesratherthan generalrulesand algorithmic procedures; its

knowledge

basegrows

asnew

faults aredetectedand

diagnosedby

theanalyzers.The

system

providesdistributed access to multiple users,and

incorporates on-line updating features thatmake

itquick toadapt tochanging circumstances.Because

itis easy to install,update,

and

integrate withexisting systems, thismethod

is well-suitedfor realmanufacturingapplications.

We

haveimplemented

a prototype version,and

tested theapproach

in anactual electronicsassembly

environment.We

describethe system's underlyingprinciples, discussmethods

toimprove

diagnostic effectivenessthroughprincipledtest selection

and

sequencing,and

discuss managerial implicationsfor successful implementation.1.

Introduction

1.1

Overview

Electronic circuitdiagnosis is theprocess ofidentifying the

component(s)

thatisresponsible for the malfunction ofacircuitboard so thatcorrective (repair)actioncan be taken.

Subsequent

exploration ofthe problem's rootcauses motivates processand

productimprovement

efforts.The

diagnosisand

repairloophas traditionallybeen

amajor

bottleneckincircuit board assembly. Recenttrends inthe electronics industry such as the

rapid technological advances,increasing product complexity,

and

shon

product lifecycles,have considerably increasedthe

imponance

ofquickand

efficient diagnosis, whilesimultaneouslyincreasing the difficultyofthe diagnosis task.

Reducing

diagnosistimeand

variability,

and improving

diagnosisaccuracybecomes

critical as electronicscompanies

strive towards lean manufacturing, quickresponse,

and

greater flexibility.This paperdescribes acase-based diagnosissupport system that

we

developed

inconsultation with a

high-volume

consumer

electronicsassembly

plant.The

plant, faced witharapid turnoverofproductsand

an increasingshonage

ofskilledtechnicians,wanted

a

means

toimprove

the efficiencyand

effectivenessofcircuitdiagnosis, reduce theworkload

on

itsfew

expert analyzers,and

develop a tool to trainnew

technicians, withoutdevoting significant

system development

resources.An

informal survey ofavailable systemsand

current practice revealed that, althoughthe literaturedescribes severalrule-based

and model-based

systems to supportdiagnosis, these systemswere

not widely used by theelectronics industry partlybecause they require considerable timeand

specialexpertise toinstall (e.g., for

knowledge

acquisition)and

update.The

case-based approachproposed

in this paperoffers apractical solution to thediagnosis support needsof industry.Itaccumulates

knowledge

on-line asanalyzers detectand

diagnosenew

faults.Using

thisinformation about priordiagnostic instances, the systemeliminates candidate defectsduring

thesequential testing process,

and

prioritizes subsequenttests.We

have

implemented

aprototype versionofthe system,

and

testeditin anactual electronicsassembly

environment

We

describe the system's underlying principles,outlinemethods

toimprove

diagnostic effectiveness

by

reducing thenumber

ottestsneeded

tocomplete

the diagnosis,and

discussimplementationaspects.1.2

Why

is circuitdiagnosis important?

Rapid changes

inelectronics productand

process technology, such as smaller,surface-mounted

components,

higherboarddensities, andmore

complex

circuitry,have

made

circuitdiagnosis

more

challenging.With fewer

accessibleconnectionsand

testpads, in-line functional testing can only identify theapproximate area orblock ofcomponents on

theboardthat isresponsible for the malfunction. Detaileddiagnosis

must

bedone

off-linethroughextensive probing

and measurement.

Each

component

and

connection on a circuitboard isa potential defect site,and

everysitecan

have

severalpossible defects such asanopen

or shortcircuit(due topoorsoldering orcomponent

misalignment),component

malfunction, inherentflaw inthe circuit design,placement

ofthewrong

component,

or defect in the board'sinternal wiring.The

failure rate ofa board containing hundreds ofcomponents

is, therefore, severalordersofmagnitude

higher than theprobability ofa singledefectivecomponent

or operation,making

testing

and

diagnosis inevitableeven

with highly capable placementand

solderingoperations. Isolating the rootcausein such

complex and

densecircuitsis arduousand

timeconsuming.

Annual

expensesdirectly related todiagnosisand

repaircanexceed

severalhundreds

ofthousands ofdollarseven

in amedium-sized

facility.Work

inprocess atthediagnosis stage

and

delayed feedbackforprocess control further increase this cost.More

importandy, the time

and

effortrequiredtodiagnose a faultyboard is highly variable(from afew

minutes toover4

hours)depending

on

the type ofdefect, the analyzer'sskill, theeffectivenessofdiagnostic tools,

and

the incentiveand performance

evaluation systems.Consequendy,

testing, faultdiagnosisand

repairoperations areoftenmajor

bottlenecks inmedium

or highvolume

printedcircuit boardassembly

facilities.The

costand

effort to train techniciansis alsobecoming

a significant concernforelectronics companies.

A

new

technician requires severalmonths

oftrainingand

experience with a particularboard to understand thecircuit'scause-effect behavior

and

thepotential rootcausesin itsmanufacturing process.

As

productlifecycles shrink, thetraining costs

must

beamortizedoversmallervolumes

foreach board. Diagnosisbottlenecksareespecially acute during thecritical production

ramp-up

period following anew

productintroduction. Capturing marketshare earlyis essential forcompetitive survivalin the electronics industry, butproduction facilitiesoften cannot achieve thenecessaryrapid

ramp-up

because yields are low,and

analyzers are least productive since theyhave

nothad

significantexperience with thenew

product.Fast

and

accuratediagnosis notonly reducesdirectmanufacturingcostand

flow time, butisalsoan essentialprerequisite forsuccessful qualityimprovement

efforts tiiroughimproved

product design (e.g.,Soederberg

[1992]), better process understandingand

characterization, tighterprocesscontrol,

and

close supplierpannership (e.g.,Wenstrup

[1991]).

The

ability toprovidequick information feedbackfrom

the diagnosis stage toprevious stages (includingvendors) is particularly important in

medium

and

highvolume

environments.

For

instance, a snick glue pin oraworn

placement

head, ifnotdetected1.3

Computer

support

for circuitdiagnosis

Manual

diagnosisofcircuit boards can be both inefficientand

error-prone. Empirical evidence(Rouse and

Morris [1985],Rouse and Hunt

[1986]) suggests thathumans

are not optimaJ diagnosticians since theyhave

difficulty ineffectively utilizing all the available testdata toprune the listof candidate defects

and

systematically selectthe testsequence.On

theother hand, building acompletely

automated

system that iscapable ofanticipating and diagnosing all possibledefectscan be prohibitively expensive; sucha systemmight

also require extensive timeand

effortby specialists (design and process engineersor software experts) toinstalland

maintain. Therefore, a system that assists, ratherthan replaces,human

diagnosticians ismore

practicable.To

cope

with thedynamic

electronicsenvironment, the

system

must

berobustand

flexible, i.e., it shouldeasily adapt todesignand

process changes. Practitionersprefera flexiblesystem

that possiblydiagnoses onlythe

most

common

defect types (thataccountfor avastmajorityofboard failures) toone

that offerscomprehensive

diagnostic coveragebutcannot easily adapttochanges.The

case-basedapproach offers the potential tomeet

these requirements. Unlike otherknowledge-based

systems, the case-based system accumulatesknowledge

on-lineby

storingdiagnostic instances (asanalyzers identify

and

diagnosenew

faults)ratherthan generalrulesoralgorithmic procedures.Each

diagnostic instanceorcasecorrespondsto a distinctdefect; itis representedby

the setoftestsconductedand

theirobservedoutcomes

for that defect.

By

comparing

the testresults for the currentboard with previous instances,the

system

can eliminatecandidatedefectsand

determine the effectivenessof subsequenttests.

Recording

diagnostic instances rather than general rules has the p)otentialdisadvantageof requiring a large database.

However,

our prototype implementation experience suggests that thevastmajority offaultsencountered in practicecorrespond toavery small fractionofthe setofall possible instances.

Because

ofits simplicity, the system can be maintainedby

the analyzers themselves, avoiding long knowledge-acquisition delaysand

the consequentsystem obsolescence. Furthermore, thestandardformat ofacasepromotes

learningand

information sharingamong

technicians (fromdifferent shiftsor productionlines),and

enables the systemtoserve also as a trainingtool for

new

technicians.These

featuresmake

the case-basedsystem

viableand

usefulfor real manufacturing applications.Although

case-basedreasoning has

been

appliedtootherdomains

such as legalargument and customer

service,we

arenotaware

ofits previousappHcation to electroniccircuitdiagnosis.We

enhance

thebasiccase-based approachtoincorporate historical data

and

other priorinformation forsystematically selectingtests

and

optimizingthe search process.To

validate the overall approach,we

implemented and

testeda prototype versionofthe system in ahigh-volume

printedcircuit board (surface-mount)

assembly

line producinga hybrid (analog-Kiigital) circuit board for a state-of-the-artconsumer

electronics product.Our

implementationpermitsdistributedusage via a local access network. Within five

weeks

of installation,thesystem

achieved90%

coverage, i.e., the system had acquiredenough

diagnostic instancestocorrectlydiagnose

90%

ofthedefects occuring in the fifth week.Based on

our implementationexpenence,

we

offersuggestions toimprove

themanagement

ofthediagnosis function; in particular,

we

propose a proactivemanagement

approach and incentiveschemes

thatemphasize

the analyzer's processimprovement

rather thanfault-findingrole.

The

restofthis paperisorganized as follows. Section 2 describes the circuitdiagnosis process inmore

detail,and

develops thegoals foran idealdiagnosissuppon

system. Section 3 discusses the underlyingstructureand

operation ofa basiccase-basedsystem

forverifying defects based

on

testoutcomes. Section4

presents systemenhancements

tooptimizetest selection usinghistorical dataand otherpriorinformation on the likelihoodof

different defects.

We

present adynamic

programming

formulationoftheoptimal testsequencing

problem

tominimize

theexpectednumber

oftestsper board, andoutlineheuristic

methods

foron-line testselection. Section 5 brieflydescnbes

ourprototype implementationand

the lessonswe

learnedfrom

this implementation exercise,and

identifies directions forfurtherwork.

2.

The

Diagnosis

Process

2.1 In-line

testing:

Capabilities

and

tradeoffs

Circuitboard

assembly

linestypically contain in-line inspectionand

testing stages, afterplacement

and

soldering operations (see, forinstance.Noble

[1989] for adescription oftheprocessing steps in printedcircuit board assembly).

The

main

purpose ofthese in-linescreening operationsis toidentifydefective boards,although they also

have

limited diagnosticcapabilities.For

instance,visualand X-ray

inspectioncan identify missingor misplacedcomponents and

possiblycertain solderdefects, but are not effectiveorreliable fordense boards with smallcomponents.

Furthermore,complete

manual

orX-ray inspectioncan

be very timeconsuming and

expensive.Two

typesofin-line electrical tests areavailable—

in-circuit testingand

functionaltesting. In-circuittestsverify the functionalityofindividual

components on

the boardusingautomated

testequipment

(see, for instance.Maunder

and

Tulloss [1990]).They

canisolate

and

precisely identifycertain typesofdefects (e.g.,open

or shortcircuits,defective passivecomponents),

but require hardfixturingand

programming

that is difficult to justify forshort production runs.Moreover,

the increasing useof surface-mount technologyand

the high costofboard"realestate"

make

in-circuit testing infeasibleorlimit theirdiagnosticcapabilities(Garcia-Rubio [1988]). In-circuit testsare alsoprone to

measurement

errors (see, forexample.

Chevalier [1992]) especiallyfor small, highperformance components.

leadingto false acceptanceor rejectionofboards. Functional tests

measure

the circuit'sresponse (atthe board's output

pons

oredge

connectors) todifferentcombinations ofinputsignals. Functional testscan confirm

whether

the interactionsbetween

variouscomponents

meet

the specifications; typically, they can trace aboard's failure to the responsible circuit,but not to aparticularcom]X)nentorconnection in this circuit.

Selecting the testing strategyfor aproduct involves addressingtradeoffs

between

higher

assembly

cycletimes (forall boards) toconductextensive in-linediagnostic testsversus higheroff-tinediagnosis effon (fordefective boards)

when

the in-line testsdo

nothave

highresolution.As

theboarddefect rate decreasesand

component

density increases, this tradeoffincreasinglyfavors the strategyofusingin-line testingonly to identifydefective boards; detaileddiagnosis

and

defectverification istiienperformed

off-line byskilledtechnicians.

We

next describethisoff-line diagnosis process,and

identifyopportunities tosupport this process usinga

computer-based

system. Forbrevity,we

willuse the

word

"diagnosis" to referto the detailed, off-line diagnosisprocedure after a board hasfailed in-line (functional) tests.2.2

Sequential

testing

procedure

for off-linediagnosis

Diagnosing

acircuitboardthat has failed functional testsentailsidentifying tiie source ofthe malfunction (e.g., acompxDnentorconnectionon

the board)so thatappropriate corrective action (e.g.,replacing or resoldering thecomponent)

can betaken torepair theboard

Diagnostic information also serves as the input forrootcause analysisand

continuous

improvement

of vendors, processes,and

product design.We

define a dfifg^las the finest grain source ofmalfunction thatcan beunambiguously

identified

by

the analyzer.Each

defect hasan associated corrective action; differentdefects

might

require thesame

correctiveaction. For instance, adefective resistorcanactaseithera shortcircuitoran

open

circuit. Ineachcase, thesymptoms

and

themeans

toidentify the

problem

are different; therefore,we

view

thesetwo

possibilitiesas separate defectseven though

bothrequirethesame

corrective action (namely, replacingtheresisitor).

Each

defect has asetofassociatedsymptoms

thatthe analyzermust

discoverby

applyingone

ormore

tests.A

testis an action thatmust

beperformed

eitherby

atechnician or

by automated

testequipment, resultingin an observation aboutthe behavior of the board.A

testmight

consistof applying a specified setofelectrical inputs, adjustingcertain circuitelements (e.g.,tuningcapacitors),

and

probing selectedlocationson

the circuit boardtomeasure

thevoltage orview

the electrical signalon

anoscilloscope.Each

test has

two

ormore

possible resultsoroutcomes

(e.g.. voltage is greater than 4.5 volts orless than 4.5 volts); observe thatif theoutputmeasurement

iscontinuous (e.g., voltage)we

discretize it by definingtherange of continuous values associated with each outcome. For convenience,and

without loss ofgenerality, allofour subsequent discussionsassume

thatevery test has

two

possibleoutcomes which

we

denote as or 1.The

outcome

ofa testdepends on

the defectin the board.We

permitdefects tohave indeterminateoutcomes

for certain tests, e.g., foracertain defect, the voltage at a particularlocation

may

beeitheror 1

depending

on, say, the state ofa tlip-flopdevice.We

also recognize thatthe analyzermight have

onlypartial priorinformation regardingwhich

defect produceswhat outcome

foreach test;

however,

we

assume

thatthe available information is adequate to uniquelyidentifyeachdefect.

To

identify the truedefect in a malfunctioning board, the analyzeruses a sequential testingprocedure

.The

process starts with a candidate set ofdefects(which

depends

on

the board'sfailuremode

during functionaltesting)and

a setoftests thatcan distinguishbetween

thesedefects.The

analyzersuccessively selectsand

applies varioustests,observes the

outcome

ateach stage,and

eliminates (fromthe candidatedefect set)alldefectsthatcannot

produce

theobserved outcomes. Ifthe initialcandidatedefect set iscomplete

(i.e.,the setcontains all possible defects),and

the setofavailabletests iscomprehensive

(i.e.,some

combination ofknown

testoutcomes

uniquely identifieseach candidatedefect), theprocedure terminateswith the truedefect as the only remainingmember

ofthecandidatedefect set.Inpractice, analyzers

might

notalways

followa systematic procedure to selecttestsand

eliminate defects. Diagnosis is oftenconsidered an "art",

and

analyzers rely largelyonintuition,

some

circuitknowledge,

memory,

and experience as theyperform

diagnosis. Often, theydo

notformally maintainand

update thesetof candidatedefectsby comparing

the defects' expected test

outcomes

with the observedoutcomes. Indeed, the setof candidatedefectsand

theirexpectedoutcomes

may

noteven bedocumented,

andmight

vary

from

technician totechnician.A

common

"myopic

"approach fortroubleshooting consistsofhypothesizing aparticular defect,attempting toverify it by performingthe

appropriate tests, revising theguess ifthe testsdisprove the first hypothesis,

and

soon.Alternatively, theanalyzer

might

follow apredeterminedtestsequencerepresented, forinstance, as afault tree.

A

purelymanual

diagnosis process can be both inefficient and inaccurate especiallywhen

itisnotsupportedby

clearprocedures and documentation. Forinstance, using a staticfault treecanresult in unnecessary tests and unproductive search (relativetoanapproach

that usesrecent defect history to guide the search). Likewise, diagnosis without adequatedocumentation

and

formal recordingprocedures canlead to replicationoftestsandfalseidentification. Also, these informal approachesare not

conducive

to learning,transfering

knowledge

toother analyzers, or generating appropriate information forqualityimprovement.

To

identifythedesirablecharacteristicsofacomputer-based system

toassist2.3

Diagnosis decision

support

requirements

Consider an intermediate stage in thediagnosis process

when

the analyzerhas applied severaltestsand

observed the resultsof each test.The

analyzernow

faces fourrelatedquestions,all

aimed

atdecidingwhat

todo

next:(1)

Given

theoutcomes

ofall previoustests, canwe

concludethat the boardcontainsa specific(known)

defect?(2)

Does

the boardcontain apreviouslyunknown

defect?(3) If

more

thanone (known)

defectremain ascandidates,which

available test(s)can distinguishbetween

these defects?(4)

What

testtoapply next?We

will refer to the firsttwo

questionsas Defect Identification,and

theremaining

two

as

Test

Selection.Consider

the information needs and actionsfor thedefect identificationquestions.An

affirmative

answer

toeitherquestion takes the boardout ofthe regulardiagnosisiteration.In the firstcase, the action consists of repairing the identified defect,possibly after

confirmingthe diagnosis. If

no

known

defectcauses theobserved

cumulative testoutcomes

(i.e.,theanswer

toquestion 2 is affirmative),we

have three possibilities: (i) theboardcontains a

new

defect,or(ii) theassumed

testoutcomes

fortheknown

defectsareinaccurate,or(iii) the actualtest

outcomes were measured

incorrectly. In all tiireesimations, the boardrequires extraordinary actions such asconfirming previous test

outcomes,

consulting with designand

process engineers, checking with suppliers,and

updatingcurrent

knowledge.

Ifmultiple

(known)

defectsremain

in thecandidate set, thetestselection questions firstseektoidentifyrelevant tests,not yetperformed, thatcandistinguish

between

theremaining

possibledefects. Conceptually, thisprocess corresponds to determining,foreachavailable test, ifthattesthasdifferentexpected

outcomes

for the candidatedefects. Ifno

suchtest is available,theanalyzermust

developand

applyone

ormore new

tests todistinguish thedefects. Otherwise,

we

must

decidewhich

among

the availableteststoperform

next.As we

shall see later, thisdecision impacts thenumber

ofiterationsneeded

to

complete

thediagnosis.Computer suppon

for the defect identification questionsmight

consistofa databaseorlogical reasoning system thatautomatically

compares

the observedtestoutcomes

with theexpected

outcomes

forall candidatedefects,and

eliminates defects with inconsistent outcomes. Similarly, to supporttestselection, acomputer-based system

can identify therelevanttestsateachstage,and apply a systematic

method

to select the nexttest.To

beinitializing

and

updating,and

quick response.We

listbelow

theseand

other desirable featuresofacomputer-based system

tosuppon

electronic circuitdiagnosis:•

Development

effort:Given

the short productlifecyclesofelectronic products,we

require asystem

thatbecomes

operational quickly and withoutsignificantexpense.•Maintainability/ robustness:

The

systemmust

be easyto update, preferably by the users themselves; relyingon

external resources to update the system (e.g., softwareexpens

and

knowledge

engineers) often introduces delays, causing inconsistenciesand

system obsolescence.Another

important requirement isthe system'sability to adaptgracefullytothe frequentdesign

and

processchanges

thatcharacterize theelectronics industry.• Compatibility: Techniciansoften

view

structured tools and methodologiesasimpediments

to creativity; compatibility with current practicesand

the cultureoftheorganization is, therefore, critical tothe success

and

effectivenessofthe system.System

ergonomics, easeofuse, flexibility,

and manual

ovemde

options aresome

of theways

toimprove

compatibility.•

Response

time/efficiency: Sinceeach

boardrequires severaltest iterations toprune thecandidate defect set, the

system must

respondrapidly tothesequestions so thatdiagnosisdoes

notbecome

thebotdeneck

activity.• Effectiveness:

The

main

purpose ofadiagnosis supportsystem

is toreduce thediagnosis time per board. Partofthissavingscomes

from

eliminating errorsand

automatingsome

oftheroutinebookkeeping and

lookup functions.Two

other features can reducediagnosistime:

• reducing the (expected)

number

oftests through systematic searchand

principledtestselection

and

sequencing; and,• providing

good

"coverage", i.e.,when

thesystem

has stabilized, itmust

correctlydiagnosea large percentageofthe defects.

Other

desirablesystem

featuresincludeabilities to: interface with existing databases, prepareperiodicsummary

reports for processimprovement,

highlight inconsistenciesand

faciUtate learning,diagnose bothdigital

and

analog (e.g., radiofrequency) circuits,and

operatein multi-userenvironments.

The

next section uses theseperformance

criteriatomotivate thecase-based

method.

3.

The

Case-based

Approach

for Circuit

Diagnosis

3.1

Knowledge

base

for

diagnostic

systems

Circuitdiagnosisrequires three broadclassesof

knowledge

—

historic, heuristic,and

fundamental

knowledge.

Historicand

otherpriorinformationon

the likelihoodofdefects can help theanalyzer prioritizecandidatedefects, thusenabling an effective choiceoftestanalyzer mightfirst

examine

thatpan

before pert'orming othertests. Heuristic orempiricalknowledge, sometimes

termed "shallow"knowledge,

refers to anempincal

associationbetween

observedsymptoms

and diagnostic conclusions. This categorymight

include rulesand

procedures,as well astricks orshoncuts thatthe analyzer hasfound

to be effectiveaftersome

troubleshootingexpenence.Fundamental

or"deep"knowledge

impliesan understanding ofthe underlying physicsofcircuitelements

which

we

use topredictcircuit response.

Design and

testengineersrelyon

such fundamentalknowledge,

often

encoded

ina circuit simulator, todesign and troubleshoot electronic circuits.Depending on

the primary sourceof diagnosticknowledge,

we

can distiguishbetween

experience-based (empirical

knowledge) and model-based

(fundamentalknowledge)

systemstosupportcircuitdiagnosis.

The

model-based

approach uses ananalyticalmodel

ora circuit simulatortodynamicallyidentify the potential causes forthe observedsymptoms

duringthe sequential testingprocess. Since diagnosisentails "backtracking"(i.e.,given ceruin

observed

symptoms

or outputs,what

valuesofcircuitelements canproduce

these outputs),we

need

a translator toconven

traditional circuitdesignmodels

(thatcharacterize the output foragivencircuitconfiguration) intocorrespondingdiagnostic models.

Davis and

Hamscher

[1988] illustrate the three basic steps—

hypothesisgeneration, hypothesistesting,

and

hypothesisdiscrimination—

inmodel-based

diagnosis. Gensereth [1984],deKleer

and Williams

[1987],and

Hamscher

[1988] describe variousmodel-based

systems todiagnosedigital circuits.The

most

common

experience -based approach

is arule-based (expen)system

that relieson

the experience ofhuman

expertstodevelop if-then rules thatenablethe systemto reason aboutthe behavioroftiie

malfunctioning board (see

Semmelbauer

[1992] for an illustration ofthis approach).One

ofthe pioneering apphcations ofthe rule-based

approach

was

for medical diagnosis (e.g.,see

Harmon

and King

[1985]). Unlike the fieldof medicine,however,

electroniccircuitsand

manufacturing processes vary widely,and

thetechnologiesundergo

frequentand radical changes. Ingeneral, the literatureon knowledge-based

diagnosticsystems focusseson

knowledge

representation issuesand

inferencemechanisms

to identify the underlying source oftheproblem,and does

not adequately addressissuesofoptimizing the sequential search process.For

electroniccircuitdiagnosis, both themodel-based and

rule-basedapproachesoffer certain advantages, but alsoimpose

limitations.By

consideringa decision suppxsrtframework

thatcombines

both approaches inacomplemetary

fashion,we

can exploittheirrespective strengths

and

overcome

the disadvantages.Model-based

systems offertheadvantage ofdirecdy integratingdesignand diagnosis:

when

the designerchanges

the circuitschematic (and addsrelevantsub-models

fornew

components), the diagnosismodel

is automatically updated, permitting instantaneous troubleshooting capability without

they arevery computationally intensive,

model-based

diagnostic systems are not well-suited foron-lineapplications. Furthermore, technicaldifficulties still remain in buildingsuitablediagnostic

models

for analogcircuits (see, forexample, Bennetts [1981], Kritz andSugaya

[1986],Tong

etal. [1989])due

to bi-directional signal propagation,and

the impact ofphysical layoutand

toleranceson

the performanceof high speed radio-frequencycircuits. Dealing with bridge defectsand

improper

(open) connections alsoposesproblems

since the basiccircuitstructure itself

changes

(PriestandWelham

[1990]).On

theotherhand, therule-based approach can incorporate heuristic

knowledge

to deal with these complexities,and

provide quickon-lineresponse during diagnosis; the infrastructure oftools to

implement

a rule-basedsystem isalso quite well-established.However,

traditionalexpert systems

might

require longdevelopment

times (Priestand

Welham

[1990]), especially for initialknowledge

acquisition (e.g.,Newstead

and

Pettipher [1986]). Furthermore, since eachcomponent

and connectionon

the board can cause malfunction, anticipatingand encoding

rules forevery possibledefectis almost impossible. For instance, the initialknowledge

thatwe

acquired forone

board tobuild aprototype system covered less than20%

ofall the defecttypes thatwere

encountered during the firstfiveweeks

ofsystem

operation. Finally, asystem

that relieson

software experts orknowledge

engineers to updatethe

knowledge

base (forinstance,when

the circuit designor manufacturing process changes) can introduceexpensive delays.To

cope

withthe rapidpace ofchange

inthe electronics industry,we

requireadiagnostic

system

thatcan both adapteasily tothe changing environment,and

reduce diagnosis time in productionby

providingquick on-line response. Next,we

describe a case-basedapproach

thatis similarto rule-basedsystems in itson-line operation, butcan exploit thecapabilities ofmodel-based

systemstoadapt tochanging circuitdesignsand

new

defects.3.2

Elements

of

case-based

reasoning

The

goalofourprojectwas

todevelopand

testa diagnostic support systemthatisviable inapracticalmanufacturing environment.

Two

importantobservations regarding practice motivated ourproposed

case-based approach:1.

The

ubiquitous80-20 law

applies also to electroniccircuitdiagnosis, i.e., less than20%

ofallpossible defectsoccur

in over80%

ofthe defective boards. Figure 1,which

shows

the cumulativerelative frequencies ofvarious defects (arrangedin decreasingorder of occurence)forour prototype system,clearly illustrates this

phenomenon.

Given

this80-20

characteristic, asystem

thatcanoperate with incompleteknowledge

, progressivelyaddingdefects asthey are encountered, is preferable toenumerating,apriori, all possible

defects. This strategyhas fourimportant advantages: (a) the developmentaleffort and timeislikely to besignificantly lower; (b)focusing

on

the relativelyfew

defectsthat haveoccured inthepastcan significantlyreduce theresponse time; (c) since it cantolerate

incomplete

knowledge and

can be updatedon-line, the system can easily adapttochanges

inprocess

and

productdesign;and

(d)by

relyingon

human

expens

todiagnosenew

defects, the systemis non-threatening and hence likely to be well-accepted.

Our

experience (reportedin Section 5)indicates that the strategyofprogressivelyadding

new

defects as they are encountered provides over

90%

coverage within justafew

weeks

of operation.2.

A

simpleway

to "learn"from

an expertanalyzer is by recordingthe actions—

the testsperformed

and

theirrespectiveoutcomes

—

as the analyzerexploresand

identifies anew

defect.The

observedoutcomes

forall the teststhat the analyzerapplied todiagnose theboardcharacterize the

new

defect,making

ita convenientknowledge

representation forsystem

maintainability,and

as ameans

tocommunicate

among

expens.Case-based

reasoning(CBR)

originated in the areaoflegalargument

(hence, the term"case").

An

early system,HYPO,

operated in thecommon

lawdomain

oftrade-secret law;the

system

combines

reasoning about the statutes (rules) with the precedents (cases) thatconcern them.

The

problem

offindingthe case(s) appropriate to the currentsituationamounts

toclever searching ofthe case baseon

anumber

ofsignificant attributes.The

"closest" cases withrespectto these attributes are selected forperusal

by

the researcher. Legalargument

continuestodominate

themost

recentcase-based reasoning literature (see, forexample,

Risslandand

Skalak [1988]). Applications ofCBR

tothe fault diagnosisare limited.Lee and

Liu [1988] applyCBR

to roboticassembly

cell diagnosis,and

Ishidaand

Tokumaru

[1990] present ageneralized approach tocase-based diagnosis using the frame theory.For

electroniccircuitdiagnosis, the case-based approachoffers the attractivefeaturesofcompatibility

and

incremental,on-hne

knowledge

acquisition; the system cantolerate incomplete

knowledge, and

its coverageincreases withtime.We

enhance

theconventional case-based approach

by

addingfeatures to incorporate:(i) robust

knowledge

acquisition: the systemidentifies incompleteand

inconsistentknowledge

(e.g.,due

tomeasurement

errors ordesign changes),and

incorporatesverification

and

updating steps tocorrect these errors;(ii)distributed usage:

by implementing

the system inadistributed client-serverenvironment

with a shareddatabase, several userscan simultaneously accessand

use thesystem; and,(iii)effectivetestsequencing: the system reduces the

number

oftestsby

applyingtestselection heuristics that accountfor priorprobabilitiesofdifferent defects.

In theelectronic circuitdiagnosis context, acase is an instance ofadiagnostic

experience, represented by itstestoutcomes.

(A

rule,by

contrast, is a generalization about diagnostic experience gathered overtime.)Each

casecorresponds toa particular defect.The

casebase

consistsofthecollection of instances correspondingto different defects observed inthe past. Recall thateachdefect haseithera deterministic or indeterminateoutcome

forevery test; funher, the valueofa deterministicoutcome

might

beknown

(0or1)or

unknown.

For

agiven defect,we

r. ^r toits setofexpectedoutcomes

for all testsas thesignature

of that defect.Suppose

we

have n

defect typesand

m

available tests.We

visualize the case base as a n xm

matrix, with eachrow

corresponding to a previouslydiagnosed

caseor defect.The

irow

in the case base represents the signature ofthe i defect type, i.e., thejelement

ofthisrow

has a 0, 1, 1, orU

depending

on whether

theexpected

outcome

oftestj fordefect iis 0, 1, indeterminate, orunknown.

We

permit theuserto

dynamically

add rows

(cases)and

columns

(tests) tothe case base asnew

defects aredetectedand

diagnosed (incrementalknowledge

acquisition).3.3

Diagnosing

a

defective

board:

Successive

refinement

through

case

matching

Diagnosing

adefective board correspondsto gatheringenough

information (byperforming

testsand

observing theiroutcomes)

about the board's signature, whilesimultaneously searchingthe case base, to identify a

matching

case. Ifno matching

case isfound, the boardcontains a

new

defector an inaccuratecase. In either situation, thecase basemust

beupdated toreflectthis latest experience.We

remark

that the general case-basedapproach goes beyond

casematching

and database updatingfunctions topossibly includereasoningand

extrapolation.Our

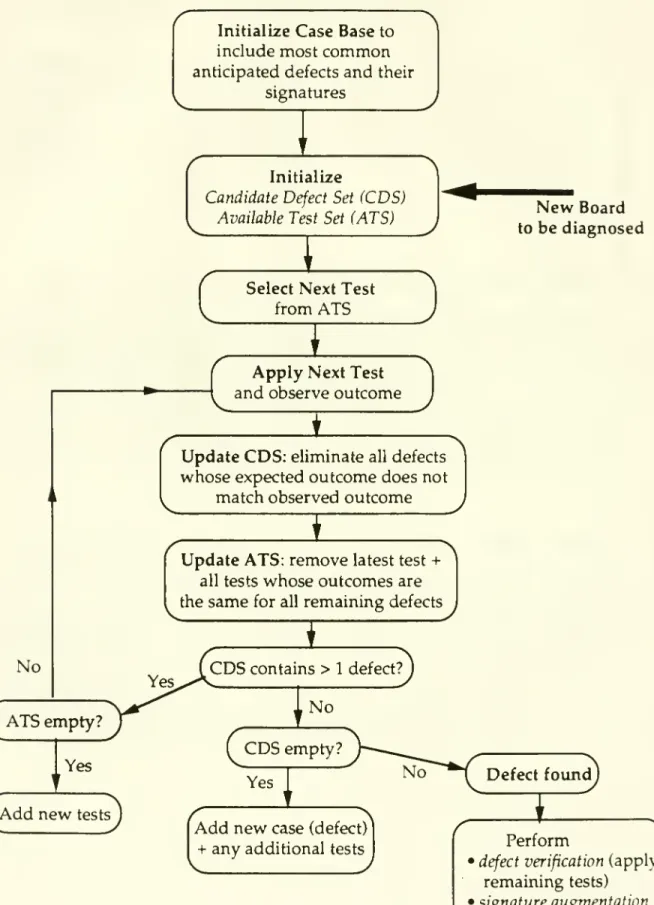

implementation doesnot exploit these additionalcapabilities. Figure 2

shows

thecomplete

flowchart forour case-basedcircuitdiagnosis supportsystem

(CDSS).

We

firstexplianhow

thesystem

operates beforedescribinghow

toupdate thecase base (Section3.4). Section

4

descnbes

enhancements

toimprove

thesystem'stest sequencing capabilities,

and

Section 5 discusseshow

tointegratethis system withamodel-based

approach.At

each stageofthe search process, thesystemmaintains: (i) a candidatedefectsetconsistingofall

known

defectswhose

signaturesmatch

theobservedoutcomes

for all the testsperformed

thusfar,and

(ii) theavailable testsetcontainingall tests that havenot yetbeen

perfonned

butwhose

outcome

differentiatesone

ormore

candidatedefectsfrom

theremaining

defects in thecandidate set. In the basic versionofthe case-basedsystem, theanalyzer

chooses

atestfrom

the availabletest set, performsthis test,and

observestheoutcome

ofthetest. (In Section4

we

describesystemenhancements

tooptimally select thenexttest).

When

theanalyzerenters the observedoutcome

into thesystem, thecandidatedefect set

and

available test set areupdated as follows:•

remove

from

thecandidatedefectsetalldefectswhose

expectedoutcome

for thelatest testdiffersfrom

theobserved outcome.

Note

thatwe

retain all defectswhose

outcome

• delete the testthat

was

justperformed from

the available test set; also,remove

any testwhose outcome

is thesame

(orunknown

or indeterminate) for all the remaining defectsin theupdatedcandidate defectset.

Ifthe initialcase base is

comprehensive

(i.e.,containsall possible defecttypes, and hasenough

information regarding expectedoutcomes

touniquely identify eachdefect)and

accurate, the process

must

terminate with the candidate defectsetcontainingonly the true defect.To

illustrate this process, considerthe simple5-component,

seriesnetwork

shown

inFigure 3.

Suppose

we

have

a boardwhose

abnormal

outputsignal for the functional testindicatesmalfunction in

one

ofthe 5components

(all the intermediateconnectionson

theboard are good); fori

=

1,2 5,defect i refers to amalfunction incomponent

i.We

have

four availableteststhatapply a stimulusattheinput terminal,

and

measure

thevoltage ateach ofthefour intermediateconnections (see Figure 3).

An

outcome

of0, corresponding toabnormal

voltage, indicates malfunctionofone

ofthe upstreamcomponents.

Thus,we

can representthe signature foreachdefect asa vectorcontaining

4

binary elements. Defect1 has the signature

{0000},

defect 2 has signature {I000),

and

so on. Table 1shows

thecasebase containing thecomplete

signatures forall 5 defects. Thisexample

does nothave

any

indeterminateoutcomes, andwe

initiallyassume complete

information(i.e.,

no

"unknown"

outcomes).For

simplicity,assume

thatthe technician always selectsthe testsinreverse sequence,i.e., he firstapplies test 4 (i.e.,

measures

thevoltagebetween

components

4

and

5), thentest 3,

and

soon

until the defect isconclusively identified.Suppose

a board contains defect3 (i.e.,

component

3 isdefective). Table 2 tracesthe successive statesofthe system, i.e.,the candidate defectset

and

theavailable test set at each stage; thecolumns

ofthis tableanswer

thedefectidentificationand

test selection questionsofSection 2.At

theend

ofthe third iteration, the candidatedefectsetcontainsa single defect (defect 3), proving conclusively thatcomponent

3on

the board isdefective. For thisexample, thechosen

testsequence eliminatesfrom

the available testsetonlyone

test(the testthatwas

justapplied)at

each

stepHowever,

ifwe

had

firstapplied test 3 insteadoftest 4. its "0"outcome

(forthisexample)

automatically eliminates test4 since allremaining candidatedefects {1, 2, 3}

have

thesame outcome

"0" fortest 4.This

example

motivates the following threeimponant

observations:1. Exploiting prior information:

Suppose

past historyor a priori information (e.g.,knowledge

aboutvendor

qualityproblems) suggeststhatthe likelihoodofdefect 3 is significantly higher than theother

perform

thesetwo

tests first. For oursample

board containingdefect 3, this strategywould

require onlytwo

iterations tocomplete thediagnosis(compared

to the 3 iterationsrequiredfor the static reverse-order sequence).

For

complex

circuits, this savings innumber

oftestscan be significant. Section4discusseshow

to exploithistoricaland

other prior

knowledge

todynamically select an effective testsequence.2.

Incomplete knowledg

e:Our

example assumes

thatwe know

thecomplete

signature for each defect, i.e.,we

know

theexpectedoutcome

ofeach testforevery defect.However,

the partial signature {0U U

U}

issufficient to isolate defect 1 (theelement

"U"

denotes anunknown

outcome)

ifwe know

thatall other defects producea "1"outcome

fortest 1; similarly,(U

1U}

isolates defect 3, i.e., tests 2and

3 are the only essential tests to uniquely identify defect 3. Table 3shows

an "incomplete" casebase containing adequateknowledge

todistinguishbetween

the 5defects.Using

thiscase baseand

ouroriginal reversetest sequence, the setof candidatedefects for the first3 iterationsremain

thesame

as before(shown

in Table 2).However,

observing a "1"

outcome

fortest2 during the third iteration eliminates defect 2 butdoes not eliminate defect 1 (since theoutcome

oftest 2 fordefect 1 isunknown).

Therefore, at the start ofthe fourth iteration, the candidate defectsetcontainstwo

defects (defects 1and

3),and

we

have

one

available test(test 1) thatcan eliminate defect 1.We

must

necessarily

perform

test 1 (in thiscase,we

willobserve a "1"outcome,

eliminating defect1) in orderto conclusively provethat the board contains defect 3. Thus,

complete

knowledge

about theexpectedoutcomes

foreachdefectcanaccelerate the pruningprocess

and

reducethenumber

oftests.Also

note that,even though

we

staned with only the partial signatures,we

canimprove

ourknowledge

afterthisdiagnostic exercise. In particular,we

canchange

defect I's expectedoutcome

for test2from "U"

to"0" in thecase base, potentially

improving

future performance.3.Multipledefects:

The

signatureofadefect represents the anticipatedtestoutcomes assuming

thatthe board containsonlythatdefect.What

happens

ifa boardcontains multiple defects? Suppose,inour

example,

theboard contained defects 3and

1.The

diagnosis, illustrated in Table2, is stillcorrect, i.e.,

component

3 isdefective.However,

afterwe

verify defect 3and

replace

component

3,we

must

againapply the functional test toconfum

properfunctioning ofthe board. Ifthe board malfunctions,the diagnosis process

must

be repeated; in this example, thesecond round

willdetectdefect 1.Although

ourexample

useda verysimplecircuit, it has servedtoillustrate several genericconcepts relating to effectivediagnosis. Realcircuits contain

many

complexities such asmeasurements,

stimuli, andcomponent

settings,and

so on.Our

methodology

applieseven

tothese

complex

circuits.3.4

Updating

the

case

base:

Incomplete

knowledge

and

inaccuracies

We

have

already seenone

opportunity to update thecasebaseand

improve

subsequent performance: supposewe

identify defect iat the end ofthe diagnosis process,and suppose

the currentcase basecontainsonly the partial signature fordefect i. Then, forevery test

j

performed

during thecurrentdiagnosiswhose

outcome

fordefectiwas

previouslyunknown,

we

canreplace theunknown

entry in the case base with the actual observedoutcome

for thecurrent board (assuming testj isknown

tohave

a deterministicoutcome

fordefect i).

We

will refer to this updating step as signatureaugmentation

.Note

that thisupdating step is not valid ifthe boardcontains other defects besides defect i; hence,

we

canaugment

defecti'ssignature onlyafterrepairing itand verifying the properfunctioning ofthe board.

Our

discussion in Section 3.4assumed

that the case base iscomprehensive

(i.e., itcovers allpossible defect types)

and

accurate. Ifthe case base isincomplete or inaccurate, thematching and

successivedefect/testelimination process mightnot necessarilyterminate witha single (truej -efectin thecandidate defect set.There

aretwo

possibilities:(i)

The

process terminates because thecandidate defectsetisempty

,i.e., thecombination

of

observed

testoutcomes

does notmatch

with the signature ofanyknown

defect.This situation couldariseeither because:

(a) theboardcontains a

new

defectthat had notoccuredpreviously;(b) atleast

one

ofthedefect signaturesrecordedin the case base is inaccurate (due todataentryerrors,design changes, etc.); or,

(c) theobservation

and

measurement

ofthe acaialtestresultswas

erroneous.In all three cases, the boardrequires "extraordinary" actionsto identify the true

symptoms

and

cause oftheproblem; these actionsmight

entaildetailed probingand

experimentation

by

theanalyzeras well as consultations withdesignand

testengineers, production staff,and

component

vendors. Ifthe board isfound

tocontain aknown

defect, itssignature in thecase base

must

bechecked and

corrected,if necessary.We

refer to this ujxiating step as signature correction.On

theother hand, if the boardcontains a

new

defect,we

must add

anew

case (row) corresponding to that defect.We

referto this step ascase addition.

The

new

case contains the expected testoutcomes

for that defect,and

possiblysome

auxiliary information such as thename

ofthe defect, theanalyzerorengineerwho

diagnosedthe defector revisedthe signature, thecorrective (repair) action required, thedefect category,

and

who

to notify(orhow

tonew

defectfrom

the previouslyknown

defects (theobserved testoutcomes

that led to theempty

defectset provide adequate"proof

forthis defect), the analyzermight

wishto

add one

ormore

new

teststhatcan quickly isolatethis defect.(ii)

The

diagnosisprocess terminatesbecause the available test setisempty

, butthecandidate defect setcontains

more

thanone

possibledefect. Thisoccurrence indicateserroneoustest

measurements,

inaccurate defect signatures, orinadequate tests."Inadequatetests" refers tothe situation

when

the currenttests cannotdistinguishbetween

the candidate defectseither becausemany

testoutcomes

areunknown

ornew

testsare required. Recall that

we

deletea testfrom

the available testsetwhen

we

perform

that testorif itsexpectedoutcome

isthesame

(same

known

value, indeterminateorunknown)

forall theremaining candidatedefects. Again, thisstoppingcondition (with multiple candidate defects

and no

remaining tests) requires extraordinary actions toverify the testmeasurements,

check

thedefect signatures storedinthecase base, complete the partialsignatures oftheremainingcandidatedefects, or

add

new

teststhatdistinguishbetween

these defects.We

refer to thisprocess as testaddition.

Figure 2 contains aflow chart

summarizing

the casematching and

updatingprocess. This process includes a defectverification step attheend

ofa successful diagnosisexercise.Verificationentailsconfirming previousobserved

outcomes and

applying any teststhatremain

intheavailabletest set; ifone

ormore

outcomes

conflict with the hypothesizeddefect, a

new

casemust

be added. Thisoptional step is especially important afterdesignchanges

and

during productionramp-up

when

many

new

casesareadded

to thecase base.During normal

operation, defectsare automatically verifiedif, afterrepairing the identified defect,the boardpassesthe functionaltest.A

board failingthe testagain requiresexplicitdefectverification todetermine

whether

the originaldiagnosiswas

erroneousor iftheboard contains multipledefects.In

summary,

thecase-based approach tosupportcircuit diagnosispermitsincremental, robust,and

distributedknowledge

acquisition.Unhke

otherknowledge-

based approaches,thecase-based

system

employs

on-lineand

incremental, ratherthan batch-oriented,knowledge

acquisition. Allcases havethesame

format; a case contains informationon

thesymptoms

thatthe useridentifies to be relevantin definingand distinguishingbetween

defects.

Because

ofthe standardizedformat, the case baseis easy to understandand

update.

The

system

begins with incompleteknowledge and

poordefect coverage, buteach unsuccessful diagnosisinitiatesa process ofcase-building toensure subsequent coverage ofthesame

defect.Our

experience suggeststhat the casecoverage increasesvery rapidly during the firstfew

weeks.By

only maintaining the diagnosticknowledge

that is needed,baseareeasyto detect: they result in unusual termination ofthe diagnosis process(empty candidate defect setor

empty

availabletest set).The

various correctionand

updating steps—

signature augmentation, signature correction, case addition,and

test addition—

make

theknowledge

acquisition processrobustand

adaptive.The

case-basedsystem

can beimplemented

using a sharedrelationaldatabase in a multi-usercomputing

environment, thus providingwide

access to analyzers atdifferent locations as well asdesign, testandprocess engineers and production supervisors. This implementation alsoallows the case baseto be integrated with other factory information systems,

conveying

current vendor, design,and

processproblems

to the diagnosisoperation,and

feeding backdefect informationforqualityimprovement.

The

system can alsokeep trackofthe cumulativerelative frequencies

and

trendsofdifferent defects;we

next describehow

touse theserelativefrequencies toguide

and

optimize the sequential testing process.4.

Optimal

Test Selection

By

automating thesearchand

updating functions,the basicCDSS

reducesthe time foreach iteration ofthediagnosis process. Decreasingthe

number

ofiterations provides anothermeans

to significantiyreduce the total diagnosis time per board.As

ourexample

of Section 3 illustrates,thenumber

ofiterationsdepends

on

thetest sequence.We,

therefore,require aneffective testselection policyorrule: ateach stage ofthe diagnosis process, the

method

helps us decidewhich

available testtoapply next (basedon

theobservedoutcomes

thus far).

We

refer toa testselectionrule thatminimizes

the expectednumber

oftests asthe optimaltestselection policy. This section presents a

dynamic

programming

formulationfor the optimaltest selection problems,

and

describes on-line heuristic rules that the basicCDSS

can incorporate toreduce the expectednumber

oftests.These

rules relyon

priorinformationconcerningthe likelihoodofdifferentdefecttypes,estimated

from

historicaldata

on

defects (relative frequenciesand

trends),knowledge

about specificproblems

atthevendor

site orin theassembly

process, inputsfrom

design engineerson

new

engineering changes, etc.4.1

Test

selection

example

We

firstconsidera simpleexample

to betterunderstand the impact ofteststructureandsequencing

on

thenumber

oftests requiredto prove the defect.Suppose

aboardcontainsone

of npotentialdefects,and

eachdefect has a singleassociatedtest thatis both necessaryand

sufficient to "prove" that defect, i.e.,test i has a "1"outcome

fordefect i,and

a"0"

outcome

forall other defects(orviceversa).We

will refer to this type oftestas nfocused

test (test 1 in Figure 3 is a focused test). Thus, the

complete

case basefor n focused testscorresponds toa n x n identity matrix.

Suppose

n=

5,and

the five possible defects havethe following probabilities of occurence: 0.1, 0.1, 0.2, 0.2,

and

0.4. Intuitively, applyingFor

ourexample, the "decreasing probability sequence" correspondsto applying the tests inreverse indexorder(i.e., 5-4-3-2-1 ) untilthe defect is identified.

The

expectednumber

of tests, say Ej, using this strategy is:Ej

=

1x0.4+

2x0.2+

3x0.2+

4x0.1+5x0.1

=

2.3 tests per board.On

theotherhand, fora static policy that appliestests in the forward sequence 1-2-3-4-5.the expected

number

oftestsE2

is:E2

=

1x0.1+2x0.1+3x0.2

+

4x0.2+

5x0.4=

3.7 tests per board.The

optimal strategy saves,on

average, 1.4 testsperboardrelative tothesecond

sequence, a43%

savings.(A

more skewed

probability distribution can giveeven

greater savings.) Thus, optimaltest sequencing hasconsiderable potential toreduce diagnosiscost,and

provide quickfeedback forquality

improvement.

Because

we

assumed

thateachdefecthas a focusedtest,ourexample

hasa simple optimal testing policy thatis static (i.e.,does

notvary withthe observedoutcomes)

and

easy to implement,i.e., sequence the tests indecreasing order ofdefect probabilities.

Since focusedtestsare infeasiblefor certaindefects (because ofconstraints

on

probing,measurement,

etc.)and

eliminateonlyone defectatatime (exceptatthe final step),analyzersrely

on

acombination

offocuseda.ndjointtests. Unlike a focused testthatisboth necessary

and

sufficient,joint testscannotisolatedefects individually but theircombined

outcomes

canjointly identifyand

prove thedefect (e.g., tests2 through 4inFigure 3). Joint testsreduce the

number

ofrequired tests todiagnose all defects,and

can,under

certaincircumstances(dependingon

their structure and the relative likelihoodof variousdefects), reduce theexpectednumber

ofiterations per board.The

"testconfiguration

problem"

of decidingwhat

combination of focusedand

joint tests toincludeintheavailable testsetposes challenging tradeoffs

between

thenumber

ofavailable testsand

theexpectednumber

ofiterations per board;we

do

notaddressthis tradeoffin thispaper,

assuming

instead thatthe available testsare predetermined.When

the available test setcontainsjointtests,theoptimal test selection policymight

bedynamic,

i.e., the decisionon what

test toapply nextdepends on

the current "state" of the system defined by theprevioustest

outcomes;

we

nextformulate this testselection problem.4.2

Test

selection:

Problem

formulation

and

optimal

solution

The

testselectionproblem

seeks an optimalornear-optimaltestingpolicythatminimizes

theexpectednumber

oftests oriterationstodiagnose amalfunctioning board.We

distinguishbetween dynamic and

static policies; adynamic

policy uses information regardingprevioustestoutcomes

to select thenexttest, while a staticpolicy selectsthesame

sequence

regardlessofthe testoutcomes.Dynamic

policiesperform

bener(i.e., they requirefewer

testson

average) since they usemore

information.The

optimizationofsequenrial search processes has been previously

modeled

(see, forexample,Whinston and

Moore

[1986]),and

applied, forinstance, tocomputer

file search(Moore,

Richmond,

andWhinston

[1988]).The

reliability literature has also addressed optimal testsequencingissues forcertain specialcircuit

and

test structures (e.g., Nachlas,Loney,

and

Binney

[1990], Butler

and Lieberman

[1984] studyseries systems with focused tests).However,

unlikeour

dynamic knowledge

acquisition context, this stream ofliterature oftenassumes

thatalldefect types

and

theirprobabilities areknown, and

the requisitetests are available,withoutprovisionsfor

unknown

orindeterminate outcomes. Furthermore, theknowledge-baseddiagnosis systems described in the literature

do

not appear toincorporate optimal search principles.4.2.1

Dynamic

Programming

Formulation

This section presents a standard

dynamic

programming

formulation to clarifytheingredients

and

tradeoffsin test selection duringcircuitdiagnosis. First,we

introducesome

notation.We

use the indices i=

1,2,. ..,nand

j=

1,2,...,m torepresent the n defect typesand

m

available tests.We

assume, without lossofgenerality, thatthe casebase contains all possible defecttypes. Otherwise,we

can introduceadummy

defect type called "unidentified"(which

includes "no trouble found"),and

a fictitiousfocused test with a"1"outcome

iftheboard has an unidentified defect,and a "0"outcome

forallotherknown

defect types

(we perform

this fictitious testonlywhen

thesetofknown

candidate defectsisempty).

We

permitincompleteknowledge

ofdefect signatures.However,

theknown

partialsignature foreach

defectmust

be accurate,and

we

must

haveenough

information(i.e., theanalyzer

must

known

the expecteddeterministicoutcomes

forenough

defect-testcombinations) to

unambiguously

identify the true defect.We

alsoassume

thatthe testobservations

and

measurements

are error-free.These

assumptions ensure thatthe diagnosis processis accurate,and always

terminates "properly" with the candidate defectsetcontainingonlythe true defect.

At

any

intermediate iteration ofthesequential search process, tiieobservedoutcomes

forthe tests

we

have performed

thus fardetermine the remaining candidatedefects (i.e.,defects

whose

expectedoutcomes

areconsistent with the observedoutcomes)

and

availabletests (thatcan distinguish

between

the remainingdefacts); hence, tiie previouslyobservedoutcomes

completely captureourcurrentknowledge

about die board.We

letX

denote the state vectorrepresentingthiscurrentknowledge.

We

specify the stateX

asthe following m-vector (wherem

isthenumber

ofinitially available tests): tiiej elementx.can take three values: X:=

iftestjwas

previouslyperformed and

itsobservedoutcome was

"0",

Xj

=

1 iftestj'soutcome

was

"1",and

X:=

N

iftestj has not yetbeen

applied.The

initialstatevector

X^

haselementsx^'=

N

for allj=

l,2,...,m. LetD(X)

and

T(X)

denote,respectively,the indexsets of candidate defects

and

available testscorresponding to anystateX. Initially,

D(X^)

=

( l,2,...,n) is the set ofall possible defects,