Publisher’s version / Version de l'éditeur:

Polymer Degradation and Stability, 49, pp. 21-28, 1995

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Surface and bulk analysis of the oxidation of polyolefins

Lacoste, J.; Deslandes, Y.; Black, P.; Carlsson, D. J.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=9898056f-b846-4c3e-88ae-54eef64a3a21 https://publications-cnrc.canada.ca/fra/voir/objet/?id=9898056f-b846-4c3e-88ae-54eef64a3a21

ELSEVIER

Surface and bulk

zyxwvutsrqponmlkjihgfedcbaZYXWVUTSRQPONMLKJIHGFEDCBAPolymer Degradation and Stability 49 (1995) 21-28

0 1995 Elsevier Science Limited

0141-3910(95)00044-5

Printed in Northern Ireland. All rights reserved 0141-3910/95/$09.50

analyses of the oxidation of

polyolefins

J

.Lacoste,*’ Y. Des1andes,2 P. Black’ & D. J. Carlsson*

zyxwvutsrqponmlkjihgfedcbaZYXWVUTSRQPONMLKJIHGFEDCBA ‘Ecole Nationale Suptrieure de Chimie de Clermont- Ferrand et URA CNRS 433, 63177- AubiZre Cedex, France21nstitute for Environmental Chemistry , National Research Council, Ottawa KIA 0R6, Canada (Received 23 December 1994; accepted 5 February 1995)

The non-uniformity of oxidation across polypropylene and polyethylene films has been measured by a combination of X-ray photoelectron spectroscopy (XPS), internal reflection infrared spectroscopy and bulk property measure- ments. Films were photo-oxidized or -y-irradiated in air. Photo-oxidized film showed detectable oxidation at a very early stage in the outermost 70 A of the film thickness (as measured by XPS). Oxidation advanced into the lilms as exposure level increased. Although y-irradiated films also showed enhanced surface oxidation, this was attributed to the reaction of the polymer surfaces with short-lived species such as ozone from the radiolysis of the moist air atmosphere. When films were -y-irradiated and oxidized under conditions which precluded these reactions. oxidation proceeded uniformly throughout the film cross-section.

1 INTRODUCTION

The main mechanisms of the photoinitiated

oxidation of polyolefins are now fairly well

understood and derivatization techniques by

reactive gases have recently allowed a quantita-

tive evaluation of important oxidation products

from differing initiation modes (UV, y or

thermal).‘** Many other approaches for the

evaluation of the oxidation products can be used,

for example oxygen uptake or spectroscopic

methods. Generally, these methods do not take

into account the essential heterogeneity of

oxidation which may result from, for example,

limited oxygen diffusion into the polymer

cross-section, morphology differences or non-

uniform initiation.

Non-uniformity of oxidation has been charac-

terized to a limited extent by several analytical methods including:

(i) the infrared (.IR) analysis of a series of microtomed slices;3

(ii) the analysis of various depths using

* To whom correspondence should be addressed.

photoacoustic IR4 or internal reflection

spectroscopy (IRS)-IR with different inci-

dent angles and/or different crystal$,’

(iii) the determination of an oxidation profile

across a microtomed slice of polymer film

by micro Fourier transform infrared

spectroscopy (FTIR);7-9 (iv) microindentation.”

In addition, theoretical oxidation profiles can

also be derived from the oxygen diffusion

coefficient.”

Surface analysis by X-ray photoelectron

spectroscopy (XPS) can directly measure the

total reacted oxygen content in the first 40-130 8, of a sample. In addition, detailed examination of the carbon (Cls) electron binding energies can

differentiate several types of oxidative products

such as hydroxyl or carbonyl groups for some conditions of oxidation.‘*,13

The aim of the present paper is to compare

XPS analysis of oxidized polyethylene and

polypropylene films with analysis by IR transmis-

sion and internal reflection spectroscopies so as

to give a detailed picture of the spatial

distribution of products. The reliability of XPS as 21

22 J. Lacoste et al.

a non-destructive analysis method for oxidized

surfaces is also examined.

2 EXPERIMENTAL

Linear low density polyethylene (LLDPE) (100

pm, unoriented DuPont Canada, Sclair resin)

and isotactic polypropylene (iPP) (25 pm, un-

oriented homopolymer, Himont Profax) blown

films were acetone extracted (Soxhlet) for 48 h to remove additives and vacuum dried. Prior to use, both films had been stored at room temperature for about 15 years since extrusion.

Photo-oxidations were performed by exposure

to a xenon arc WeatherOmeter (Atlas, 2500 W)

equipped with a light monitor set at 313 nm with an interference filter. The xenon arc emission was filtered with borosilicate inner and outer filters (solarized 24 h before use) to eliminate wavelen- gths below 290 nm. Incident light varied with the

arc and filter age but usually corresponded to

about 0.25 kJ/m’ in each hour at 313 nm. This wavelength was chosen as being most important

for the photo-oxidation of polyolefins. In the

WeatherOmeter, the silver panel temperature

was controlled at 55”C, with a black panel

temperature of 75°C. No additional humidifica-

tion was used.

For comparison purposes, some films were

oxidized by exposure to y-irradiation in an

AECL GammaCell 220 at a dose rate of 0.70

Mrad/h (7.0 kGy/h). To minimize any post-

irradiation effects, all oxidized samples were

either analyzed immediately after 20 h at room

temperature in air or were stored at this point

under vacuum at -80°C until analysis was

possible, to prevent completely further oxidative changes.

Oxidation products were identified and quan-

tified by FTIR. Interference ripples in transmis-

sion spectra were eliminated optically by the

method of Harrick14 (polarized IR radiation with each film tilted at the Brewster angle).

FTIR spectra of the surfaces of photo-oxidized

films were recorded by internal reflection

spectroscopy (IRS) as described previously.’

Films were pressed firmly against either a Ge or a

KRS-5 reflection element (2 X 20 X 52.5 mm) and

then mounted into a Wilks No. 9 IRS attachment

which occupied the sample side of either a

Nicolet 7199 (liquid nitrogen cooled MCT

detector) or a Nicolet 520 G FTIR spectrometer

(TGS detector). Use of these crystals of differing refractive index (although both with 45” facets) allowed the collection of spectra corresponding to polymer surface layers of increasing thickness.

Recording meaningful surface spectra with the

Ge crystal was particularly difficult because of the need for very good contact between the film and

the crystal and because of the difficulty of

removing all absorbed water in the spectro-

meters. Water vapour is removed shortly after sample installation by the dry air purge of the

spectrometer. However, traces of absorbed water

( - 3400 and 1640 cm-‘) on the spectrometer

optics were still visible at the high scale

expansion necessary to detect the weak spectra of

oxidation products on Ge crystals. The water

absorption at 3400 cm-’ overlaps that of -OH

groups in the polymer. This problem was

minimized by purging for a controlled time (2 h) before each spectrum from the bare crystal, or the crystal with film, was recorded. For both Ge

and KRS-5 studies, spectra were recorded on

both the front (xenon lamp facing) and obverse

surface of photo-oxidized films.

XPS spectra were acquired on a Perkin Elmer Physical Electronic’s Model 5500 and on a Kratos Axis HS system. For both cases, photoelectrons were collected normal to the sample surfaces and

‘angle resolved’ measurements were not made.

Typical analytical conditions were as follows. The

size of the analyzed area was about 1 mm2

(Kratos) or 2 X 5 mm (Perkin Elmer). Monoch-

romatized Al Ka radiation was used for

excitation and a 180” hemispherical analyzer with

a three channel detector was employed. The

spectrophotometer was operated in fixed analy-

zer transmission (FAT) mode throughout the

study using electrostatic magnification. Survey

spectra were collected using 160 eV pass energy while 20 eV was used for high resolution. The pressure in the analyzer chamber was 10mx to 10 -‘) torr. An electron flood gun was used to minimize sample charge during a measurement.

However, because of small shifts caused by

residual charging, binding energies were re-

ferenced to the carbon-carbon bond which was

assigned a binding energy of 285 eV. Atomic

compositions were estimated by standard pro-

grams provided with the instruments using the

sensitivity factors supplied by the manufacturers. The surface oxygen content of each oxidized film was the average of a minimum of three analyses on different film areas.

Surface and bulk analy ses

On some samples, total hydroperoxides

(ROOH) were estimated by iodometry as

reported elsewhere.1,2 This method is extremely

sensitive to trace levels of oxidation because of

the very high extinction coefficient of the I,-

product (25 000 (mole/l)-’ cm-’ at 355 nm).

3 RESULTS

3.1 zyxwvutsrqponmlkjihgfedcbaZYXWVUTSRQPONMLKJIHGFEDCBAPhoto-oxidation of polypropylene

Film samples were photo-oxidized for increasing

times in the WeatherOmeter and then analyzed

by XPS, iodometry, transmission IR and IRS-IR (on both Ge and KRS-5 crystals). Fresh film

samples were used for each photo-oxidation time

and for each analytical method.

3.1.1 X- ray photoelectron spectroscopy

Although X-ray excitation generates core electr- ons from atoms located at depths in a sample, only the electrons close to the surface escape the

sample and are detected by the XPS spectro-

meter. For a detector normal to a flat polymer

surface, detected electrons are collected

of the oxidation of poly olefins 23

from a layer having a thickness of about 70 A.13 All elements can be detected except for hydrogen

and helium and have well established binding

energies.12*13 XPS survey spectra of a series of increasingly oxidized iPP films are shown in Fig. 1. In all cases the Cls peak at 285 eV is

normalized to constant height. Compositions of

the 70 8, surface layers can be data by the use of established coefficients.

derived from this atomic sensitivity With XPS it is often possible to resolve spectra

into peaks attributable to specific atomic

linkages. From the ‘high resolution’ XPS

spectrum of the Cls electrons from the most

highly photo-oxidized film shown in Fig. 2, peaks

at +1.6 eV (-C-O-), +2*8 eV (C = 0) and +4*0

eV ( - C( = 0)-O-) can be detected relative to

the dominant combined C-C and C-H peak (at 285 eV). Peaks were assigned from XPS spectra of polymer samples containing specific functional groups. In theory such spectra should allow the

identification and quantification of many of the

groups on the oxidized polymer. In reality this is difficult because of the inherent low resolution of

XPS, peak widths and deconvolution limitations,

and sample sensitivity to X-rays (see below) and zyxwvutsrqponmlkjihgfedcbaZYXWVUTSRQPONMLKJIHGFEDCBA

loo0 900 800 700 600 500 400 30

Binding energy (eV)

Fig. 1. Evolution of oxygen content by XPS (Perkin Elmer XPS) during the photo-oxidation of iPP. Sensitivity factor O/C = 2.4. Cls peak height is normalized to a constant count value (100%). Spectra from survey scans are off-set for clarity.

24 J. Lacoste et al. zyxwvutsrqponmlkjihgfedcbaZYXWVUTSRQPONMLKJIHGFEDCBA

6000 -

Binding energy/eV zyxwvutsrqponmlkjihgfedcbaZYXWVUTSRQPONMLKJIHGFEDCBA

Fig. 2. Maximum resolution XPS spectrum of photo- oxidized iPP (23.8 kJ/m2 exposure). High energy deconvol- uted peaks are absent prior to irradiation (Perkin Elmer

XPS).

at best is only semi-quantitative for the complex

mixtures of oxidation products identified from

oxidized polyolefins.‘2 Deconvolution at low

oxidation levels is at best highly speculative.

Consequently in this study we have simply used

XPS to quantify the total percentage of oxygen

averaged over the surface ( - 70 A) layer.

Concentrations are expressed as oxygen atom to

carbon atom percentages.

One of the dominant oxidation products from

polyolefins, the hydroperoxide group (-OOH), is

expected to be readily destroyed by radiation

(y-rays, fast electrons, X-rays) by analogy with

the behaviour of alcohols.” This raises the

possibility of problems in the quantification of

8- 6- 4-

l

-ewe\ 2- *\., 5-n

=-L.-:.-.._._ I I I I 0 4 8 12 16X-ray exposure time (min)

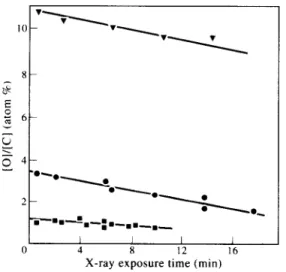

Fig. 3. Oxygen content changes during X-ray exposure by XPS of photo-oxidized iPP films. (Perkin Elmer XPS): n ,

1.3 kJ/m2; 0, 10.3 kJ/m2; ‘I, 29.5 kJ/m’.

the overall surface oxidation because of rapid

-0OH destruction during the duration of an

XPS analysis. This was confirmed by a study of the oxygen atom percentage as a function of XPS

counting time (Fig. 3). The oxygen atom

percentage drops progressively under the X-ray

exposure, levelling off at -60% of the initial

level for extreme exposures (not shown), possibly

corresponding to complete conversion of -0OH

to -OH and carbonyl products. Quoted oxygen

atom percentages were derived by back ex-

trapolation to zero X-ray exposure time (Fig. 3).

Loss of. -OH species at 3400 cm-’ (pre-

dominantly -0OH in oxidized polypropylene)

and formation of carbonyl species (at -1720

cm-‘) during X-ray exposure was clearly

indicated by transmission IR on a photo-oxidized sample after XPS analysis. Care was taken to

examine the film area that had been X-ray

exposed ( - 2 x 5 mm in the Perkin Elmer XPS)

by IR. Destruction of samples during XPS

analysis has been extensively studied.” However,

reported rates of X-ray induced degradation are

very much less than reported here. For example a ‘degradation index’ (atomic percentage loss after 500 min exposure) of 25% is normally considered to be quite high, as found for the [Cl]/[C] of PVC

(Scienta, ESCA300).” I n contrast to Fig. 2, the

‘degradation index’ for [O]/[C] is -250%

calculated in the same way (extrapolated to 500

min) and -80% for the PVC [Cl]/[C] ratio (for the purpose of cross comparison) under our XPS

analysis conditions (Perkin Elmer XPS). (This

‘index’ must be instrument dependent and the

overall result of a complex series of parallel and sequential reactions in an oxidized surface.)

Oxygen atom percentage values from XPS for

a series of increasingly photo-oxidized samples

are shown in Table 1. Some measurements on the

obverse surface (facing away from the xenon arc) of films showed a very similar surface oxidation to the front (Table 1).

3.1.2 zyxwvutsrqponmlkjihgfedcbaZYXWVUTSRQPONMLKJIHGFEDCBABulk oxidation products

Transmission IR and iodometry both detect

oxidation products throughout the total film

cross-section. Values for these techniques are

also shown in Table 1. Iodometry quantifies

hydroperoxide and any peracid or perester. From

previous studies, hydroperoxide is by far the

dominant species.‘*2 Dominant IR absorptions in

Surface zyxwvutsrqponmlkjihgfedcbaZYXWVUTSRQPONMLKJIHGFEDCBAand bulk analy ses of the oxidation of polyolefins 25 zyxwvutsrqponmlkjihgfedcbaZYXWVUTSRQPONMLKJIHGFEDCBA

Table 1. Polypropylene photo-oxidation yields from the various analytical methods”

Incident Oxidation product concentration (mmol/kg) [WC] (at.%)

flUX

(kJ/m’ at [-OOH] -OH >c=o -OH >c=o OH >c=G Bulk -2.0 pm -0.25 pm IO A

313 mm) from oxidationb surface’ surfaced surface’

iodometry From transmission IR From IRS-IR From IRS-IR on

KRS-5145” Gel45 0 0 0.5 0.6 0 0.5 1.3 0.14 00M4 1.2 1.9 066 0~0019 ND 2.2 0.63 13 0 0.0018 0.04 ND 5.1 5.5 54 24 0.015 0.18 1.9 7.8 14.9 12 6.7 63 27 135 0 0.051 0.22 0.38 2.2 10.3 108 89 35 111 40 270 0.35 0.37 0.75 3.5’ 2.68 17.6. 246 220 127 240 157 660 235 0.87 0.9 1.26 5.9 23.8 450 580 507 ND ND 2120 1350 2.0 ND 4.9 8.s’ 8.69 u Blanks indicate undetectable; ND, not determined. b -0OH from iodometry plus total ketones from transmission IR. ’ From -0OH and ketones from IRS-IR on KRSJ. d From -0OH and ketones from IRS-IR on Ge. ’ From XPS. f Front film surface (facing UV).

R Obverse surface.

(- 3400 cm-‘) and ketones (1718-1724 cm-‘).

Many other carbonyl species can be detected, but at levels appreciably below the total ketone level.

Extinction coefficients have been listed

previously.2

3.1.3 IRS- IR

Oxidation products in surface layers can be

quantified by IRS-IR of oxidized films. The

crystals employed have very different refractive

indices which leads to quite different depths of

penetration of the evanescent wave at the

reflection interface.16 Penetration is also depen-

dent on beam polarization and IR wavelength.

Circular polarization of the spectrometer IR

beam has been assumed and average effective

depths are calculated to be 0.18 pm (at 3400

cm-‘) and 0.36 pm (at 1700 cm-l) for Ge at 45”

incidence on polypropylene and 1.3 pm (at 3400

cm-‘) and 2.5 pm (at 1700 cm-‘) for KRS-5 at

45” incidence against polypropylene (refractive

index assumed to be l.5).16 Because of problems with perfection of optical contact between a film

and a crystal (especially for Ge), surface

concentrations of oxidation products were calcu-

lated for -OH and ketonic species by the use of

polypropylene absorptions of known absorption

coefficient measured for each sample to calculate

effective beam penetration. For the -OH

absorption (3400 cm-‘), the 2730 cm-’ absorption

of the polymer was used whereas for ketones

(- 1720 cm-‘), the 1260 cm-’ absorption was

used. Actual spectra of oxidized polyolefins have been shown previously1*2 and are not reproduced

here, However, surface concentrations from

IRS-IR are shown in Table 1.

For comparison with the low resolution XPS

data, all PP photo-oxidation data have been

converted into total oxygen atom to carbon atom

percentages (Table 1). For the IRS-IR data, the

-OH species have been assumed to be all

hydroperoxide. This is consistent with the

reasonable agreement between the iodometric

-0OH level and the -OH concentration from

transmission IR (Table 1).

The oxygen to carbon atomic percentage ratio is plotted as a function of UV flux exposure for

polypropylene in Fig. 4(A). Obviously only

concentrations of residual (non-volatile) oxida-

tion products have been estimated. Appreciable

volatilization of low molecular weight scission

products is reported from photo-oxidized

polypropylene.”

3.2 Photo-oxidation of LLDPE

In a more limited study, films of UV-exposed LLDPE were examined by XPS (70 8, surface

oxidation), iodometry (bulk -0OH) and trans-

26 J. Lacoste et al.

Xenon arc exposure (kJ/m’)

I

BI

From XPS

0 20 40 60

Xenon arc exposure zyxwvutsrqponmlkjihgfedcbaZYXWVUTSRQPONMLKJIHGFEDCBA(kJ/ m ’) zyxwvutsrqponmlkjihgfedcbaZYXWVUTSRQPONMLKJIHGFEDCBA

Fig. 4. Oxygen product accumulation in photo-oxidized

polyolefin films: (A) iPP film and (B) LLDPE film.

acid). For ease of comparison, collected data are

expressed again in terms of oxygen atom to

carbon atom percentage ratio in Table 2 and

plotted in Fig. 4(B).

Table 2. Oxygen product yields from LLDPE pboto-

oxidation Incident flux (kJ/m2 at [O]/[C] (at.%) 313 nm) Bulk oxidation 70 A surface”

-0OH” c=o total( %)’

0 0 0.5 7.5 0 2.3 11.4 0.020 0.05 0.07 2.2 17.6 0.032 0.11 0.14 2.3 20.1 0.027 0.18 0.21 2.8 23.8 0.029 0.14 0.17 3.0 39.0 0.084 0.45 0.53 4.1 45.9 0.10 0.68 0.78 4.0 52.6 0.12 0.71 0.83 4.9 63.0 0.14 1.0 1.1 5.4

“From XPS. ‘From iodometry. ‘From transmission IR. ’ -0OH plus ketone and carboxylic acid.

3.3 y-Initiated oxidation

Initiation of oxidation by y-irradiation can be

expected to be uniform across a film cross-

section. In fact for relatively thin films ( 5 120

pm) the bulk oxidation rate of polyethylene and

polypropylene is independent of thickness and

linear in absorbed dose ( - 50 mmol/kg -0OH

per Mrad for polypropylene and 2.2 mmol/kg

-0OH per Mrad for LLDPE) at -0.7 Mrad/h

dose rate.’ At higher dose rates or greater thicknesses, oxygen diffusion limitation will lead to lower oxidation levels in the core as compared

to the surface. Based on this information, a

y-oxidization of thin films would seem to be a

good test vehicle for checking the validity of the

techniques for examining surface/bulk oxidation

effects. However, surprisingly rapid preferential oxidation of iPP and PE films was found by XPS (Fig. 5) in conflict with the expected uniform oxidation. Munro” has reported a similar effect

for y-irradiated LDPE. An additional surprise

was the similarity in the surface oxidation level as seen by XPS for iPP and PE. As already mentioned, for identical rates of initiation, iPP is well known to undergo free radical oxidation at a rate appreciably faster than PE.’ This is clearly

visible from the transmission IR data shown in

Fig. 5.

The enhanced surface oxidation for y-

irradiated polyolefins may result from the well

known production of ozone (0,) and other

short-lived oxygen species in the GammaCell.‘”

0, and other products such as . OH, ‘02, HO, . ,

etc., are produced as a normal consequence of

irradiation of oxygen in air and the familiar

odour related to 0, is always detectable in and

‘t l -

.- zyxwvutsrqponmlkjihgfedcbaZYXWVUTSRQPONMLKJIHGFEDCBA

0 2 4 6 8

y-irradiation dose (Mrad)

Fig. 5. Oxidation product accumulation in y-irradiated

polyolefin films. Surface oxidation from XPS: 0, iPP: A, LLDPE. Bulk oxidation from transmission IR: 0. iPP: &

Surface and bulk analy ses of the oxidation of poly olefins 27

around the equipment. To eliminate these effects, iPP film was placed in borosilicate glass tubes and

y-irradiated at -196°C under vacuum in the

GammaCell. This irradiation generated a frozen

population of carbon centred radicals. The

sample was removed from the GammaCell and

then allowed to react with 0, at -78°C (in dry

ice) to convert these radicals quantitatively to

peroxyl radicals in the complete absence of 0,.19 After 16 h at -78”C, the samples were warmed

to room temperature and then analyzed by XPS

and transmission IR after 20 h. In these samples surface and bulk oxidation levels agreed quite well (O-5 at.% [O]/[C] by XPS and O-3 at.% by iodometry and transmission FTIR). This reaction sequence effectively decouples radical formation

from oxidation and allows for a purely free

radical oxidation without interference from 0,

and any other y-generated gaseous species. 0, is much more reactive than 0, and is reported to

attack unsaturated polymers very rapidly and

saturated polyolefins quite slowly with low

selectivity.20

There is a remote possibility of short-lived

species such as 0, being formed in the xenon arc

WeatherOmeter and causing the observed

surface photo-oxidation effects (Fig. 3). However

a control experiment in which an iPP film was

mounted inside the operating equipment for 48 h, but shielded from the light, showed only a small

change in surface oxidation (-0.3 at.%) in

comparison to samples directly irradiated (3.5

at.% [O]/[C] for 10 kJ/m2 direct exposure for 48 h).

4 DISCUSSION

Polypropylene and polyethylene give quite

different proportions of oxidation products

during photo-oxidation (see Tables 1 and 2). For

the former, hydroperoxide groups clearly domin-

ate over carbonyl species, whereas in poly-

ethylene, carboxylic acid and ketone groups

predominate over hydroperoxide groups.‘q2

Despite this difference, from Tables 1 and 2 and Fig. 4, it is clear that overall oxidation occurs

very rapidly in the surfaces of both

polypropylene and polyethylene films during UV

exposure. Analysis of the obverse surface of

several polypropylene films (i.e. the surface away

form the direct light exposure) showed that this surface also oxidized rapidly (Table 1).

From a comparison of the oxygen atom

percentage values corresponding to the (some-

what approximate) depths sensed by the

analytical methods, it is possible to build up a

series of ‘snapshots’ of the growth of the

oxidation into the polypropylene film. This is

shown in histogram form in Fig. 6.

In the early stages of photo-oxidation, a simple

calculation shows that all of the oxidation is

confined to the back and front -70 A layers. For

example, at l-3 kJ/m* exposure, 1.21 at.%

[O]/[C] in each 70 8, layer represents an

averaged oxidation percentage over the whole

(25 pm) film cross-section of 2 zyxwvutsrqponmlkjihgfedcbaZYXWVUTSRQPONMLKJIHGFEDCBAX 1.21 X 70 X

10p4/25, i.e. -6 X 10p4%. This is slightly greater

than the average level measured by iodometry

(4 X 10p4%). For the higher levels of photo-

oxidation shown in Fig. 4, surface layer oxidation does not account for all of the internal oxidation.

Successive zone concentrations into the interior

have been corrected for the oxidation level in the more highly oxidized outer layers.

Preferential surface oxidation of photo-

oxidized polypropylene has been previously

reported for polypropylene (by IRS-IR).”

5 ORIGIN OF SURFACE OXIDATION

Detection of photo-oxidation products in the

surface by XPS could be attributable to the rapid migration of low molecular weight products to

the surface or morphology-controlled effects.

6’ From GelIRS rom KRS-S/IRS -.-.-.- _---:

cy

/

zyxwvutsrqponmlkjihgfedcbaZYXWVUTSRQPONMLKJIHGFEDCBA 0 I 2 ’ 1.3 kJ/m2 Film depth (pm)Fig. 6. Approximate oxidation cross-sections through

28 zyxwvutsrqponmlkjihgfedcbaZYXWVUTSRQPONMLKJIHGFEDCBAJ. Lacoste

However, the absence of preferential surface

oxidation in the y-irradiated films (in the absence

of 0, effects) largely eliminates these pos-

sibilities. We have previously attributed surface

photo-oxidation to the dominance of UV-

absorbing chromophores in this outer layer and

show that 0, exposure can generate these

chromophores.’ The surface layer chromophores

could result from oxidation caused by air cooling of the film during fabrication and/or attack by

species in the atmosphere such as Oj, during

shelf storage. Prior to oxidation, a small but finite level of oxidation was detectable in the extracted

and vacuum dried films (Tables 1 and 2)

consistent with these suggestions.

Munro has reported surface oxidation levels

for both UV and y-exposed LDPE by XPS but

without a clear measurement of bulk changes.”

His y-exposure was at a very low rate (O-08

Mrad/h) where diffusion control of oxidation is extremely unlikely. It is possible that this surface

effect from the y-irradiation is also due to

reaction with, for example, 0,. His reported

levels of surface oxidation under UV exposure are about three times greater than in the present

study (Fig. 4), but the difference may be

attributed to his use of a rather shorter

wavelength (254 nm) UV.

Our conclusion that y-initiated oxidation

normally leads to strong surface layer oxidation

could have interesting consequences for poly-

olefin stabilization against -y-initiated oxidation.

As well as an additive package that can scavenge

free radicals in the post-irradiation period,

antiozonants could also play a role in overall

stability.

et al.

Irrespective of the origin of the rapid surface

photo-oxidation, XPS offers a highly sensitive

way to detect the onset of oxidative degradation.

REFERENCES 1. 2. 3 _ . 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20.

Lacoste, J. & Carlsson, D. J., J. Polym. Sci. A, 30 (1992) 493.

Lacoste, J., Vaillant, D. & Carlsson, D. J., J. Polym. Sci. A, 31 (1993) 715.

Fourneaux, G. C., Ledbury, K. J. & Davis, A., Polym. Deg. Stab., 3 (1981) 431.

Delprat, P. & Gardette, J.-L., Poly mer, 34 (1993) 933. Carlsson, D. J. & Wiles, D., M acromolecules, 4 (1971)

174, 179.

Lucas, P. C. & Porter, R. S., Polym. Deg. Stab., 22 (1988) 175.

Jouan, X. & Gardette, J.-L., Polym. Comm., 28 (1987) 239.

Adam, C., Lacoste, J. & Lemaire, J., Polym. Deg. Stab., 24 (1989) 185; 25 (1989) 247.

Jouan, X., Adam, C., Fromageot, D., Gardette, J.-L. & Lemaire, J., Polym. Deg. Stab., 25 (1987) 239.

Clough, R. L. & Gillen, K. T., Amer. Chem. Sot. Symp. Ser., 280 (1985) 411.

Cunliffe, A. V. & Davis, A., Polym. Deg. Stab., 4 (1982) 17.

Munro, H. S., Polym. Deg. Stab., 12 (1985) 249. Beamson, G. & Briggs, D., High Resolution XPS of

O rganic Poly mers. J. Wiley, NY, 1992.

Harrick, N. J., Appl. Spectroscopy , 31 (1977) 548. Whelan, D. J., Chem. Rev., 69 (1969) 179.

Harrick, N. J., & du PrC, F. K., Appl. Opt., 5 (1966) 1739.

Gijsman, P., Hennekens, J. & Vincent, J., Polym. Deg. Stab., 42 (1993) 95.

Willis, C., Boyd, A. W., Young, M. J. & Armstrong, D. A., Can. J. Chem., 48 (1970) 1505.

Carlsson, D. J., Dobbin, C. J. B. & Wiles, D. M., M acromolecules, 18 (1985) 2092.

Razumovskii, S. D. & Zaikov, G. E., Deu. Polym. Stab., 6 (1983) 239.