Publisher’s version / Version de l'éditeur:

ACI Materials Journal, 93, Nov-Dec 6, pp. 609-612, 1996-11-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Corrosion protection of reinforcement in modified high- alumina

cement concrete

Fu, Y.; Ding, Jian Dept.; Beaudoin, J. J.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=21029ca4-3304-4633-9299-f00fd7040d8d https://publications-cnrc.canada.ca/fra/voir/objet/?id=21029ca4-3304-4633-9299-f00fd7040d8dhttp://www.nrc-cnrc.gc.ca/irc

Corrosion prot e c t ion of re inforc e m e nt in m odifie d high- a lum ina

c e m e nt c onc re t e

N R C C - 3 9 0 1 6

F u , Y . ; D i n g , J i a n D e p t . ; B e a u d o i n , J . J .

N o v e m b e r 1 9 9 6

A version of this document is published in / Une version de ce document se trouve dans:

ACI Materials Journal,

93, (6), Nov-Dec, pp. 609-612, November 01, 1996

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d'auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d'identifier la source de l'information et, dans certains cas, d'interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

to .nt

:th

m

ACI MATERIALS JOURNAL

TECHNICAL PAPER

TItle no. 93-M69

Corrosion Protection of Reinforcement in

Modified High-Alumina Cement Concrete

in In Df 'j-Ie le J, )-y, d if e :-i

by

Van Fu, Jian Ding, and James J, Beaudoin

Corrosion ciulracteristics of reinforcement in modified high-alumina cement (HAC) containing a conversion-preventing additive (CPA) was studied. An investigation was carried out using ordinary portland cement, high-alumina cement, and modified high-alumina cemem, Results includ-ing compressive strength, bond strength, porosity, cr permeability, and extent ofsteel bar corrosion are presented. The effect of a deicing salt, cal-cium chloride, un formation of hydrogarnet and strtitlingiteinHAC and modified HAC mortars is also reported. This work indicthis that HAC mor-tar, after conversion, is unable to protect the reinforcement from corrosion in an environment containing chloride ions. Conversion-inhibited high-alumina cement has the capability of protecting the reinforcement from corrosion under severe test conditions due to its effective resistance to the penetration ofchloride ions.

Keywords: chlorides; corrosion; C3AH6; high-alumina cements; rein-forced concrete.

INTRODUCTION

The use of high-alumina cement (HAC), invented by J. Bied in 1908 and commercialized by the Lafarge Co. in 1913, has many advantages compared to portland cement. These include high early strength, high temperature resis-tance, and good chemical resistance. Significant reduction of strength due to conversion of hexagonal calcium aluminate

hydrates (CAHlOor C2AH8)to cubic hydrogarnet (C3AH6)

in hydrated HAC concrete has been a major problem limiting its use. Improved sulfate resistance was one of the original objectives of the HAC invention. Case studies by Midgley indicated that converted HAC concrete was highly vulnerable

to sulfate attack.1Many high-alumina cement concrete

struc-tures built in the U.K. in the 1940s and 1950s experienced problems due to later conversion. As a direct result of those investigations, the British government issued a document on July 20, 1974, Ref. BRA. 1068/2, entitled "High-Alumina Cement Concrete in Buildings." This document stated that "high-alumina cement should not be used for structural work in buildings until further notice." The application of high-alumina cement in structural members has been banned in virtually every country in the world. A new conversion-pre-venting additive has been recently developed at the National ACI Materials Journal/ November-December 1996

Research Council, Canada.2The conversion-inhibited HAC

products do not undergo strength reduction when water-cured at 38 C.

It is estimated that the cost of damage to U.S. concrete bridges and parking structures resulting from deicing salts is

about $325,000,000 to 1,000,000,000 per year.3Penetration

of chloride ions into reinforced concrete highway structures is mainly responsible for the corrosion. The mobility of chlo-ride ions in OPC and HAC concrete depends on 1) concrete porosity and 2) stability of calcium aluminate hydrates. It has been reported that the calcium aluminate hydrates derived

from tricalcium aluminate (C3A) in ordinary portland cement

can bind chloride ions to form calcium chIoro-aluminate

hy-drate (Friedel's ウ。ャエINセV A high C3A content minimizes the

degree of reinforcement corrosion by lowering the concen-tration of corrosion-inducing free chloride in the pore solu-tion. It does, however, lead to another durability problem in terms of sulfate attack. The synergistic attack resulting from ingress of chloride and sulfate ions causes extreme deterio-ration of ordinary portland cement concrete in a marine

en-vironment.7Portland cement concrete containing silica fume

has a much better resistance to sodium sulfate solution, but

is particularly vulnerable to magnesium sulfate attack.8

HAC concrete was reported to have high resistance to

chlo-ride mobilization8and to magnesium sulfate attack.9,IOThe

hexagonal hydrates formed in HAC will also react with chlo-ride to form Friedel's salt. This significantly reduces the pen-etration rate of chloride ions into the concrete and delays interaction with the reinforcement. The effect of chloride on the corrosion of reinforcement in HAC mortar was studied

by Goni, Andrade, and Page.ll Conversion of calcium

alu-minate hydrates to hydrogarnet is accelerated in the presence of chloride ions. This makes it ineffective with respect to

ACl Marerials Journal,V. 93, No.6. November-December 1996,

Received May 8, [995. and reviewed under Institute publication policies. Copyright © 1996, American Concrete Institute. All rights reserved, including the making of copies unless pennission is obtained from the copyright proprietors, Pertinent discussion

willbe published in the September-October 1997ACI Materials Journalifreceived by June I, 1997.

ACI member fan Fu isIIPhD candidate in the Department ofCMI Engineering, Uni·

versity of Ottawa, Call1lda. His research is carried out at the l1l'ititute for Researchin Construction, National Research Council of Canada. His research interests include high·alumina cement-based expansive cement, delayed ettringite formation in port-land cement concrete, and zealite-based lightweight concrete products.

lion Ding is a graduate research associate in the Department ofCivilEngineering, University of Ottawa. Her researchiscarried out allhe Institute for Researchin Con-struction, National Research Council of Canada. She received her first degree in chemistry in/983from Fudan UniversityinShanghai, and was a materials engineer al the Shanghai Research Institute of Building Sciences prior to entering the MASc program at the University of Ottawa. Her research interests are in the area of con-crete admixtures and additive

ACI member JamesJ.Beaudoinisa principal research officer and head ofthe Mate· rials Laboratory of Ihe Institute for Research in Construclion, National Research Council ofCanada. He is the author ofmore than 200 research papers and two books on concrete materials. He is a member of ACI Commillee 209, Creep and Shrinkage in Concrete. His current research focuses on microfiber reinforced cement systems and the application ofa.c. impedance spectroscopy in cement and concrete science.

corrosion protection of the reinforcement.It is apparent that

conversion-inhibited HAC may provide an alternative for corrosion protection of concrete structures in environments containing chloride ions. The purpose of this investigation

wastodetennine the relative effectiveness of

conversion-in-hibited HAC systems in reducing corrosion of reinforcing steel in aggressive environments.

RESEARCH SIGNIFICANCE

The application of high-alumina cement in structural members has been banned since the early 1970s in virtually every country in the world. The results of this study suggest that the use of conversion-inhibited high-alumina cement in reinforced concrete structural members, especially in aggres-sive environments, is a potential solution to these limitations.

COMPRESSIVE STRENGTH OF OPC, HACt AND MODIFIED HAC MORTARS

A conversion-preventing additive (CPA), comprising mainly a natural zeolite and a sodium sulfate, was used to in-hibit conversion of high-alumina cement (HAC). Details of

Table 1-0xlde compositions of OPC and HAC

Si02 CaO A120 3 Fe203 MgO Na20+KP OPC 19.8 61.2 4.2 3.2 4.1 1.27

HAC 4.5 39.8 41.2 11.3 0.6 0.1

Table 2-Compressive strength of cement mortars (MPalpsl)

OPC HAC HAC/CPA

1 day 2012900 65/9425 46/6670

28 days 6118845 36/5520 47/6815 180 days 69/10,005 37/5365 69/9998

Table 3-Hydrated phases detected by XRD

Friedel's salt Hydrogamet Striitlingite Calcium Cement (C3A·CaCl2,H2O) (C3AH6) (C2ASHg) hydroxide

OPC Detected -

-

DetectedHAC Detected Detected

-

-HACICPA Detected Trace amount Detected

-610

the CPA preparation are described in aU.S. patent application.2

An ASTM Type I ordinary portland cement (OPC) and a Ci-ment Fondu (HAC) were used. Three ceCi-ment mortars made with Type I portland cement (OPC), Ciment Fondu (HAC), and Ciment FonduJCPA (HAC/CPA), respectively, were prepared. The oxide composition of OPC and HAC is listed in Table 1. The HAC/CPA mortar contained 43 percent CPA by mass of HAC. The water-cement and sand-cement ratios were 0.4 and 2.75, respectively. The cost of CPA is expected to be less than the HAC. Therefore, an addition of a high vol-ume of CPA will lower the cost of the concrete material. The effect of CPA content on the strength of HAC concrete has

been reported.12-14A conversion-inhibited HAC mortar

con-taining about 12 percent CPA had a I-day compressive strength above 60 MPa (8700 psi). Normal construction sand was used in all the mixes. The mortar specimens for the com-pressive strength test in this study were cast in 50 x 50 x

50-rom (2 x 2 x 2-in.) brass molds and moist-cured at 23 C (73F)

for the first 24hr.One-day compressive strength was

mea-sured after demolding. The companion specimens were then

water-cured at 38 C(laOF). Compressive strengths were

de-termined at designated ages. Compressive strength values of the cement mortars are given in Table 2.

The I-day compressive strength of the OPC mortar was significantly lower than that of the HAC mortar. The HAC/ CPA mortar had a relatively low I-day strength compared to the unmodified HAC mortar. The 28-day strength of the OPC mortar significantly increased; the 28-day strength of the HAC mortar dropped dramatically due to the conversion reaction. The strength of both OPC and HAC mortars changed only slightly after 28 days. A large increase (31.8 percent) of strength occurred in HAC/CPA mortar between 28 and 180 days. The strength of the HAC/CPA mortar was equivalent to the OPe mortar at 180 days. No strength reduction

was foundinthe HAC mortar containing a CPA additive.

X-RAY DIFFRACTION ANALYSES

X-ray diffraction (XRD) analysis was carried out on the test mortars at 180 days using an x-ray diffractometer sys-tem. The hydrated crystalline phases in the OPC, HAC, and HAC/CPA mortars detected by XRD are shown in Table 3. It was evident that conversion from hexagonal calcium

alu-minates to cubic hydrogarnet (C3AH6)was significantly

sup-pressed in the HAC mortar containing CPA. Stratlingite

(C2ASHg) formation was detected in the HAC/CPA mortar.

Friedel's salt (C3ACaC12,H20)was formed inall the samples.

CORROSION PROTECTION OF REINFORCED MORTARS IN CALCIUM CHLORIDE SOLUTION

A steel bar, 8 rom (5/16 in.) in diameter and 149 mm (5.87 in.) long, was used as reinforcement and positioned in the center of 25 x 25 x I52-mm prism specimens. The steel bar contained approximately 99.82 percent Fe and 0.18 percent C. The minimum thickness of the mortar cover, e.g., OPC, HAC, or HAC/CPA, on the steel bar was 8.5 mm. The

spec-imens were moist-cured at 38 C

(lOa

F) for 28 days and thensubjected to drying/wetting (d/w) cycles. The d/w regime was 4 days' drying and 6 days' exposure to calcium chloride

solutions at 38 C (CI- concentration

=

3 molJL). Drying wascarried at 38 C and about 50 percent relative humidity. The ACI Materials Journal/November-December 1996

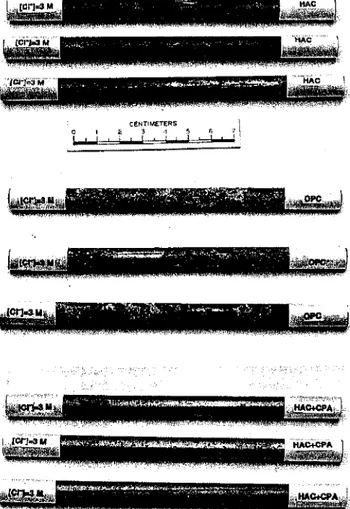

Fig. i-Corrosion of reinforcement in cement mortars based on cement binders indicated

IreResearch, V. 46, No. 167,

re,Prentice-Hall,Inc., 1981. "Corrosion Behavior of Steel Effect of Chloride," Cement 646.

Effect of Different Inorganic -Alumina Cement Products," id for publication)

Effect of Different Pozzolans ina Cement Products," II

:ffect of Different Zeolites on nent Products," ACI Materi-1,..; AI-Sayed, M. H.; and Al->ride Penetration Chaiacteris-(owance Concrete, SP-149,

p.123-134,

Iska. B., "Behavior of High-7alcium Aluminate Cements. ·229.

'roperties of Some Blended 'te Research.V. 22. 1992, pp. C£NTIMETERS 3 ., ! t セ⦅ I I セL 'i' }10 セ ,.--,

Ji

8k!YfPA

-

-ッセ

HACt\

>1

I II-

-10

6ope

-0 . . セB|-

i-J!

セ 4-Ie

2Aエセ

- f -e--ill!

-

=8-uc.

0'---

' - セiAAi...

lIII't5

0 0.01 0.1 1 10 100t

Pore

Dlafmlter (j.tm)characteristics (see Fig. 1). The rusted area of the steel bar in the HAC/CPA mortar was only 5 percent. Areas in the OPC

or HAC mortar were all higher than80 percent.

Fig. 2-Pore size distribution of cement mortars based on cement binders indicated

CONCLUSIONS

High-alumina cement mortar after conversion appears to be unable to protect the reinforcement from corrosion in an environment containing chloride ions. Conversion-inhibited high-alumina cement appears to have the capability of pro-tecting the reinforcement from corrosion under severe test

Properties OPC HAC HAC/CPA Steel bar-mortar bond strength, 7.9/1145 5.1/740 10.1/1465

MPa/psi

cr

concentration, kglm3/lb/yd3Free 29.4/49.6 27.3/46.1 14.7/24.9 Combined 4,7/8.0 1.8/3.0 1.9/3.2 Rusted area of steel bar, percent 83 88 5

Total porosity, percent 5.7 7.1 8.9

steel bars were extracted by breaking the mortars after 14d/w

cycles. Photographs of the steel bars are shown in Fig. 1. Pat-terns of the surfaces of steel bars illustrating the corroded ar-eas were carefully drawn on squared paper and the percentage of rusted area was estimated. A pullout test was also carried out on each specimen. Mortar samples were tak-en at a 5-mm (O.2-in.) depth from the outer surface of the mortar bars for the determination of pore size distribution us-ing mercury intrusion analysis and chloride ion

concentra-tion after 14d/wcycles. The mercury intrusion analysis was

carried out using a porosimeter. The chloride ion concentra-tions were determined using a pHlISE meter. Mortar parti-cles 3 to 5 mm (0.12 to 0.20 in.) in diameter were used for the mercury intrusion test. Ground mortar powder was used for CI" concentration determination. The free CI" concentra-tion was determined by an extracconcentra-tion method after Mindess

and Young.15The samples for measuring combined chloride

ions were prepared according to ASTM C 114-88. Durabil-ity-related parameters of the cement mortars including the steel bar-mortar bond strength, CI" concentration, rusted area

of the steel bar, and total porosity are listed in Table4. The

pore size distribution of different mortars is shown in Fig.

2.

The HAC/CPA mortar had a higher bond strength to the steel bar than the OPC mortar. The HAC mortar after

con-version had a low bond strength. The total porosity of the

HAC/CPA mortar was higher than the OPC or HAC mortars. This was due largely to the increase of pores with a diameter

less than0.1 Mm. The volume of pores with diameter larger

than0.1 /lm in the HAC/CPA mortar was slightly less than

that in the OPC mortar. The free Cl" concentration in the

HAC mortar was slightly lower than that in the OPC mortar and about double that of the HAC mortar containing CPA. A

large value of freeCl"concentration might be the result of

the dlw cycles in concentrated calcium chloride solution.

The amount of combinedCl-in the OPC mortar was much

higher than that in the other mortars. The CI" penetration rate in HAC and OPC mortars appeared to be similar, since they

had similar values of freeCI-concentration. It was

conclud-ed that the HAC hydrates after conversion have a rconclud-educconclud-ed ability to combine with Cl' relative to the OPC hydrates. The HAC/CPA system was apparently effective in reducing the Cl" penetration. This resulted in a much lower free CI- con-centration at the same depth in the mortar. The HAC/CPA mortar had a low Cl" penetration rate. Nevertheless. a relatively high amount of combined CI- compared to the HAC mortar was present. It was evident that the HAC/CPA mortar had a reasonably high potential to bind Cl". Correspondingly, the HAC/CPA mortar had excellent corrosion protection

Table 4-Durability-related parameters of cement mortars 7 cd 3. I-). :e

r.

i

t

ni

セZ

IC).

,ere ted PA ios ted "01-'helas

In· ive .nd m- iO-F)as

C/ to he of )n rs.8

Ie I..

as m 1 e r it en le-of セ。MACI Materials Journal/November-December 1996 611

conditions. The HAC/CPA mortar appears to effectively re-sist the penetration of chloride ions.

ACKNOWLEDGMENTS

Financial support from NSERC and the Network of Centers of Excel-lence on High-Perfonnance Concrete (Canada) is gratefully acknowledged.

REFERENCES

1. Midgley,H.G.• "High-Alumina Cement inConstruction-AFuture Based on Experience," Calcium Aluminate Cements.Chapman and Hall, New York, 1990, pp. 1-13.

2. Fu,Y,;Ding, 1.; and Beaudoin, J. I" "Conversion-PreventingAdditive for High-Alumina Cement Products," U.S. Patent Application No, 08/377,109,

Jan. 23, t995.

3. Highway Deicing-Comparing Salt and Calcium Magnesiuma」・セ tate, Transportation Research Board, National Academy of Sciences,

Washington, D.C., 1991.

4. Monfore. G. M., and Verbeck. C.1.,"Corrosion of Prestressed Wrrein Concrete," ACI JOURNAL.ProceedingsV. 57, No.5, Nov. 1960, pp. 491-516.

5. Baumel, A., "Effect of Calcium Chloride on the Corrosion Behavior of Steel in Concrete,"Beton Herstellung- Venvendung(Dusseldorf), V. 10, 1960, p. 256.

6. Mehta, P.K.,"Effect of Cement Composition on Corrosion of ReinforcM ing Steel in Concrete,"Chloride Convsion of Steel in Concrete,STP-629, American Society for Testing and Materials, Philadelphia, 1977, pp. l2M19.

7. AlMAmoudi,O.S.8.; Rasheeduzzafar; Maslehuddin,M.; and Abdul-jauwad, S. N., "Influence of Chloride Ions on Sulfate Deterioration in Plain

612

and Blended Cements,"Magazine of Concrete Research,V. 46, No. 167, 1994. pp. 113-123.

8. AIMKhaja, W. A; Rasheeduzzafar,W.A; Al·Sayed, M. H.; and AIM Khoder, A A; "Sulfate Resistance and Chloride Penetration CharacterisM tics of HighMStrength Concrete," High-Performance Concrete, SPM149, American Concrete Institute, Detroit, 1994, pp. 123·134.

9. Kurdowski,

w.;

Taczuk, L.; and Trybalska, B., "Behavior of High-Alumina Cement in Chloride Solutions," Calcium Aluminate Cements,Chapman and Hall, New York, 1990, pp. 222-229.

10. Majumdar, A. J., and Singh, B., "Properties of Some Blended High-Alumina Cement,"Cement and Concrete Research.V. 22, 1992, pp. 1101-1114.

II. Gani,S.;Andrade, C.; and Page, C. L., "Corrosion Behavior of Steel in High-Alumina Cement Mortar Samples: Effect of Chloride,"Cement and Concrete Research,V. 21, 1991, pp. 635-646.

12. Ding, J.; Fu, Y.; and Beaudoin, J. J., "Effect of Different Inorganic Additives oncッョカ・イウゥッョセpイ・カ・ョエゥッョ in High-Alumina Cement Products,"

Advanced CementMBased Materials.(submitted for publication)

13. Fu, Y.; Ding,J.; and Beaudoin, J. J., "Effect of Different Pozzolans on ConversionwPrevention in High-Alumina Cement Products," Il Cementa.(submitted for publication)

14. Ding,J.; Fu,Y.;and Beaudoin, J. J., "Effect of Different Zeolites on Conversion-Prevention in HighMAlumina Cement Products,"ACI Materi-als Journal.(submitted for publication)

15. Mindess, S., and Young,1.E,Concrete,Prentice-Hall. Inc., 1981, pp.211-212.