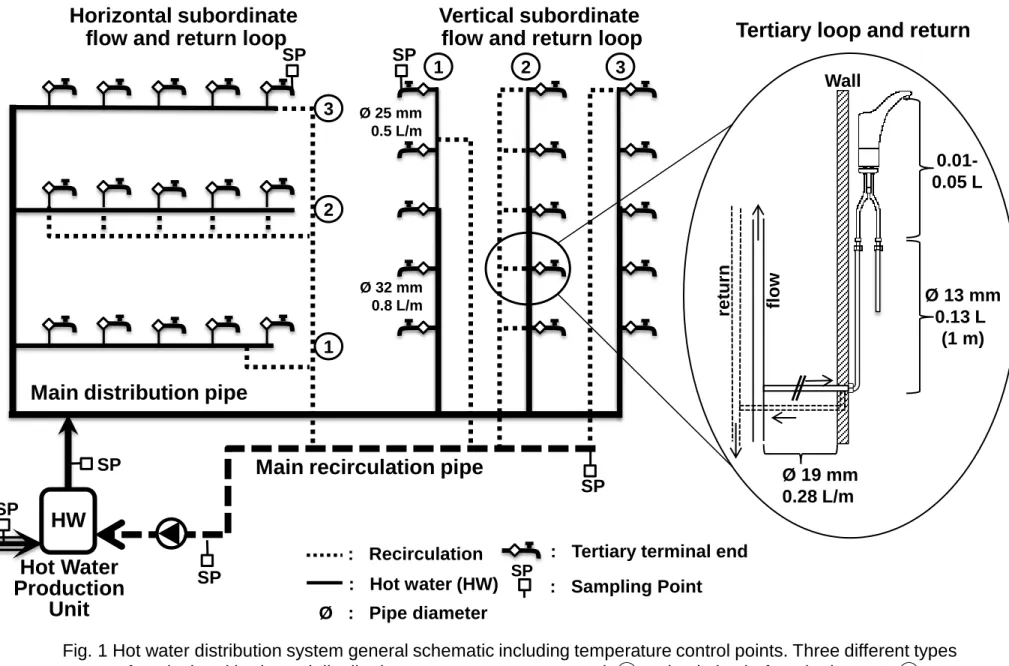

Fig. 1 Hot water distribution system general schematic including temperature control points. Three different types of vertical and horizontal distribution systems are represented: ① recirculation before the last tap; ② recirculation connected after each device; ③ recirculation connected after the last device.

Ø 19 mm 0.28 L/m Ø 32 mm 0.8 L/m Ø 25 mm 0.5 L/m

Main distribution pipe

Main recirculation pipe

HW

Ø 13 mm 0.13 L (1 m) 0.01- 0.05 LHot Water

Production

Unit

Horizontal subordinate

flow and return loop

Vertical subordinate

flow and return loop

3 2 1 1 2 3 SP SP SP SP SP SP SP : Sampling Point

.

Wall flow : Recirculation re tu rnTertiary loop and return

: Tertiary terminal end : Hot water (HW)

40

50

60

70

01/11/13 01/12/13 01/11/13 01/12/13 01/11/13 01/12/1330

40

50

60

70

02/09/13 02/10/13 02/11/13 02/12/13 04/13/14 04/14/1470

60

50

40

30

System no 1

System no 2

System no 3

System no 4

System no 5

Fig. 2 Examples of continuous temperature monitoring at water heater outlet for each studied system (black line) and at the return loop for system 4 and 5 (blue line). No continuous monitoring data was available for systems 1 to 3. Date format is MM/DD/YY.

T

emp

era

ture

(

°C)

70

60

50

40

Fig. 3 Heat loss during stagnation of hot water in 1.25 cm diameter copper pipes with and without insulation at room temperature.

0

10

20

30

40

50

60

70

0

50

100

150

200

T

e

mpe

ra

tu

re

(

C)

Elapsed time (minutes)

Type 1 insulation

Type 2 insulation

Non-insulated

Optimal growth temperature for Lp 45min 86min 131minFig. 4: Hot water temperature profiles at points-of-use as a function of volume for a) systems 1, 2 and 3 grouped, n = 7; b) system 4, n = 7; c) system 5, n = 36. Mean temperature at the hot water production unit outlet and at the return loop are shown for each system.

1 2 0 10 20 30 40 50 60 10 20 30 40 50 60 70 1 2 0 10 20 30 40 50 60 10 20 30 40 50 60 70 1 2 0 10 20 30 40 50 60 10 20 30 40 50 60 70

____ : Hot water outlet T° --- : Recirculation loop T° : 25 – 75% I : Non-outlier range Volume (L)

T

emp

er

atu

re

(

°C)

63.0°C 55.5°C 54.3°C 51.0°C 61.6°C 53.9°Ca

b

c

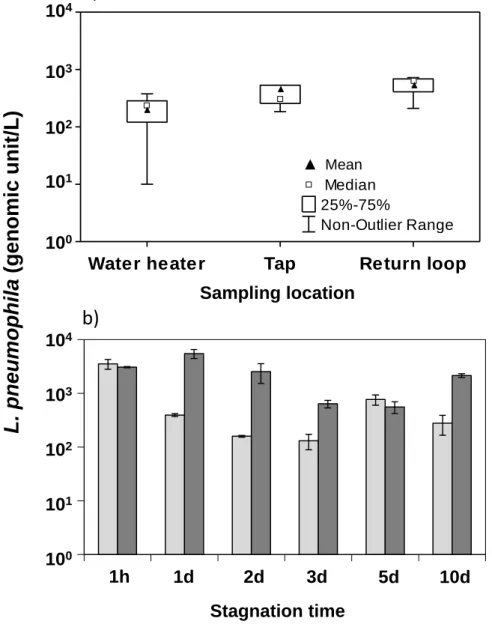

Fig. 5 Variability of L. pneumophila concentration measured by qPCR (a) in system 4, for repeat sampling events without prior stagnation (n = 5, Jan-Oct 2013) (b) in system 5, after different water stagnation times for tap A (light gray) and tap B (dark gray) (n = 2, Nov-Oct 2012).

a)

b)

L

.

p

n

eu

mo

p

h

il

a

(

g

en

o

mi

c

u

n

it/

L

)

101 102 103 104 100 1h 1d 2d 3d 5d 10d Sampling locationWater heater Tap Return loop

Median 25%-75% Non-Outlier Range 101 102 103 104 100 Stagnation time ▲ Mean

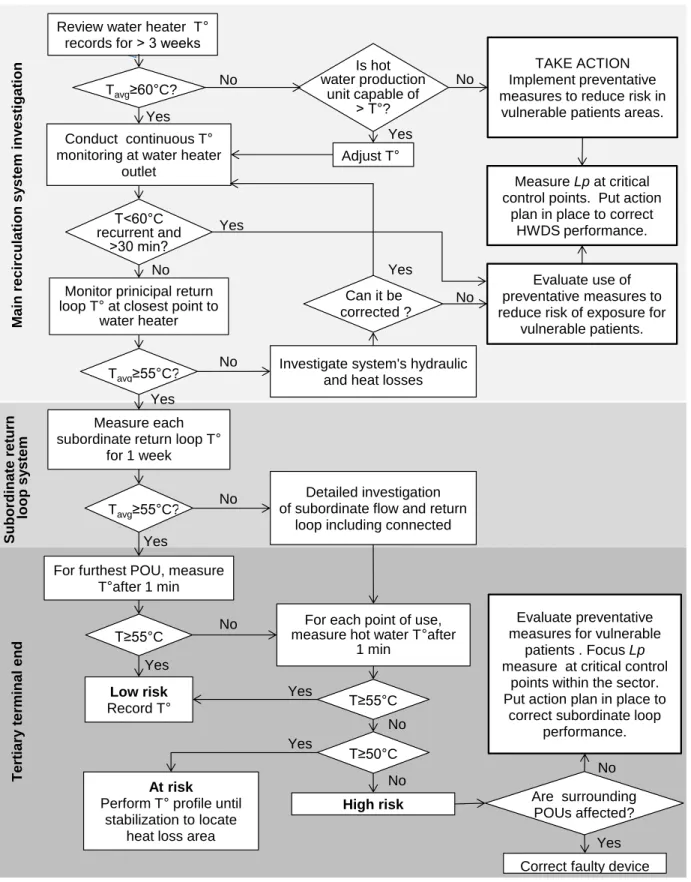

Fig. 6 Diagnostic flowchart for the initial assessment of Legionella risk in an existing HWDS Conduct continuous T°

monitoring at water heater outlet

Investigate system's hydraulic and heat losses

Adjust T°

For each point of use, measure hot water T°after

1 min Low risk Record T° Yes No Yes Yes No No Yes No Yes Yes No Yes Yes T Tavg≥60°C? T T˂60°C recurrent and ˃30 min? T Tavg≥55°C?

Monitor prinicipal return loop T° at closest point to

water heater

Measure each subordinate return loop T°

for 1 week T Tavg≥55°C? T T≥50°C At risk

Perform T° profile until stabilization to locate

heat loss area

High risk

Detailed investigation of subordinate flow and return

loop including connected Is hot water production unit capable of ˃ T°? Mai n re c irc ula ti on s y s te m inv e s ti gation S ubordina te re turn loop s y s te m Ter tia ry t e rmina l e nd No No TAKE ACTION Implement preventative measures to reduce risk in

vulnerable patients areas.

Evaluate use of preventative measures to reduce risk of exposure for

vulnerable patients.

Evaluate preventative measures for vulnerable

patients . Focus Lp measure at critical control

points within the sector. Put action plan in place to

correct subordinate loop performance. T Yes No Are surrounding POUs affected?

Correct faulty device Measure Lp at critical control points. Put action

plan in place to correct HWDS performance.

No Yes

For furthest POU, measure T°after 1 min T T≥55°C T T≥55°C Yes No Review water heater T°

records for ˃ 3 weeks

Can it be corrected ?