To link to this article

: DOI: 10.1016/j.jeurceramsoc.2011.06.003

URL:

http://dx.doi.org/10.1016/j.jeurceramsoc.2011.06.003

This is an author-deposited version published in:

http://oatao.univ-toulouse.fr/

Eprints ID: 5556

To cite this version:

Gurt Santanach, J. and Estournès, Claude and Weibel, Alicia and

Chevallier, Geoffroy and Bley, Vincent and Laurent, Christophe and

Peigney, Alain Influence of pulse current during Spark Plasma Sintering

evidenced on reactive alumina–hematite powders.

(2011) Journal of the

European Ceramic Society, vol. 31 (n° 13). pp. 2247-2254. ISSN

0955-2219

O

pen

A

rchive

T

oulouse

A

rchive

O

uverte (

OATAO

)

OATAO is an open access repository that collects the work of Toulouse researchers

and makes it freely available over the web where possible.

Any correspondence concerning this service should be sent to the repository

administrator:

staff-oatao@listes.diff.inp-toulouse.fr

Influence

of

pulse

current

during

Spark

Plasma

Sintering

evidenced

on

reactive

alumina–hematite

powders

Julien

Gurt

Santanach

a,

Claude

Estournès

a,

Alicia

Weibel

a,

Geoffroy

Chevallier

a,

Vincent

Bley

b,

Christophe

Laurent

a,

Alain

Peigney

a,∗aUniversitédeToulouse,InstitutCarnotCIRIMAT,UMRCNRS-UPS-INP5085,UniversitéPaul-Sabatier,118routedeNarbonne,31062ToulouseCedex9,France bUniversitédeToulouse,LAPLACE,UMRCNRS-UPS-INP5213,UniversitéPaul-Sabatier,118routedeNarbonne,31062ToulouseCedex9,France

Abstract

SparkPlasmaSintering(SPS)isincreasinglyused.Thetemperatureandcurrentarenotindependentparameters,makingitdifficulttoseparatethe currentintrinsicrolefromJouleheating.ThereisadebateonwhetherthereareanyspecificSPSmechanisms.Theinfluenceofakeyparameter,the (on:off)pulsepattern,isstudiedontheSPSofreactivea-Al2−2xFe2xO3(x=0.02;0.05;0.07;0.10)powders.Changingitmodifiesthecurrentcrest

intensityandhasagreatinfluenceonthematerialsmicrostructure.Comparisonswithrunswherethecurrentisblockedandhot-pressingreveal threecompetingphenomena:formationofFeAl2O4,dominantinthecoreandnotpeculiartoSPS,formationofFe,producingFe-Al2O3composite

surfacelayers,andmostnotablyelectrical-fieldinduceddiffusionofFe3+ionstowardsthecathode,whichcouldhavefar-rangingimplicationsfor

theconsolidationofionicmaterialsandtheinsitureactiveshapingofcompositesandmultimaterials.

Keywords:SparkPlasmaSintering;A.Hotpressing;B.Nanocomposites;B.Electronmicroscopy;Fe-Al2O3

1. Introduction

Spark Plasma Sintering (SPS)1 is becoming increasingly popularforthepreparationof manymaterials,includingionic materials,2–8becauseithasseveraladvantagesoverpressureless sintering and hot-pressing,including lower sintering temper-atures and shorter holding times. SPS typically differs from hot-pressingbytheapplication of aDCpulsed currenttothe pressingdie andsample.The temperatureandcurrentarenot independentparametersanditmaybedifficulttoseparatethe intrinsicrole of the current fromits thermaleffect, i.e. Joule heating.Therefore,thereisadebateonwhetherthereareany mechanismsspecifictoSPS.9–22Reviewsofthefield2,19show that most papers reportresults on the densification of nano-materials with little grain growth or on materials bonding, withorwithoutareactionattheinterface.Severalauthors15–22 investigatetheSPSprocessofmodelmaterials,conductingor insulating,butourapproachistoinvestigateitviathesintering

∗

Correspondingauthor.Tel.:+330561556175;fax:+330561556163.

E-mailaddress:peigney@chimie.ups-tlse.fr(A.Peigney).

ofareactivepowder.Itwasshown23thatSPSof nanocompos-itepowderssuchasFe-Al2−2xFe2xO3producesmaterialswitha

surface-layercompositionandmicrostructuredifferenttothatof thecore.IncreasingthethicknessoftheFe-Al2O3surfacelayer

provokedanincreaseinbothVickersmicrohardnessandfracture strength.Theaimofthispaperistogetabetterunderstanding of theprocesses involvedinSPS,using thereactivesintering ofa-Al1.86Fe0.14O3(corundum-typestructure),bystudyingthe

influence of a key SPSparameter, the (on:off) pulsepattern. Thisis comparedwithexperimentswherethe current pathis blockedandalsowithhot-pressing.Moreover,theinfluenceof thesamplecomposition(ironionscontentofthestartingoxide) isinvestigated.

2. Experimentalprocedure

2.1. Powdersynthesis

Forthefirstpartofthestudy,apowderofa-Al1.86Fe0.14O3

solid solution(corundum-type structure)was preparedbythe mixed-oxalateprecipitation/calcinationroute.24Thecalcination

(air, 1200◦

C, 2h) produced apowder in which micrometric grainspresentingavermicularmicrostructureform agglomer-ates15–20mminsize.TheBETspecificsurfaceareaisequalto 2.3m2/g.ItwasverifiedbyX-raydiffraction(XRD)thatonly the peakstypicalof thecorundum-typeoxide arepresentand thatnoFeAl2O4ispresent.Thepowderwasdividedintoseven

batches,asrequiredforthestudy.Inaddition,a-Al2−2xFe2xO3

powderswithdifferentironcontentswerepreparedbythesame route. Twoof them (x=0.02and0.05)contain less ironthan thepreviousone(x=0.07)andaremadeupsolelyofthe cor-responding a-Al2−2xFe2xO3 solid solution. Fora higher iron

content(x=0.10),XRDrevealstracesofahematite-richsolid solution(a2)inadditiontothealumina-richsolidsolution(a1),

whichindicates24thatthesaturation(ofhematitedissolvedinto alumina)wasreachedforthissample(i.e.thatthelimitof substi-tutingFe3+ionsforAl3+ionsinthecorundumlatticeisreached).

2.2. SparkPlasmaSintering(SPS)andhot-pressing

Threea-Al1.86Fe0.14O3(x=0.07)powderbatcheswere

con-solidatedbySPS(DrSinter2080,SPSSyntexInc.,Japan).They wereloadedintoan8mminnerdiametergraphitedie.Asheet ofgraphiticpaperwasplacedbetweenthepunchandthe pow-deraswellasbetweenthedieandthepowderforeasyremoval. Thisensemble isknown as thestack. Thepowders were sin-teredundervacuum(residualcellpressurelowerthan5Pa).A heatingrateof250◦

C/minwasusedfromroomtemperatureto 600◦

C,whereaholdof 1min was appliedinorderto stabi-lizethetemperaturereading.Then,aheatingrateof250◦

C/min wasusedfrom600to1350◦

C,wherea3-mindwellat1350◦

C wasapplied.Anopticalpyrometer, focusedonalittleholeat the surface of the die, was used to measureandmonitor the temperature.Theuniaxialpressurewasgraduallyappliedupto 100MPa within the first minuteof the dwell at 1350◦

Cand maintainedat100MPaduringtheremaining2min.The cool-ingratewascloseto600◦C/minforthefirstminuteandthen

wasnatural.Theuniaxialpressurewasgraduallyreleased dur-ingcooling.Theheat-treatmentdescribedabovewasperformed using threedifferent (on:off)pulsepatterns: (12:2), (2:2)and (2:6),eachpulsecorrespondingto3.3ms,producingmaterials denotedA7,B7andC7,respectively(Table1).Notethat(12:2)

isthedefaultpatternofthemachine.Forthesecondpartofthe study,thepowderswithdifferentironcontents(x=0.02,0.05 and0.10)wereconsolidatedbySPSinthesameconditionsas specimenC7,producingsamplesC2,C5andC10,respectively (Table1).Thenextpartaimedatinvestigatingtheinfluenceof ahighertemperatureandalongertreatmenttime.Thus, spec-imenD7was consolidatedusing the(12:2)pulsepattern,but withamuchlowerheatingrate(20◦C/min),uptoahigher

tem-perature(1450◦C),wherealongerdwell(15min)wasapplied

(Table1).Apressureof43MPawasappliedduringtheheating ramp.TheseconditionsforD7werechosentobesimilartothat usedforasamplepreparedbyhot-pressing(seebelow).Forthe lastpartofthestudy,threemorespecimenswerepreparedusing theremaininga-Al1.86Fe0.14O3powder batches:specimen E7

(Table1)was consolidatedbySPSinthesameconditions as A7,exceptthat oneachsideof thestack, analuminapowder bedabout 1.5mmthick wasplacedbetweenthe punchesand thegraphitepaperdisks,whichmoreoverweresmallerin diam-eterthanthepunches(i.e.theydidnotcovertheouterradialpart ofthe powderanddidnotmake contactwiththedie). Speci-menF7(Table1)wasconsolidatedinthesameconditionsasE7 butthegraphitepaperdiskswereremovedaltogether,inorderto blockanyaxialcurrentflowinthematerial.Finally,specimenG7 (Table1)waspreparedbyhot-pressing(AstroIndustries,USA) at1450◦

CusingacyclesimilartothatusedforD7.Allmaterials insidethehot-pressingcell(resistor,felts,stack,punches)arein graphiteandfull-sizegraphitepaperdiskswerepresent.

2.3. Characterization

Thesinteredspecimenswereintheformofpellets8mmin diameter andabout 2mm thick.The density was determined using Archimedesmethod after removal of the graphitic sur-facecontaminationlayerby lightpolishing. Thedensityis in therangeof3.9–4.0forallspecimens,whichcorrespondstoa densificationintherangeof98–100%.Thespecimenswerecut intheirmiddlealongthepressingaxisusingadiamondblade. Onehalf wasused as across-sectionandwaspolishedup to a1mmdiamondsuspension.Thecross-sectionswereobserved byfield-emission-gunscanningelectronmicroscopy(FESEM, JEOLJSM6700F).TheotherhalfwasusedforX-raydiffraction

Table1

Samples,ironcontentinthestartinga-Al2−2xFe2xO3powder(x)andconsolidationexperimentalconditions:SPSpulsepattern(on:off),maximumtemperature(T),

heatingrate(r)from600◦CtoT,dwelltime(t)atT,uniaxialpressure(P).Remarks:seetextfordetails.GDP:graphitepaperdisks.

Sample x (on:off) T(◦C) r(◦C/min) t(min) P(MPa) Remarks

A7 0.07 (12:2) 1350 250 3 100 – B7 0.07 (2:2) 1350 250 3 100 – C7 0.07 (2:6) 1350 250 3 100 – C2 0.02 (2:6) 1350 250 3 100 – C5 0.05 (2:6) 1350 250 3 100 – C10 0.10 (2:6) 1350 250 3 100 –

D7 0.07 (12:2) 1450 20 15 43 LongerSPStreatment,similartoHP E7 0.07 (12:2) 1350 250 3 100 Al2O3barriers,smalldiameterGPD

F7 0.07 (12:2) 1350 250 3 100 Al2O3barriers,noGPD

Table2

Samples,crystallizedcompoundsdetectedbyXRDinthecompositelayerandinthecore(Fe=a-Fe,A=a-Al2O3,SP=FeAl2O4),compositelayerthicknessand

depletionlayer(DL)thicknessatthetopandbottomsidesofthespecimen;no:notpresent;nm:notmeasured;GDP:graphitepaperdisks. Sample Compositelayer(XRD) Compositelayerthickness

top(mm)/bottom(mm) DLthickness top(mm)/bottom(mm) Core(XRD) A7 Fe+A 38/32 Ill-defined/no SP+A B7 Fe+A 48/32 Well-defined/no SP+A C7 Fe+A 48/32 9/no SP+A C2 Fe+A 20/nm 11/no SP+A C5 Fe+A 31/nm 7/no SP+A C10 Fe+A 55/nm Ill-defined/no SP+A D7 Fe+A 20/64a 25/20a SP+A

E7 Fe+A,belowGPD/SP+A,whennoGPD nm No/no SP+A F7 SP+A No/no No/no SP+A G7 SP+A(Fe+Ainsomeplaces) Irregular No/no SP+A

aReversedpositionscomparedtoothersamples.Seetextfordetails.

(XRD)(Cu Ka radiation,BrukerD4Endeavor)investigations

performedonthesemi-circularsurfaces,firstontheunpolished one,thenonsamplesgroundeverdeeper,inordertorevealthe crystallizedphasespresentatvariousdepthsintothematerial.

3. Resultsanddiscussion

3.1. Influenceofthepulsepattern

Theresultspresentedbelow,obtainedbyXRDpatterns anal-ysisandFESEM observations,aresummarizedinTable2.A visualexaminationofthecross-sectionsofspecimensA7,B7 and C7 (Table 1) revealed a difference in color, as already observedpreviously23:agraycolorforthesurfaceandagreen colorforthecoreofthesample.TheXRDpatterns(notshown) oftheunpolishedspecimensrevealeda-Feanda-Al2O3peaks

andveryweakFe3Cpeaks.Thespecimenswereslightlyground

andonlya-Feanda-Al2O3weredetected,suggestingthatFe3C

wasproducedby reactionbetweenFeandthe graphitepaper disk.Aftersome moregrinding, onlyFeAl2O4 anda-Al2O3

weredetected.FESEMimages(back-scatteredelectronimages inchemical contrast mode)of the cross-sections (topside of thespecimens,closetotheupperpunch,i.e.thecathode)show Fe(whitedots)andFeAl2O4 particles(light-gray)ona

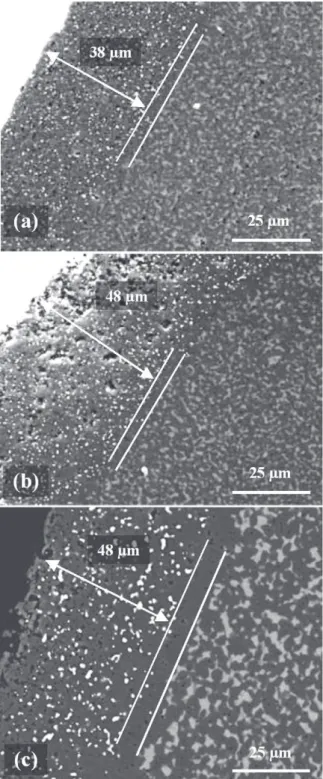

dark-graybackgroundofthe corundum-phasematrix(Fig.1).The averagethicknessofthecompositelayerisabout38mmforA7 andca.48mmfor B7andC7. The Feparticlesare equiaxed for A7 and B7 (diameter 0.5–0.8mm)and appearlarger and elongated(maximumlength ca.5mm)for C7.Regardingthe core,theFeAl2O4andAl2O3grainsaremuchcoarserforC7.

Interestingly, the composite layer is separated from the core by alayer without any Fe particles or FeAl2O4 grains. This

so-calleddepletion-layer(DL)isill-defined(ornon-existingat someplaces) for A7, more clearlydetected for B7 andvery prominent for C7 (ca. 9mm thick).For the bottom side, the thicknessof the composite layerisabout 32mmfor all three samplesandnoDLisobserved,althoughcarewasexercisedfor theprecisepositioningof thesamplewithinthestack.Onthe peripheralsurfaceofthespecimen(i.e.theareaclosetothedie),

theFe-Al2O3layerisalsoobservedforallthreespecimensand

noDLisobserved.

3.2. Influenceoftheironcontent

TypicalFEG-SEMimagesofthetopsides(Fig.2)of speci-mensC2,C5andC10(Table1)revealedamicrostructuresimilar tothatobservedforC7, notablyfor C2(Fig.2a)andC5 (not shown).ForC10,theDLisill-definedornon-existing(Fig.2b andc). Thethicknessof thecomposite layerincreases(upto about55mm)upontheincreaseinironcontent,whereasby con-trasttheaveragethicknessoftheDLtendstoslightlydecrease (Fig.3).

3.3. Influenceofthetemperatureandduration

ForD7(Table1),comparedtoA7,atthetopside(Fig.4a), the composite layer isthinner (20mm)and theDL isclearly definedandverythick(25mm).Atthebottom side(Fig.4b), mostinterestingly,theDL(ca.20mmthick)isobservedclose tothepunchandisseparated fromthecorebythe composite layer(ca.64mmthick),themicrostructureofwhichismoreover differentfromtheotheronesobservedsofar,showingalower densityoflargerFeparticles.

3.4. Current-blockinginSPSandhot-pressing

ThepartofspecimenE7(Table1)thatwasbelowthegraphite paperdisk(notedGPDinFig.5)issimilartospecimenA7,the thicknessoftheFe-Al2O3layerdecreasingwhenonegetscloser

totheedgeofthedisk(i.e.theplacewherethegraphitepaper diskends)(Fig.5a).Bycontrast,nosuchlayerisobservedinthe areaswherethepowderwasdirectlyincontact withalumina, whichwasdifficulttoseparatefromthe material(arrowedon theimage)duetostrongdiffusion-bonding.Thus,forthispart of E7,thewholematerialismadeupofFeAl2O4andAl2O3.

The same isobserved (Fig.5b) for all areasof specimen F7 (Table 1).Specimen G7, prepared byhot-pressing (Table 1), containsFeAl2O4andAl2O3andthecompositesurfacelayer,

Fig.1.FESEMimagesofacross-section(topside)ofspecimens(7cat.%Fe,

x=0.07)preparedbySPSwithdifferentpulsepatterns(on:off):(a)A7,(12:2); (b)B7,(2:2);and(c)C7,(2:6).

when present, ismuch less regularthanfor the SPS samples (Fig.5c–e).

3.5. Discussion

TheformationofFeAl2O4,oftheDLandoftheFe-Al2O3

compositelayerandtheirrespectivepositionswithinthe speci-menswillbediscussed.Firstly,theconsequenceofchangingthe pulsepatternonthecrestintensityofthecurrentwillbe

exam-Fig.2.FESEMimagesofacross-section(topside)ofspecimenswithdifferent ironcontentspreparedbySPSwitha(2:6)pulsepattern:(a)C2(x=0.02);(b) and(c)C10(x=0.10).

ined.Thewaveformofthe“on”periodiscomposedofseveral pulses.25Thenumberofpulsespersecondcalculatedfromthe ratioof thenumberofpulsesandthetotalpatterndurationis equalto260,152and76forthe(12:2),(2:2)and(2:6)patterns, respectively. The intensity delivered by the SPSgenerator to heatthestackat1350◦

Cwasrecordedusingamagneto-electric amperometer.Theevolution(528,436and432Aforthe(12:2), (2:2)and(2:6)patterns,respectively)isinagreementwith ear-lierresults25andweproposethatthiscouldmeanthattheSPS

Fig.3.ThicknessoftheFe-Al2O3top-sidecompositesurfacelayer(solid

dia-monds)andofthedepletionlayer(opensquares)versustheironcontentfor specimenspreparedbySPSwitha(2:6)pulsepattern.

Fig.4.FESEMimagesofacross-sectionofspecimenD7(7cat.%Fe,x=0.07) preparedbySPSwitha(12:2)pulsepattern,butusingalowerheatingrate,a highertemperatureandforalongerdwelltimethanallothersamples,showing (a)thetopside,closetotheupperpunch(i.e.thecathode)and(b)thebottom side.

Fig.5.FESEMimagesofacross-section(topside)of(a)specimenE7and(b) specimenF7preparedbySPSindifferentcurrent-blockingconditions(seetext fordetails)and(c–e)specimenG7preparedbyhot-pressing.GPD=graphite paperdisk.

isnotasimpleresistivebutapartiallyinductivesystem.From themeanintensityvalues,itisdeducedthatduringonesecond ofpulsecurrent,thedeliveredelectricchargesare528,436and 432Candthusthatthecorrespondingcrestintensity(Ic)foreach

pulse(i.e.foreach3.3ms“on”period,consideringeachpulse as rectangular)is equalto615,869 and1722A,respectively, showingagreatinfluenceofthe pulsepattern.Thecrest volt-agesweremeasuredandfoundbetweenabout10Vfor(12:2) andabout20Vfor(2:6).Thesevaluesaretobeconsideredas averages,becausethepulsesinagiventrainareneitherthesame involtagenorincurrentintensity.25

The formation of FeAl2O4 is observedfor all specimens,

preparedbySPSorhot-pressing,showingthatitisnotpeculiar toSPS. Itis proposedthat it occurs byphase partitioningas describedbyreaction(1),23whichisaconsequenceofthehigh temperatureandlowP(O2).26

Al1.86Fe0.14O3→ 0.14FeAl2O4+0.79Al2O3+0.035O2 (1)

ThehighersizeoftheFeAl2O4grainsforC7(comparedtoA7

andB7)reflectsahigherrateofphasepartitioning,suggesting ahighertemperatureinthecorebecauseofthehigherIc.The

presenceofFeAl2O4extendstoallareasofthespecimensthat

arenotincloseproximitytothesurroundinggraphitefromeither the die or graphitepaper because reaction(1) competes with theformationoftheFe-Al2O3compositelayer,whichwillbe

discussedlater.

LetustrybeforetoexplaintheformationoftheDL.ForA7, B7andC7,theDListhickerwhenIcishigheronthetopside

of thesamples(Fig.1)butnotonthebottom side.An expla-nationthatwasconsideredtoexplaintheasymmetryisthatthe bottomside(i.e.theanode)mayexperiencealowertemperature duetotheaxiallyasymmetriccurrentflow.27However, consid-eringthatthespecimenisthin(<3mm),thetemperatureofthe surroundinggraphitedieisprobablyidenticalalongthelength ofthespecimen,andthusthedifferencebetweenthetop-and bottom-side temperaturesis probablylow.Moreover,aDLis presentattheverybottomofsampleD7preparedlikeA7but atahighertemperatureandwithamuchlongertreatment.This suggeststhattherewerenoremainingFe3+ionsatthebottomof D7toformeitherFeAl2O4orFeandthereforepointstowards

upward diffusion. Taking into account the crest voltagesand the lowthicknessof thesamples,itisproposedthatthe elec-tricalfieldissufficientlyhightoactivatethe diffusionof iron ions,mostprobablyFe3+ions,towardsthecathode.Shenetal.9

reportedthatbothgrain-boundarydiffusionandgrain-boundary migrationareenhancedbytheelectricalfieldoriginatingfrom thepulsedcurrent.ForD7,thisphenomenonhastimetotake placebeforethereductionofironspeciestoFe,butnotsoforC7 (andallthemoresoforA7andB7),thusexplainingthatthereis noDLatthebottomsideforA7,B7andC7.Thethickertop-side DLforC7comparedtoA7andB7couldreflectthattheFe3+ ionssupplyisstoppedbecause,asmentionedabove,higherbulk temperaturesachievedforC7duetohigherIcandcrestvoltage,

would favorahigherphase partitioningrate inthecore, pro-ducingmoreFeAl2O4.ThisimpliesthattheFe2+ionsarenot

involvedontheupwardsdiffusionprocessandthusarenot nec-essarilyinvolvedintheformationof Fe(as discussedbelow), becauseotherwiseFeAl2O4wouldbedetectedintheDL.Thus,

there isa competition betweenthe formation of FeAl2O4 by

reaction(1),whichalsocorrespondstoareductionofFe3+into Fe2+ ions,andelectricalfield-inducedFe3+ diffusion.Usinga pulsepatternwithhighIcandcrestvoltagesuchas(2:6)favors

theformerforrapidtreatmentsbecauseitallowsforhigher tem-peraturestobereachedinthebulkofthesamplebutfavorsthe latterforslowtreatments.

Thereisacompetitionofreaction(1)withtheformationof theFe-Al2O3compositelayer,whichcanoccurviareactions(2)

and/or(3).23

FeAl2O4→ Fe +Al2O3+(1/2)O2 (2)

Al1.86Fe0.14O3→ 0.14Fe +0.93Al2O3+0.105O2 (3)

Notethat(3)correspondstoadirectreductionofFe3+ions intoFeobviatingtheFe2+ions(FeAl2O4)intermediatesandthus

reaction(2).FortheH2reductionofsimilarsolidsolutions,28,29

Feis formedeither directlyor via FeAl2O4 for temperatures

higheror lowerthan1000◦

C,respectively.Itisprobable that atthepresent temperatures,(3) ispreeminent, supportingthe abovepropositionthatFeAl2O4isnotinvolvedintheformation

ofFe.From thecurrent-blockingexperiments(E7andF7), it appearsclearlythattheabsenceofgraphitepaperpreventsthe formationofthecompositelayer,showingthattheseconditions aremorefavorabletotheformationofFeAl2O4by(1).

Withthegraphitepaper,SPS,butnothot-pressing,leadsto aFe-Al2O3layer ofafairly regularthicknesson thetop and

bottomsidesofthespecimens,pointingtowardssome character-isticeffect(s).Moreoverthetopcompositelayeristhickerwhen usingahigherIc.Thiscouldreflectthat for SPSthetopside

ofthespecimeniscontinuouslysuppliedbyFe3+ionsthrough field-induceddiffusion, as long as the formation of FeAl2O4

hasnot started.Specimen A7 canbe comparedtoour previ-ouslystudiedsample(codenamedR0SinRef.23),forwhichthe compositelayerthicknesswasonly10mm.Thesamesintering parameterswereusedexceptforthetemperatureofapplication of the uniaxialpressure, whichwas gradually appliedduring the600–1350◦

CrampforR0Sandat1350◦

Cforthepresent specimenA7.Thestudyofshrinkagecurves(notshown)reveals thattherelativedensityat1300◦

C(assuming noreactions)is equalto97% forR0Sandonly68%for A.Thus,the forma-tionoftheFeparticlesduringtheSPStreatmentappearstobe easierwhenthedensityofthecompactremainslow,duringthe heating,i.e.whenthepressureisappliedlateas forspecimen A7.Thiscouldreflectthepossibleroleofopenporosityinthe process.Applyingthe pressureatlow temperaturemayfavor theclosingofporositybeforetheformationof Febyreaction

(3)isthermallyactivated,whichwoulddecreasethepossibility ofO2leavingthesampleandthusresultinathinnerreaction

zoneandthusathinnercompositelayer,asobservedforR0S. Thiscouldalsoberelatedtothepossibilitythatwhenthe cross-sectionalareasofparticle–particlecontactsaresmall,veryhigh localcurrentdensitiesmaybeobtained,assuggestedbyother authors,13,16whichmayresultinsignificantlyhigherlocal tem-peratures,whichwouldalsofavorFeformationbyreaction(3)

andthe coalescence of Fe particles at the grain junctions of Al2O3,thusexplainingthedifferencesinparticlessizeandthe

elongatedshape observedfor C7. Thiseffectwould be more prominentwithpulsepatternsproducinghighercrestintensities, asforspecimenB7(Fig.1b)andmostnotablyforspecimenC7 (Fig.1c).Theresultsobtainedwithmaterialsdifferingbytheir ironcontent(Fig.3)supporttheabovehypotheses.An increas-ingcontentofFe3+ionssubstitutingforAl3+ionscanalsobe describedasahigherhematitecontentdissolvedintoalumina,

uptothesaturationreachedforthesamplewithx=0.10as indi-catedin Section2.1. The increasing saturation degreefavors bothreactions(1) and(3) atagiventemperature. Insamples withlowiron contents(C2andC5), differencesinthe kinet-icsof Fe3+ionsdiffusionandFeAl2O4 formationbyreaction

(1)couldexplaintheformationoftheDL.Bycontrast,forC10 almostnoDLisformedbecausethecorecontainsasufficient excessofFe3+ ionstosupplythetop sideintime. Moreover, asthesespecimenswereprepared withthe(2:6)pulsepattern (Ic=1722A),the microstructure evolutionobserveduponthe

increaseoftheironcontentcouldbeaconsequenceofchanges inthelocalcompositionandonthelocalelectrical conductiv-ity,whichwouldchange local currentdensities, andpossibly diffusionprocessesorlocaltemperatures.

Thegraphitepaper diskspresent betweenthepunchesand thepowdercouldalsoplayaroleinhelpingtochannelelectrons intothesample.Thiscouldresultinhighlocalcurrentdensities orhighlocalvoltagesinthematerial.Theelectricalconductivity ofthesolidsolution,whichisprobablythelimitingparameter forthepenetrationofcurrentatsomedepthintothespecimen, is probably quite low even at 1350◦C (10−7–10−8S/cm by

comparisonwithdataat1500and1600◦C30).Thiswouldbe

in agreement withresults on the distributionof current den-sitywithinandaroundthematerialdependingonitselectrical conductivity.16,31 Note that although modelling the electrical conductivity,ironcationsdiffusionanddefectstructureofsuch amaterialathightemperatureandlowP(O2)isfairlycomplex,30

theelectricalconductivitycanbesignificantlyhigherthanthat of pure a-Al2O3. This could allow for the penetration of a

higher current, andthis deeper into the specimen, thanwhat wasreportedfora-Al2O3.32,33Thus,electricdischargeeffects

betweengrainsandinclosedporosities cannotbe ruledout. Itwasreported34thatcarboncomingbydiffusionfromthedie isareactantfor the formationofW2Cduringthe SPSof

W-Al2O3composites.However,thepresenceofFe3Cappearsto

be limited tothe top-most surface andnothingwas found to indicatethatthereiscarbondiffusionalongthewholesample as indicatedin Ref. 34.Moreover,if carbonactedas a reac-tant,therewouldbeagradientinthepresenceofFeparticles withinthe composite layer(withmore, andalsolarger, parti-clesnearthegraphitepaper),whichisnotobserved.Theroleof carbonasareactantforcarburizationand/orreduction,ifany, does notextendvery deepinto thespecimen (afew microm-eters atmost) andthusFe3+ reduction by carbonor COwas ruledoutasthemaincausefortheformationofthecomposite layer.

However,theabovehypothesesfailtoexplainwhy,forthe bottomsizeofspecimenD7(Fig.4b),alarge(64mm)composite layeris formedabove the DL,inanarea notincontact with graphite.It is notpossible toexplainthat reaction(3) would haveoccurredwithsuchaclearseparationfromthecorewhere reaction (1) tookplace because such a marked difference in temperatureisnotthoughttoberealistic.Asnotedabove,the microstructureofthiscompositelayerisdifferentfromtheother ones,showingalowerdensityoflargerFeparticles.Thiscould reflectthattheFeparticlesoriginatefromFeAl2O4particles,i.e.

theyareformedbyreaction(2).Thisisobservedonlyforsample

D7becauseitistheonlyonepreparedwithaverylongcycle.A verylongtreatmentwouldprobablytransformallFeAl2O4into

Fe.

4. Conclusions

The influence of a key SPS parameter, the pulse current, wasinvestigatedonthesinteringofreactivealumina–hematite solidsolutionsbyvaryingthepulsepattern.Foragiven sinter-ingcycle,changingthepulsepatternmodifiesthecurrentcrest intensities andhasa greatinfluenceon the microstructure of thematerial.ItiscomposedofaFe-Al2O3compositelayerat

theperipheralsurfaces(top,bottomandradial),abiphasedcore (FeAl2O4 andAl2O3)and adepletion-layer (DL)withoutFe

norFeAl2O4 betweenthe compositelayerandthecoreatthe

top sideof thespecimen, i.e.nearthe cathode.ForlongSPS treatment, there is also a DL at the very bottom side of the specimen.Animportantroleofcarbon(fromthedieorgraphite paperdisks)asareactantwasruledout.However,graphitepaper diskscouldplayaroleinhelpingtochannelelectronsintothe sample, which could result in highlocal current densities or voltagesinthematerial.Threemainphenomenaarein competi-tion:formationofFeAl2O4favoredbylowerP(O2)andhigher

temperatures,whichisnotpeculiartoSPS,formationofFe, pro-ducingFe-Al2O3compositelayersofaregularthickness,and

electrical-fieldinduceddiffusionofFe3+ionstowardsthe cath-ode(i.e.upwards).Tothebestofourknowledge,thisisthefirst timethatsuchuni-directionalcationicmigrationisobserved dur-ingSPSdensificationofmaterials.Thismechanism,linkedto thepotentialgradientimposedbytheSPStechnique,isenhanced withthecrestintensityoftheappliedcurrent.The microstruc-tureevolutionwiththechangeofpulsepatterncouldalsoreflect inducedvariationsoflocaltemperatures.Thesefindingscould havefar-rangingimplicationsfortheSPSconsolidationofionic materials,for the insitu(reactive)shaping of novel compos-itesandmultimaterials.TheformationoftheFeparticlesduring theSPStreatmentappearstobeeasierwhenthedensityofthe compactremainslow,duringtheheating,i.e.whenthepressure is applied late, whichcould reflect the possible role of open porosity.Futureworkswillincludethestudyoftheinfluenceof porosity,notablytoinvestigatesurfaceeffects,andthemodelling ofthecurrentandtemperaturedistributionsalongthestack.

Acknowledgements

TheSPSwasperformedatthePlateformeNationaleCNRSde Frittage-Flash(PNF2,Toulouse).Electronmicroscopywas per-formedatTEMSCAN,the“ServiceCommundeMicroscopie Electronique”, UniversitéPaul-Sabatier. The authorsthank J. FaberandY.Paranthoen(SociétédesCéramiquesTechniques, Bazet,France)forJGSdoctoralthesisgrant.Thisworkis per-formedundertheprogrammeANR-06-NANO-049.

References

1.TokitaM.TrendsinadvancedSPSSparkPlasmaSinteringsystemsand technology.JSocPowderTechnol1993;30(11):790–804.

2.ChaimR,LevinM,ShlayerA,EstournesC.Sinteringanddensification of nanocrystallineceramicoxidepowders:a review.AdvApplCeram

2008;107(3):159–69.

3.ArtemenkoA,ElissaldeC,ChungU-C,EstournèsC,MornetS,Bykov I,etal.Linkinghoppingconductivitytogiantdielectricpermittivityin oxides.ApplPhysLett2010;97(13):132901–3.

4.GurtSantanachJ,WeibelA,EstournèsC,YangQ,LaurentCh,Peigney A.SparkPlasmaSinteringofalumina:parametersstudy,formalsintering analysisandhypothesesaboutthemechanism(s)involvedindensification andgraingrowth.ActaMater2011;59(4):1400–8.

5. MarderR,ChaimR,ChevallierG,EstournèsC.Effectof1wt%LiFadditive onthedensificationofnanocrystallineY2O3ceramicsbysparkplasma

sintering.JEurCeramSoc2011;31(6):1057–66.

6. MillotN,LeGalletS,AymesD,BernardF,GrinY.Sparkplasmasintering ofcobaltferritenanopowderspreparedbycoprecipitationandhydrothermal synthesis.JEurCeramSoc2007;27(2–3):921–6.

7. Kakegawa K, Suzuki SS, Uekawa N. Design of pyroelectric prop-erties by controlling compositional distribution. J Eur Ceram Soc

2006;26(4–5):613–7.

8.XuT,WangP,FangP,KanY,ChenL,VleugelsJ,etal.Phaseassemblyand microstructureofCeO2-dopedZrO2ceramicspreparedbysparkplasma

sintering.JEurCeramSoc2005;25(15):3437–42.

9.ShenZJ,JohnssonM,ZhaoZ,NygrenM.Sparkplasmasinteringof alu-mina.JAmCeramSoc2002;85(8):1921–7.

10.ShonIJ, MunirZA.Synthesis ofMoSi2–xNb andMoSi2–yZrO2

com-posites by the field-activated combustion method. Mater Sci Eng A

1995;202(1–2):256–61.

11.TokitaM.Developmentoflarge-sizeceramic/metalbulkFGMfabricated bysparkplasmasintering.MaterSciForum1999;308(11):83–8. 12.OmoriM.Sintering,consolidation,reactionandcrystalgrowthbythespark

plasmasystem.MaterSciEngA2000;287(2):183–8.

13.ChaimR. Superfastdensificationofnanocrystalline oxidepowders by SparkPlasmaSintering.JMaterSci2006;41(23):7862–71.

14.ChaimR,Marder-JaeckelR,ShenJZ.TransparentYAGceramicsby sur-facesofteningofnanoparticlesinsparkplasmasintering.MaterSciEngA

2006;429(1–2):74–8.

15. ChaimR.Densificationmechanismsinsparkplasmasinteringof nanocrys-tallineceramics.MaterSciEngA2007;443(1–2):25–32.

16.Anselmi-Tamburini U, Gennari S, Garay JE, Munir ZA. Fundamen-tal investigations on the spark plasma sintering/synthesis process II. Modeling of current and temperature distributions. Mater Sci Eng A

2005;394(1–2):139–48.

17.Anselmi-TamburiniU,GarayJE,MunirZA.Fundamentalinvestigations onthesparkplasmasintering/synthesisprocess.III.Currenteffecton reac-tivity.MaterSciEngA2005;407(1–2):24–30.

18.HulbertDM,AndersA,AnderssonJ,LaverniaEJ,MukherjeeAK.A dis-cussionontheabsenceofplasmainsparkplasmasintering.ScriptaMater

2009;60(10):835–8.

19.MunirZA,Anselmi-TamburiniU,OhyanagiM.Theeffectofelectricfield andpressureonthesynthesisandconsolidationofmaterials:areviewof thesparkplasmasinteringmethod.JMaterSci2006;41(3):763–77. 20.Bernard-Granger G, Guizard C. Spark plasma sintering of a

com-mercially available granulated zirconia powder. I. Sintering path and hypothesesaboutthemechanism(s)controllingdensification.ActaMater

2007;55(10):3493–504.

21.Bernard-GrangerG,AddadA,FantozziG,BonnefontG,GuizardC,Vernat D.Sparkplasmasinteringofacommerciallyavailablegranulatedzirconia powder:comparisonwithhot-pressing.ActaMater2010;58(9):3390–9. 22. LocciAM,CincottiA,ToddeS,OrruR,CaoG.Amethodologyto

inves-tigatetheintrinsiceffectofthepulsedelectriccurrentduringthespark plasmasinteringofelectricallyconductivepowders.SciTechnolAdvMater

2010;11(4):045005–45013.

23. Gurt Santanach J,Estournès C,Weibel A, Peigney A,Chevallier G, Laurent Ch. Sinteringas a reactive sintering tool forthe preparation ofsurface-tailoredFe–FeAl2O4–Al2O3 nanocomposites.ScriptaMater

2009;60(4):195–8.

24.DevauxX,LaurentCh,RoussetA.ChemicalSynthesisofmetal nanopar-ticlesdispersedinalumina.NanostructMater1993;2:339–46.

25.ChenW,Anselmi-TamburiniU,GarayJE,GrozaJR,MunirZA. Funda-mentalinvestigationsontheSparkPlasmaSintering/Synthesisprocess.I. Effectofdcpulsingonreactivity.MaterSciEngA2005;394(1–2):132–8. 26.Elrefaie FA, Smeltzer WW. Thermodynamics of the system iron–aluminum–oxygen between 1073K and 1573K. Metall Trans B1983;14(1):85–93.

27.TobiEven-ZurO,ChaimR.Effectofgreendensityandelectricfield direc-tionondensificationofYAGnano-powdersbySparkPlasmaSintering.J MaterSci2009;44(8):2063–8.

28.DevauxX,LaurentCh,BrieuM,RoussetA.Iron–aluminainterfacein ceramicmatrixnanocomposites.JAlloysCompd1992;188(1–2):179–81. 29.LaurentCh,RoussetA,VerelstM,KannanKR,RajuAR,RaoCNR.

Reduc-tionbehaviourofFe3+/Al

2O3obtainedfromthemixedoxalateprecursor

andtheformationoftheFe0-Al

2O3 metal–ceramiccomposite.JMater

Chem1993;3(5):513–8.

30. KoripellaCR,KrögerFA.Electricalconductivity,diffusionofironandthe defectstructureofa-Al2O3:Fe.JPhysChemSolids1986;47(6):565–8.

31.MakinoY.Characteristicsofsinteringprocessbasedonpulsedhighcurrent.

NewCeram1997;10:39–42.

32.TominoH,WatanabeH,KondoY.Electriccurrent pathand tempera-turedistributionforSparkSintering.JJapSocPowderPowderMetall

1997;44(10):974–9.

33.MakinoY,SakaguchiM,TradaJ,AkamatsuK.Consolidationof ultra-finealuminapowderswithSPSmethod.JJapSocPowderPowderMetall

2007;54(4):219–25.

34.Rodriguez-SuarezT,DiazLA,TorrecillasR,Lopez-EstebanS,TuanWH, NygrenM,etal.Alumina/tungstennanocompositesobtained bySpark PlasmaSintering.CompSciTechnol2009;69(14):2467–73.