Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Building Research Note, 1967-07-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=ad914ebb-dfab-4dda-9fa7-1cde20f54c96 https://publications-cnrc.canada.ca/fra/voir/objet/?id=ad914ebb-dfab-4dda-9fa7-1cde20f54c96

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40000649

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Poultice method for treating bituminous stains on masonry products

Stafford, B. F.

P O U L T I C E

METHOD

FOR TREATING BITMUINOUS STAINS ON MASONRY PRODUCTSby

B.F.

StaffardBuilding materials are selected with great care and attention, not only far their performance characteristics, but a l s o f o r their aesthetic value- Further care is exercised in t h e fxansportatiarm and handling of t h e s e materials in an attempt to have them installed un- marked and clean. All t o ~ often, however, this is not achieved, Lack

of appreciation of t h e problems associated with the u s e of

a U

materialsin t h e system or negligence in application may result in unsightly stain- ing.

This Note is concerned with some of t h e organic stains that are

m o s t

difficult ;to removefrom

porous materials, those of the bitumens generally known as coal-tar pitches, asphalt, and asphalt emulsions. Although t h e s e s t a i n s can never be completely removed from some masonry surfaces, a marked reduction in t h e intensity of the stain canbe achieved

by

using a poultice consisting of a solvent and a chemically inert material applied to the stained surface.The u s e of solvent-based poultices o f f e r s several advantages: they prevent t h e stain from spreading during trea-hent, and they S'puLI1' the stain out of the pores of the masonry. They are also more conven-

ient to u s e in small or a w k w a r d areas and can be used in situations

where a mess carmot be tolerated. They are easily prepared, relatively inexpensive, and require minimum use of mechanical equipment f o r application and removal.

The mechanism of a poultice-cleaning system is quite simple:

the solvent in t h e paste is absorbed into the surface pores of the masonry. The absorbent inert material controls the rate of evaporation, t h u s

giving the solvent s d i c i e n t t i m e to dissolve the stain. As evaporation

takes place,

the

solvent together with t h e material that caused the stain is d r a w n out of the masonry surface into the inert material. The stain isdeposited in t h e absorbent which, when dried, can be easily removed

from the masonry as a loose powder,

Before actually attempting t o remove .the stain, it is advisable

Because of the many and varied characteristics of building materials,

it

is impossible t o predict the effe ctivene s s of such a cleaning system. Difference sin such aspects as eolour, absorption, and texture of

the

masonry materials all affect the degree of success.It is

recommended, therefore, that a trial removal ofthe stain be attempted in an inconspicuous area to determine t h e efficacy ofthe system and its freedom

from undesirable side effects.

2.

If the

stains to be removed are on new construction, it follows that t h i s should be one of the l a s t phases of construction,but

again,a

-

trial removal should be attempted e a r l y incase replacement of the materialis the only acceptable solution.

3 .

If

the material involved has been in u s e far a con-siderable pexiod of time, it i s likely t h a t the surface

will

be discoloured through d i r t accumulation. The treatment far the withdrawal of the stain will probably remove the dirt in the treated area leaving it lighter in colour. Therefore, the effect an t h e final appearance of the surface should be considered,4.

It

should be noted that solvents a r e generally toxic and flammable and should be u s e d with caution and only in well-ventilated areas.THE SOLVENT

The liquid used in t h e poultice must be a solvent of the material

to be removed. The evaporation of this solvent must be rapid enough

to allow the inert material to d r y within a reasonable length of t h e , but not so fast that there is insufficient; t h e for t h e solvent to act o n

the stain.

.

A solvent fox bitumens could be any one of the following

hydrocarbons;

xylene,

toluene, trichloroethylene

or mineral spirits. Xylene and toluene offer a moderate evaporation rate and a high degree of solvent strength. Trichloroethylene a l s o has high solvency p o w e rhas fhe weake st dissoLving action and t h e slowest evaporation rate but

is t h e most readily available and could be acceptably employed where

t h e s k i n is light and t i m e is n o t an important factor, Benzene ranks

with trichloraethylene but i t s extreme toldcity ne ce s sitate s stringent precautions: it must be employed only in well-ventilated areas and

prolonged contact with tbe skin must be avoided. THE INERT MATERIAL

A variety of chemically i n e r t materials can be used as absorbents

iq the preparation of the poultice. These finely divided materials have varying properties when mixed as a paste, some offering better adhesion

to vertical surfaces than others. They are used a s agents to hold the

solvent in contact with t h e surface;, and act to control evaporation of the

solvent. They must Rave a h i g h absorbency value and must not react chemically w i t h the liquid

with

which they are being mixed. In o r d e r f o r t h e reverse migration af t h e solventinto

the poultice to 'be effective,it

is necessary f o r t h e s e absorbents to have a finer pore structure thanthe surface on which they are t o be applied.

These i n e r t materials or fillers may be talc, whiting, F u l l e r T s Earth, bentonite or powde red silica, all of which meet the aforementioned requirements. In selecting from these, one need only consider the avail- ability of the material.

APPLICATION AND REMOVAL

OF

THE P O U L T I C EBefore proceeding with the application of the solvent poultice, it is desirable that excessive bihunen s t a k deposits be carefdly r e m o v e d by manual means. This will minimize t h e number of treabnents necessary to effect satisfactory removal and reduce the hazard of further stain

penetration into the pores as solvent thinning takes place. It is recommended

that the implements employed h this removal be wooden paddles or similar

instruments that are no&jurious to the surface itself,

Enough solvent is mixed w i t h t h e filler to form

a

smooth paste ofa consistency that, when applied, will retain its shape and still o f f e r adhesion to vertical surfaces.

At

l e a s t 1/4 inch of this mixture is then applied by a spatula er trowel over t h e stain, ensuring that more than the entire stained area is covered. The poultice i s left in place for at least one hour after all t h e solvent has apparently evaporated and thenremoved as a dry powder. Since all of the stain

may

not dissolve during the first attempt, h e process is repeated until satisfactory results a r eachieved or until i t

is

considered to be impractical or uneconomical to continue.

9f the surrounding areas will permit, a final washing, using

water and a s t i f f bristled brush, will remove any o f the filler particles that remain in the surface pores of the masonry materials.

RESULTS

OF

A SIMPLE L A B O M T O R Y TESTT o

appreciate better the difficulties involved in t h e u s e of sucha poultice system, a small-scale laboratory t e s t was condncted in an attempt t o remove stains resulting from bitumens most commonly used

in

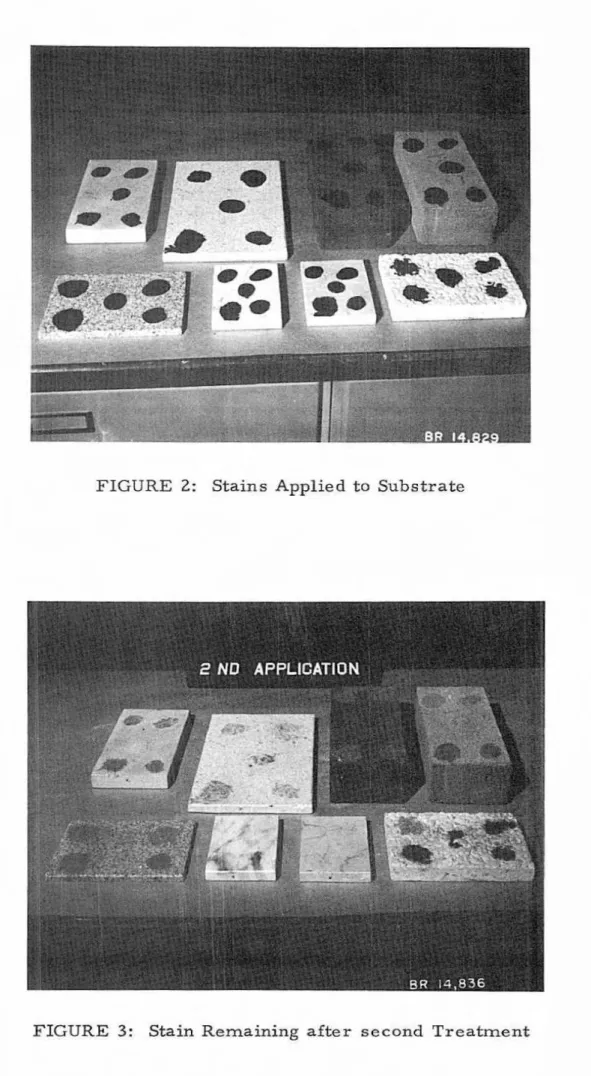

t h e construction industry. Small samples of masonry materials (described inFigure 1 ) w e r e used onto which the fallowing materials w e r e applied: a CSA type 1 , ~ 4 softening 0 ~ point asphalt; ~ a solventcut-back of

the

same material; coaldtar pitch; an asphalt emulsion type applied undiluted a n d a further application of t h i s material thinned t o awater -like consistency,

In

addition to indicating which masonry productw a s used, F i g u r e 1 identifies the area of the surface to

which

each particular stain w a s applied.The

asphalt and coal-tar pitch were heated toa

temperature of approximately 400°F: in a heating apparatus and poured onto the surfaceof the sample s in the appropriate area producing a stain of approximately one inch in diameter. A small a m o u t of the 140 asphalt was t;h-inned w i t h solvent and this cut-back asphalt was applied cold, again by pouring onto

the surface.

A

stain of asphalt emulsion o f the s a m e general dimensionwas produced, using a spatula as the instrument of application, a n d the *:inned emulsion was applied

in

a

similar manner (Figure 2 ) -Sufficient b e was allowed f o r materials that were applied h o t to reach room temperature

and

excessive bitumen deposits were thenremoved manually, taking care to not injure t h e masonry surfaces.

A poultice was prepared using

talc

mixed with benzene t o form a smooth paste.This

paste was evenly applied witha spabla over the stained area to a thickness of at least 1 / 4 inch covering morethan

thewith

a

s t i e f bristled brush, Nearly compkte success was achievedin

removing the asphalt and coal-tar pitch stains from t h e two marblesamples in this f i r s t attempt,

but

only a moderate degreeof

successwas achievedinthe remainder of the c a s e s ,

The

procedure was re-peated, resulting

i

n

completeremoval

ofall atains on

the marble samples as shownin

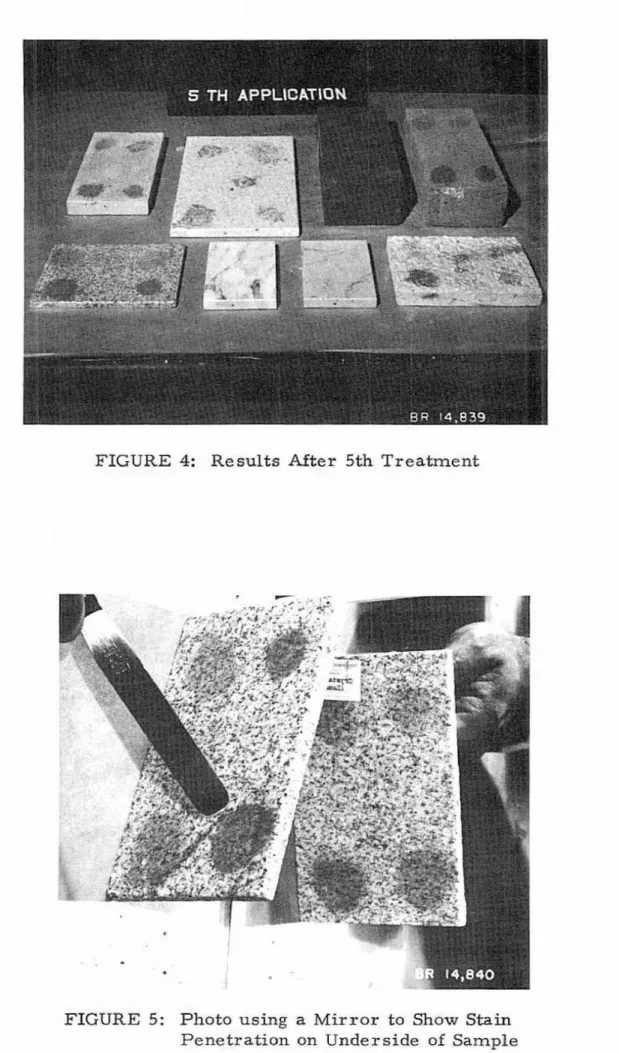

Eigure 3, This aperation w a s repeated a t o t a lof five t i m e s with a continued increase in removal

of

t h e remaining stains evident up to the four& attempt. Afterthe

fifth trial, it wasdecided that no more effective removal could be obtained and

that

this

represented a pradical limit,It

is evident f r o m Figure 4 that it was impossible to completelyremove fie biturnens from a l l the surfaces. Excellent results were

achieved on the marble products after the second attempt. C o a l t a r pitch stains were satisfactorily removed e x c e p t from t h e white terrazzo

and the exposed aggregate concrete surfaces, where stains w e r e stir1 r c b j x l e d in fhe poses of the matrix,

Gut-back asphalt removal was considered acceptable in six c a s e s but tRe Indiana l j m e stone and white terrazzo surfaces still

showed an unacceptable amount of stain, The 140 asphalt w a s not completely removed from the Indiana limestone, the white terrazzo

,

and the white exposed aggregate concrete surfaces. The asphaltemulsion stains offered t h e m o s t resistance to removal. Much of this bitumen was removed

but

(except on marble)it

would appear that the poultice system is ineffectivein

elk-ninating this stain.The effect of solvent in causing stain penetrat5on can be seen

By comparing stains 1 and 2 .

In

these cases, the solvent-thinned asphalt, when applied, was c a r r i e d further into the pores than t h e undiluted asphalt.This

penetration wasm o s t

apparent t:on the Georgiagranite (Figure 51 where this thinned bitumen had campletely penetrated

the material

and

the stain intensity was as severe on the underside as on the surface.S U M M A R Y

The u s e of

a

poultice-cleaning system can be most u s e m inthe t r e a b e n t of bituminous stains on porous materials. It is completely

effective when employed on a marble surface and offers varying degrees

of: success on other masonry materials. The system is quite convenient to use, is economical, and involve s

lime

skiill in it.ts application.The ready availability of the components in the poultice and its capability to

be

used in.awkward

areas, without causinga

m e s s ,make the system a desirable one. From 'the experiment conducted, it i a evident that the m o s t notable limitation of a solvent based

poultice system is its relative inability to remove stains resulting

from thinned asphalt emulsions.

The difficulty of removing bituminous stains from some

masonry surfaces emphasizes the need to take every precaution during construction t o avoid staining t h e masonry.

F I G U m 2: Stains Applied t o Substrate

FIGURE 4:

Re

sults After 5 t h TreatmentFIGURE 5: Photo u s k g a M i r r o r t o Shaw S b i n