Publisher’s version / Version de l'éditeur:

ACS Symposium Series, 113, pp. 157-179, 1979

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Development of test procedure for predicting performance of sealants

Karpati, K. K.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=91a5559e-da3c-4594-97b4-5d87fc63870d https://publications-cnrc.canada.ca/fra/voir/objet/?id=91a5559e-da3c-4594-97b4-5d87fc63870d

Ser

National Research Conseil nationalTH1

Council Canada de recherches CanadaN21d

no.

894

tC'.lb 3 tC;

C b Q .

2

DEVELOPMENT OF TEST PROCEDURE

FOR PREDICTING PERFORMANCE OF SEALANTS

A N A ~ . V T F D

by K.K. Karpati

Reprinted from

American Chemical Society Symposium Series No. 113

Plastic Mortars, Sealants, and Caulking Compounds

1979, p. 157 179

DBR Paper No. 894

Division of Building Research

RBSLMG

L'enveloppe extdrieure d'un bztiment subit des mouvements cycliques sous l'effet des conditions changeantes de tempgrature et d'humiditb. Les blbments ou sections d'un bztiment se dilatent ou se contractent en bloc sous l'effet de ces changements et ce sont les joints qui absorbent les mouvements. Pour prbvenir le passage de l'air, de l'eau ou de la poussisre, il faut sceller les joints. Les agents de scellement sont fortement sollicit6s 1 cause des importantes variations de tempdrature 2 11ext6rieur d'un bltiment, particuliSrement dans les rdgions froides. Pour l'btude de leur rendement, il fallait une mdthode d'essai qui permette d'dtablir une relation entre leur comportement en laboratoire et sur place. Dans le pr6sent article, l'auteur ddcrit la mise au point d'une telle mbthode.

Development of Test Procedure for Predicting

Performance of Sealants

K. K. KARPATI

Building Materials Section, Division of Building Research, National Research Council of Canada, Ottawa, Canada K1A OR6

The o u t s i d e envelope of a b u i l d i n g undergoes c y c l i c movements i n responding t o changing temperature and moisture c o n d i t i o n s . I t may c o n s i s t of b u i l d i n g elements such a s p a n e l s of v a r i o u s

m a t e r i a l s with j o i n t s between o r l a r g e wall s e c t i o n s i n t e r r u p t e d by expansion j o i n t s . These b u i l d i n g elements o r s e c t i o n s expand a i d c b n t r a c t i s one u n i t w i t h any change of temperature o r moisture c o n t e n t and t h e r e s u l t i n g movements a r e accommodated a t t h e j o i n t . To prevent t h e passage of water, a i r o r d u s t t h e j o i n t s must be s e a l e d . Organic m a t e r i a l s , c a l l e d s e a l a n t s ,

a p p l i e d a s v i s c o u s l i q u i d s a r e used f o r t h i s purpose. To r e g u l a t e t h e c r o s s - s e c t i o n of t h e s e a l a n t bead, a s o l i d back-up m a t e r i a l t h a t i s most f r e q u e n t l y a f l e x i b l e c l o s e d - c e l l polyethylene foam rod of c i r c u l a r c r o s s - s e c t i o n i s f i r s t placed i n t o t h e j o i n t . I t h a s t o be wider than t h e j o i n t and i s f o r c e d i n t o t h e opening i n

such a way a s t o allow t h e a p p l i c a t i o n of t h e s e a l a n t t o an even depth. The l i q u i d s e a l a n t i s applied a g a i n s t t h e back-up

m a t e r i a l , t o which i t has no adhesion, but adheres t o t h e edges of t h e b u i l d i n g elements.

The s e a l a n t i s so formulated t h a t it keeps i t s shape a s a p p l i e d and hardens through chemical o r p h y s i c a l processes t o form a v i s c o e l a s t i c r u b b e r - l i k e m a t e r i a l t h a t withstands extension o r compression. The s e a l a n t i s extended a t low temperatures and compressed a t h i g h temperatures because t h e b u i l d i n g elements meeting a t t h e j o i n t c o n t r a c t with decreasing temperature and expand with r i s i n g temperature.

The demands on s e a l a n t s a r e severe because of t h e l a r g e temperature changes imposed on t h e o u t s i d e of b u i l d i n g s ,

e s p e c i a l l y i n c o l d c l i m a t e s . To i n v e s t i g a t e t h e i r performance, a t e s t i n g procedure i s needed t h a t provides a connection between l a b o r a t o r y and outdoor behavior. A g r e a t many f a c t o r s i n f l u e n c e s e a l a n t performance and s y s t e m a t i c experimenting i s needed t o f i n d a way of t e s t i n g t h a t d e f i n e s t h e e s s e n t i a l s e a l a n t p r o p e r t i e s and d i s c a r d s t h o s e t h a t a r e secondary. Such a t e s t procedure i s based on complex r e l a t i o n s between t h e d i f f e r e n t f a c t o r s t h a t govern polymer behavior, but it can be made e a s y t o perform by means of

158 PLASTIC MORTARS, SEALANTS, AND CAULKING COMPOUNDS v a r i o u s s i m p l i f y i n g s t e p s i n t h e development of p r a c t i c a l t e s t i n g c o n d i t i o n s .

T e n s i l e T e s t

The f a c t o r s t h a t govern t h e behavior of s e a l a n t s a r e : s t r e s s , s t r a i n , temperature, r a t e o f deformation, humidity, a i r , l i g h t , type and c o n d i t i o n o f s u b s t r a t e , and presence of water o r chemicals. Of t h e s e , s t r e s s , s t r a i n , deformation r a t e , and temperature a r e of primary importance. They have t o be known simultaneously i n d e s c r i b i n g a m a t e r i a l a t any given age, humidity, s u b s t r a t e c o n d i t i o n , e t c

.

Consequently, t h e s e f o u r f a c t o r s must be included i n any t e s t method devised t o measure mechanical p r o p e r t i e s , while t h e o t h e r v a r i a b l e s must be kept c o n s t a n t a t v a l u e s considered t o be r e a l i s t i c .Cyclic t e s t s provide t h e b e s t r e p r e s e n t a t i o n of t h e c o n d i t i o n s t o which s e a l a n t s a r e s u b j e c t e d i n p r a c t i c e . They a r e v e r y complex t e s t s , however, and can be designed s a t i s f a c t o r i l y o n l y i f t h e m a t e r i a l p r o p e r t i e s a r e well known from t h e r e s u l t s o f t e s t s using s i m p l e r loading p a t t e r n s and i f t h e r a t e s a r e r e l a t e d t o t h o s e of a c t u a l j o i n t s . T e n s i l e extension a t c o n s t a n t r a t e , s t r e s s

r e l a x a t i o n under c o n s t a n t s t r a i n , and c r e e p under c o n s t a n t s t r e s s a r e t h r e e of t h e simpler t e s t s used t o o b t a i n t h e m a t e r i a l

p r o p e r t i e s of polymers. T e n s i l e e x t e n s i o n i s not t h e s i m p l e s t of t h e t h r e e t e s t s (of t h e f o u r b a s i c v a r i a b l e s o n l y temperature can be kept c o n s t a n t ) , b u t it h a s been chosen because it i s t h i s type of loading t h a t occurs i n t h e s e a l a n t i n a j o i n t when t h e chance of f a i l u r e i s most probable. There i s l e s s l i k e l i h o o d o f f a i l u r e when t h e s e a l a n t i s compressed i n summer t h a n when i t i s extended i n w i n t e r . I n a d d i t i o n , t h e t e n s i l e t e s t i s t h e l e a s t time- consuming and most l a b o r a t o r i e s a r e equipped f o r i t .

Model Specimens

A f t e r s e l e c t i n g t h e t e n s i l e t e s t a s t h e b a s i c method f o r i n v e s t i g a t i n g s e a l a n t behavior, i n b o t h l a b o r a t o r y t e s t s and o u t - door performance, t h e s i z e and shape of t h e specimen have t o be considered. T e n s i l e t e s t s a r e u s u a l l y c a r r i e d out on dumbbell o r ring-shaped specimens, s t r e s s f i e l d s of which remain p a r a l l e l during e x t e n s i o n . The t r u e s t r e s s can b e c a l c u l a t e d , t h e r e f o r e , through t h e minimum c r o s s - s e c t i o n a t any time d u r i n g t h e

experiment. S e a l a n t beads i n b u i l d i n g j o i n t s , however, have an extremely complicated s t r e s s f i e l d because t h e s i d e of t h e bead curves i n on e x t e n s i o n and t h e s t r e s s changes d i r e c t i o n ,

c o n c e n t r a t i n g a t t h e ends and edges a s e x t e n s i o n p r o g r e s s e s . Consequently, t h e specimen chosen f o r t h e i n v e s t i g a t i o n i s a model of t h e s e a l a n t bead used i n b u i l d i n g j o i n t s , i . e . , i t h a s a s t r e s s f i e l d s i m i l a r t o t h a t of t h e s e a l a n t i n a b u i l d i n g j o i n t . The model can f a i l e i t h e r cohesively o r a d h e s i v e l y , a s does a s e a l a n t i n a j o i n t . T h i s i s a d i s t i n c t advantage compared with dumbbell

12. KARPATI Testing Plustic Mmars and Sealants 159

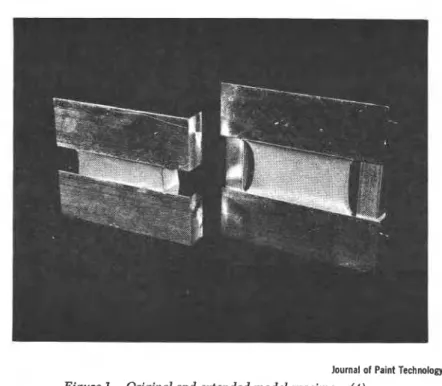

o r ring-shaped specimens t h a t can f a i l only cohesively. The model a l s o p e r m i t s t h e study of adhesive p r o p e r t i e s of s e a l a n t s on v a r i o u s s u b s t r a t e s . Another advantage of t h e model specimen i s t h a t most s t a n d a r d s c a l l f o r it and many i n v e s t i g a t o r s use i t , so t h a t d a t a a r e a v a i l a b l e f o r comparison of m a t e r i a l s o r c o n d i t i o n s . The s i z e of t h e s e a l a n t bead i s

3

x4

x 2 i n . ( 1 . 3 x 1 . 3 x 5.1 cm), a s i l l u s t r a t e d i n Figure 1, unextended and extended, t h e l a t t e r showing curved s i d e s .Deriving t h e T e s t Procedure

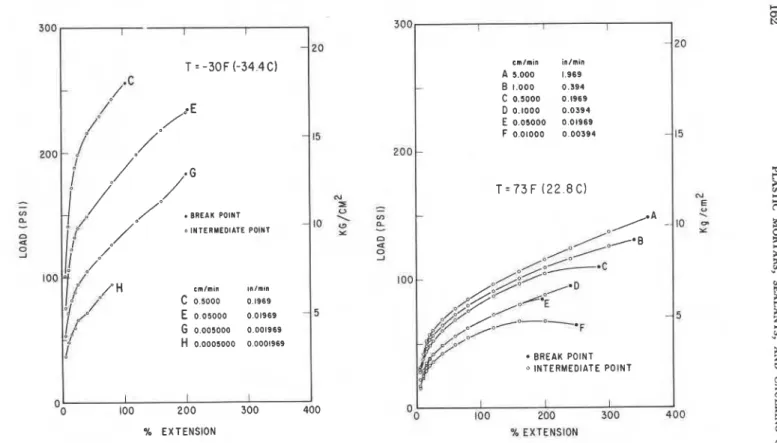

Three-Dimensional Representation. Whatever t h e c o n f i g u r a t i o n of t h e specimen, an i n f i n i t e number of t e n s i l e curves can be obtained by changing e i t h e r temperature o r t e n s i l e extension r a t e . Figure 2, f o r one-part chemically curved s i l i c o n e , and Figure 3, f o r two-part p o l y s u l f i d e model specimens, show a few examples t h a t a r e o b t a i n e d by v a r y i n g t h e t e s t c o n d i t i o n s . The q u e s t i o n a r i s e s , which of t h e t e n s i l e curves d e f i n e s t h e mechanical p r o p e r t i e s of a s e a l a n t unambiguously?

I t is known t h a t f o r some polymers, and using specimens with p a r a l l e l s t r e s s f i e l d s , a l l t e n s i l e curves can be reduced t o a s i n g l e one a t a given temperature i f t h e s t r e s s and s t r a i n a t each p o i n t o f t h e curve a r e divided by t h e s t r a i n r a t e (producing time a s a b s c i s s a ) and i f an e m p i r i c a l c o r r e c t i o n f a c t o r , A , t h e

extension r a t i o , i s a p p l i e d t o s t r e s s

(1).

T h i s treatment of r e s u l t s has a l s o been a p p l i e d (2) t o t e n s i l e curves obtained with t h e model specimens. The r e s u l t i n g s i n g l e curves of u n i t s t r a i n r a t e a r e shown i n Figures 4 and 5, derived from Figures 2 and 3 , r e s p e c t i v e l y . A s may be seen, t h e f i t of t h e i n d i v i d u a l t e n s i l e curves t o t h e s i n g l e curve of u n i t s t r a i n r a t e i s e x c e l l e n t f o r s i l i c o n e and w i t h i n a c c e p t a b l e l i m i t s f o r p o l y s u l f i d e s e a l a n t s . T h i s proves t h a t t h e model specimen can be used f o r ani n v e s t i g a t i o n intended t o e s t a b l i s h t h e interdependence of t h e t e n s i l e curves. I t would permit t h e d e r i v a t i o n of a simple and r a t i o n a l method f o r p r e s e n t i n g t h e deformation c h a r a c t e r i s t i c s of s e a l i n g m a t e r i a l s .

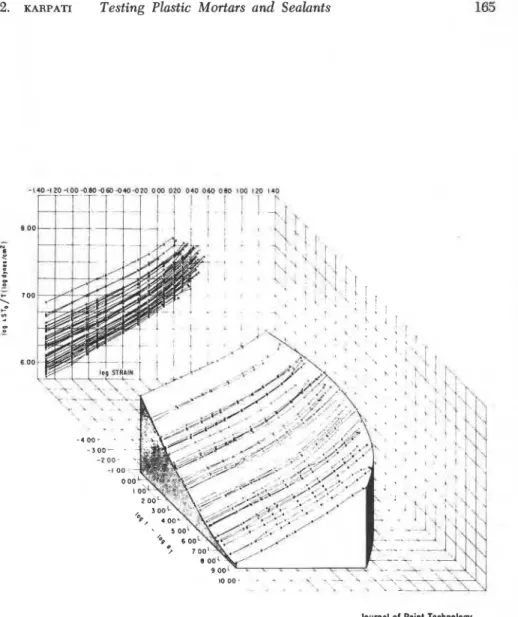

The u n i t s t r a i n r a t e curves a r e n o t f u l l y s u i t a b l e f o r d e s c r i b i n g t h e behavior o f s e a l a n t s , f o r they give l i t t l e information on f a i l u r e behavior because t h e f a i l u r e p o i n t s f o r given c o n d i t i o n s f a l l a t v a r i o u s p o i n t s on them. To i n v e s t i g a t e f a i l u r e p r o p e r t i e s a s a f u n c t i o n of t h e f o u r b a s i c v a r i a b l e s a three-dimensional system has t o be used: an example i s shown i n Figure 6 f o r two-part p o l y s u l f i d e s e a l a n t . Each l i n e r e p r e s e n t s a t e n s i l e curve, c a l c u l a t e d from t h e o r i g i n a l curves, and t h e f a i l u r e p o i n t s form t h e upper curved edge of t h e three-dimensional r e p r e s e n t a t i o n .

There a r e s e v e r a l s t e p s of c a l c u l a t i o n involved i n a r r i v i n g a t t h e three-dimensional p r e s e n t a t i o n . They a r e necessary i n o r d e r t o reduce t h e number of v a r i a b l e s from f o u r t o t h r e e . The f i r s t s t e p i n o b t a i n i n g t h e curves i n Figure 6 i s t o r e c a l c u l a t e

160 PLASTIC MORTARS, SEALANTS, AND CAULKING COMPOUNDS

Journal of Paint Technology Figure 1 . Original and extended model specimens (4 )

3 0 0 I I I T = -30F (-34 4C) - zoo 300 2 0 I5 200 I I I 20 c m l m l n l n l m l n A 5 000 1969

-

-

B I 0 0 0 0 394 c 0 5000 0 1969 D 0 I000 0 0 3 9 4 E 0 05000 0 01969 F 0 OlOOO 0 00394 - (U T = 7 3 F ( 2 2 8C) N 15 V) 0-

o INTERMEDIATE POlNT n 4: 0 -1 '0° "Hc

c n l m t n 0 5000 0 1969 lnlmln E 0 05000 001969 - G 0 005000 0 001969d

H 0 0005000 0 0001969Z

=: U E3

n 1-

.

- 1 0 Q Xz

n 0 a 0?3

J b"Z

100 0) m 2- F -- 5 BREAK POINT k INTERMEDIATE POINT8

n Oo I I I 100 2 0 0 3 0 0 4 0 0 Oo I00 I 200 I 3 0 0 I 400 E % EXTENSION % EXTENSION n 0Journal of Paint Technology

Figure 3. Tensile curves of polysulfde specimens at different extension rates and two tempem-

8

z tures ( 4 )Journs! of Paimt Technology Figure 4. Tensile curves reduced to unit strain rate for silicone specimens at difment tempera-

164 PLASTIC MORTARS, SEALANTS, AND CAULKING COMPOUNDS I 1 I I I -2.00 -1.00 0 00 1 0 0 2 0 0 3.00 4.00 l o g I (mi111 T = 7 3 F ( 2 2 8 C I To= -3OF(-34 4C) t.l.8. I"1.II A so00 IS'* B l a 0 0 0 334 c OSOOO 0 191% D 0 IWO 0 0 3 9 4 E 0 05000 0 air** F o o l o o o o o o r r r I R E & # WtUl " IWlERUEDIAT€ POlUT lop I lminl

Journal of Paint Technology Fi use 5. Tensile curves reduced to unit strain rate for polysulfide specimens at d i e r e n t temperatures (4): A, extension ratio; R, strain rate; T, test temperature, degree Keluin; To, reference temperature, degree Keluin; t, time; and S , load.

12. KARPATI Testing Plastic Mortars and Sealants 165

Journal of Paint Technology

Figure 6. The property surface for polysulfide sealant (4); A, extension ratio; S , load; T , test temperature, degree Kelvin; To, reference temperature, degree Kel-

166 PLASTIC MORTARS, SEALANTS, AND CAULKING COMPOUNDS

each p o i n t of t h e o r i g i n a l t e n s i l e curves f o r p l o t s of t h e type shown i n Figure 7 . The a b s c i s s a i s t h e logarithm of time, d e r i v e d by d i v i d i n g t h e s t r a i n by t h e s t r a i n r a t e , and t h e o r d i n a t e i s t h e load c o r r e c t e d f o r " t r u e s t r e s s " by

A,

t h e extension r a t i o , and by To/T, t h e r e f e r e n c e temperature divided by t h e t e s t temperature, b o t h i n degrees Kelvin(2).

The temperature c o r r e c t i o n i s t h a t r e q u i r e d by t h e t h e o r y of r u b b e r l i k e e l a s t i c i t y . Figure 8 i s t h e p r o j e c t i o n of t h e o r i g i n a l t e n s i l e curves on t h e s t r e s s v e r s u s time p l a n e . These curves a r e shown a s d o t t e d l i n e s i n F i g u r e 7 . The continuous l i n e s a r e t h e b e s t f i t s connecting t h e t e n s i l e curves a t 5, 10, 15, 20, 25, 40, 60, 80, 120, 160 and 200 p e r cent e x t e n s i o n s . From t h i s p l o t t h e i s o c h r o n a l s t r e s s - s t r a i n curves can be derived by r e a d i n g v a l u e s from t h e b e s t f i t t i n g l i n e s f o r a given time. The times chosen were t h o s e a t which f a i l u r e occurred f o r each specimen. The a c t u a l breaking s t r e s s e s and a s s o c i a t e d s c a t t e r were thereby p r e s e r v e d . The i s o c h r o n a l curves a r e shown i n t h e background of Figure 6 i n t h e log s t r e s s - l o g s t r a i n p l a n e . The t h i r d dimension i s added by s h i f t i n g t h e c u r v e s along t h e time a x i s , which i s p e r p e n d i c u l a r t o t h i s plane, according t o t h e time a t which each curve was r e a d . T h i s procedure i s followed f o r each temperature, and with t h e h e l p of t h e WLF s h i f t f a c t o r , a ~ , curves o b t a i n e d a t a l l temperatures a r e i n c o r p o r a t e d i n t h e onethree-dimensional r e p r e s e n t a t i o n .

I t must b e recognized t h a t f o r s i l i c o n e s e a l a n t s t h e time- temperature s u p e r p o s i t i o n was not n e c e s s a r y because t h e u n i t s t r a i n r a t e curves f e l l on t h e same cumulative s i n g l e l i n e a t each temperature (Figure 4 ) . I n o t h e r words, t h e s i l i c o n e s e a l a n t was i n s e n s i t i v e t o temperature changes w i t h i n t h e temperature r e g i o n observed and w i t h i n experimental e r r o r .

The WLF s h i f t f a c t o r was a l s o i n v e s t i g a t e d and experimentally d e r i v e d f o r p o l y s u l f i d e s e a l a n t u s i n g t h e model specimen

(A).

The b e s t - f i t t i n g (continuous) l i n e s of t h e v a r i o u s e x t e n s i o n s (Figure7) were used a s g u i d e l i n e s f o r manually s h i f t i n g t h e p l o t s o b t a i n e d a t d i f f e r e n t temperatures along t h e time a x i s u n t i l t h e l i n e s f o r each e x t e n s i o n formed a smooth curve ( F i g u r e 8 ) . From t h e measured s h i f t s t h e c o n s t a n t s o f t h e WLF equation, o f t e n r e f e r r e d t o a s " u n i v e r s a l c o n s t a n t s , " were c a l c u l a t e d and compared w i t h c o n s t a n t s o b t a i n e d f o r o t h e r polymers. The d i f f e r e n c e

between t h o s e c a l c u l a t e d h e r e and t h e u n i v e r s a l c o n s t a n t s was small, b u t it was l a r g e enough t o r e q u i r e u s e o f t h e former i n s h i f t i n g t h e s e a l a n t d a t a .

The s u r f a c e formed by t h e c a l c u l a t e d curves s h i f t e d along t h e log t

-

l o g a ~ a x i s (Figure 6) i s t h e p r o p e r t y s u r f a c e of t h e p o l y s u l f i d e s e a l a n t . A s i m i l a r s u r f a c e could be derived f o r t h e s i l i c o n e s e a l a n t . The three-dimensional system g i v e s a complete and coherent d e s c r i p t i o n o f s e a l a n t p r o p e r t i e s , i . e . , from a s i n g l e t e n s i l e curve any o t h e r can be c a l c u l a t e d once t h i s system i s known. I t i s , however, t o o complex f o r everyday use and i n t h e n e x t phase of t h e i n v e s t i g a t i o n s t e p s were taken t o d e r i v e a s i m p l e r way o f c h a r a c t e r i z a t i o n .12. KARPATI Testing Plastic Mortars and Sealants 167 cmlmin ~ m l m i l BREAK POINT A 5.000 1.969 INTERMEDIATE POINT 8 1.000 0.394 c 0 5000 0.1969 0 O.lOO0 0 0394 E 0.05000 0 01969 F O.OlOO0 0 00394 log t(m1n1

Journal of Paint Technology

Figure 7. Time dependence of stress at 73OF ( 4 )

8 . 0 0 1 1 1 1 1 1 , 1 1 1 1 1 - 3

.

-wr.

-*or.

OF s mr 7JF.

100f 7.00 --

2 6.00 - T = T o = -30F(-34.4C3 5 0 0 1 1 1 ~ ~ ~ 1 1 1 1 1 1 - 4 0 0 -3.00 -2.00 -1 0 0 0 0 0 1.00 2 0 0 3.00 4.00 5.00 6 0 0 7.00 8.00 log t-

log OTJournal of Paint Technology

168 PLASTIC MORTARS, SEALANTS, AND CAULKING COMPOUNDS P r o j e c t i o n s o f t h e Three-Dimensional System. To s i m p l i f y t h e three-dimensional system, i t s p r o j e c t i o n s i n t o t h e v a r i o u s p l a n e s I can b e used. I n p a r t i c u l a r , t h e p r o j e c t i o n of t h e break p o i n t s i s

important because they d e f i n e t h e l i m i t a t i o n s s e a l a n t s have i n p r a c t i c e . Their p r o j e c t i o n i n t h e log s t r e s s - l o g s t r a i n plane i s t h e f a i l u r e envelope

(5) shown f o r p o l y s u l f i d e s e a l a n t i n Figure

9 .The o u t e r l i m i t of t h e envelope is well d e f i n e d and i s drawn i n with a dashed l i n e , b u t t h e i n n e r one d i s a p p e a r s i n t h e s c a t t e r . For t h e s i l i c o n e s e a l a n t , Figure 10 gives t h e f a i l u r e envelope where both t h e upper and lower l i m i t s a r e well d e f i n e d .

The f a i l u r e envelope i s used i n t h e l i t e r a t u r e t o c h a r a c t e r i z e polymers because it i s independent of time and temperature, but i t s u s e f u l n e s s i s l i m i t e d with s e a l a n t s . From t h e p o i n t of view of s e a l a n t performance, t h e p r o j e c t i o n o f t h e f a i l u r e p o i n t s i n t o t h e log s t r a i n - l o g time plane i s t h e most important c h a r a c t e r i z a t i o n ; it i s t h e s t r a i n t h a t i s imposed on t h e s e a l a n t by t h e movement of t h e j o i n t and t h e s t r e s s develops a s a consequence of t h e imposed s t r a i n . Consequently, t h e design o f a s e a l e d j o i n t i s u s u a l l y based on an e s t i m a t e o f s t r a i n , n o t of s t r e s s , and t h e s e a l a n t i s chosen according t o i t s movement c a p a b i l i t y , t h a t i s , t h e

+

p e r c e n t movement t h e s e a l a n t can t a k e without f a i l u r e i n a y e a r l y movement. S t r e s s h a s t o be considered only i n t h o s e r a r e c a s e s where t h e s u b s t r a t e i s a f r a g i l e , porous m a t e r i a l whose t e n s i l e s t r e n g t h approaches t h a t of s e a l a n t s . In t h i s c a s e , a s e a l a n t w i t h t h e lowest s t r e n g t h p o s s i b l e has t o be chosen. P r o j e c t i o n s of t h e f a i l u r e p o i n t s a r e shown i n F i g u r e s 11 and 12 f o r s i l i c o n e and p o l y s u l f i d e s e a l a n t s , r e s p e c t i v e l y . The p o i n t s p l o t t e d i n t h e curves r e p r e s e n t t h e s t r a i n a t break a t t h e time needed t o reach t h e b r e a k . For s i l i c o n e s e a l a n t s it was found t h a t t h e break p o i n t s o b t a i n e d a t room temperature a r e s u f f i c i e n t f o r a f i n a l a n a l y s i s . For p o l y s u l f i d e , d a t a o b t a i n e d a t seven d i f f e r e n t temperatures a r e used, reduced t o -30°F(-34.4OC)

.

The time dependence of t h e s t r a i n a t break i s v e r y d i f f e r e n t f o r t h e two t y p e s o f s e a l a n t . The break p o i n t s of t h e s i l i c o n e d a t a can be f i t t e d by a s t r a i g h t l i n e , and confidence l i m i t s a t v a r i o u s l e v e l s can be drawn on t h e p l o t (Figure 1 1 ) . The b r e a k I p o i n t s of t h e two-part p o l y s u l f i d e s e a l a n t form a broad band, t h e

upper and lower l i m i t s o f which a r e drawn q u a l i t a t i v e l y . The upper l i m i t i s b e t t e r defined t h a n t h e lower one ( a s f o r t h e f a i l u r e envelope). Because of t h e d i f f e r e n c e between t h e p l o t s f o r s i l i c o n e and p o l y s u l f i d e s e a l a n t s t h e f u r t h e r s i m p l i f i c a t i o n o f c h a r a c t e r i z a t i o n i s d i f f e r e n t f o r t h e two t y p e s of s e a l a n t .

S i l i c o n e S e a l a n t . F a i l u r e o f t h e s i l i c o n e specimens occurred a t i n c r e a s i n g l y l o n g e r t i m e s w i t h d e c r e a s i n g s t r a i n r a t e s ,

covering 46 time decades, measured i n minutes. With an e x t r a p o l a - t i o n o f

14

time decade, t h e e x t e n s i o n a t f a i l u r e a t h a l f a year can be e s t i m a t e d . In Figure 11 t h e v a l u e obtained i s 28 p e r c e n t ,12. KARPATI Testing Plastic Mortars and Sealants 169

log STRAIN

Journal of Paint Technology

170 PLASTIC MORTARS, SEALANTS, AND CAULKING COMPOUNDS 9 00 4

-

10°F (-23 3 "C) 8.00 3-

-

2

z z_ WF

-

X n m-

a-

2

5

7,OO 2 6.00 -1.20 - 0 8 0 -0 40 0.00 0.40 0 8 0 120 LOG STRAINJournal of Paint Technology

12. KARPATI Testing Plastic Mortars and Sealants 171

MIN HR DAYS MO YEARS

H +-

-

-41 10 1 3 1 7 1 3 6 1 2 10

0 0 0 2 0 0 4 0 0 6 0 0 8 0 0 LOG TIME (MINI

Journal of Paint Technology Figure 11. Time dependence of strain at break; silicone sealant at 72OF (22°C)

12. KARPATI Testing Plastic Mortars and Sealants 173

with 95 p e r cent confidence l i m i t s of 57 and 14; t h a t i s , 95 out of 100 t e s t s w i l l give f a i l u r e p o i n t s i n s i d e t h i s confidence i n t e r v a l . Although t h e c h a r a c t e r i z a t i o n could be done a t any time v a l u e , t h e choice of h a l f a y e a r has t h e advantage of being a c r i t i c a l time i n t h e l i f e of a s e a l a n t a s , on average, h a l f a y e a r i s reached i n w i n t e r , a t maximum e x t e n s i o n . I f a s e a l a n t does n o t f a i l during t h e f i r s t w i n t e r , t h e r e i s a good chance t h a t it w i l l

l a s t f o r many y e a r s .

I t has t o be pointed out t h a t t h e s i n g l e v a l u e , 28 p e r c e n t , i s based on one b a t c h of a one-part chemically-cured white

s i l i c o n e s e a l a n t . This s i n g l e v a l u e i s p r e s e n t e d o n l y a s an i l l u s t r a t i o n of t h e t e s t i n g procedure. One can expect v a r i a t i o n s from b a t c h t o b a t c h and from manufacturer t o manufacturer. Another important f a c t o r t h a t may i n f l u e n c e t h e c h a r a c t e r i s t i c s i n g l e v a l u e i s t h e aging process t o which t h e s e a l a n t i s s u b j e c t e d b e f o r e t e s t i n g (one month a t 70°C i n t h i s c a s e ) . I t i s o n l y a f t e r i n v e s t i g a t i o n o f a l l t h e above f a c t o r s t h a t a s i n g l e extension value with i t s confidence l i m i t s can be d e r i v e d t o c h a r a c t e r i z e a l l chemically-cured s i l i c o n e s e a l a n t s a v a i l a b l e on t h e market. Such work would need cooperation on t h e p a r t of manufacturers, but

it would remove much of t h e u n c e r t a i n t y involved i n s e a l e d j o i n t d e s i g n .

P o l y s u l f i d e S e a l a n t . The s i n g l e value and i t s confidence l i m i t s have t o be derived i n a d i f f e r e n t manner f o r two-part p o l y s u l f i d e s e a l a n t s because of t h e f l a t maximum formed by t h e break p o i n t s . Another d i f f e r e n c e from t h e r e s u l t s obtained f o r s i l i c o n e s e a l a n t s i s t h a t t h e t e n s i l e p r o p e r t i e s change w i t h temperature. To c h a r a c t e r i z e extreme w i n t e r c o n d i t i o n s when f a i l u r e i s most probable t h e e x t e n s i b i l i t y i s given f o r -30°F (-34.4OC) (Figure 12)

.

According t o t h e lower l i m i t (drawn by dashed l i n e ) , t h e s e a l a n t can l a s t about 20 y e a r s a t about 100 p e r c e n t extension a t t h i s temperature. T h i s e s t i m a t e i s supported by only a few p o i n t s i n t h e neighborhood of t h i s r e a d i n g . A b e t t e r way o f c h a r a c t e r i z i n g t h e s e a l a n t i s t o c o n s i d e r t h a t a l l t h e r e a d i n g s belong t o t h e same "populationt1 and c a l c u l a t e t h e mean of t h e l o g a r i t h m i c s t r a i n ; t h i s can be done because of t h e f l a t maximum. From t h e mean and i t s standard d e v i a t i o n one canc a l c u l a t e t h e e x t e n s i b i l i t y a t which o n l y 1 per c e n t o f t h e t e s t s

w i l l f a i l ; t h i s was 119 per c e n t i n t h e p a r t i c u l a r b a t c h used. The same a p p l i e s f o r p o l y s u l f i d e a s f o r s i l i c o n e s e a l a n t s : s e v e r a l manufacturerst p r o d u c t s and b a t c h e s would have t o b e t e s t e d

following t h e method described and t h e aging process i n v e s t i g a t e d i n o r d e r t o d e r i v e an e x t e n s i b i l i t y v a l u e t h a t a p p l i e s t o a l l good q u a l i t y two-part p o l y s u l f i d e s e a l a n t s .

I C y c l i c T e s t s

1

S e a l a n t s undergo d a i l y c y c l e s superimposed on t h e y e a r l y one a s b u i l d i n g movements follow weather c o n d i t i o n s . To i n v e s t i g a t e

174 PLASTIC MORTARS, SEALANTS, AND CAULKING COMPOUNDS

t h e connection between t e n s i l e and c y c l i c a l behavior, model specimens of one-part chemically-cured s i l i c o n e s e a l a n t were

s t r a i n cycled on a t e n s i l e t e s t e r

(6).

The amplitude and r a t e oft h e c y c l e s occurring i n p r a c t i c e were known from j o i n t movement

i n v e s t i g a t i o n s

(z,

8,

9,

E).

The average d a i l y movement i s about24 per cent of j o i n t width f o r a j o i n t t h a t moves '25 p e r c e n t a

y e a r . The s i l i c o n e s e a l a n t model specimen, t h e o n l y s e a l a n t type

used f o r t h e c y c l i c a l experiments so f a r , showed rubbery behavior when cycled a t 24 p e r c e n t . To cause f a i l u r e , t h e d a i l y c y c l e s

had t o be superimposed on t h e maximum y e a r l y e x t e n s i o n . For

example, specimens were cycled between 25+4 and 25-4 p e r c e n t

e x t e n s i o n s . By choosing t h e c y c l e s i n t h i s manner t h e l a b o r a t o r y

s t r a i n r a t e s were brought a s c l o s e a s p r a c t i c a l l y p o s s i b l e t o

a c t u a l j o i n t movement r a t e s . I t was a l s o n e c e s s a r y t o d e f i n e t h e

number of d a i l y c y c l e s t o be imposed. Various c o n s i d e r a t i o n s led

t o t h e s e l e c t i o n of 120 c y c l e s . I t became c l e a r from t h e

experiments t h a t a number of c y c l i c a l t e s t s a t i d e n t i c a l

c o n d i t i o n s were needed i n o r d e r t o e s t a b l i s h t h e p r o b a b i l i t y of 50 per cent f a i l u r e . F a i l u r e s occur with a s c a t t e r , and i f a l l

t e s t s pass o r f a i l one does not know what t h e f a i l u r e l i m i t i s .

In a s e r i e s of experiments t h e i n i t i a l extension, t h e super-

imposed c y c l e s , and t h e r a t e of movement were v a r i e d . For t h e

p a r t i c u l a r b a t c h of s i l i c o n e s e a l a n t used i t was found t h a t f o r a

1

25 p e r c e n t e x t e n s i o n a c y c l i c a l movement of '8 per c e n t had t o besuperimposed a t a r a t e of movement of 1.0 cm/min i n o r d e r t o a c h i e v e c l o s e t o (but l e s s than) 50 p e r c e n t f a i l u r e i n t h e number

of specimens t e s t e d . Lower r a t e s o r h i g h e r e x t e n s i o n s a t t h e same

r a t e of movement produced more f a i l u r e s . For example, t h e number of f a i l u r e s i n c r e a s e d t o f o u r - f i f t h s o f t h e t o t a l number of t e s t s when e i t h e r t h e above 28 p e r c e n t t o 212 p e r c e n t were i n c r e a s e d o r when t h e r a t e from 1 . 0 t o 0 . 1 cm/min was decreased.

These r e s u l t s can be explained i f t h e y a r e examined i n conjunction with Figure 13, which i s s i m i l a r t o Figure 11 except

t h a t another b a t c h of s e a l a n t was used. The s t r a i n s and r a t e s

used i n t h e c y c l i c a l t e s t s can be l o c a t e d i n t h i s p l o t . The

f a i l u r e p o i n t s a t each r a t e form a l i n e almost p e r p e n d i c u l a r t o t h e b e s t - f i t l i n e , t h e alignment of t h e p o i n t s being i n d i c a t e d by

arrows. Close t o t h e i n t e r s e c t i o n of a l i n e formed by t h e break

p o i n t s and t h e lower confidence l i m i t one may read t h e e x t e n s i o n

on which t h e d a i l y c y c l e should be superimposed t o o b t a i n

approximately 50 per c e n t f a i l u r e i n a c y c l i c a l experiment. The

i n i t i a l l y imposed s t r a i n with t h e superimposed d a i l y c y c l e s should reach l e s s t h a n h a l f way t o t h e b e s t - f i t l i n e . The f u r t h e r one e n t e r s i n t o t h e confidence l i m i t s by changing any of t h e c y c l i n g c o n d i t i o n s , i . e . , proceeding v e r t i c a l l y on t h e p l o t by i n c r e a s i n g t h e s t r a i n o r h o r i z o n t a l l y toward decreasing s t r a i n r a t e , t h e g r e a t e r t h e chances of f a i l u r e

I f t h i s c o r r e l a t i o n of t e n s i l e b r e a k s and f a i l u r e s obtained

from t h e c y c l i n g t e s t s i s v a l i d a t r a t e s of t h e n a t u r a l l y

o c c u r r i n g average d a i l y c y c l e s (0.00014 cm/min

(k)),

then f a i l u r e12. KARPATI Testing Plastic Mortars and Sealants 175 13 one r e a d s approximately 13 p e r cent extension a t 0.00014 cm/min r a t e a t t h e lower confidence l i m i t . This p r e d i c t s a f a i l u r e f o r t h i s p a r t i c u l a r batch o f s i l i c o n e s e a l a n t a t a much lower y e a r l y e x t e n s i o n than t h e 220 t o +25 p e r c e n t claimed by manufacturers a s movement c a p a b i l i t y . The b a t c h used f o r o b t a i n i n g t h e d a t a

published by Karpati

(9

i s , however, w i t h i n t h e claimed v a l u e s . Apart from t h e l a r g e v a r i a t i o n from batch t o b a t c h , t h i s shows t h a t t h e c o r r e l a t i o n of t e n s i l e d a t a with c y c l i n g t e s t s should be experimentally v e r i f i e d . Laboratory c y c l i n g t e s t s a r e i m p r a c t i c a l a t t h i s r a t e o f one c y c l e p e r day and t h e c y c l i n g f a c i l i t i e s used f o r exposure o f s e a l a n t s have t o be u t i l i z e d .Weathering S e a l a n t s

Once a simple but e f f e c t i v e means of c h a r a c t e r i z i n g t h e s e a l a n t by a l a b o r a t o r y t e s t method was found, outdoor exposures were s t a r t e d . The r e s u l t i n g changes i n s e a l a n t p r o p e r t i e s a r e being followed by t h i s t e s t procedure a s w e l l a s by v i s u a l a s s e s s - ment of t h e degree o f f a i l u r e . D i f f e r e n t methods o f exposing s e a l a n t specimens t o outdoor weathering a r e used: a s t r a i n c y c l i n g weathering rack, a rack t h a t imposes no movement on t h e specimens, and v i c e - t y p e devices where t h e movement i s produced by manual adjustments.

A v e r t i c a l weathering r a c k 12.5 m (41 f t ) long and 1 . 1 m (3.5 f t ) wide, accommodating 216 model specimens

(g),

was e r e c t e d i n a p o s i t i o n f a c i n g s o u t h (Figure 1 4 ) . The rack u t i l i z e s t h e d i f f e r e n c e i n t h e thermal c o e f f i c i e n t s of expansion o f s t e e l and aluminum t o produce c y c l i c movements i n response t o temperature changes. I t has a r i g i d s t e e l frame t o which aluminum b a r s a r e a t t a c h e d a t one end, l e a v i n g them f r e e t o move on t h e o t h e r end. D i f f e r e n t i a l movement between t h e b a r and t h e frame i s t r a n s f e r r e d t o t h e s e a l a n t specimens with t h e h e l p of v e r t i c a l aluminum p l a t e s a t t a c h e d t o t h e s t e e l o r t o t h e aluminum b a r s . Figure 15 shows t h e b o l t i n g of t h e specimens t o t h e v e r t i c a l p l a t e s . The frame i s so c o n s t r u c t e d t h a t on t h r e e q u a r t e r s o f t h e t o t a l a r e a t h e y e a r l y movement i n c r e a s e s from about +9 t o 230 per c e n t i n 36 increments, t h e amount of movement b e i n g dependent on t h e weather of each y e a r .On t h e remaining one q u a r t e r o f t h e a r e a movement i s t h e same on a l l specimens, being about ?13 p e r c e n t p e r year. With t h i s arrangement t h e l i m i t i n g movement above which a s e a l a n t s t a r t s t o f a i l can b e determined from a s e r i e s o f specimens exposed t o v a r i o u s amounts o f y e a r l y movement. Specimens t h a t do n o t f a i l can be s u b j e c t e d t o t h e t e s t i n g procedure d e s c r i b e d above a t chosen time i n t e r v a l s . Visual assessment of t h e specimens provides i n f o r - mation on t h e i r performance c h a r a c t e r i s t i c s ; t h e t e n s i l e t e s t s made on t h e specimens provide a b a s i s f o r t h e d e s i g n of a c c e l e r a t e d aging t e s t s r e l a t e d t o performance. The e v a l u a t i o n o f t h e

performance o f v a r i o u s types o f s e a l a n t during a t h r e e - y e a r p e r i o d i s i n p r o g r e s s and w i l l be published i n t h e n e a r f u t u r e .

176

-

PLASTIC MORTARS, SEALANTS, AND CAULKING COMPOUNDS M I N H t, _MO_ Y E A R S 0 . 2 0-

0 1I 1 01 1I 3 1 7 1 3 6 1 10 I I I I I l l 1 ' 160-

120-

100 9 0-

80-

70 - 0 . 2 0-

-

6 0-

5 0 2 0 Z-

25-

20*

- 0 . 8 0-

c m l m i n-

15 - 1 . 0 0-

-

10 - 1 . 0 0 0 . 0 0 1 . 0 0 2..00 3 . 0 0 4 . 0 0 5 . 0 0 6 . 0 0 7 . 0 0 LOG TIME. M I NFigure 13. Time dependence of tensile strain at break for the batch of silicone sealant used in cyclical tests (13)

~ ~ - - - ~

Journal of Paint Technology

12. K A R P A ~ Testing Plastic Mortars and Sealants 177

S u f f i c i e n t l y l a r g e d i f f e r e n t i a l movements c a n o n l y b e produced w i t h a l a r g e s i z e r a c k . Because few u s e r s o r manufac- t u r e r s c a n a f f o r d t h e c o n s t r u c t i o n o f t h i s r e l a t i v e l y e x p e n s i v e r a c k , t h e r e i s need f o r a s i m p l e , i n e x p e n s i v e d e v i c e t h a t c a n s u b j e c t s e a l a n t specimens t o e x t e n s i o n and compression w h i l e exposed o u t d o o r s o r t o v a r i o u s imposed c o n d i t i o n s . The d e v i c e shown i n F i g u r e 1 6 w a s developed t o meet t h e s e r e q u i r e m e n t s

(12).

The d e v i c e i s d e s i g n e d t o h o l d a s i n g l e specimen a n d t o i n p o s e i n t e r m i t t e n t movement on t h e s e a l a n t by manual a d j u s t m e n t of width, i n c o n t r a s t w i t h t h e c y c l i c a l movement' on t h e w e a t h e r i n g r a c k where it is c o n t i n u o u s and a u t o m a t i c . The d e v i c e r e s e m b l e s a v i c e ; t h e d i s t a n c e between t w o aluminum b l o c k s c a n b e a d j u s t e d by a screw t r a v e r s i n g t h e c e n t e r of b o t h b l o c k s s o t h a t t h e d i s t a n c e between them c a n b e v a r i e d between 0 and 5 cm ( 2 i n . ) . The specimen i s a t t a c h e d t o t h e aluminum b l o c k s . Tension o r compression can b e imposed on t h e s e a l a n t bead by v a r y i n g t h e d i s t a n c e between t h e b l o c k s . Up t o 300 p e r c e n t e x t e n s i o n can b e produced on a s t a n d a r d

1 . 3 cm (0.50 i n . ) specimen. Exposure and e v a l u a t i o n of v a r i o u s t y p e s o f s e a l a n t u s i n g t h i s d e v i c e a r e i n p r o g r e s s .

Summary

The p r o p e r t i e s of h i g h performance b u i l d i n g s e a l a n t s have been s t u d i e d a s a f u n c t i o n o f f o u r v a r i a b l e s : s t r e s s , s t r a i n , time and t e m p e r a t u r e , u s i n g t e n s i l e t e s t s . By t i m e - t e m p e r a t u r e s u p e r p o s i t i o n t h e number of v a r i a b l e s c a n b e reduced t o t h r e e and t h e m a t e r i a l p r o p e r t i e s c h a r a c t e r i z e d i n a t h r e e - d i m e n s i o n a l c o o r d i n a t e system. For s e a l a n t s t h e p r o j e c t i o n o f t h e f a i l u r e p o i n t s t o t h i s system i n t h e l o g s t r a i n v e r s u s l o g time p l a n e i s s u f f i c i e n t f o r c h a r a c t e r i z a t i o n . F u r t h e r s i m p l i f i c a t i o n c a n b e made depending on t h e p r o p e r t i e s of t h e v a r i o u s t y p e s o f s e a l a n t . S i l i c o n e s e a l a n t t e n s i l e f a i l u r e d a t a c a n be f i t t e d by a s t r a i g h t l i n e i n t h e l o g s t r a i n v e r s u s l o g time p l o t and t h e equa- t i o n of t h e l i n e c h a r a c t e r i z e s t h e s e a l a n t . A p o s s i b l e f u r t h e r s i m p l i f i c a t i o n i s t o s p e c i f y a s a c h a r a c t e r i s t i c o f t h e s e a l a n t t h e s t r a i n o f f a i l u r e , w i t h i t s c o n f i d e n c e l i m i t s , f o r a n a r b i t r a r i l y chosen t i m e . The f a i l u r e p o i n t s o f p o l y s u l f i d e s e a l a n t s f a l l on a b r o a d band w i t h a f l a t maximum. T h i s f a m i l y o f s e a l a n t s i s b e s t c h a r a c t e r i z e d by t h e a v e r a g e o f t h e l o g s t r a i n a t f a i l u r e and t h e a s s o c i a t e d c o n f i d e n c e l i m i t s f o r a s u f f i c i e n t number of t e s t s . C y c l i c a l movements a r e more d i f f i c u l t t o a n a l y s e t h a n t e n s i l e b e h a v i o r and have been i n v e s t i g a t e d f o r s i l i c o n e s e a l a n t s o n l y . A

c o n n e c t i o n between c y c l i c a l and t e n s i l e t e s t s h a s been found b y

, comparing t h e s t r a i n a t f a i l u r e f o r c y c l e t e s t i n g on a l o g s t r a i n

;

v e r s u s log time p l o t w i t h t h a t f o r f a i l u r e i n s i m p l e t e n s i o n . T h i s c o n n e c t i o n e n a b l e s some d e g r e e of p r e d i c t i o n o f performance,i . e . , b e h a v i o r f o r c y c l i n g t h a t o c c u r s under n a t u r a l c o n d i t i o n s . The c y c l i c a l t e s t s have shown t h a t lowering t h e c y c l i n g r a t e o r i n c r e a s i n g t h e s t r a i n a t a g i v e n r a t e i n c r e a s e s t h e p r o b a b i l i t y of

178 PLASTIC MORTARS, SEALANTS, AND CAULKING COMPOUNDS

I

Figure 15. Bolting the specimens to the strain cycling weathering rack

Journal of Paint Technology

12. KARPATI Testing Plastic Mortars

and

Sealants 179f a i l u r e . I f it can be shown t h a t t h e r e l a t i o n between s t r a i n t o f a i l u r e f o r c y c l i c a l and t e n s i l e t e s t s i s a l s o v a l i d f o r c y c l i n g a t a d a i l y r a t e , then p r e d i c t i o n o f performance can be made based on t e n s i l e t e s t s . The r e s u l t s suggest t h a t f a i l u r e o f s i l i c o n e s e a l a n t might o c c u r under n a t u r a l c y c l i n g c o n d i t i o n s a t a lower e x t e n s i o n than t h e claimed e x t e n s i b i l i t y . A t slow r a t e s (one c y c l e per day) l a b o r a t o r y c y c l i n g i s n o t p r a c t i c a l . An exposure rack and a hand-adjusted d e v i c e have been developed f o r imposing d a i l y c y c l e s o f s t r a i n s on s e a l a n t specimens. T h i s i n v e s t i g a t i o n of t h e e f f e c t o f weathering and s t r a i n c y c l e s on s e a l a n t s i s c o n t i n u i n g and r e s u l t s w i l l be published i n t h e n e a r f u t u r e .

This paper i s a c o n t r i b u t i o n from t h e Division of Building Research, National Research Council of Canada and i s published with t h e approval o f t h e D i r e c t o r of t h e Division.

L i t e r a t u r e C i t e d

1. Smith, Thor. L . , J . Polymer Science, 1956,

-

XX, 89. 2. Karpati, K . K . , J . P a i n t Technol., 1972,44,

(571), 75-85. 3. Williams, M.L., Landel, R.F. and Ferry, J . D . , J . Amer. Chem.SOC., 1955, LXXVII, 3701.

-

4 . Karpati, K. K . , J . P a i n t Technol., 1973,

-

45, (580), 49-57. 5. "Fracture Processes i n Polymeric solid^,^^ B.

Rosen, Ed.,I n t e r s c i e n c e Publs. 1964, p. 379.

6. Karpati, K.K., I1Extension Cycling o f S e a l a n t s , " Proceedings, XI 1 PATIPEC Kongress 1974, Garmisch- Partenkirchen, May 1974, p. 455-459.

7. Karpati, K . K . and Gibbons, E . V . , Mats. Res. Standards, 1970, 10, ( 4 ) , 16-21.

-

8. Karpati, K . K . and Sereda, P .J

.,

A.S .T. M., J . T e s t i n g and Evaluation, 1976,-

4, ( 2 ) , 151-156,9 . Karpati, K . K . and Sereda, P.J., Bztiment I n t e r n a t i o n a l / Building Research and P r a c t i c e , CIB, November/December, 1976, p. 346-355.

10. Karpati, K.K. and Sereda, P.J., flMovement of Brick Panel Cladding

."

To b e published.11. Karpati, K.K. and Sereda, P.J., J . Coatings Technol., 1977, 49, (626), p . 44-47.

-

12. Karpati, K.K., J . Coatings Technology, 1978, 50, (641), 27-30.

13. Karpati, K.K., "New T e s t i n g Methods f o r S e a l a n t s . "

Presented t o F i r s t I n t e r n a t i o n a l Conference on D u r a b i l i t y of Building M a t e r i a l s and Components, Ottawa, Canada, 1978. RECENED June 5, 1979.

Reprinted from ACS SYMPOSIUM SERIES, No. 1 13

PLASTIC MORTARS, SEALANTS, AND CAULKING COMPOUNDS Raymond B. Seymour, Editor

Copyright 1979 by the American Chemical Society Reprinted by permission of the copyright owner

T h i s publication i s being d i s t r i b u t e d by t h e Division of Building R e s e a r c h of the National R e s e a r c h Council of Canada. I t should not be r e p r o d u c e d in whole o r in p a r t without p e r m i s s i o n of the o r i g i n a l publisher. The Di- v i s i o n would b e glad t o b e oi a s s i s t a n c e in obtaining s u c h p e r m i s s i o n .

P u b l i c a t i o n s of t h e Division m a y b e obtained by m a i l - ing the a p p r o p r i a t e r e m i t t a n c e ( a Bank, E x p r e s s , o r P o s t Office Money O r d e r , o r a cheque, m a d e payable t o t h e R e c e i v e r G e n e r a l of Canada, c r e d i t NRC) t o t h e N a t i o n a l R e s e a r c h Council of Canada, Ottawa. K1A OR6. S t a m p e a r e not acceptable.

A l i s t of a l l publications of the Division i s a v a i l a b l e and m a y be obtained f r o m the P u b l i c a t i o n s Section, Division of Building R e s e a r c h , National R e s e a r c h Council of Canada, Ottawa. KIA OR 6.