Publisher’s version / Version de l'éditeur:

Macromolecules, 24, 11, pp. 3098-3110, 1991-05-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.1021/ma00011a012

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

A new approach to modeling the cure kinetics of epoxy/amine

thermosetting resins. 2. Application to a typical system based on

bis[4-(diglycidylamino)phenyl]methane and bis(4-aminophenyl) sulfone

Cole, K. C.; Hechler, J. J.; Noel, D.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=7b54d765-52b1-4e33-bd84-e08028aec153 https://publications-cnrc.canada.ca/fra/voir/objet/?id=7b54d765-52b1-4e33-bd84-e08028aec1531991, 24, 3098-3110

A New Approach

to

Modeling the

Cure

Kinetics

of

Epoxy Amine

Thermosetting

Resins.

2.Application

to

aTypical

System

Based

on

Bis

[4-(diglycidylamino)phenyl]

methane and

Bis(4-aminophenyl)

Sulfone

K.

C. Cole,*J.-J. Hechler, and D. NoelIndustrial MaterialsResearchInstitute, NationalResearch Council ofCanada,

75boulevarddeMortagne, Boucherville,Québec, CanadaJ4B6Y4 ReceivedJuly31,1990;RevisedManuscriptReceivedNovember9, 1990

ABSTRACT: Differentialscanningcalorimetry in dynamicandisothermalmodeswasusedto study thecure

kinetics ofthecommercial epoxy system Narmco5208, whosemain componentsare

bis[4-(diglycidylamino)-phenyljmethaneand bis(4-aminophenyl) sulfone. Thedatawere analyzedintermsofa new mechanistic approach describedinthe preceding paper. The treatment explicitlytakesintoaccountboththe

epoxide-aminereactions andthe subsequentetherification reaction. The kineticscan becompletelydescribedin

terms ofthreerateconstants, whichobeytheArrhenius relationship. Excellentagreementwiththe experimental

dataisobtainedif theetherificationreactionisassumedtobefirstorderwithrespecttothe concentrations

ofepoxide groups,hydroxylgroups, and thetertiaryamine groups formedintheepoxide-aminereaction.

Thismodel appliesover the wholerangeofconversion uptothepointwherethe resinvitrifiesandthe reaction

becomesdiffusion-controlled. Theeffectofthediffusion controlisdescribed very well byan approachbased onsimple equations proposedintheliterature. Altogether,the model allows accurateprediction ofthe degree

ofconversionover thewhole rangeofcure andover the temperaturerange160-200 °C,whichcovers the usual curing conditions. Although the rate constants derived are specific to Narmco 5208, the modelitself is

generally applicabletootherepoxy aminesystems.

Introduction

Background.

Mathematical modelingoftheformingprocess in composite materials can lead to significant

savingswithrespectto the amountofexperimental work

involvedin determining the optimumprocessing condi-tionsforaparticularpart.1 For thermoset matricessuch

as epoxy resins, probably the most important aspect of

the model is an accuratedescription ofthe polymeriza-tionreactionkinetics. Becauseofthe complexity ofthe chemistry involved, existingmodelsare usually

semiem-piricalapproximations, which workwithvaryingdegrees ofsuccess. The work tobedescribed hereinwas under-takenwiththe aimofdevelopinganaccuratekineticmodel

forthe commercialproductNarmcoRigidite 5208.

Be-cause the existingmodelsthatwere tried were found to worklesswell thandesired,a new mechanistic approach

was developedas described inthe precedingpaper.2 In

thispaper,wedescribeits application totheNarmco5208

system and demonstrate that it provides an excellent

description ofthe curing kinetics.

Narmco 5208. Narmco Rigidite 5208, produced by BASF Narmco Division, is reported to consist ofthree

components.3 The mainone isan epoxy resin basedon

tetraglycidyldiaminodiphenylmethane(TGDDM);a

well-known commercial product of this type is Ciba-Geigy’s AralditeMY 720. Thesecondcomponentistheprimary

amine curingagentdiaminodiphenylsulfone (DDS),also

availablefrom Ciba-Geigy as Hardener HT 976. These two monomers also form the basis of several other commercial products. The third componentofNarmco

5208is an epoxy resinbasedon a bisphenol A Novolac;

sucha productissoldbyCelaneseunder thename

Epi-Rez SU-8.

PreviousWork. Thegeneralnatureoftheepoxy amine

reactionandsome well-known equationsusedtodescribe

the kineticshave been discussedin part1 ofthisseries.2

*Author towhom correspondence shouldbeaddressed.

Barton4hasreviewedmuchoftheliterature. Therehave beennumerous studiesofmixturesof TGDDMandDDS

andofcommercial systemscontainingtheseproducts.5*21

These have involved differentapproaches to describing

the kinetics,withvaryingdegreesofsuccess. Insome cases, agoodfit to experimental datawas obtainedinthe early

stagesofthereaction,butdeviationswere observedinthe later stages. In other cases, reasonably good overall

agreementwas obtainedbutonlybytakinga

phenome-nological approach in which empirical parameters are introduced and varied to

fit

the data.It

appears to bewell establishedthattheetherificationreactionis signif-icantandcannotbeignored.4 Onequestionthathasnot

beensatisfactorilyresolved,however,isthatoftherelative reactivitiesoftheprimaryaminegroups

initially

presentandthesecondaryaminegroupsformedinthe reaction.

While it is frequently stated that the secondary amine

groupsare muchslowertoreact,theevidencefor thisis

not entirely convincing. Gupta and co-workers8 used

differentialscanningcalorimetry(DSC),Fourier transform infraredspectroscopy(FT-IR),andelectron spinresonance (ESR) to study mixtures involvingTGDDM,DDS, and

thesecondaryamineDMDDS

(bis[4-(methylamino)phe-nyl]sulfone). They concludedthatin the earlystagesof

cure themain reactionisbetweenprimaryamineand

ep-oxide(PA-E), thatthereactionbetween secondary amine

and epoxide (SA-E) is negligible, and that the cure is

completedbythehydroxyl-epoxide(OH-E)reaction.The rate constant forthelatterwas estimated tobean order

ofmagnitude smaller than thePA-E rate constant, and the enthalpy ofreactionabout eight timesless. However,

Barton17 has provided conflicting data showing that

TGDDM-DDSmixtureswithamine/epoxide ratios

rang-ing from0.61to1.14haveaconstant enthalpyofreaction

ofabout110

kJ/mol

ofepoxide. Thissuggeststhatbothprimaryand secondary amine groups react completely

withepoxideand that residual epoxideis consumed by

the OH-Ereaction, all these reactions having

approxi-mately equal exothermicity. The calorimetric data of

0024-9297/91/2224-3098$02.50/0 Published 1991 by the American Chemical Society Downloaded via NATL RESEARCH COUNCIL CANADA on September 11, 2018 at 20:39:54 (UTC). See https://pubs.acs.org/sharingguidelines for options on how to legitimately share published articles.

Macromolecules, Vol. 24,No. 11, 1991 Modeling the Cure Epoxy

Gupta et al. mayalso be interpreted in this way.

Fur-thermore,theirresults concerning theratioofthesulfone

peaksat1150and1105 cm"1intheIRspectrum mayalso

besubject to other interpretations. Morganandothers9"11

have alsostudied themechanismofTGDDM-DDScuring

by means ofFT-IR spectroscopy. Their dataindicated

thatthe epoxidehomopolymerization reactionissome 200

timesslowerthan thePA-Ereaction. TheSA-Ereaction

was assumedtobeaboutten timesslower,on thebasisof

dataobtained byBell22 forthe reactionof DGEBA

(di-glycidyl etherofbisphenol A)with MDA (methylenedi-aniline). Similarly,theOH-Ereactionwas also assumed

tobetentimes slower,on thebasisoftheabove-mentioned

work ofGupta etal.7-8 While theseassumptions appear

to be in agreement with their results, this does not

constituteproof that theyare valid,sincethe data may notbesufficientlysensitive. Infact,some of theirdata11

suggestthattheSA-Ereactionisrather significant, and

therecentworkby Zukas etal.12indicatesthattheprimary

and secondary amine groups have approximatelyequal

reactivity. Thisimportantquestionwillonlyberesolved

by further experimental work, preferably involving a techniquethatcan directly quantifythedifferenttypes

ofaminegroups.

Publisheddata for Narmco5208are ratherlimited.

Ciz-mecioglu and Gupta6studiedthe kinetics by dynamicDSC

and analyzed the results in terms ofa single nth-order

reaction. This isan oversimplification,since

it

hasbeenclearly establishedthatthe epoxy-amine reaction is

au-tocatalyticandthat etherificationcan alsobeimportant.

Recently,Chiao21hasanalyzedtheTGDDM-DDSdata

of Mijovic et al.15 in terms of a mechanistic model incorporating an epoxide-hydroxyl reaction in addition to the epoxide-amine reactions. The kineticequations were not solvedanalytically,so anumericalsolutionwas

usedto

fit

thedata,andgoodagreementwas obtained.No assumptionwas madeconcerning the relative reactivityofthe secondary andprimaryaminegroups. However,in

orderto

limit

thenumberofparameterstobefittedtoareasonable number, the ratiosofthe rate constants for

catalysisbyhydroxylgroupsformed in the reactionand

forcatalysis byimpurities

initially

presentwere fixed atvaluesobtained by analyzing earlierdata23forthereaction

between phenyl glycidyl ether and diethylamine or

n-butylamine. The apparent activationenergiesobtained

forthePA-E,SA-E,andOH-Ereactionswere respectively

55.1, 71.6,and 97.2kJ/mol.

Experimental

SectionMaterials. In addition tothe composite Narmco5208,some

mixturesoftheindividualcomponents knowntobepresentin this system were studied. Samples of Araldite MY 720 and

HardenerHT976were obtainedfromCiba-Geigy andEpi-Rez SU-8 from Celanese. The epoxide content ofthe resins was

determinedby reacting the resinwithexcess hydrochloricacid

in acetone/water solutionandthentitratingtheexcessacidwith

sodiumhydroxide. Theequivalentweights obtainedwere 130.2

(

= 2.1%)forMY 720and227.3(

= 0.4%)forSU-8. Theseare ingoodagreementwiththetypicalvaluesreportedby the

manufacturersforthesematerials(117-134forMY720,215for

SU-8). FortheHardener HT976,whichisnear 100% pure, the

equivalentweightwas calculated tobe62.1. Thisis basedonthe assumptionthateachofthefourN-H bonds presentcan react

withan epoxidegroup.

Theprepregstudiedwas Narmco Rigidite5208/WC3000-42

fromNarmcoMaterialsInc. It consistsofwoven carbon-fiber reinforcementimpregnatedwithNarmco5208resintoanominal

resincontentof42 %by weight. Therecommendedcure schedule

involvesa 1-hdwellat135°Cfollowed bya2-hcure at177°C. Thevolatilescontent, measured by weighing samples before and

afterheatingat177°Cfor20min,wasfoundtobe 1.90±0.03 %, basedon totalprepreg weight.

Theprepregasreceivedispartlypolymerized,or “B-staged". Aspointed outby Roberts,1foraccurate modelingofthecure it isessentialtocharacterize theinitialchemical stateoftheresin,

i.e.,itscomposition andinitialdegreeofadvancement (polym-erization). Thiswas donebyreverse-phaseliquid

chromatog-raphy.24 Different mixtures of MY720,SU-8, andHT976were

preparedinacetonesolutionandtheacetonewas removedunder

vacuum withoutheating. Sampleswere then polymerized to two

differentdegreesofadvancement by heating at120°Cfor30and

80min. AnalysisbyRPLCgave chromatogramsin whichthe

areas ofthefollowing fourpeaks couldbemeasured: TGDDM

(main component of MY 720), DDS (HT 976), DGEBA = diglycidyletherofbisphenolA(major componentofSU-8), and theinitialreactionproductbetweenTGDDMandDDS. These

quantitieswere then related to themixture composition and

degreeofadvancement. On analyzing the Narmco5208resin and comparing its chromatogram to that of the calibration mixtures, itscompositionwas estimatedtobe65.9% by weight

MY720,13.2% SU-8, and20.9% HT976,andtheinitialdegree

of polymerizationa0in theprepregasreceivedwas 0.038. This

composition correspondstoan initialamine-to-epoxideratioB

equal to0.60, basedon the epoxideequivalentweightsreported above.

Somebinaryandternary mixtures of MY720,SU-8, andHT

976were alsostudied byDSC. Thesewere preparedby dissolving precisely weighedquantities ofthematerialsinacetone,pouring

thesolutionintoashallowaluminumdish, and evaporatingthe

acetoneundervacuum withoutheating.

Thermal Analysis. Theprepregcure was studiedbyboth

dynamicand isothermalDSC4 on a Setaram Model CDP111

calorimeter. Dynamicruns were doneonbothpreparedmixtures

and prepreg. Approximately50mgofsamplewas placedinan

open platinum crucible that was suspended vertically in the

calorimeter. An empty cruciblewas usedasthereference. The

samplewas heatedinanitrogenatmosphereatafixedrateof

5 °C/minfromroom temperature toaround300 °C,atwhich pointsome decompositionisobserved. Inthecase ofprepreg

samples, the exactweight ofresin presentafterthe DSCrun was

determinedbythermogravimetricanalysis(TGA)on aSetaram B70thermobalance equippedwithagraphite resistance furnace.

The samplewas heatedinan oxygen atmosphereat10°C/min

fromroom temperature to9006C.26

IsothermalDSCruns were doneon prepregonly,at temper-atures rangingfrom160to210°C. Forthese experimentsthe

samplesizewasaround100 mgand unsealedaluminumcrucibles

were used. Inorderto minimizethetime required for

equili-bration after the sampleis introducedinto thecalorimeter, a

warmingoven was addedto preheatbothsample and reference

for about 10min at125°C before introductionintothemain

oven. RPLCanalysisindicatedthatlessthan0.5% ofthe

ep-oxidegroupsreact during this treatment. Thereference consisted

ofacruciblecontainingfullypolymerized prepreg, and sample andreferenceweightsaswellasthe corresponding crucible weights were matchedascloselyaspossible. The calorimetersignal (heat

flux=

dQ/dt)was measuredforabout6-7h, exceptat210°C where1.5-2hwassufficient. Aftereachisothermal run,adynamic

run was performedon thesame sample to complete the

polym-erizationanddeterminetheresidual heatofcuring. Threeruns were doneateachtemperature.

Thedigitizeddatawere acquiredbyaHewlett-Packard

HP-85computer and subsequentlytransferred toaVAX11/750or an Apple Macintosh for further treatment.

In isothermal DSC, there is a briefperiod oftemperature

equilibration afterthe sampleisintroducedintotheinstrument.

Inorder to estimate thetime requiredby thecalorimeter togive ameaningfulsignal,afew sampleswere run twice, thefirstrun

givingtheraw polymerizationcurve,thesecondgivingthe

cor-respondingexperimentalbaseline, whichisthenusedtocorrect the raw curve.4 It was foundthat theshapes ofthe raw and

corrected curves are identical after about 2 minandare only

slightly different before the point where the signal becomes

exothermic. Since thetime requiredtoobtaintheexperimental

baselinecan bequitehigh (up to 6-7 h), theextrapolationmethod

Cole Macromolecules, Vol. 24, 11, 1991

Table I

DynamicDSCData for theMixtures InvolvingMY 720,HT 976,and SU-8

mixture MY720, % HT976, % SU-8,%

amine-to-epoxideratio 7W,eC Mí,aJ/g

AH,kJ/mol ofepoxide 1 77.97 22.03 0 0.59 252 643.7(5.4) 107.5 2 77.02 22.98 0 0.63 250 637.9 (3.9) 107.8 3 73.17 26.83 0 0.77 234 605.2(5.9) 107.7 4 68.99 31.01 0 0.94 220 563.3(3.7) 106.3 5 67.58 32.42 0 1.01 218 556.3(4.5) 107.2 6 77.78 13.17 9.05 0.33 267 657.5 (4.8) 103.2 7 68.92 22.05 9.03 0.62 250 595.7(4.1) 104.7 8 59.49 31.54 8.97 1.02 217 533.3(4.6) 107.4 9 68.80 13.13 18.08 0.35 268 623.5 (3.0) 102.6 10 59.73 22.27 18.00 0.67 248 565.6(7.8) 105.2 • Valuesinparentheses

correspond tostandard deviationsbasedon threedeterminations.

obtainedbyhorizontal extrapolationusing the last tenpoints of thecurve, and thepointwhereitintersectswiththe onsetofthe

reaction exothermwastaken tobethe starting time ofthereaction

(t = 0). Thetotalheatsof polymerizationobtained bythe two

methodsofbaselinecorrectionwere identicalwithinlessthan

1%. Consequently, the extrapolation methodwas chosen for

correctionof alltheexperimentalcurves. These experiments showedthatthepoints obtainedwithinthefirst 2 minofthe

polymerizationrun aresubjecttosome error, andtheir ordinate values(dQ/dt)are lowerthanthe real values.

Results and Discussion

Mixtures. Dynamic

DSC. Inorder to relatetheep-oxide conversion to the heat evolution in the DSC

experiment,

it

is necessarytoassume thattheheatreleasedon reactionofan epoxidegroupisthesame regardlessof

thetype ofepoxyor thenatureofthereaction. To confirm

thishypothesis,severalmixturesofMY720,

HT

976,andSU-8 were analyzed by dynamic DSC. The results are

given inTable I. The mixturescover a rangeof compo-sitionsandamine-to-epoxide ratios. Attemptstoanalyze

some binary mixtures ofSU-8 and

HT

976wereunsuc-cessful. First, it is

difficult

to remove all the acetonewithoutheating the mixture. Second,it isbelievedthat

thehigherfunctionality ofSU-8leadsto rapidvitrification,

whichcauses the reaction tostopwellbeforecompletion. Figure 1 shows the DSC curves for three different mixturesofMY720andHT 976withvarying

amine-to-epoxideratios. The effecton the nature ofthe reaction

is evident. Mixture 5 (Figure la) is a stoichiometric

mixture in which the number of epoxide rings is just sufficienttoreactwith allthe

N-H

bonds present: hencetheamine-epoxidereactionisbelievedtobethedominant one. TheDSCcurve showsastrong exothermicpeakwith

amaximum at218°C. In mixture3 (Figure

lb),

thereisa30%excess ofepoxidegroupswithrespect to amine, and

theseare believedto polymerize by etherification. This

occurs atasomewhat highertemperatureandsubstantially

broadens the DSC exotherm peak; the maximum now

occurs at234°C. In mixture2(Figurelc),thereisa60%

excess of epoxide groups. The etherification reaction

becomeseven more importantand shifts the peak

max-imumto 250 °C.

The other mixturesgavesimilarcurves,andtheresults

are summarized inTable I. The temperature at which the peak maximum occurs is highly dependent on the overall amine-to-epoxide ratio but is not significantly

affected by the replacementof part of the MY 720 by

SU-8. AplotofTm..versus the amine-epoxideratiogives agoodlinear relationship(squaredcorrelationcoefficient

0.982). The enthalpies of polymerizationforthedifferent

mixtureswere determined by computer integrationofthe

exothermpeak usingalinearbaseline. The results,based

on threetofour determinations foreachmixture,are listed

Figure1. DynamicDSCcurves formixturesof MY720andHT 976withamine-to-epoxide ratiosof (a) 1.01,(b) 0.77, and (c) 0.63;heating rate5°C/min.

in thetable. Thevaluesvarywiththe mixture,but if they

are converted to kilojoules per equivalent of epoxide

present,aconstantvalueofabout107

kJ/mol

isobtained.This is in excellentagreementwith the results reported

byBarton.17 The factthatthesame resultisobtainedfor

mixture 5,wheremostofthe epoxide groupsreactwith

amine, and mixture 2,where at leastone-third react by

etherification, indicatesthatthe enthalpies forthesetwo reactions are very similar. Likewise, comparison of mixtures1and10suggeststhattheenthalpy for theSU-8

is not muchdifferentfrom that for the MY 720. Both

mixtureshavesimilaramine-to-epoxide ratios,but mixture 1containsno SU-8,whilein mixture10,14% ofthe epoxy

groupscome fromSU-8. The two mixtureswithverylow

amine-to-epoxide ratios(0.33and0.35)giveslightlylower

enthalpiesofreaction. Thiscouldbedueto incomplete

Macromolecules, Vol. 24,No. 11, 1991 Modeling the Cure Epoxy

Prepreg.

Dynamic

DSC. FivespecimensofNarmco 5208prepregwere analyzedbydynamicDSCandTGAasdescribedinthe ExperimentalSection. TheDSC curve

isverysimilarto Figure

lc,

withamaximum around 250°C. Theaverageweightlossduring theDSCexperiment

was 2.1 ± 0.5%, which is close to the value of 1.9%

determinedfor the volatiles content. Thisindicatesthat

the amountofdegradationthat occurs isnegligibleand

thattheweightloss ismainlyduetononreactivevolatiles

suchaswaterand acetone,whichare known tobepresent

inthe prepreg. Foreach specimen, the weightofresin

remainingaftertheDSC experimentwas determinedby

TGAandthiswas taken to bethetrue weightofresinin

the prepreg, exclusive ofvolatiles. The energy released on polymerizationwas determinedbyintegratingthe DSC

peak andwas thendivided bythisweight togivethe

en-thalpy of polymerization AH. The average of the five valueswas 620.4J/g, withastandarddeviationof7.5J/g.

It

was pointed out inthe Experimental Sectionthat this resinispartlypolymerized,or B-staged,to the extentof0.038;inotherwords, 3.8% ofthe epoxide groups

initially

present in the system have already reacted. Thus, for completely unreacted Narmco5208,AHwouldbe620.4/ (1-0.038)or 645.1J/g. On thebasisoftheother results given inthe Experimental Section,the enthalpy per

ep-oxide group is calculated to be 114.3 kJ/mol. This is slightlyhigher thanthe valueof107-108kJ /mol reported

in Table

I

for prepared mixtures but within the range100-118

kJ/mol

typically observed for epoxide ringopening.26 The averagefibercontent ofthe prepregfor

thefivespecimensanalyzedwas 59.0 ± 0.9% by weight.

Prepreg.

Isothermal

DSC. Three experimentswere performed ateachofsixtemperatures ranging from 160to210°Cin10-degincrements. Atypicalcurve,showing

heatflow(dQ/dt)as afunction oftime at160°Cisgiven inFigure2a. Thiscurve hasbeencorrected bymeans of the extrapolation method describedinthe Experimental

Section. Integrationgivestheevolvedheatas afunction

oftime:

Q(t) =

J/dQ/dt

dt (1)Thetotalheatevolvedduringtheisothermal experiment

is given by thetotalarea under the isothermalcurve:

Qi=

J0ifdQ/dt dt (2)

where

tf

is the time corresponding to the end of theexperiment, when the rate of heat evolution becomes

negligible. Sincethe polymerizationmaynotbecomplete aftertheisothermalrun,

it

iscompleted in thesubsequentdynamicrun, as showninFigure2b. Integration ofthis curve gives the residual heat of polymerization Qr.

At

higher temperatures, the isothermal cure occurs much faster,ahigherdegreeofpolymerizationisachieved, and Qrislower.In order to analyze the kinetics, the curves must be

expressedin termsofa,thedegreeofpolymerization. To

dothis, theusualassumptionwas made,namely,thatthe

heatevolvedisdirectly proportionaltothenumberof

ep-oxidegroups reacted, regardless ofthe typeofreaction.

As discussed above,the results forthe various prepared

mixtures supportthis assumption.

Inmostanalysesofthekineticsofprepregsystems,it is assumedthatthe extent ofB-stagingisnegligible,that

is,thatthedegreeofpolymerization at the beginningof

the cure (ao) is equal to zero. In this work, the initial

degreeofcure, determined byliquidchromatographyto

Figure2. DSCcurves forNarmco5208prepreg: (a)isothermal

run at160°C; (b)dynamiccurve recordedafter isothermalrun, heating rate 5°C/min.

beequalto0.038,was takenintoaccountintheanalysis.

Thisleadsto the following equationsforderivinga and

da/dt

asfunctions oftime:“(í)

= ao+(¿+^)Q(í)

da _(

1~ ao\dQ

dt ~ \Q¡+Q,/dt

(3) (4)Withthese data

it

is possible to constructa curve ofda/dt

versus a foreachtemperature. Theseare thenusedto test thekineticmodel. Oftheseveralthousand points

ina given curve, 50-100were selected atequalintervals

for this analysis.

Analysis of

theData

by Meansof

SomeExisting

Models. Thefirst test applied to the data involved the simplifiedHorie equation:27

da/dt

={

+2 ){1- ) ß- )

(5)where the rateconstantsK\andK2correspondrespectively

to catalysis by groups

initially

presentin the resin andcatalysisbyhydroxylgroupsformedinthe reactionand

Bis the ratioof primary amine

N-H

bonds to epoxidegroupsinthe

initial

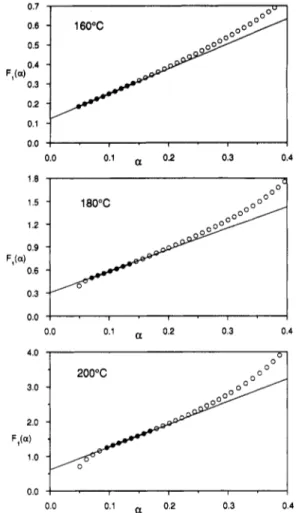

mixture. Figure3showsplotsofthe reducedrate function¥\{oi) = (1)-1(

-a)-1(da/dt)

versus a forthree differenttemperatures. This should

giveastraightlinewith intercept

K\

andslopeK2. ThevalueofBwas fixed at0.6,asdetermined byliquid chro-matography. Except for the

first

few points, linear behaviorisobserved uptoaabout0.2,withslight deviationbetween0.2and0.3and significant deviation beyondthis

point. The deviationobserved athigher temperatures for thefirstfewpointscan beexplainedby the factthatthese

occur withinthefirst2min oftheexperiment, before the

system has

fully

equilibrated. The deviation observedwhen a > 0.3 isattributed to thelackof validity ofthe modelin thisregion, wheretheetherificationreactionis

believed to become significant. Linear regression was performedby using the pointsshownbyfilledsymbolsin

the figure. The intercepts of these lines were used to determine the values of

da/dt

corresponding to a = 0.3102 Cole etal. Macromolecules, Vol. 24, 11, 1991

0.0 0.1 „ 0.2 0.3 0.4

Figure3. Plotsof Fi(a)- (1

-a)~l(B

-a)-1(da/dt)as afunction

ofa forthreedifferenttemperatures;unitss"1x 1000.

Anextension ofthis approach,usedby Springer etal. forthe commercial productHercules3501-6,®separates

the reaction intotwo distinctstages.

It

isassumedthat inthebeginning (a<0.3)onlytheepoxide-amine reactionneedbeconsidered, andeq 5 isused. Whenthe

epoxide-aminereactioniscomplete,the epoxide-hydroxyl reaction

takes over, and, sincethehydroxylconcentrationisnow constant, the reaction is assumed to be

first

order withrespecttoepoxideconcentration. Thusitcan bedescribed

by thefollowing equation:

da/dt

-K3(1

-a) (6)

In thiscase thereducedfunction

F^a)

= (1-a)-1(da/d£) should be constant and equal to K¡. To test this

hypothesis, the quantity Fi(a) was plotted againsta as

shownin Figure4. Interesting behaviorisobserved. Only

at the higher temperatureof200 °Ccould the approxi-mationbeconsideredtobevalid,and,even then, only up toacertain point. Generallyspeaking,thequantityFata)

risesto a maximum valueat arounda = 0.3,butinstead

ofremaining constantitgraduallydeclines

until

areachesabout0.7 or 0.8.

At

this pointthere is a rather abrupt dropandthe reaction rate falls to zero beforecompletion.This is believedto be due to vitrification ofthesystem

andtheonsetofdiffusion control. This willbediscussed

in more detail later.

It

is interesting to note that in Springer’s work,although thisapproachgaveareasonablygoodfitto the experimental data fora up toabout0.6,in order to achieve it it was necessary to assume negative

valuesforthe rate constant Kzl The problemliesinthe

factthatHercules 3501-6isacomplexmixturecontaining not onlyTGDDMandDBSbutalsotwootherepoxiesas wellas aborontrifluoridecatalyst. Asaresult, thecurve

Figure4. PlotsofFi(a) = (1

-a)-1(da/dt)as a function ofa

forthreedifferenttemperatures;unitss"1 x 1000.

of

da/dt

versus a does not clearly show the maximumtypical of an autocatalytic reaction, which eq 5 was

designedto represent.

An attempt was also made to

fit

the data with the semiempirical equationproposed byKamal:28da/dt

=(Kr+ K2am)(1

-a)n (7)

The fourunknownswere determinedsothatthecalculated

and experimental data matched with respect to the

followingfour values: (1) the

initial

value ofda/dt,

as determinedfrom the interceptsinFigure3; (2) amax,the locationofthemaximum valueofda/dt;

(3) (da/dt)™.».the maximumvalue;(4)thevalueof

da/dt

ata = 0.5.Theresultsare shownin Figure5.

At

160°C,an excellentfit

was obtained up to thepoint of vitrification.At

180and200°C,the

fit

wasgooduptoa= 0.5butpoorbeyondthat point. Furthermore, the values of m and n varied

significantly withtemperature,asindicatedinthe figure. Equation7 isthus lessthan ideal for this system.

Analysis

of the Databy

Means of the New Approach. The modeldevelopedintheprecedingpaper involvesa mote rigourous approach thanthosethathavejustbeenapplied. It isamechanistic approachinwhich the Horie modelisextendedtoincludetheetherification

reaction. The conversion of epoxide groups intoether groups isdescribed by thefollowingkineticexpression:

dE_ d[ether] _ „

“dt~

di

-fe^A3

(8)where E, [ether], H, andA3are the concentrationsof

ep-oxide, ether,hydroxyl,andtertiaryamine groups,

respec-tively. The exponents m and n (which should not be

Macromolecules, Vol. 24,No. 11, 1991

Figure5. Resultsobtainedon fittingexperimental data forda/ dtversus a witheq7.

Table II

Different Possibilities fortheEtherification Reaction Mechanism

case featerm m n z natureof reaction 1 EH 1 0 epoxide-hydroxyl, uncatalyzed 2 EH1 2 0 epoxide-hydroxyl,catalyzedby

hydroxyl

3 EHAS 1 1 1.5 epoxide-hydroxyl,catalyzedby

alltertiaryamine groups 4 EHAS 1 1 0 epoxide-hydroxyl,catalyzed

only bytertiaryamine groups

formed in reaction

5 E 0 0 homopolymerization,firstorder inepoxide

6 EA3 0 1 1.5 homopolymerization,catalyzed

by alltertiaryamine groups 7 EAs 0 1 0 homopolymerization,catalyzed

onlybytertiaryamine groups

formedin reaction

scenariosforthe reaction mechanismasshownin Table

II.

Thefirst

corresponds to the case of anepoxide-hydroxylreactionthatoccurs eitherwithoutcatalysisor

withcatalysisbygroups whoseconcentrationisconstant and therefore maybeincorporatedintothe rate constant

*3· The secondis similarexceptthata secondhydroxyl

groupacceleratesthe reaction, givingrisetoan EH?term rather than EH. The

third

and fourth scenarioscorre-spond to an epoxide-hydroxyl reaction catalyzed by

tertiaryaminegroups. In thiscase,adistinctionismade betweenthetertiaryamine groups

initially

present in thesystem (in this case, in the TGDDM resin) and those

produced by the epoxide-amine reaction. The coefficient

Zisdefined2as ZA^/BEq,whereA30andEqare theinitial concentrations of tertiaryamineand epoxide. Onthebasis

Modeling the Cure Epoxy

oftwoTAgroupsforeveryfourTGDDMepoxide groups

(butnone forSU-8) and B= 0.60,Zisestimatedtobe 1.5

forNarmco5208. Case3(withZ= 1.5)includesthesein

the calculation. Case 4(with Zsetto0) assumes thatonly thetertiaryamine groupsproducedinthe epoxide-amine

reactioncatalyze the epoxide-hydroxylreaction. Cases

5-7 correspond to etherificationwithouttheparticipation of hydroxyl groups, i.e., homopolymerization. This is

assumedto occur either bya simplefirst-orderreaction

withrespecttoepoxide(case5)or withtheparticipation

of tetiaryaminegroupsasjustdiscussed(cases6 and7).

The kineticsare describedinterms ofthefollowing two variables: 8 II (-* (9) 2Al+ A2

H

-H0 GO)/3~1

2A10 " 2A10where A\isthe concentrationof primary aminegroups,

Aa is the concentrationofsecondary aminegroups,and the subscript “0” designates the

initial

value of the concentration to whichit isattached. The variable a is the usual overall extentofconversionofepoxide groups.The variable ßisequalto thefraction of primaryamine

N-H

bonds that have reacted with epoxide groups toproduce linkagescontaininghydroxylgroups;thusitisa measure of the extent of the epoxide-amine reaction. Together these two variables cover the two reaction

pathways.

Thekineticequationscan besolved2togivethe following

two equations: =

ß

+ K*3bk [CJ

+ C2d2+ C3In(1+RT'fi

+ C4In(1 -ß)] (11)da/dt

=[ {

+2ß)(1

-ß)+3( +ß +ß2 (1-«)

(12)where

is the rate constant for the epoxide-amine

reactioncatalyzedbygroups

initially

present(including hydroxyl),K2 isthe rate constant forthesame reactioncatalyzedbyhydroxylgroupsformedinthe reaction,K3

isthe rate constant forthe etherificationreaction, Y =

Hq/BEo, and R =

K1/BK2. The coefficients Ci to C4

dependontheparticularvaluesofmandn andare given

in Table

II

oftheprecedingpaper.With

these equations,although

da/dt

cannotbeexpressedanalytically intermsofa, the relationship betweenthe two can be expressed

intermsofa setofcalculated points.

Regardless ofthe particular scenario, there are three

rate constants that must be determined to best fit the experimental datafor

da/dt

as afunctionofa. Because the dependent variableda/dt

cannotbe expressedas a simple function ofthe independent variable a,it

is notpossibletousestandard regression techniquestodetermine

theconstants. Instead,an iterativeprocedurewas used.

After

initial

estimatesforK\,

K2,and K3were chosen,foreachexperimental valueofa the corresponding valueof

j3wascalculatedby numerical solution

ofeqll.

Thevaluesofaandßwere thenusedineq12to calculate

da/di.

The coefficient Y (relatedtotheinitial

hydroxylcontent)wasassumedtobenegligible. The calculatedvaluesof

da/dt

were comparedwiththe experimentalvaluesandthe rate

constantswere adjusted until the calculated and exper-imentalcurves matched according to the following three criteria: (1) They shouldhave thesame value of

da/dt

3104 Coleetal. Macromolecules, 24,No. 11,1991

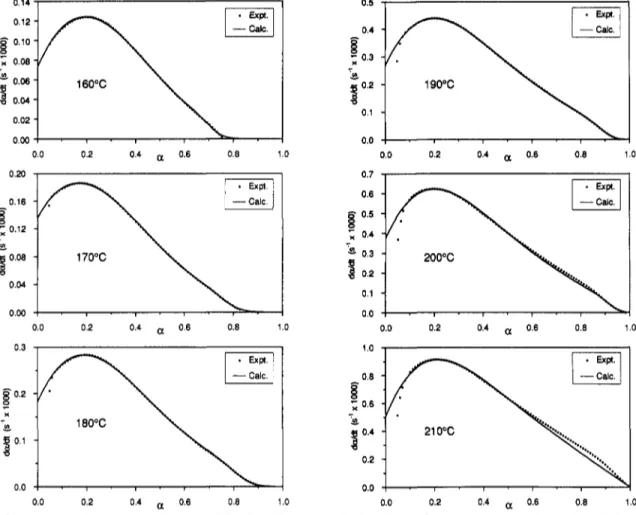

Figure6. (a,Top)Comparisonofexperimental valuesofda/dtwithcurves calculated accordingtocases1,5,and6ofTableII,for one experimentat180°C. (b,Bottom)Comparisonof experimentalvaluesofda/dtwithcurves calculated according tocases 2-4 and7 of TableII,forone experimentat 180°C.

were obtained by extrapolation,basedon the intercepts

ofthelines givenin Figure

3.(2)

The maximum calculated value ofda/dt

should be the same as the maximum experimentalvalue(butnotnecessarilyat thesame valueofa). (3)The twocurves shouldhavethesame valuesof

da/dt

ata = 0.5. Oncethe threerate constantsthat meet thesecriteriawere found, the overallquality ofthefitwas judged by graphically comparing the calculated andexperimentalsets ofdata.

Figure 6 shows the results for the seven different

scenariosappliedto one setofdata obtained at 180°C.

Threeofthecases,showninFigure6a, gaverather poor fits. These include a bimolecularepoxide-hydroxyl re-action(case 1),uncatalyzedhomopolymerization(case5),

and homopolymerizationcatalyzedbyall tertiaryamine

groups(case6). Oftheremainingcases,depicted in Figure

6b,threegaveagoodfit butone was

virtually

perfect.(Asalready mentioned, the deviation observed forthe first point or two is due to incomplete equilibration ofthe

calorimeter, and the deviationobservedat highvaluesof

a isduetovitrification ofthe resin.) The perfectfit

cor-respondsto case 4,wherethe reactionisfirst-order with

respect to epoxide groups,hydroxylgroups, andthe tertiary amine groups formedin thereaction(butnotthose present

in theTGDDM). Whether the slight differencebetween

this case and theother three in Figure6b is significant

(i.e.,whethercase 4correspondstothe true mechanism)

needs to be confirmed by further experimentation. A

possibleexplanationisgiveninthe nextsection. Because

the case 4mechanism gives the best agreement, it was

used to analyze the data and determine the three rate

constantsfor all18experiments (three ateachofthe six temperatures studied).

Asmentionedabove,the deviationobservedat higher valuesofa(seeFigure6b,case 4) isdue tothevitrification oftheresin. Theeffectsofthisvitrificationare even more evident in Figure 4, where the function F¡(a) shows a

Macromolecules, Vol. 24,No. 11, 1991 Modeling the Cure Epoxy

a

Figure7. “Diffusion factor"obtained bydividing experimental

valuesforda/dtbyvaluespredicted according to chemicalkinetic model. Symbols correspond to experimental points, lines to

regressionfit obtainedwitheq15.

andtheresincross-links, theglasstransitiontemperature

Tg ofthe system rises. When it approaches the curing

temperature, the resinpasses fromarubbery toa glassy

state,themobility ofthereactinggroupsishindered,and

the reaction is controlled by diffusion rather than by chemicalfactors. Various workershaveattempted

math-ematical treatments of thisphenomenon.29"35 Atypical approach31 isto express Tgin termsofa usingDi

Bene-detto’s equation and then to express the

diffusion-controlled rate constantintermsofT-Tgbya Williams-Landel-Ferry typeequation. Thus theoverallrelationship

is rather complex. Chern and Poehlein have recently

proposedasomewhatsimpler semiempiricalrelationship

basedon freevolumeconsiderations.30 When thedegree

ofcure reachesacertaincriticalvalueac,diffusioncontrol

takesover andthediffusion-controlled rate constant K¿

is given by

Ká=

Kcexp[-C(a

-ac)] (13)

whereKc istherateconstant fornon-diffusion-controlled

(chemical) kinetics and C is a constant. This equation

correspondstoaratherabruptonsetofdiffusion control ata = ac. In reality,theonsetissomewhatmore

gradual andthereisa regionwhere both chemicalanddiffusion

controlare significant. According to Rabinowitch,36the overalleffective rate constantKe can beexpressedin terms

ofK¿andKcas follows:

1—L+-L

Ke Kd kc

(U)

Combiningeqs13and14,we can definea“diffusionfactor”

/(a) as follows:

_1_

1+ exp[C(a-ac)] (15)

The effective reactionrateisequal to the chemical reaction

ratemultipliedbythisfactor, which followsan S-shaped curve. Forvaluesofa significantlylowerthanac,f(a) is approximatelyequal to1anddiffusion controlisnegligible.

Whena approachesac,f(a) beginstodecrease,reaching

0.5whena = ac.

Beyond thispoint

it

continuestodecrease,eventually approachingzero,sothatthereactionbecomes very slow andeffectivelystops. In thiswork, data for f(a) were obtained bydividingthe experimentalvaluesof da/

di

bythosepredictedon thebasisofthechemicalkineticmodel. Figure7showsthe resultsforone experiment at

eachtemperature. Thedropoffin rate due to theonset

ofdiffusion controlisobvious. An interestingphenomenon

isobserved athigher temperatures. At200°C, whena is

greater than0.6 the reaction rate increases slightly (by

about 10%)abovethatpredicted by the model,beforeit

dropsoffbecauseof diffusion control.

At

210°C,asimilar effectisobservedbut itismuchmore pronounced. Thisisbelievedtobeduetoanother reaction, not included in

themodel,whichbecomesimportantonly at higher

tem-peratures. Thesame phenomenonhasbeenreported by

Mijovicet al.15foran

MY

720/HT976mixturecuredat210 °C. On the basisof FT-IR results, Morgan et al.10

have suggestedthatat temperatures greater than200°C

two hydroxylgroups combinewithlossofwater to form an ethergroup,andthiscouldexplain theresults. Values

ofCand acineq 15 were determined by applying non-linearregressionto the dataforKe/Kcfortemperatures

between160and200°C. Exceptforthe slight deviation

at 200 °C just mentioned, very good agreement was obtained,as shownin Figure 7.

Figure8showsthe resultsforone experiment ateach

temperaturewhenthe experimentalvaluesof

da/dt

are compared tothosecalculated by the model(case4),withthediffusionfactor included. Exceptforthe deviations previously mentioned, the agreementis excellent. The

average constants obtained from the analysis are

sum-marizedinTable

III,

together withthe standard deviations.The corresponding Arrhenius plotsofInKversus 1/Tare

shownin Figure9. Individualdata points forthethree

experiments at eachtemperature are shown in order to

givean indicationofthescatter. Goodlinear correlations are observed,whichlead to theparametersgiveninTable

IV. The activation energies for the X-catalyzed and

hydroxyl-catalyzed epoxide-amine reactionsare 61.4and

72.5 kJ/mol, respectively, while that forthe

etherifica-tionreactionissignificantlyhigherat101.4kJ/mol. These valuesare verysimilartothoseobtained byChiao.21 The

variation ofthe quantitiesacand Cwithtemperatureis

shown in Figure 10. For ac, the relationship can be

consideredlinearwithin experimentalerror, and regression

givesthe following equation (squaredcorrelation

coeffi-cient0.987):

ac= 0.005376T-0.1350 (16) whereTisexpressedindegreesCelsius. Thusthediffusion factor defined ineq 15isalsoafunctionoftemperature. For the coefficientC,thereisconsiderablymore scatter,

andno discernible trend with temperatureis observed.

Theaverage valuefor the experiments from160to190°C

is 30.1 (standard deviation 5.1). Thevalues for200 °C

were not used in the averaging because of the slight

deviationobservedatthistemperature,attributedto the

hydroxyl-hydroxylcondensationreaction.

Summary oftheModel andGeneralDiscussion.

It

hasbeenshownthatan excellent

fit

tothe experimentalDSC dataforthe curingofNarmco5208inthe

temper-aturerange 160-200 °Cisobtained byusingamodel based on the following assumptions: (i) a reaction between

primaryamineand epoxide groups(PA-E) thatproduces secondary amine andhydroxylgroups andthatiscatalyzed bothbygroups

initially

present in theresin(rate constantKi)

and by the hydroxylgroups formed inthe reaction(rate

constant^);

(ii)asimilarreaction between secondaryamine and epoxide groups(SA-E),whoserateconstant is

one-halfofthat forthe previous reaction; (iii)areaction

between epoxide andhydroxylgroupsthatiscatalyzed by

the tertiaryamine groups formed in the SA-Ereaction (rateconstantKz);(iv)adiffusion control correction factor

for which a semiempirical equation is given and which

becomes important when the degree of conversion

ap-proachesacertaincriticalvalueac,whichisdependenton the temperature.

Cole et Macromolecules, Vol. 24,No. 11, 1991

0.14

0.0 0.2 0.4 0.6 0.8 1.0 0.20

0.0 0.2 0.4 0.6 0.8 1.0

Figure8. Comparisonofexperimental valuesofda/dtwith control, forsix temperatures.

0.0 0.2 0.4 0.6 0.8 1.0

calculated according to the proposed model,including diffusion Table III

AverageConstants(withStandardDeviationsin Parentheses)for theProposed Model*

temp, “C Ki,s'1 X1000 Ki,s"1X 1000 K3,s'1 X1000 «C C

160 0.134(0.011) 1.232(0.057) 0.062(0.008) 0.725 (0.012) 34.7(7.2) 170 0.238 (0.014) 1.682(0.056) 0.112(0.007) 0.779 (0.002) 26.7(1.2) 180 0.321(0.026) 2.750(0.053) 0.218 (0.023) 0.827(0.005) 27.0(2.0) 190 0.474 (0.025) 4.199(0.235) 0.444(0.070) 0.898 (0.016) 31.9(4.3) 200 0.602 (0.026) 6.288(0.231) 0.637(0.061) 0.934(0.020) 40.6 (9.0) 210 0.836 (0.004) 9.503(0.037) 1.130 (0.038) «Valuesin

parentheses correspond to standard deviationsbasedon threedeterminations.

Theprogressofthepolymerizationisdescribedin terms

oftwoparameters,a and ß. The

first

(a) is the overalldegreeofconversionasexpressedin terms ofthefraction

ofepoxidegroups reacted. Thesecond (ß) isthefraction

of amine

N-H

bonds that have reacted. These twoquantitiesarecloselyinterrelatedandtheirevolutionwith

time isgiven by the followingequations:

ß/dt

=[(K,

+)(

-ß)](1 -<x)f(a,T) (17)da/dt

=[B^

+2ß)(

1-ß)

+Kg/fKl

-a)f(a,T) (18)where thediffusioncontrol factorf(a,T) is givenby f{a,T) =

[1+ exp(30.1a + 4.06

-0.1617T)]"1 (19) with Texpressedindegrees Celsius. Equations17and18 correspondto case 4ofthe general model (m= =

1)with

Y= Z= 0. Equation19isobtained by combining

eqs15

and 16. If the reaction is carried out at constant tem-perature, therelationshipbetweena andßisdescribedby

eq 11. ThequantityBistheratio ofamineN-H bonds to epoxide rings, and fora typical lot ofNarmco 5208it isequalto0.60. Also,theinitial degreeofconversionao in Narmco5208isnotzero becauseofresinadvancement

duringthemanufacturingprocess(B-staging) and possibly

duringsubsequenthandling. Typicalvaluesforanewly

received batch are ao = 0.038 and ß = a0/B = 0.063.

Accuratevaluesmaybedeterminedforagivenbatch by physicochemicalanalysis.

The three rate constants obeythewell-known Arrhe-nius relationship

= A¡

exp(-E¡ú/RT) and may be

calculatedfrom the parameters giveninTableIV.

The amountofheat produced by 1gofNarmco5208

resinon goingfroma = 0toa = lis 645J. Thisis based

on the true resinweight,exclusiveofvolatile components (solventandmoisture).

Somediscussionisin orderconcerningtheassumptions

ofthe model. Assumption ii referred to above implies

thatthe secondary amine groups showthesame reactivity

withrespecttoepoxideastheprimaryamine groups.This importaint questionhasbeenextensively studied,andthe results have been summarized by various authors.4-26’37 While many ofthe experimental values that have been

reportedfor this ratioare closeto0.5,others are

signif-icantlylower, especially inthecase ofaromatic amines.

However,as was recently pointedoutbyCharlesworth,38

Macromolecules, Vol. 24,No. 11,1991

Figure9. Arrhenius plots for therate constants determined

from theanalysis.

150 160 170 180 190 200 210 Temperature (°C)

Figure 10. Dependenceof«„andthecoefficientC (eq 15)on

temperature, T.

Table IV

Arrhenius ParametersfortheProposedModel

rateconst,

a-1_InA_£,/£,

K£„

kJ/molK, 8.243 7389 61.4

K2 13.36 8719 72.5

K3 18.53 12221 101.4

solutionsinalcohol, anditisknownthatalcohols havea strongcatalytic effecton epoxideringopeningreactions.

Hence the situation in alcohol solution may be quite

differentfromthatinbulkmixtures involvingno solvent.

Infact, data obtained byCharlesworth37-38and by other workers39·40on bulkmixturesofepoxyresin and aromatic

Modeling the Cure Epoxy

Figure 11. Structure of thecross-linked polymer formedby

reaction betweenTGDDMandDDS.

amines suggest that the assumption ofequal reactivity

can bequite valid in such cases. In the specificcase of

TGDDMand DDS,asmentionedintheIntroduction,there

are conflictingresultsintheliteratureandthe question

willonly beresolved throughfurther work.

Assumptioniii impliesthattheetherificationreaction

proceeds through a ternarycomplex involving epoxide,

hydroxyl, andtertiaryaminegroups. Thisisnot

unrea-sonable, since bothhydroxyland tertiaryaminegroups

are knowntoacceleratetheetherificationreaction.41"44In

fact it is the same type of complex proposed for the hydroxyl-catalyzed epoxide-amine reaction, exceptthat

whentheaminegroupbearsahydrogen atom the reaction

followsadifferentpath.

It

is interesting,however, thatthebest

fit

to the experimental data isobtainedif

it

isassumedthatthetertiaryaminegroupsproducedinthe

reaction are more effective in catalyzing the etherifica-tionthanarethoseinitiallypresentintheTGDDM. Figure

11 shows the structure of the polymer formed by the

TGDDM-DDS reaction. The tertiary amine groups formedinthe reaction originate from the DDS and are attachedtoa phenylring withan SO¡group inthe para position. Thegroups

initially

present, however,are intheTGDDMand are attachedto a phenyl ring with a GHz groupinthe para position. Thestrong effectofsuchgroups

on kinetics,even though theymaybefarfrom thereactive

site,is well-known. Forexample, Tanakaet al.42found

thatthe rateofreactionofthe epoxy compound phenyl glycidyl ether with different substituents in the para positionvariedbyafactor of4. Thus

it

isnotunreasonableto postulatethatthe two typesof tertiaryaminegroups

showninFigure 11might havewidelydifferent

reactiv-ities, given thedifferentelectronicnatureoftheSO2and

GHz groups. If thisis thecase, though, it is

difficult

toarguethatthetertiaryamine groupsfrom theDDSshould

bemore active, becausethe electron-withdrawing nature

oftheSO2groupswouldbe expectedto makethemless

nucleophilic. A more plausible explanation may exist

based on steric arguments. The newly formed tertiary

amine groups are located in a position wherethey can bring about intramolecular catalysis ofreactionsofthe remainingepoxidering,asshownat thebottomofFigure

11. Dusek andMatéjkahave usedthisargument to explain

the apparentenhanced reactivity ofthesecond epoxide ringin N^V'-diglycidylamines.46·46 Theirdetailed study

of NJV'-diglycidylaniline showed that intramolecular

etherificationissignificantandoccurs faster than the in-termolecularreaction. Similarresultshave beenobtained byothers47and

it

hasbeen suggestedthatintramolecular reaction and ring formationare quite important in theTGDDM-DDSsystem.11 Theseargumentsprovidesome support forassumptioniii ofour model.

Although vitrification was found to have a profound effecton the kinetics,no effectswere observedthatmight

3108 Coleet al. Macromolecules, 24, 11, 1991

Figure12. Calculatedcurves forda/dtas afunctionofaat180

°C, showing the separatecontributionsfromthePA-E, SA-E,

andOH-Ereactions.

bedue to gelation, whichoccurs at lower valuesofa.

It

may be that because the epoxide-amine reaction ispredominantbeforegelationandetherification afterward, the corresponding rate constants reflect thestateofthe resin ateach stage. However,

it

ismore likelythat,ashasbeen suggested by others, diffusion control becomes

important only on

vitrification

and not on gelation.48·49It

is interesting to compare our results withthose of Chiao.21 Inbothcases,agoodfitwas obtained by varying threerate constants,oneofwhich corresponds to theether-ification reaction. However, the assumptionsmade are

different. In our case, we assume equal reactivity of

primaryand secondary amine groups;thismakesitpossible

topartlysolvethekineticequationsand developcertain analyticalexpressionsto model thecure. InChiao’scase, heassumes afixed value for theratiooftherateconstants

forhydroxyl-catalyzed and noncatalyzed amineaddition, on thebasisofresultsobtainedon adifferentepoxy amine

system. Thisisquestionablebecausethe “noncatalyzed”

reaction, at leastin thecase ofcommercial materials,is

generallyacknowledgedto involvecatalysisbyimpurities

present in theresin,andtheirtypeandconcentrationmay vary substantially fromone systemtoanother. Thus both treatmentsare subject tosome question,andthe factthat

agoodfit isobtainedinbothcases suggeststhattheDSC

dataare not greatly sensitive to either. Onlyfurtherwork

will

determine which approach is more valid for theTGDDM-DDS system.

Twofactorshave beenneglectedinour treatment, which mayhavesome influenceon theresults. Thefirst isthe

presence oftheminor epoxy resininNarmco 5208;

it

isknown tobesomewhatmore reactivethanthe majorresin.3

Thesecondisthepresencein the kinetics equationsofthe

coefficient Y,whichisrelatedto the concentrationof

hy-droxylgroups

initially

present in theresin. In thisworkitwas assumedtobenegligible,as no experimentalvalue

was available. It would be interesting to further refine themodel by doingastudyofthe binaryTGDDM-DDS

system in which the

initial

concentration of hydroxylgroups isdetermined and includedin themodel.

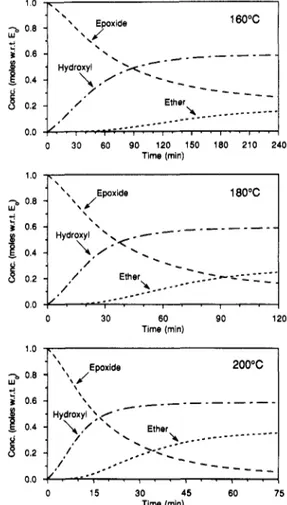

Calculated

Results.With

theproposed model,it

ispossible to perform calculations in order to better

un-derstand how the system behaves in different

circum-stances. Forexample,Figure12showsthe predictedcurve

for

da/dt

as afunction ofa forisothermal curingat 180°C, including the effects Of vitrification, which occurs aroundac = 0.83. Thecurve isdecomposedtoshowthe

contributions from the threedifferentreactionsinvolved,

namely,PA-E,SA-E,andOH-E. Thefigureclearlyshows

why the approximation mentioned earlier,in which the

30 60 90 120 150 180 210 240 Time (min) -b 0.8 -LU

Í

0.6 -$I

0.4 -J 0.2 -0.0 \ Epoxide\z

Hydroxyl x / / Ether/

>.-180°C 30 60 Time (min)Figure13. Calculated concentrationsofepoxide,hydroxyl,and ether groupsas afunctionoftimeforisothermalcuring at160, 180,and200°C.

reactionisseparatedintotwodistinctstages, isnot really

applicable. Thegeneralbehavioristhesame regardless

ofthetemperature. Fora = 0-0.2theOH-E contribution

isnegligible and theapproximationisvalid. Between0.2

and0.8,however,allthreereactionsare significant. From

0.2to0.6,the epoxide-aminereactionsare more important than the OH-E reaction.

At

a = 0.6thePA-E

reactionbecomesnegligibleandthe OH-Ereaction becomesthe

most important. Finally, at a around 0.8, the SA-E reactionbecomesnegligible. Only then couldeq 6serve as a goodapproximation, but

it

cannotbe usedbecausein the realsystemvitrificationoccurs near this pointand

the reactionbecomesdiffusion-controlled. Thus,inspite

ofthe significant difference inactivationenergyforthe amine and etherification reactions, the two cannot be

clearlyseparatedintime. Thisdescriptionofthecuring

process isingeneral agreementwiththefindingsofMorgan

and MonesforTGDDM-DDS,asillustratedin Figure10

ofref 11.

It is also possible to predictthe evolutionofthe cure

withtime, by applyingeqs17and 18 on an incremental

basis. The concentrationsofthedifferentspeciescan be

calculatedfroma andßbymeans oftheequations given in the preceding paper.2 Figures 13 and 14 show the predicted concentrations of the different species as a

function oftimefor isothermal curingat 160,180,and200

°C. In all threecases,thereis a“turning point”around a = 0.45. This occurs after71 min at 160°C,30min at

180°C,or 14min at 200°C. At this point, over 90% of

the primary amine groups have disappeared but ether

formationisjust starting tobecomeimportant. However,

theSA-E reaction, whichproducestertiaryamine groups,

Macromolecules, 24, 11, 1991

Time (min)

Figure14. Calculatedconcentrationsofprimaryamine (PA), secondary amine (SA), and tertiary amine (TA) groups as a

function of time for isothermal curing at160,180, and200°C.

effectoftemperatureisthat,beyond theturningpoint, at higher temperatures theconversion ofepoxideto ether

proceedsfaster and to a greater extent.

At

160°C, thecriticalvaluefor diffusion control(ac = 0.72) isreached

after218min.

At

this point,58% ofthe epoxide groups havereactedwithamine,14% have reactedwithhydroxyl,and 28% remain unreacted.

At

180 °C, ac (=0.83) isreached after 117 min, at which point 59% of epoxide

groups have reactedwithamine, 24% have reactedwith

hydroxyl, and17% are unreacted. Finally,at200°C,ac (=0.94) is reached after 73 min, where 59% ofepoxide

groups have reactedwithamine, 35% have reactedwith

hydroxyl,and6%are unreacted. Thus at thepointwhere

vitrification slows down the reaction significantly, the epoxide-amine reactionis

virtually

complete,regardless oftemperature, but theepoxide-hydroxyl reactionisonly partiallycomplete. Athigher temperatures, more ether linkagesare formed,asexpected. After vitrification,the cure proceedsatan ever-decreasingrate,sothatcomplete cure may notbeachieved. Aftertwice the time required toreachac,thedegreeofcure iscalculatedtobe78% at160°C, 89% at 180 °C,and 98% at 200 °C.

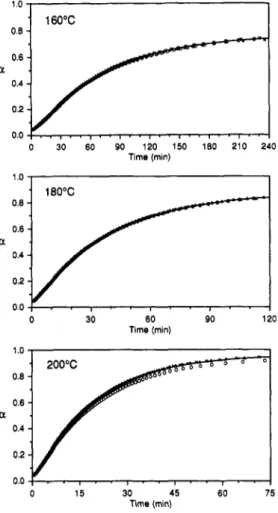

Finally,toillustratethe overallaccuracyofthemodel, Figure 15 shows the evolution ofa with time at three

differenttemperatures, comparingthebehavior predicted by the general model with the results for the three

individual DSC experiments.

Conclusion

Amechanistic modelhasbeen proposedfor the kinetics

ofpolymerizationofNarmco5208,whichconsistsmainly

oftheepoxy resinbis[4-(diglycidylamino)phenyl]methane

Modeling the Cure Epoxy

Figure IS. Evolutionofa with time at threedifferent

tem-peratures, as predicted by the general model (line) and as

measuredin three separate DSC experiments(O, X,

).

(TGDDM) and theaminehardener bis(4-aminophenyl)

sulfone (DDS). This model represents a significant

improvementover muchofthepreviouslypublished work

inthat

it

explicitlytakesintoaccountboththeepoxide-amine reactions and the subsequentetherificationreaction.

The kineticsare completelydescribed interms ofthree

rate constants,whichwere determined tofitthedata.The

best fit was obtained on the assumptionthatthe

ether-ificationreactionis catalyzedby thetertiaryamine groups

formed in the epoxide-amine reaction; further experi-mental workisrequiredtoconfirmthis. Therate constants obeythe Arrhenius relationship and values ofthe pre-exponential factor A and the activationenergyE& have

beendetermined. Theseare specific to the Narmco5208

system,butthegeneralapproach couldbeapplied toany

amine-curedsystem.

Apartfromthe three rate constants,no otherparameters were varied to

fit

thedata. The amine-to-epoxideratioBwas assignedavaluedetermined by independentmeans

(liquidchromatography) andwas not varied as in some previouswork.5 Furthermore, the kineticswere assumed

tobe

first

orderwithrespecttoall participatingspecies, andit

was notnecessarytointroduce nonintegerexponentsasin the widelyusedeq7. Although themodelisthusless

empirical than previousones, it givesan excellentfit to the experimental data for all values of the degree of conversionaup to thecritical pointwherethe resinvitrifies

andthe reactionbecomesdiffusion-controlled. Todescribe

the cure in this region, a diffusion factor has been

introducedon thebasisofacombinationoftwo equations

proposedby otherworkers.30-36 Withthe inclusionofthis factor, it ispossibleto calculatewithexcellent precision thedegreeofconversionover thewhole rangeofcure and