READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

An Erector transporter for the installation and removal of specialized

mining equipment underground

Palmer, J. H. L.; Cox, W. C.; Geller, L. B.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=4a9c3081-d294-4d67-8eb1-1cd185c0764a https://publications-cnrc.canada.ca/fra/voir/objet/?id=4a9c3081-d294-4d67-8eb1-1cd185c0764a

Ser 1 - 2 - \ p -

TH1 I, + < - \

N21d

0. 1301

,

National Research Conseil national c . 2I$

Council Canada de recherche. Canada BLDG Division of Division des- -- Building Research recherches en biitiment

An Erector Transporfer for the Installation

land Removal of Specialized Mining

Equipment Underground

by J.H.L. Palmer, W.C. Cox and L.B. Geller

Appeared in

1985 Rapid Excavation and Tunneling Conference, New York, New York, June 16-20, 1985

Proceedings, Vol. 2, p. 91 7

-

925Reprinted with permission

DBR Paper No. 1301

Price $1 .OO

L'engin "Erector Transporter" a t conqu pour soulever, transporter et monter des Elements de machinerie lourde, notamment les composants d'une foreuse de 7,6 m de diamstre, dans les galeries d'une mine de charbon sous-marine de l'est du Canada. L'engin peut manoeuvrer dans un tunnel de 7,6 m tout en plaqant avec precision des tilements pouvant atteindre 6 m de diamstre et pouvant peser jusqui3 27 tonnes. I1 peut porter des charges de 30 tonnes sur des pentes de 20%.

La presente etude dCcrit les principales caractCristiques techniques de l'engin, ainsi que les essais de verification et de rendement auxquels il a 6tC sournis. Sa polyvalence est telle qu'on peut envisager de nombreuses autres possibilites d 'utilisation.

Chapter

55

AN ERECTOR TRANSPORTER FOR THE INSTALLATIONAND REMOVAL OF SPECIALIZED MINING EQUIPMENT UNDERGROUND J.H. Laverne Palmer, W. (Bill) C. Cox, Lorant B. Geller

Head, Geotechnical Section, Division of Building Research, National Research Council of Canada, Ottawa, Ontario, KIA OR6

Director, Beaver Construction Group Limited, Dorval, Quebec, H9P 2N6

Research Scientist, Mining Research Labortories, CANMET, Energy, Mines and Resources Canada, Ottawa, Ontario, K1A OG1

ABSTRACT

An erector transporter (ET) has been designed and built to lift, carry and erect heavy machinery components, in particular the

components of a 7.6 m diameter tunnel boring machine (TBM), within the access tunnels of a submarine coal mine in Eastern Canada. The ET is capable of manoeuvring within a 7.6 m tunnel while precisely positioning components as large as 6 m in diameter and weighing up to 27 tonnes each. The unit can negotiate 20% grades while carrying loads of 30 tonnes.

The major design features, verification tests and performance trial results are presented. The versatility of the ET is such that many other applications are possible.

INTRODUCTION

Most tunnels commence and end at either a portal or a shaft. It is relatively easy therefore to assemble and dismantle a tunnel boring machine (TBM)

.

However, tunnels for mines, particularly submarine mines, often must dead end. If a TBM is used to mine such a tunnel conventionally, erection or dismantling of the TBM is done using overhead gantry cranes or monorails working in large chambers specifically mined for this purpose.Erection chambers are expensive and may be difficult to mine and support even in comparatively good rock. For the conditions

encountered in the development of a coal mine, these chambers are even more expensive and may require months to establish. After

1 9 8 5 RETC PROCEEDINGS, VOLUME

2

removal of the TBM the chambers seldom serve a useful secondary purpose; instead they become a significant maintenance problem.

The erector transporter (ET) described in this paper was

specifically designed to dismantle a 7.6 m diameter TBM in a coal mine environment while working within the confines of the circular tunnel excavated by the TBM and to reassemble the TBM in a

similar-sized opening. By using the ET, the time and expense required for the development of an erection chamber is eliminated. Thus, TBM availability and productivity is enhanced and many months of costly development time can be saved.

BACKGROUND

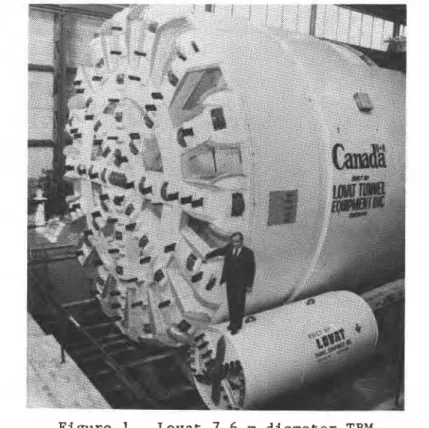

In March 1982, a contract was awarded by the federal government of Canada to Lovat Tunnel Equipment Inc. of Toronto, Ontario, for the construction of a 7.6 m diameter TBM to be used to drive haulageways for a new coal mine, the Donkin-Morien mine, near Sydney, Nova Scotia. The Donkin-Morien mine plan calls for the drivage of four parallel access tunnels up to 4 km in length

(Marsh et al., 1983). Because the coal deposit is situated offshore beneath the Atlantic Ocean, the specifications required that the TBM be designed for easy removal from the tunnels, which would blind-end at the intersection of the coal seam. This implied that the TBM would have to be both fully assembled and disassembled inside each

ERECTOR TRANSPORTER FOR EQUIPMENT 919 of the four tunnels. The first assembly was completed at a portal at the ground surface in 1983 (Palmer, Lovat and Marsh, 1985) but the remaining seven operations will have to be done underground.

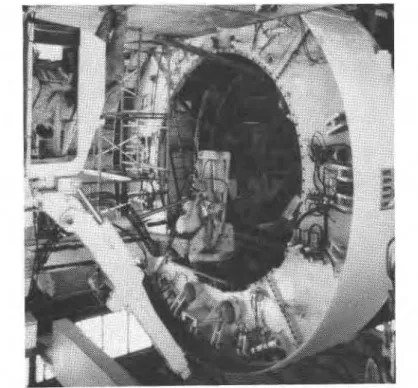

The Lovat TBM that was developed is a full-face, fully shielded design with electrohydraulic drive certified for use in a coal mine

(Figure 1). Because the TBM is fully shielded with all operating components mounted radially inside the shell (Figure 2), the design is unique, with several important operational advantages. The machine can be dismantled in a gassy atmosphere within a tunnel cut by itself and reassembled in a similar-sized chamber. In order to fully exploit this original design a piece of equipment was required which was capable of manoeuvring within a 7.6 m diameter tunnel while lifting and precisely positioning the components of the TBM. This requirement led to the development of the ET.

THE ERECTOR TRANSPORTER

The heaviest component of the TBM weighs 27 tonnes and its largest component measures 6 m in diameter and 0.5 m in thickness. The total weight of the TBM is in the order of 350 tonnes. A

machine capable of transporting, handling and accurately positioning such components inside a coal mine, within the confines of a 7.6 m diameter tunnel was not available, nor was there any company in Canada in a position to undertake, on its own, the design and development of such a unit.

920

1985 RETC PROCEEDINGS, VOLUME 2

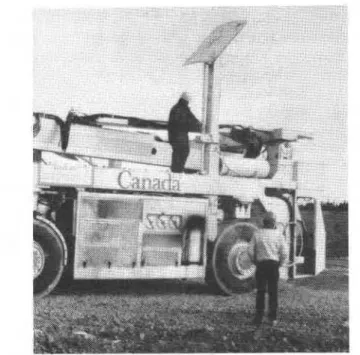

F i g u r e 3. E r e c t o r t r a n s p o r t e r l i f t i n g 30 t o n n e t e s t l o a d

A d e c i s i o n was made by t h e Canadian government t o s u p p o r t a n u n s o l i c i t e d p r o p o s a l from Beaver C o n s t r u c t i o n Group L i m i t e d of D o r v a l , Quebec, f o r t h e d e s i g n and c o n s t r u c t i o n of such a machine. The f i n a l d e s i g n and f a b r i c a t i o n of t h e ET was u n d e r way by J a n u a r y

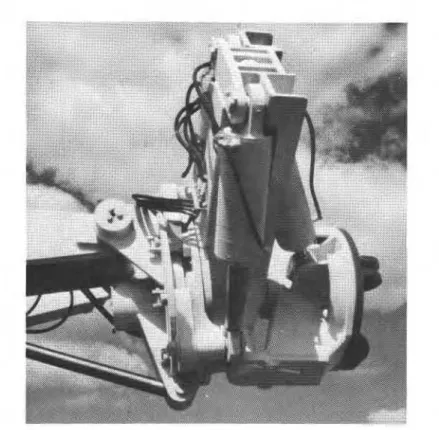

1983 w i t h a t a r g e t completion d a t e of September 1983. Although t h e ET i t s e l f c o u l d b e d e s i g n e d and b u i l t i n d e p e n d e n t l y of t h e TBM i t was c o n s i d e r e d e s s e n t i a l t o f a b r i c a t e t h e n e c e s s a r y i n t e r f a c e a d a p t o r s f o r t h e TBM's s u b a s s e m b l i e s b e f o r e t h e TBM was s h i p p e d t o t h e mine s i t e . The ET ( F i g u r e 3 ) i s i n e f f e c t a h i g h l y manoeuvrable t e l e s c o p i c boom mounted on a n e x p a n d a b l e , s e l f - p r o p e l l e d s t r a d d l e c a r r i e r . A key f e a t u r e of t h e ET i s t h e m a n i p u l a t i n g "head" ( F i g u r e 4 ) which i s mounted a t t h e end of t h e t e l e s c o p i c boom. The head can b e r o t a t e d w i t h h y d r a u l i c c o n t r o l s 210' i n a v e r t i c a l p l a n e ( t h e p l a n e of t h e photo, F i g u r e 4 ) , 105O i n a p e r p e n d i c u l a r v e r t i c a l p l a n e , and 95" i n a p e r p e n d i c u l a r h o r i z o n t a l p l a n e . It can be a c c u r a t e l y p o s i t i o n e d anywhere w i t h i n t h i s wide range.

PRINCIPAL PHYSICAL CHARACTERISTICS

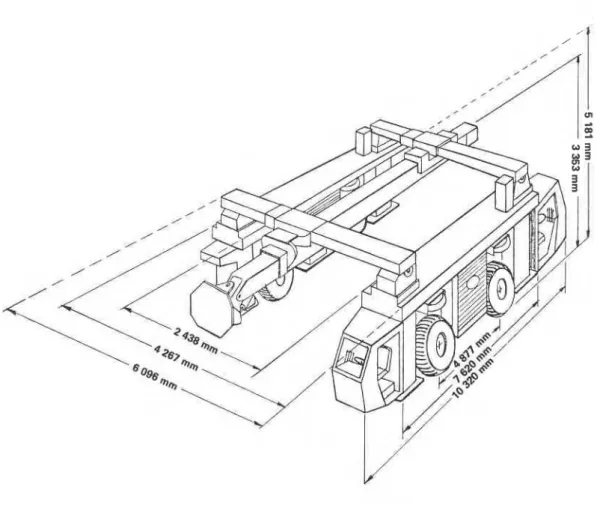

F i g u r e 5 i l l u s t r a t e s t h e major dimensions of t h e ET. Other p e r t i n e n t p h y s i c a l c h a r a c t e r i s t i c s a r e l i s t e d i n T a b l e 1. The

o v e r a l l w i d t h of t h e u n i t can b e expanded by 1829 mm and t h e o v e r a l l h e i g h t can b e expanded by 1828 mm, which p e r m i t s i t t o s t r a d d l e a n o b j e c t 4100 mm wide by 4100 mm h i g h . Each end frame i s

ERECTOR TRANSPORTER FOR EQUIPMENT

921

Figure 4. Manipulating head of main boom

TABLE 1

-

Principal Physical Characteristics Wheel baseSideframe length Vehicle length

Rear boom projection Minimum height, retracted Maximum height, expanded Roof jack extension Outrigger clearance Control cab width Combined grade peak Grade approachability Outrigger extension Front boom projection Telescopic boom stroke Min. width, closed Max. width, expanded Inside clearance, closed Inside clearance, expanded Inside turntng radius

Outside turning radius, closed Outside turning radius, expanded

1985 RETC PROCEEDINGS, VOLUME 2

Figure 5. Overall dimensions of erector transporter

is the ability of the unit to rotate about a circle of only 228 mm.

A feature not illustrated in Figure 5, but clearly shown in

Figure 6, is the roof jacks which can be extended 4572 mm and which

serve to stabilize the unit in the tunnel when the maximum load of

30 tonnes is lifted at the maximum extension of the main boom. For

surface operations, such as the trial dismantling of the TBM, counterweights are required to replace the function of the roof

jacks. These weights can be seen in Figure 3. Another feature not

well illustrated in Figure 5, but clearly shown in Figure 3, is the auxiliary service booms on either side of the main frame, which provide additional flexibility to the machine by safely handling

loads up to 1.2 tonnes.

MECHANICAL FEATURES

The ET has a 4-wheel hydrostatic drive powered by a 100 HP

Caterpillar 3304 diesel engine. The pair of wheels on each side is

ERECTOR TRANSPORTER FOR EQUIPMENT

923

Figure 6. Roof jack, partially extended

tight turning circle, allows the unit to be manoeuvred anywhere within the tunnel confines. In the event of a power pack failure the unit is equipped with a 40 HP auxiliary electric motor which can provide adequate hydraulic pressure to operate all the hydraulics except the propulsion. The hydraulic system operates on a 60140 waterloil emulsion. Fluid operating pressures are restricted to 21,000 kPa. In case of a malfunction, a series of pilot check valves ensure that all hydraulic cylinders remain in position until

the auxiliary power is activated.

There are two control cabs so that at all times the operator is in a safe working position with a clear view of the work area. Another safety feature is the provision of duplicate braking

systems, capable of bringing the unit to a safe stop from full speed down a 22% grade while carrying 30 tonnes.

VERIFICATION TESTS

A series of tests was undertaken in July and August 1983 at the Beaver site in Dorval and at a nearby quarry where various grades were available in order to verify that the unit met all

specifications. To test transportation capability, the machine was required to traverse a gradient of 22% at a speed of 1 km/hr while carrying a load of 30 tonnes. A major test of load handling

capability was to extend the main boom 3.65 m while lifting a load of 28.9 tonnes. For this test (Figure 3) the outriggers were down

924

1985 RETC PROCEEDINGS, VOLUME 2

and a counterweight was used in place of the roof jacks. The capability of the telescopic service booms to safely handle

1.2 tonnes while extended 5.5 m was also verified. All other

specifications were verified on site before the unit was transported to the Lovat plant in Toronto.

TESTS WITH 7.6 m TBM

Although the versatility of the manoeuvrable boom and head had been verified, it was still considered essential to demonstrate the machine's ability to dismantle and reassemble all the major

components of the TBM under shop conditions prior to its shipment to the mine site. Each major component of the TBM was removed and set on the shop floor as would be required in the tunnel and then placed back into position as required for the TBM's reassembly. Prior to each dismantling sequence it was necessary to manufacture

appropriate attachments to interface with the head of the ET and the respective TBM components. In spite of this necessary delay at each stage, all major components of the TBM were disassembled and loaded onto trucks for shipment within a period of only 19 days.

CERTIFICATION

During and after manufacture of the ET, various components were tested and the entire machine was inspected and tested as required to certify the unit as acceptable for use in a coal mine. Since this was a new design, certification was a major task. The fact that certification was obtained in the relatively short time period available (about nine months) attests to the excellent support given to this task by CANMET personnel.

APPLICATIONS

Testing to date under both shop and field conditions has proven conclusively that the ET is capable of performing its design

function of safely and speedily dismantling and assembling the 7.6 m diameter Lovat TBM within the confines of a similar-sized tunnel in a coal mine. The considerable expense and delay involved in the construction of underground erection chambers has therefore been eliminated. The versatility of the ET, however, is such that it could easily be used for other purposes, even though the prototype was designed specifically for handling the TBM components under the Donkin-Morien underground mine conditions. Subsequent versions of the ET can be reduced in size, powered by an electric-hydraulic power pack and otherwise modified as may be required for specific applications.

ERECTOR TRANSPORTER FOR EQUIPMENT

925

Suggested potential uses are very diverse, including surface mining operations such as loading, unloading, and transporting, use at surface construction projects, utilization as an extended

straddle carrier and even use within a ship's hold to handle

specialized bulk cargo. Any situation where low overhead clearance poses a problem and heavy lifts and precise handling of components is required, is a potential field of application for the ET.

ACKNOWLEDGEMENTS

Funding for this project, which was sponsored by the Department of Energy, Mines and Resources Canada (EMR), was provided by the Department of Supply and Services Canada and the Cape Breton

Development Corporation with the scientific support of EMR and the

National Research Council of Canada (NRCC). The project was closely

coordinated with the NRCC-sponsored development of the Lovat TBM and received excellent cooperation and support from Lovat Tunnel

Equipment Inc. Much of the original design was done by the late George Leskien, owner of GL Designs and Technical Services. Certification of the ET could not have been achieved without the exceptional cooperation of the staff of the Canadian Explosive Atmospheres Laboratory, EMRICANMET, in particular Mr. G. Lobay.

This paper is a contribution from the Division of Building

Research, National Research Council of Canada, and is published with the approval of the Director of the Division.

REFERENCES

Marsh, J.C., et al., 1983, "The Donkin-Morien Mine: Building the Mine of the Future," Presented at the 2nd Coal Operators

Conference, Sydney, Nova Scotia, October, 24 p.

Palmer, J.H.L., Lovat, R.P. and Marsh, J.C., 1985, "Performance of a

7.6 m Diameter Full-Face Tunnel Boring Machine Designed for a

Canadian Coal Mine," Fourth International Symposium, Tunnelling '85, Brighton, England, March.

T h i s p a p e r , w h i l e b e i n g d i s t r i b u t e d i n r e p r i n t form by t h e D i v i s i o n of B u i l d i n g R e s e a r c h , remains t h e c o p y r i g h t of t h e o r i g i n a l p u b l i s h e r . It s h o u l d n o t be r e p r o d u c e d i n whole o r i n p a r t w i t h o u t t h e p e r m i s s i o n of t h e p u b l i s h e r . A l i s t of a l l p u b l i c a t i o n s a v a i l a b l e from t h e D i v i s i o n may be o b t a i n e d by w r i t i n g t o t h e P u b l i c a t i o n s S e c t i o n , D i v i s i o n of B u i l d i n g R e s e a r c h , N a t i o n a l R e s e a r c h C o u n c i l of C a n a d a , O t t a w a , O n t a r i o , K I A OR6.

C e document est d i s t r i b u g s o u s forme de t i r 6 - 3 - p a r t par l a D i v i s i o n d e s r e c h e r c h e s e n b s t i m e n t . Les d r o i t s de r e p r o d u c t i o n s o n t t o u t e f o i s l a p r o p r i 6 t G de l l C d i t e u r o r i g i n a l . C e d o c u m e n t n e p e u t S t r e r e p r o d u i t en t o t a l i t 5 ou en p a r t i e s a n s l e consentement de 1 1 6 d i t e u r . Une l i s t e d e s p u b l i c a t i o n s d e l a D i v i s i o n p e u t Btre o b t e n u e en g c r i v a n t 3 l a S e c t i o n d e s p u b l i c a t i o n s , D i v i s i o n d e s r e c h e r c h e s e n b 3 t i m e n t , C o n s e i l n a t i o n a l d e r e c h e r c h e s Canada, Ottawa, O n t a r i o , K l A OR6.