Concrete Prefabrication and Offsite Construction in Brazil: A Development Case Study in Mato Grosso by

Daniel Smicka

B.Sc., International Trade, 2011 University of Economics in Prague M.Sc., Entrepreneurship and Innovation, 2014

EMLYON Business School

Submitted to the Program in Real Estate Development in Conjunction with the Center for Real Estate in Partial Fulfillment of the Requirements for the Degree of Master of Science in Real Estate Development

at the

Massachusetts Institute of Technology February, 2021

©2021 Daniel Smicka All rights reserved

The author hereby grants to MIT permission to reproduce and to distribute publicly paper and electronic copies of this thesis document in whole or in part in any medium now known or hereafter created.

Signature of Author_________________________________________________________ Center for Real Estate

January 8, 2021

Certified by________________________________________________________________ John Kennedy

Lecturer, MIT Center for Real Estate Thesis Supervisor

Accepted by________________________________________________________________ Professor Siqi Zheng

Samuel Tak Lee Professor of Urban and Real Estate Sustainability

Faculty Dicrector, MIT Center for Real Estate & Sustainable Urbanization Lab

CONCRETE PREFABRICATION AND OFFSITE CONSTRUCTION IN

BRAZIL: A DEVELOPMENT CASE STUDY IN MATO GROSSO

by

Daniel Smicka

Submitted to the Program in Real Estate Development in Conjunction with the Center for Real Estate on January 8, 2021 in Partial Fulfillment of the Requirements for the Degree of

Master of Science in Real Estate Development

ABSTRACT:

With a large, growing, and young population, Brazil suffers from a chronic shortage of affordable housing. This crisis, in particular, negatively affects new and economically ascending entrants to the housing market. This economic crisis is unfolding concurrently with the global environmental challenges associated with climate and sustainability.

This thesis explores the application of modular construction in an affordable housing project in Cuiaba, Brazil. This thesis is comprised of three distinct sections.

Section I provides a historical overview of offsite construction with a particular focus on precast concrete in modular construction. It describes the forces and some of the most notable projects and figures that shaped precast construction - especially in its European cradle. It further provides a comprehensive classification of current modular construction and discusses its benefits and limitations.

Section II analyzes Brazil’s ongoing housing crisis and Brazil’s economic trends and realities. It discusses Brazil’s National Housing Policy and its flagship program – Minha Casa, Minha Vida.

Section III takes the reader to Cuiaba, Mato Grosso's capital, and proposes a 528-unit affordable housing development project there. It explores the establishment of a mobile concrete precasting plant and analyzes the production and application of a novel modular concrete system in the project. Particular attention is paid to the financial viability of the project.

Thesis Supervisor: John Kennedy

TABLE OF CONTENTS

1. INTRODUCTION ...8

1.1. GLOBAL TRENDS ... 8

2. WHAT IS MODULAR, WHAT IS OFFSITE, AND WHAT IS PREFABRICATION ... 10

3. A BRIEF HISTORY OF CONCRETE PREFABRICATION ... 11

3.1. THE BEGINNINGS ... 11

3.2. INDUSTRIAL REVOLUTION ... 12

3.3. BAUHAUS ... 14

3.4. LE CORBUSIER ... 15

3.5. AFTER THE WWII ... 17

3.5.1. Eastern Bloc ... 17

3.5.2. The Camus System ... 18

3.6. AFTERTHOUGHT ... 19

4. CATEGORIZATION AND CLASSIFICATION ... 19

4.1. VOLUMETRIC MODULES ... 22

4.2. NON-VOLUMETRIC MODULES ... 23

4.3. 2D & 3D HYBRID ... 23

5. TRANSPORT AND LOGISTICS ... 24

5.1. ON-SITE LOGISTICS ... 24

6. THE BENEFITS OF MODULAR CONSTRUCTION ... 25

6.1. TIME SAVINGS ... 25 6.1.1. Design ... 25 6.1.2. Foundations ... 26 6.1.3. Offsite construction ... 26 6.1.4. Onsite construction. ... 26 6.1.5. Rework ... 26 6.2. COST SAVINGS ... 27 6.2.1. Construction costs ... 27 6.2.2. Site overheads ... 28 6.2.3. Materials. ... 28 6.2.4. Labor force. ... 29

6.2.5. Transportation and Logistics ... 29

6.2.6. Factory costs ... 29 7. BRAZIL ... 30 7.1. ECONOMY OVERVIEW ... 30 7.2. ORGANIZATION ... 33 7.3. POPULATION... 34 7.4. INCOME DISPARITIES ... 36

8.1. RESIDENTIAL MARKET ... 38

8.2. HOUSING DEFICIT ... 39

8.3. HOUSING POLICY - MCMV ... 40

8.4. HOUSING FINANCIAL SYSTEM AND ITS ACTORS ... 40

8.4.1. Federal Government ... 41

8.4.2. The Ministry of Cities (Ministério das Cidades) ... 41

8.4.3. Caixa Econômica Federal ... 41

8.4.4. States and Municipalities ... 41

8.4.5. Private Sector ... 41

8.5. MORTGAGE MARKET ... 42

9. DEVELOPMENT PROJECT ... 44

9.1. MATO GROSSO ... 44

9.2. CUIABA ... 44

9.3. RESIDENTIAL MARKET IN CUIABA ... 45

9.4. THE SITE ... 49 10. THE FACTORY ... 55 11. THE PRODUCT ... 62 12. AREAS A & B ... 69 13. FINANCIAL ANALYSIS ... 72 13.1. IMPACT ANALYSIS ... 76 13.2. CAPITAL STRUCTURE ... 77 14. CONCLUDING THOUGHTS... 79 15. BIBLIOGRAPHY ... 80

ACKNOWLEDGMENTS

I would like to sincerely thank my thesis advisor, John Kennedy, for his encouraging words, patience, and wisdom. I would also like to thank him for introducing me to Campbell Mayer. Campbell, thank you for all your invaluable feedback and perspectives! Special thanks go to Martin Maas of Progress Group, Samuel Goncalves of Summary Architects, and Jennifer Cookke – you have been a great support; thank you for your thoughts and pointing me in the right direction.

I will always be grateful for the knowledge and support provided by my professors, classmates, and the entire community at the Center for Real Estate and MIT at large. The time at MIT flew by far too fast, but I will forever cherish the memories and experiences we shared.

Thank you to my loving girlfriend, Elena, for being patient and putting up with my process throughout the research and completion of this thesis. Thank you also to the whole Cavalca family – especially Aigle and Arlindo for making my (unusually long) stay in Brazil absolutely unforgettable.

Finally, thank you to my family – my mother Olga, my dad Bretislav, and my brother Jakub for always being there for me. I do not know where I would be without you.

Mens et Manus

PREFACE

Rarely is there an event that affects every living person on this planet. The 2020 COVID-19 global pandemic has been such an event. It has affected every single one of us – some of us less, some of us more.

I am grateful to say that the effect on me has been rather unexpected. I left my beloved MIT campus for a Spring break and what was supposed to be a week-long trip turned out to be an unexpected four-month adventure in Brazil.

While in Brazil, I kept my eyes open, as would any other entrepreneurially-minded student of real estate at MIT. I could not but notice that virtually all new residential construction (including 40+ stories high-rises in Balneario Camboriu, where I spent most of my time, while in Brazil) still uses old fashioned bricks and mortar as the primary building method. How is that possible in a country plagued by cost and time overruns and an alarming housing deficit, was I thinking. Why is it that, paradoxically, the countries with housing deficits do not utilize that advancements in offsite construction, so prevalent in my native Czech Republic? So, when an opportunity presented itself to get access to a large affordable housing project in Cuiaba, deep inside the Brazilian hinterland, I dug deeper. The results of my findings are this thesis.

Daniel Smicka

1. INTRODUCTION

It’s without a doubt that industrialization and standardization have shown us their capacity to offer to the vast majority of people, at a relatively affordable price, almost all the

products available on the market today – such as automobiles, fast consumer goods, computers, etc. Why is it then, that standardization and industrialization haven’t affected the construction industry much more? It’s true that some construction materials and components are already industrialized – such as trusses, slabs, curtain walls, windows and doors, it is still not the case, however, for a building as a whole. Conventional construction hasn’t changed much in centuries. We no longer have the master-builder, but at its most profound level, construction is still a client-initiated, very labor-intensive endeavor. A different architect–engineer team, a new set of designs and drawings for each project, a different general contractor and myriad of various sub-contractors are formed each time a building or a group of buildings is built. It is as if every new building was as a prototype, developed from scratch.

Whenever a new car or a new iPhone (or any other technically complex product) is rolled out and launched in the market, it’s sold with a long list of features that are supposed to make our experience with the product better, safer, or that are supposed to solve some of our problems or needs. This has been the case in the automotive industry for over 50 years and in the consumer electronics sector since its inception. Moreover, the last couple of decades have been characterized by customization and individualization of these mass products. We have long since accepted a high degree of standardization in our products – from cars to furniture, from clothing to electronics. In spite of this standardization,

advertisements for these products suggest they can express a great deal of individuality and feature a wide variety of designs.

This begs the question: if standardized mass products can successfully meet individual needs, why do we keep designing buildings from scratch? We do we insist that buildings be different from one another at all costs? Why do we insist on individualizing the most costly and complex part of our everyday tasks – that of accommodation and living?

1.1. GLOBAL TRENDS

This is happening at a backdrop of much bigger, secular trends: ▪ Growing and rapidly urbanizing global population

▪ A construction sector that has been increasingly inefficient ▪ Declining construction rates

Figure 1.1 Houses Built per 1000 people

Source: How housing became the world’s biggest asset class. (2020, January 16). The Economist.

https://www.economist.com/special- report/2020/01/16/how-housing-became-the-worlds-biggest-asset-class

Figure 1.2 Global Average House prices

Source: How housing became the world’s biggest asset class. (2020, January 16). The Economist.

https://www.economist.com/special- report/2020/01/16/how-housing-became-the-worlds-biggest-asset-class

Figure 1.3 Productivity in Manufacturing and Construction

Source: McKinsey Global Institute. (2017). Reinventing Construction: A Route to Higher Productivity.

The construction industry is infamously one of the least efficient and seemingly untouched by disruption happening in other industries. This, among other factors, means that for the average person, it is oftentimes impossible to purchase a home within her lifetime. As a result, the building rates and deliveries of new housing have been steadily declining and housing deficits across the world have been growing. Could standardization and modular construction be the answers to the above woes?

2. WHAT IS MODULAR, WHAT IS OFFSITE, AND

WHAT IS PREFABRICATION

One can get easily lost in the myriad of terms such as modular construction, off-site

construction, prefabrication, modern methods of construction, etc. Smith and Quale1 define offsite construction as “Planning, design, fabrication and assembly of building elements at a

location other than their final installed location to support the rapid and efficient construction of a permanent structure. Synonyms: prefabrication, industrialized

construction, modular, manufactured construction, pre-assembly, systems building, modern methods of construction.”

In broad terms, modular construction (or any of the above synonyms) involves a production or manufacturing of standardized components of a building in an offsite factory, and their subsequent assembly on the project’s site.

Modular construction, under certain conditions (more on them later), can provide significant benefits over traditional methods of construction. The most significant and sought-after benefits are:

▪ Overall cost reduction (lower cost to build and lower building maintenance costs) ▪ Shorter construction times (and thus cheaper construction financing and faster

income generation)

▪ Greater certainty on both build times and costs

▪ Higher building quality, including better energy and/or seismic performance These benefits are amplified when there is a degree of repeatability in the product (i.e., a module), the module is designed as such that it can be relatively easily transported from the factory and the cost savings of offsite production outweigh the logistics costs. Therefore, the decision to implement modular/offsite construction in a project (i.e., in a building’s design) needs to be made a priori. Any building being manufactured needs to be designed for the manufacturing process and hence constrain the number of different variations required.

Despite these benefits, there are of course barriers that are slowing the rate at which modular construction is adopted in the industry. Somewhat limited flexibility in the design process is the obvious ones. The American Institute of Architects, however, mentions a limited supply chain as the main one2. Currently, many modular manufacturers focus on

specific market segments and on low-to mid-rise buildings and are not readily able to produce a wide range of project types and sizes. A general lack of experience may also keep owners and project teams from feeling comfortable with modular construction. But this is likely to change over time as more in the industry gain familiarity with the approach.

1 Ryan E. Smith, and John D. Quale (2017). Offsite Architecture: Constructing the Future. Taylor & Francis Group.

2 AIA American Institute of Architects. Design for Modular Construction: An Introduction for Architects. https://www.aia.org/resources/6119840-modular-and-off-site-construction-guide

3. A BRIEF HISTORY OF CONCRETE

PREFABRICATION

It may seem that modular construction is a recent trend but in reality, it is nothing new. Whole cities have been built with modular construction in my native Czech Republic (former Czechoslovakia), and of course in many places around the world. For us to better

understand modular construction, I think it’s essential we look back in time – especially at the discourse that was happening in architectural circles in Europe in the early 20th century.

3.1. THE BEGINNINGS

It’s hard to pinpoint who built the first fully prefabricated building. Some of the first recorded examples are tied to the military that needed to rapidly deploy hospitals on the battlefield. In 1788, the Austrian Imperial Army sent twenty military hospitals to the front lines via the Danube river during the Austro-Turkish wars.3 By the mid nineteenth century,

prefabricated military hospitals became relatively wide-spread. For instance, in 1855 during the Crimean War, a British engineer Isambard Kingdom Brunel4 was commissioned to design

a prefabricated modular hospital. In five months, he designed the Renkioi Hospital5, which

was a 1,000-patient hospital, with innovations in sanitation, ventilation and a flushing toilet. The 16-unit hospital was shipped directly to Dardanelles and used only used from March 1856 to September 1857. During that time it reduced the death rate from 42% to 3.5%. Some of the first prefabricated building elements started to appear around the mid nineteenth century. At that time, the first industrial revolution was in full swing, especially in the UK and northern Europe and many minds were exploring how to creatively harness the newly invented manufacturing techniques also in the construction sector.

For instance, the Crystal Palace in London was designed and built for the Great Exhibtion in there in 1851. It was designed by Joseph Paxton (a former greenhouse designer). His design could be built within just a few months, which was crucial for its selection, given the limited time available for construction. After the end of the exhibition, the Crystal Palace was

dismantled and moved with minor modifications to Sydenham Hill in London. It stayed there until it was destroyed by a fire.6

3 Meuser, P., & Albus, J. (2020). Prefabricated Housing: Construction and Design Manual. DOM publishers. 4 https://en.wikipedia.org/wiki/Isambard_Kingdom_Brunel

5 https://www.thebrunelmuseum.com/hospitalatrenkioi/

Figure 3.1 Crystal Palace

Source: https://www.britannica.com/topic/Crystal-Palace-building-London#/media/1/145293/5089

It’s clear that these examples, however, do not qualify as standardized, widely built architecture or a building system adopted en masse.

3.2. INDUSTRIAL REVOLUTION

The second half of the nineteenth century saw drastic social changes with the ongoing industrial revolution and the growing social inequality. Large parts of the population, lured by higher incomes and shifts in the overall economy, moved to the cities, which were not prepared for this level of population growth. The global population increased by a third between 1850 and 1900 alone.

This was also the time when engineers discovered the basic materials that would later be used to make precast concrete parts, blocks and panels. Portland cement7 was invented by

Isaac Charles Johnson in the UK, and Joseph Luis Lambot wove together iron bars and covered them with cement (so called ferro-cement)8, in order to make the structure

withstand tensile forces. It wasn’t until Joseph Monier9 (a trained gardener) who perfected

ferro-cement with processes of reinforcing and stiffening concrete with iron, and thus invented reinforced concrete. These first sprouts of modular construction were generally manufactured at a temporary construction site or a workshop near the construction site. At the beginning of 20th century, a British civil engineer John Alexander Brodie10, who is

famous for inventing the goal net for use in football, also built a small story house for the Cheap Cottages Exhibition in London. Brodie had a personal experience with the slums of the working class in the British cities, which motivated him to invent a construction method that could be used to build affordable, sanitary housing for the poorest classes, in the

7 https://www.britannica.com/technology/portland-cement 8 https://en.wikipedia.org/wiki/Joseph-Louis_Lambot 9 https://en.wikipedia.org/wiki/Joseph_Monier

shortest time possible. This effort became a house on the 158 Wilbury Road11 and is now a

listed building and one of the first residential buildings made of prefabricated reinforced concrete in the world.

The provision of sanitary, affordable housing for the population was not only an urgent social need, but it was also a political issue that in the post-war era even became a matter of survival for political systems. Therefore, the need to provide low-income housing became a central part of the public discourse after the First World War and the fall of the monarchies (after 1918) and shaped the course of mass housing schemes in Europe and the newly established Soviet Union.

Across the Atlantic, the prefabrication efforts were led by Grosvenor Atterbury12 who began

to experiment with prefabricated building elements made of concrete. Atterbury

successfully completed the Forest Hills estate project in Long Island, which was built from approximately 170 standardized precast concrete elements. He subsequently exported his system to the Netherlands and Germany, where it was used to construct the Splaneman Siedlung13 in 1926 – Germany’s first buildings constructed with large, prefabricated panels.

Figure 3.2 Splaneman Siedlung nowadays

Source: https://de.wikipedia.org/wiki/Splanemann-Siedlung#/media/Datei:Splanemannstraße_3-10.jpg

Probably because of the novelty of the system, the architects, didn’t consider a crucial part of prefabrication – the transportation. The panels were large (7.5m x 3m) and heavy. They were also pre-fitted with doors and windows, which made them sensitive to damage. The gentry cranes back then, were not flexible enough and difficult to maneuver. Therefore, the logistics of the project ultimately proved to be very timely and costly. The project was also not large enough (only 140 flats in 27 buildings) and the technology not yet fully developed. Berlin’s chief city planner and the proponent of the project – Martin Wagner – later

acknowledged that the small scale of the project was one of the main obstacles to implementing this “rational and economic building process”.

11 Meuser, P., & Albus, J. (2020). Prefabricated Housing: Construction and Design Manual. DOM publishers. 12 https://en.wikipedia.org/wiki/Grosvenor_Atterbury

13 https://www.berliner-woche.de/friedrichsfelde/c-bauen/die-splanemann-siedlung-war-der-versuch-industriellen-wohnungsbaus_a198046

Meanwhile, industrialization was proceeding at full speed and reached one of its milestones when a car rolled off the assembly line for the very first time in Henry Ford’s factory. This new production method enabled ford to reduce the purchase price of the Model T from USD 900 to USD 36014. He would go on to produce 15 million units of this model by 1927. In

producing the black Model T, Ford introduced a new aesthetics of car manufacturing in the first quarter of the 20th century.

3.3. BAUHAUS

The beginning of the 20th century in architecture was marked by departure from excess

ornamentation, floral motives and various decorations with their apex in the Art Nuveau movement. One of the most prominent architects and architectural theorists of the time was Adolf Loos (born in Brno, what is now my native Czech Republic). His essay Ornament and Crime advocated smooth and clear surfaces in contrast to the lavish decorations of the fin de siècle15. In the essay, he explored the idea that the progress of culture is

associated with the deletion of ornament from everyday objects. He called for the elimination of ornamentation altogether “ornamentation is wasted labor and wasted health. This has always been the case. But now, ornamentation is also wasted material, and both of these represent wasted capital”.16

The discourse continued the Staatliches Bauhaus School (aka Bauhaus) that became famous for its approach to design, which attempted to unify the principles of mass production with individual artistic vision and strove to combine aesthetics with everyday function.

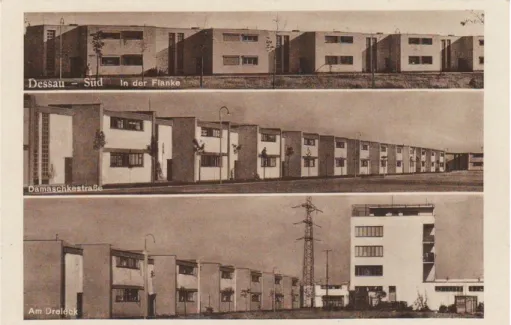

One of the key figures was the school’s founder and first director - Walter Gropius17. Among

other pivotal buildings, he designed and oversaw the construction of the Dessau-Törten Housing Estate18 (built between 1926-1928), where he applied an innovative approach to

construction. In total, 314 two story houses were built with precast concrete elements. Each house had its own kitchen and garden measuring from 350 to 400 m2 to grow vegetables and practice animal husbandry, thus promoting self-sufficiency. The construction was site organized like a production line at an industrial plant, which allowed the last 130 houses built in staggering 88 days (including the production of all parts at the construction site).

14 https://en.wikipedia.org/wiki/Ford_Model_T 15 The turn of the century

16 Meuser, P., & Albus, J. (2020). Prefabricated Housing: Construction and Design Manual. DOM publishers. 17 After his emigration from Germany, he lived in Cambridge, MA and taught at Harvard Graduate School of Design and sat on MIT’s visiting committee

18 https://www.bauhaus-dessau.de/en/architecture/bauhaus-buildings-in-dessau/dessau-toerten-housing-estate.html

Figure 3.3 Dessau Torten Estate

Source: https://www.fostinum.org/bauhaus.html

After Walter Gropius, Mies Van der Rohe became the director of Bauhaus. He continued with Gropius’ efforts to further implement modern materials into housing construction (such as reinforced concrete). Van der Rohe emphasized the fact that reinforced concrete forces architects to plan all details of the final building in advance. He points out that an architect working with reinforced concrete would even need to consider installation of electrical and heating systems during the planning phase, which was usually not the case back then,

Another Loos’ devotee and a proponent of standardization, prefabrication and concrete in construction was Le Corbusier, who famously asked “as so many cannons, airplanes, lorries and wagons have been made in factories, why not make houses?”

3.4. LE CORBUSIER

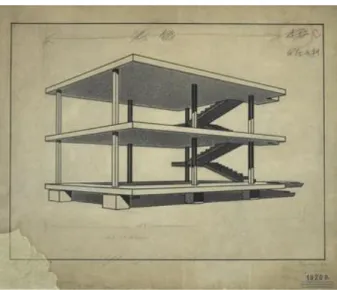

Le Corbusier invented (and patented) the Dom-Ino19 (acronym by combining the words

domus and industry) system already in 1914 – a reinforced concrete structure with recessed columns. The system was originally designed to provide large numbers of temporary

residences after World War I, producing only slabs, columns and stairways, and residents could build exterior walls with the materials around the site.

Figure 3.4 Dom-Ino

Source: https://www.archweb.it/dwg/arch_arredi_famosi/Le_corbusier/maison_dom-ino/Sistema_dom-ino.htm In 1921, Le Corbusier designed the Maison Citrohan as an experiment in mass housing. The name intentionally evokes associations with the French automaker Citroen. “A house, like a motor car, conceived and carried out like an omnibus or a ship’s cabin. The actual needs of the dwelling can be formulated and demand their solution. We must fight against the old-world house, which made a and use of space. We must look upon this house as a machine for living.”

In 1926, Le Corbusier received the opportunity he had been looking for; he was commissioned by a Bordeaux industrialist, Henry Frugès, to build a complex of worker housing, the Cité Frugès20, at a suburb of Bordeaux. Le Corbusier took into account

prevailing social and economic factors and was determined to build the plan to provide people with low-cost, predetermined, homogeneous cubist structures. The Frugès project became his first laboratory for a residential housing; a series of rectangular blocks

composed of modular housing units made of concrete, located in a garden setting.

Le Corbusier wrote “there’s no shame in living in a house without a pointed roof, with walls as smooth as sheet iron, with windows like those of factories. And one can be proud of having a house as serviceable as a typewriter”21.

One of Le Corbusier’s buildings that embodies the notion of ‘the machine for living’ is Cite Radieuse in Marseilles. The building is an extension of his Dom-Ino system and Cité Frugès and was built by inserting prefabricated elements into a concrete skeleton of beams and columns.

The debate between architects and engineers on industrialization of construction methods, and the various trial projects in Europe during the first four decades of the 20th century,

were the intellectual foundations and paved the way for the wide-spread use of

prefabricated housing in Europe and the Soviet Union after WWII. That was coupled with new manufacturing technologies and materials along with social revolutions and political 20 https://en.wikipedia.org/wiki/Cité_Frugès_de_Pessac

reforms that enabled what were once experimental designs to become the basis for one of the largest housing programs in history. Demand for new homes increased at an

unprecedented pace after 1945, particularly in war-torn Europe and the Soviet Union, where urbanization was rapidly taking place. It is therefore no surprise that architects and city planners turned to industrial production methods in order to meet housing targets. It was the ruin that virtually all of Europe and Soviet Union found themselves in that was the pivotal moment that called for the mass adoption of standardization, rationalization and prefabrication in the construction industry. Most of Europe had to be rebuild and millions of people had to be housed rather quickly. A standardized building system based on an

assembly with buildings made of concrete and steel seemed to be the answer.

3.5. AFTER THE WWII

There are two figures that stand out in the widespread adoption of prefabrication (with concrete) after the WWII - Hans Schmidt and Raymond Camus.

3.5.1. Eastern Bloc

Hans Schmidt, a Swiss architect was the theoretical mind that pioneered radical

standardization in GDR22 . was also the head architect of Institut fur Typung (Institute of

Standardization) in GDR and had extensive experience with planning cities in the Soviet Union, where he had been invited as an expert to help with the transfer of expertise from the west to the east (similarly as Le Corbusier).

Raymond Camus was a French engineer and inventor of the globally successful Camus System – a concrete prefabrication system.

The push for mass adoption of prefabrication of course needed a political backing, which came from Nikita Khrushchev23 in 1955, with his core demand to introduce prefabrication

methods in order to solve the housing crisis. After this, prefabrication became the virtually the sole method of housing construction in the Soviet Union and its satellites (including GDR and my native Czechoslovakia). In the Eastern Bloc, the first prefabricated-panel factory went into operation in Hoyerswerda (East Germany) in 1957, which put the GDR at the international cutting edge of construction technology.

Between 1.8 – 1.9 million homes were built in GDR during the 1970s and 1980s using large, prefabricated panels. This method of construction was extremely economic, since the wall and floor elements, which formed a closed building system, were mass produced with a high degree of repetition. Political pressure and a sole focus on efficiency and quantity led to the construction of buildings with major aesthetical and architectural shortcomings. The form of these buildings was very large which was another factor that led to the skepticisms towards prefabricated buildings from a general society. Nowadays, these shortcomings are easily avoidable.

22 German Democratic Republic (aka East Germany) 23 Led the Soviet Union between 1954 - 1963

3.5.2. The Camus System

In 1951, Raymond Camus, a former Citroen24 employee, built first housing with his system

of prefabricated concrete panels. The project was a success, so he went on to build a first precasting factory (modelled on the processes he observed while at Citroen) in 1954 and in 1956, received a French government contract to build 4000 homes25.

Each of his panels was of high quality enough to make any post processing or modification on site unnecessary, which essentially eliminated the practice of rotating different trades on site, the coordination of which was prone to causing delays.

The economic success of Camus’s large, prefabricated panel system, it was one of the means by which the French government reached the very ambitious objective of constructing 20,000 dwellings a month26, can be attributed to a number of factors.

First, it made it possible to construct buildings in far greater numbers at a constant rate of production. Second, the system prefabricated larger, high-quality building elements with finished surfaces and built-in windows, doors and installations. Third, machines (for example, stationary molding machines with heat treatment systems and slip formers) extensively replaced manual work. Fourth, the system drastically reduced the work required for assembly and finishing. Fifth, the large concrete panels made it economically viable to even erect buildings with up to 20 floors.

Camus then went on to build factories in other French cities and was producing enough building parts to building approx. 20,000 residential units each year. He also licensed his system for use in Austria, Germany, the Soviet Union and French overseas territories and former colonies in Africa. By the mid-1960s, Camus had six factories in France and 16 factories in other countries, such as the U.K., Germany, Italy, Russia, and Algeria.

Concrete prefabrication was not, of course, centered solely on Europe and Soviet Union. In the 1960s and 1970s, architects and engineers started experimenting with spatial modules (3d volumetric modules). Some of the best examples are Habitat 67 and the Nakagin Capsule Tower. Habitat 67 was designed and built by Moshe Safdie for the Expo 67 in Montreal and Nakagin Capsule tower by Kisho Kurokawa in Tokyo.

24 A French car manufacturer

25 Meuser, P., & Albus, J. (2020). Prefabricated Housing: Construction and Design Manual. DOM publishers. 26 http://postwarbuildingmaterials.be/material/heavy-prefab-systems/

Figure 3.5 Habitat 67 Source:

https://en.wikipedia.org/wiki/Habitat_67#/media/File:Habitat_67,_southwest_ view.jpg

Figure 3.6 Nakagin Capsule Tower Source:

https://www.archdaily.com/110745 /ad-classics-nakagin-capsule-tower-kisho-kurokawa

3.6. AFTERTHOUGHT

Our architectural culture in Europe holds reservations towards standardized construction systems. And these reservations stem from futile attempts of the past to build mass housing that would be accepted by broader society using a uniform construction method. We can find many examples in Czech Republic, Germany, France, where pilot projects, celebrated by politicians, very often led to socially deprived areas, or even ended up being demolished. Prefabrication methods have been used and are still used particularly during times of crisis – such as during the post-war housing shortage. Historical examples of mass prefabricated housing have therefore often neglected the aesthetic and creative aspects for the sake of greater efficiency, which has in turn lead to the poor reputation of prefabricated buildings But we cannot blame these architectural plights on the construction method – on

prefabrication – itself.

4. CATEGORIZATION AND CLASSIFICATION

Nowadays, all conventional construction materials are used for prefabrication (steel, wood, concrete, and hybrids/alloys). Concrete is still the predominant material in prefabricated housing in Europe. In contrast, in North America, timber is the most predominantly used material in prefabricated housing.

We can categorize modular or prefabricated construction in a myriad of ways. In the following text, I will explore the most common classifications:

▪ Volumetric (3-D) ▪ Non-volumetric (2-D)

We can further divvy it up into four broad building methods, that all utilize various materials. These methods are:

▪ Block construction

▪ Panel construction (i.e. ceiling height self-supporting elements) ▪ Skeleton frame construction (a frame/skeleton with infill walls)

▪ Modular (prefabricated volumetric/spatial/three-dimensional modules)

McKinsey and Company then distinguishes the above classification (which is based on scale) by its complexity - as we can see in the following figure.

Figure 4.1 Classification and complexity of prefabricated building systems

Source: McKinsey & Company. (2019). Modular construction: From projects to products.

https://www.mckinsey.com/business-functions/operations/our-insights/modular-construction-from-projects-to-products In the left bottom corner, we can see the simplest single elements that are clipped/bound together using standard connections and interfaces.

As we move up on the y-axis, we find two-dimensional panels (which can be part of open or closed end systems) with increased complexity in the form of pre-fitted fixtures (such as doors, or windows) and services (HVAC, electrical/network).

The x-axis moves us from single blocs to three-dimensional volumetric units with full fixtures.

When applied, modular projects often involve multiple types of prefabrication. For instance, volumetric modules can incorporate non-volumetric materials such as structural

volumetric modules (e.g., apartment buildings, or hotels) that in turn include smaller volumetric modules for restrooms or mechanical rooms.27

These classifications can be of course extended to consider the distance of the factory to the construction site. The current trend are near-site factories (as it had been at the beginning of last century).

The choice of a particular prefabricated system depends on the project requirements and its value proposition. For instance, projects that should express the owner’s individuality will require a higher design flexibility – for such projects, high-end, fully fitted panels will be a better solution than fully premade 3D modules. On the other hand, projects that are driven by costs, volume, and repeatability, will likely benefit from factory made volumetric units (modules).

Figure 4.2 Classification by decision factors

Source: McKinsey & Company. (2019). Modular construction: From projects to products.

https://www.mckinsey.com/business-functions/operations/our-insights/modular-construction-from-projects-to-products

4.1. VOLUMETRIC MODULES

As maximizing factory production is the normal path to industrialization, the factory-made 3D module divides a building into volumetric modules completely finished at the plant and easily connected to the infrastructure once at the site.

The factory-made 3D module category implies that all spaces and all components of the building are entirely made, assembled and finished at the plant as structural 3D modules, requiring only a simple onsite assembly, which involves lifting the modules into place and connecting them to the foundations, to services such as electrical and plumbing and simple connections between the modules.

McKinsey notes that a 3D volumetric approach delivers the potential for maximum efficiencies and time savings. But there is a flipside too. The trade-offs include increased

27 Ryan E. Smith, and John D. Quale (2017). Offsite Architecture: Constructing the Future. Taylor & Francis Group.

transportation costs and size limitations of the modules due to traffic regulations. The maximum width for road transport that does not require a special escort is typically around 3.5 meters in width. This either limits the size of the modules or increases the cost of transporting larger modules because carrying the 3D module from the factory to the site implies paying for transportation of “air”, since most of the volume is occupied by empty space and since transportation is usually calculated in terms of volume.

In terms of product uses, 3D modular prefabrication is currently mainly applied in affordable housing projects (both multifamily and single-family buildings) and hotels (such as

CitizenM)28. It is also advantageous for rooms with a more complex finishing, such as

bathrooms and kitchens. As already mentioned, 3D volumetric approach is most suitable for projects with a high level of repeatability, which does not mean that all products need to look the same. Instead, a variety of standardized modules can be pieced together differently to produce a customized end result.

Strategically, significant capital investment is obviously required to initiate and operate a 3D module plant.

4.2. NON-VOLUMETRIC MODULES

A 2D panelized solution resembles a flat-pack assembly approach used in home furniture. Where necessary, panels contain the necessary conduits for services such as heating, ventilation, and air conditioning (HVAC), and plumbing that can be linked together with standard connectors.

The assembly work onsite is much simpler than a traditional build, but it is more complex than putting together 3D modules and requires more internal finishing (and thus labor). On the upside, it is much easier to transport panels than bigger 3D modules – especially for longer distances. In an ideal case, the components required to build several rooms can fit in a single ISO container. 2D panels therefore make it possible to transport materials for a significantly greater floor area at one time.

2D panelized solutions offer greater flexibility than 3D modules: large open-plan offices, for example, are not very suitable for single 3D modular elements. 2D panels are more relevant for high-end residential projects, whether single-family homes or apartments, that require higher design flexibility since differentiation matters and the ratio of wet areas to dry areas is lower than for instance in hotels.

4.3. 2D & 3D HYBRID

It is also possible to use a mix of 3D modules and 2D panels on a project or to combine those approaches with traditional site work (for instance, for the basement and first floor of a larger project). Typically, bathroom pods/kitchen areas are prefabricated, while the remainder of the building is made from 2D panels. According to McKinsey, this optimizes the process for the two different areas of the building. However, the manufacturing process required to deliver both solutions become more complex as most likely multiple

manufacturers/suppliers with multiple systems get involved, as does coordination of the rest of the supply chain.

5. TRANSPORT AND LOGISTICS

Transportation plays such a crucial role in prefabricated construction that I want to devote a separate segment to it. In the end, whatever is prefabricated offsite, must be able to be transported and assembled on site; transportation and logistics therefore represent an important consideration and constraint.

The cost of transportation is an integral part of offsite fabrication that determines the feasibility of the specific applications. Generally, the growing distance between the job site and prefabrication facility makes offsite production less effective compared to conventional construction.

The maximum operational radius varies by country, its quality of road networks, cost of fuel and the type and material of the modules (for instance, concrete is approximately four times heavier than timber per cubic meter and thus a lot more costly to transport). There is not a consensus what the maximum operational radius is. The range varies between 150 – 300 km. Generally, allowing one transportation cycle per day (i.e. ±200km) is advisable. According to industry expert opinions from a UK engineer at Buro Happold and Pulte Home Sciences in the US29, about 200 km or 125 miles from the plant are proposed as the limit of cost-effective shipping, which coincides with the regional distribution of modular builders.

As such, transportation is an important factor in determining the viability of prefabrication approaches. As previously mentioned, it does impact the size and shape of elements (linear, flat components vs. volumetric modules) that can be economically shipped. Therefore, on-site or near-on-site prefabrication approached should be considered also.

5.1. ON-SITE LOGISTICS

We must consider not only transportation from factory to site but also transportation and logistics on site. In case of precast concrete elements and modules, weight is a significant constraint the requires the use of various types cranes.

A wide range of different types of cranes can be used on construction sites as means for lifting and moving materials and other building elements from place to place. The choice of crane for a given site will depend a number of different factors, including:

▪ The weight of the loads that need to be lifted.

▪ The height and horizontal distances that need to be covered. ▪ The radius of the swing.

▪ The time period of the lifting operations.

29 Ryan E. Smith, and John D. Quale (2017). Offsite Architecture: Constructing the Future. Taylor & Francis Group.

▪ The degree of mobility required.

We can differentiate between mobile (truck mounted or gentry cranes) and static/tower cranes.

In general, mobile (truck mounted) cranes are used for smaller or medium sized projects (lower to mid height). The main advantage of mobile cranes being their flexibility (mobility), lower cost to rent, and a quick site preparation. The disadvantage are the limited lifting capacities, although it’s not uncommon that mobile cranes can lift around 50t.

Static cranes are required when building vertically (tall towers) or lifting especially heavy elements (such as bespoke trusses, etc.).

6. THE BENEFITS OF MODULAR

CONSTRUCTION

A modular construction method is more likely to succeed if the industrial production process is considered from the outset, during the preliminary design stage. If implemented properly, modular construction can provide significant efficiencies and benefits to the project’s stakeholders.

6.1. TIME SAVINGS

As we have seen in some of the previous examples, and as McKinsey30 observed, early

modular projects have a mixed track record of cost savings, however, they have consistently been completed 20–50 percent faster than conventional onsite builds. Let’s divide a

construction project into three main stages (Design, Foundations, Construction/Production) and describe the benefits when built with volumetric modules.

6.1.1. Design

The design and planning phase initially take longer when building with modular construction as opposed to building with conventional methods. Design decisions need to be made upfront, need to be more detailed (concept design, architectural design and technical drawings need to be completed before moving into production) and changes later in the process are not possible or more costly and more difficult. This can also be an advantage that can prevent revisions and change orders. Needless to say, that the industry is currently not used to working in this way. McKinsey notes that modular projects currently tend to take longer to design than traditional projects, as designers learn to align to the

manufacturing process. However, as potential repeatability is one of the a priori factors that affect the use of modular construction, the design period can be shortened on any future projects that re-use the same modules. The design period will likely shorten in the future as designers develop libraries of various modules for the manufacturing process.

30 McKinsey & Company. (2019). Modular construction: From projects to products.

https://www.mckinsey.com/business-functions/operations/our-insights/modular-construction-from-projects-to-products

6.1.2. Foundations

The effect on the time that it takes to build the foundations of the project very much depends on the type and size of the project and type of modules used. Modules made from lightweight alloys/cross laminated timber might require less complex foundations. The biggest advantage of offsite construction is that it can begin simultaneously with the foundation work, whereas conventional construction can logically begin only with completed foundations.

6.1.3. Offsite construction

The lean offsite manufacturing process is significantly faster than the equivalent building process onsite. Factory environment is enclosed and controlled, activities can be better planned and coordinated, some of them also automated (which is currently difficult on site). Capacity and output are also impacted by the number of shifts; factories can work

theoretically with three shifts on multiple projects and are not affected by adverse weather conditions.

6.1.4. Onsite construction.

The construction work on-site, when building with 3D modules, is significantly simplified from conventional construction methods. As previously mentioned, it boils down to transporting the modules to their location on site, connecting the modules to their

foundations, services and between each other. McKinsey writes that “typically, one team of five workers can assemble up to six 3D modules, or 270 square meters of finished floor area, per day. This is significantly faster, and therefore cheaper, than traditional construction”.

6.1.5. Rework

Quality control is much easier and better in a factory environment than on a construction site which has a big impact on rework. The repeatability of work in a factory environment improves the quality of the output. Reducing or eliminating rework significantly improves construction schedules, potentially by up to several months.

Shorter project timelines have a huge impact on the overall financial performance of the project. Developers can start selling or renting out the project sooner, which means a faster revenue generation, which in turn improves the project’s IRR (internal rate of return) and reduced market cycle risks. Shorter project timelines also mean cheaper construction financing (less interest paid). In the end, all stakeholders benefit from certainty in schedules and costs.

McKinsey observes 20-50% faster building schedules when building with prefabricated 3D modules, compared with conventional construction.

Figure 6.1 Time Savings and Benefits of Modular Construction

Source: McKinsey & Company. (2019). Modular construction: From projects to products.

https://www.mckinsey.com/business-functions/operations/our-insights/modular-construction-from-projects-to-products

6.2. COST SAVINGS

Economies of scale and cost savings are some of the fundamental benefits of a

manufacturing/industrialized approach in other industries. But based on McKinsey’s report and my conversations with modular manufacturers (DMD Poland, Progress Group) there is not a clear track record of consistent cost savings among projects built with modular construction following this model.

However, there are two further aspects relating to costs that are important to consider: the first pertains to the full life-cycle costs and the impact that modular construction can have on them; the second is the cost of the factory investment itself and how this impacts the overall cost savings that can be delivered.

6.2.1. Construction costs

The integrated processes involved in modular construction remove the need for engaging various subcontractors on site and the margins that they include in their quotes. Next, significant cost savings can be achieved on onsite labor (and the rework / inefficiencies caused by different trades) These savings, however, can be offset by an increase in logistics costs.

Modular projects also tend to have higher upfront design costs (at least for the initial

project) against lower costs for rework and redesign. Therefore, the projects which are most likely to deliver the greatest cost savings are those that have the highest proportion of labor-intensive activities and the greatest levels of repeatability (such as student

accommodation, hotels and affordable housing). As noted above, high-end apartments and office buildings are examples of where significant savings are currently harder to achieve.

Figure 6.2 Potential Cost Savings of Modular Construction

Source: McKinsey & Company. (2019). Modular construction: From projects to products.

https://www.mckinsey.com/business-functions/operations/our-insights/modular-construction-from-projects-to-products

6.2.2. Site overheads

As noted above, modular construction can reduce project schedule by up to 50%, which in turn reduces the costs associated with site overhead (e.g. construction management).

6.2.3. Materials.

Material costs represent a major variable. On one hand, their costs can be reduced by centralized and bulk procurement for a production in factory (rather than for a single project). Factory production can also lower costs by reduction of material waste, which can

be achieved by planned production, repeatable processes and the overall controlled environment. On the other hand some duplication of materials is required to produce a transportable product. Buildings need to be structurally sound in situ, but buildings built using offsite construction methods also need to be structurally sound while being raised and lowered throughout the transportation and assembly stages on site, which increases the amount of material needed for their construction.

6.2.4. Labor force.

McKinsey notes that in a modular construction, up to 80 percent of the traditional labor activity can be moved offsite to the manufacturing facility. Some of the most skill-intensive and expensive types of work (including mechanical, electrical, and plumbing) can be handled by lower-cost manufacturing workers, reducing the wage bill.

More importantly, the more standardized, automated, and controlled operating environment of a factory can increase productivity above what can be achieved with traditional builds and eliminate a great deal of down time onsite due to coordination between different trades. Additional benefits (time savings) in offsite construction can be establishing because of simplified, repetitive processes or advanced automation equipment. Overall, McKinsey estimates a transition to offsite manufacturing to reduce the labor costs on a project by up to 25 percent. The savings are more substantial when more of the high-value activities such as electrical, plumbing, and HVAC installation can be migrated offsite. This is, however, country dependent.

6.2.5. Transportation and Logistics

As discussed above, transportation and logistics play a crucial role in modular construction. According to McKinsey, the total cost of a project can increase by up to 10 percent in locations with restrictive transport regulations or poorly managed transportation.

6.2.6. Factory costs

Last but not least, the cost of building the factory needs to be considered against any cost savings. Repaying the capital investment and the ongoing operational expenses of running the factory need to be included. By building a business case for the factory itself and assuming a reasonable rate of return on the facility as well as depreciation, operating expenditure, and machinery replacement a cost impact can be estimated. McKinsey notes that depending on the type of modules and the level of the factory, factory costs can make up between 5 percent and 15 percent of total costs on a construction project.

7. BRAZIL

7.1. ECONOMY OVERVIEW

Brazil is the world's fifth-largest country (and the largest contiguous territory in the Americas); it is the sixth-largest country by population with its 212 million people31 and currently the ninth32 in terms of nominal GDP. It is currently the world's eighth-largest economy and is expected to be the world's fifth-largest economy by 205033.

Brazil is the world's largest exporter of beef, orange juice, sugar, coffee, and iron ore and competes with the US to be the world's biggest soya bean exporter. Almost half these soya bean exports go to China, and the share is rising due to the US-China trade war.

Brazil's economy has become much more diversified in the past decade. Agriculture employs 12.6% of the workforce. Manufacturing accounts for 11.0% of GDP and employs 11.0% of the workforce. In comparison, Brazil's service sector makes up 72.7% of GDP, of which the tourist sector, with an estimated 6.7 million tourist arrivals in 2019, accounts for around 8.1% of total GDP.34

The country still depends on the production of minerals, farm products, and other raw materials, but this dependence is much less than in the past. Economic success brought significant improvements in poverty reduction, but inequality remains relatively high for a middle-income country. Brazil's GDP per capita is ± USD 15 000 in PPP terms and has been following a recovering path since 2016, with a dent caused by the COVID-19 pandemic.

The real GDP contracted by 3.5% and 3.3% in 2015 and 2016, respectively. It grew on average by 1.2% between 2017 and 2019. However, Brazil's economy will contract

substantially in 2020 (between 5-6%). The domestic activity has been affected by measures taken to contain The Coronavirus (COVID-19) pandemic, although there are signs that a recovery got underway in quarter 3. Assuming the pandemic is contained, the Brazilian economy should bounce back in 2021, with real GDP growth of 3.2% in 2021 and annual growth averaging around 2.4% per year in 2025-2027.35

31 https://en.wikipedia.org/wiki/List_of_countries_and_dependencies_by_population 32 https://en.wikipedia.org/wiki/List_of_countries_by_GDP_(nominal)

33 https://www.pwc.com/gx/en/research-insights/economy/the-world-in-2050.html 34 Economist Intelligence Unit

Figure 7.1 Brazil GDP Growth Rates: 2000-2020

Source: OECD. (2020). OECD Economic Surveys: Brazil 2020. https://www.oecd-ilibrary.org/content/publication/250240ad-en

The recorded unemployment rate in 2019 was 11%; however, this year's (2020)

unemployment rate is expected to reach almost 16% and then stay above 10% until 2024.

Figure 7.2 Unemployment and Employment in Brazil: 2012-2020

Source: OECD. (2020). OECD Economic Surveys: Brazil 2020. https://www.oecd-ilibrary.org/content/publication/250240ad-en

Low inflation (from 2016, inflation stayed below 4%) combined with more disciplined fiscal policy and global deflationary pressure have allowed Brazil to practice all-time low-interest rates.

The following figure shows the four major economic indicators with a forecast based on three scenarios. The blue line depicts a baseline scenario; the green line depicts a favorable scenario with better improvements in the economy (for instance, by better-than-expected containment of the pandemic); while the orange line depicts slower improvements in the economy (for instance, caused by prolonged global pandemic).

Figure 7.3 Projection of key macroeconomic indicators in Brazil (Real GDP Growth Rate, Inflation, Interest Rate, Unemployment Rate)

Source: © Euromonitor International 2020

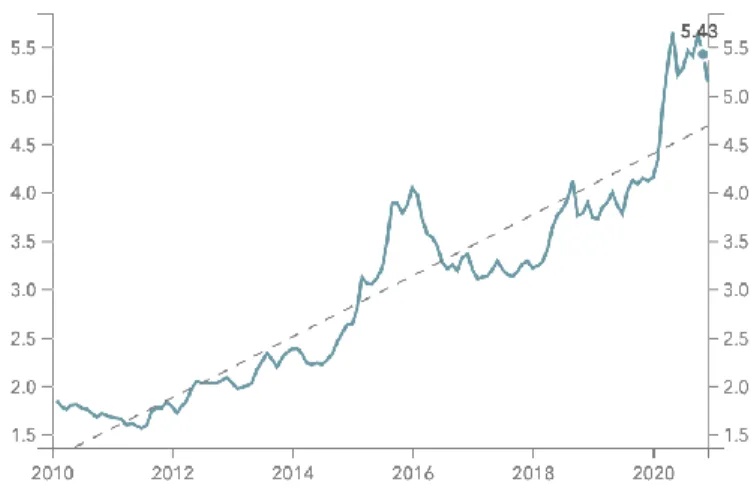

Lastly, let us take a look at the evolution of the Brazilian currency – the Real against the US Dollar. Brazilian Real is currently at all-time historic lows against the US Dollar, as shown in the following exhibit. However, the Economist Intelligence Unit expects the currency to strengthen against the USD and stay below the psychological line of five Reais per USD in 2021 and 2022.

Figure 7.4 Evolution of the Brazilian Real agains the US Dollar

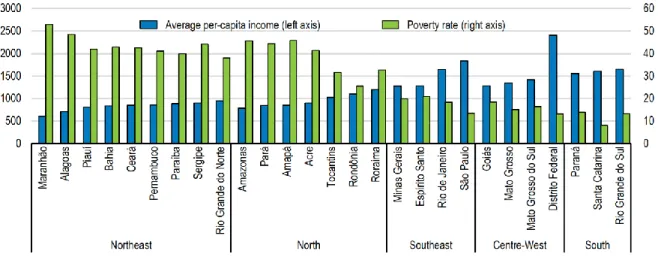

7.2. ORGANIZATION

Administratively, Brazil is divided into 27 federal units or states, including the federal district with Brazil's capital Brasilia. We can group the states into five broad geographic regions – the North, Northeast, Central-West, Southeast, and South. The regions vary considerably in size and characteristics. Several Northern states (those in the Amazon Basin) are very new, having formed only in the past few decades. The Northern states are growing yet remain very small, underdeveloped, and remote. In contrast, Sao Paulo state alone would be the second-largest economy in all of Latin America (after only Mexico) if it were a separate country. The state of Sao Paulo contributes over a third of Brazil's GDP

Figure 7.5 States and Regions of Brazil

Figure 7.6 Per-capita Incomes in Brazilian States

Source: OECD. (2020). OECD Economic Surveys: Brazil 2020. https://www.oecd-ilibrary.org/content/publication/250240ad-en

7.3. POPULATION

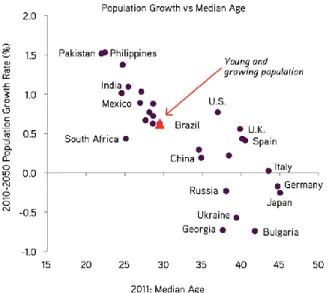

As previously mentioned, Brazil is the world's sixth-most populous country with

approximately 212 million inhabitants. The population is relatively young (especially for an upper-middle-income country), and it is growing. Brazil's youthful demographic profile is a tremendous asset for its real estate investment potential. The median age in Brazil was 33 in 2019 and is not forecast to surpass 40 before 204036. This is a positive sign that household formation should remain strong and thus demand for new housing too. Furthermore, Brazil is aging at a much slower pace than Europe, Japan, North America, or emerging markets such as China or Russia37.

36 Euromonitor International

Figure 7.7 Population Growth vs. Median Age

Source: KKR. (n.d.). InsIghts Global Macro Trends: Brazil. Retrieved December 19, 2020, from https://www.kkr.com/sites/default/files/KKR_Insights_120509.pdf

Figure 7.8: Brazil Population by Age Group

Source: OECD. (2020). OECD Economic Surveys: Brazil 2020. https://www.oecd-ilibrary.org/content/publication/250240ad-en

Brazil is a highly urbanized country with some 86% of Brazilians living in cities, a proportion that rose from 36.2% in 1950 to 75% in 1990. Urbanization is expected to continue to grow going forward, although at a slowing pace, reaching approximately 90% by 2030.

Cities thus became the core of economic activity (90 percent of gross domestic product, GDP), with large cities becoming diversified, taking advantage of large markets for inputs and ideas.

According to the national census, Brazil had approximately 67.2 million households in 2020; 86.5 percent lived in detached homes, and the rest in apartments. In 2020, 73 percent of households (83% of urban) owned their homes, 19% lived in rental housing, and the rest in

shared accommodation. As we can see, Brazilians have a propensity to homeownership, and the shift to homeownership has been a response not only to culture and believes but also to favorable government policies. Homeownership is quite high even among the poorer strata of Brazilians, and this is achieved because their housing is of poor quality and is often self-built.

7.4. INCOME DISPARITIES

Income inequality is a negative feature of Brazilian society and has been entrenched in the country for centuries. Brazil exhibits one of the world's highest (and the highest in Latin America) Gini coefficients38 (53.9 in 2018 and 63.3 in 1989).39 A statistical measure of income inequality within countries.

The richest 10% of the population earn more than four times as much as the bottom 40%. The following exhibit shows us that inequality and poverty have fallen over the past two decades due to strong growth, improvements in education, and social transfers. However, the 'double-dip' recession from 2014 – 2015 and 2020 somewhat stopped the poverty reduction, which has stabilized at around 20% of the population.

Figure 7.9 GINI Coefficient

Source: OECD. (2020). OECD Economic Surveys: Brazil 2020. https://www.oecd-ilibrary.org/content/publication/250240ad-en

The middle class has expanded rapidly in the last decade, and as of 2020, it comprises approximately 55% of the country's total population. In the period 2002–2014, the middle class expanded considerably, and the lower segments have decreased even more, from 43% of the total in 2002 to 32.5% in 2008 and down to approximately 20% in 201440. Such a positive development in Brazil contrasts with the erosion of the middle classes in some

38 The Gini coefficient measures the deviation of the distribution of income (or consumption) among individuals or households in a given country from a perfectly equal distribution. A value of 0 represents absolute equality, whereas 100 would be the highest possible degree of inequality.

39 World Bank

developed countries where high debt burdens, job insecurity, and falling values of household assets are translating into weaker real estate demand

Figure 7.10 Middle Class Population and its Growth Globally Source: KKR. (n.d.). InsIghts Global Macro Trends: Brazil. Retrieved December 19, 2020, from

https://www.kkr.com/sites/default/files/KKR_Insights_120509.p df

Figure 7.11 Middle Class Growth in Brazil

Source: https://www.wsj.com/articles/middle-class-brazil-lifts-voice-1411511724

8. REAL ESTATE MARKET

Brazil's stock of real estate has not kept up with the quantity and quality required by businesses and households. The country has enormous catch-up potential relative to the developed global economies and ample opportunity to innovate and build market share.41

Investment has been primarily focused in the markets of Rio de Janeiro and Sao Paulo; however, secondary markets also offer compelling growth dynamics. Growth in Brazil is underpinned by surging global and local demand—GDP growth, incomes, population, urbanization, demand for a higher quality product, and other factors are strong and will continue to fuel real estate.

The for-sale residential industry has boomed in recent years and should continue to enjoy healthy fundamentals as demand continues to outstrip supply. Mass housing development in the for-sale category should continue to do well as Brazilians have little propensity to participate in the rental market. Lynn believes that home builders targeting developments in well-located submarkets of first- and second-tier cities should continue to do well in the coming years.42

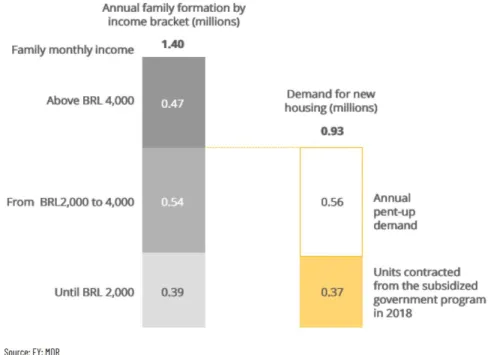

This view is shared by analysts at IMERI capital, who write, "Brazil has a growing pent-up

demand in the residential segment: every year ±1.4 million new families are formed, whereas new constructions are limited to a total of 800 thousand. This 600 thousand

household deficit is concentrated on the low-income segment. Homebuilders focused on this

41 Lynn, D. J. (2010). Emerging market real estate investment: investing in China, India, and Brazil. Wiley. 42 Lynn, D. J. (2010). Emerging market real estate investment: investing in China, India, and Brazil. Wiley.

segment have been enjoying both sales growth and high returns (50%+ IRRs and 5x MOICs) on the back of the unprecedented low cost of capital levels."43

Figure 8.1 Annual Family Formations in Brazil and Demand for New Housing

Source: IMERI Capital. (2020, July). Brazilian Real Estate: Market Overview. https://imeri.com/wp-content/uploads/2016/01/20200706_Imeri_Real.Estate_Insights.original.pdf

David Lynn further notes that "The quality of the competition ranges considerably. Most are

new companies lured to the high returns and the perceived glamour of real estate development. Most of these companies are inefficient, have little knowledge of best practices, and produce a dubious-quality product. There are few regional players and national firms. Many firms are relatively unsophisticated, with most personnel having limited real estate experience. However, by and large, the real estate and construction industries are characterized by inefficient techniques and technology, resulting in sub–Class A product. Sao Paulo and Rio de Janeiro tend to have the best developers and construction capabilities and are attracting the vast majority of foreign investors and developers."44

As is the case in many emerging markets, the market is not entirely transparent. It is

relationships driven. Relationships must be developed with business partners as well as with local, in case of major developments, regional, and national governments.

8.1. RESIDENTIAL MARKET

The residential sector can be characterized by three (four for international investors) favorable patterns:

▪ First, there is a deficit of more than 6 million units of housing.

43 IMERI Capital. (2020, July). Brazilian Real Estate: Market Overview. https://imeri.com/wp-content/uploads/2016/01/20200706_Imeri_Real.Estate_Insights.original.pdf

▪ Second, the highly unequal nature of Brazil's society has meant that the shortage is most acute in the lower-middle-class, working-class, and affordable housing strata. ▪ Favorable monetary policy and all-time low-interest rates (discussed above)

▪ Weakness in Brazilian Real, which is at historic lows against the US Dollar (discussed above)

Let us take a look at the housing deficit, as I've described the other three forces in the previous chapters.

8.2. HOUSING DEFICIT

The housing deficit in Brazil is comprised of units that meet the following criteria, including (a) excessive spending on rent (more than 30 percent of household income); (b) involuntary cohabitation (when more than one household living in the same premise); (c) quality of building and access to infrastructure; and (d) a number of persons per unit or over-crowding.

Brazil's housing deficit is one of the largest in the world. Since the former president Luiz Inácio Lula da Silva, governments have been taking significant steps to address this problem. In 2003, the "Ministério das Cidades" (Ministry of Cities) was created, and the "Política Nacional de Habitação" (PNH) was approved. These measures signaled a broader effort to deal with urban development challenges and housing in general.

Between 2007 and 2014, the housing shortage in Brazil increased from 5,8 to 6,1 million dwellings, ranking as one of the country's major social problems.

Fundação Getulio Vargas (FGV), a renowned Brazilian university, was hired to conduct a study to estimate scenarios for housing demand until 2025. The analysis projects a need of 14.5 million units between 2015 and 2025 on top of the existing housing deficit (of ±6 million units) to house the growing population and newly formed households.

The analysis projects a needed annual increase of the housing stock for the five regions as follows: the Northern region 2,21% p.a., followed by the Center-West (2,13% p.a.),

Northeast (1,98% p.a.), Southeast (1,63% p.a.) and finally the most developed Southern region with 1,59% p.a.

In terms of income, the most significant increment (6.8 million units) should occur for the lowest-earning households (Faixa 1) with incomes between R$1.600 (U$488.27) and R$3.275 (U$999.42), followed by 3.3 million units for Faixa 2 households with incomes between R$3.275 and R$5.000 (U$1,525.83) and 1,6 million units for Faixa 3 households with an income higher than R$10.000 (U$3,051.66).45

45 Hamilton de França Leite, Elsinga, M., & Hoekstra, J. (2016). LAR: a new affordable housing rental system for Brazil. http://www.hamiltonleite.com.br/lar.pdf