Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

ASCE Pipeline Conference 2010: 28 August 2010, Keystone, Colorado, USA [Proceedings], pp. 1-11, 2010-08-28

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=b126c138-6549-4bb8-a83d-240763b0f8ba https://publications-cnrc.canada.ca/fra/voir/objet/?id=b126c138-6549-4bb8-a83d-240763b0f8ba

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Condition assessment methods for AC pipe and current practices Hu, Y.; Wang, D. L.; Chowdhury, R.

http://www.nrc-cnrc.gc.ca/irc

Condit ion a sse ssm e nt m e t hods for AC pipe a nd c urre nt pra c t ic e s

N R C C - 5 3 5 2 3

H u , Y . ; W a n g , D . L . ; C h o w d h u r y , R .

S e p t e m b e r 2 0 1 0

A version of this document is published in / Une version de ce document se trouve dans:

ASCE Pipeline Conference 2010, Keystone, Colorado, USA, August 28-September 1, 2010, pp. 1-11

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d'auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d'identifier la source de l'information et, dans certains cas, d'interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

Condition Assessment Methods for AC Pipe and Current Practices

Yafei Hu1*, Dunling Wang1, and Rudaba Chowdhury1

1

NRC Centre for Sustainable Infrastructure Research

Institute for Research in Construction, National Research Council Canada #301, 6 Research Drive, Regina, SK S4S 7J7

ABSTRACT

Asbestos cement (AC) pipe was first introduced in North America in 1929 and became a common choice for potable water main construction from the 1940s to the 1970s. To understand the condition of AC pipe in North America, a survey was conducted that obtained information about AC pipe inventory, pipe conditions, working environments, rehabilitation/replacement methods, and safety and health-related management practices. This paper summarizes the AC condition assessment techniques used by the surveyed utilities. It also reviews other available condition assessment methods for AC pipes.

1. INTRODUCTION

Asbestos cement (AC) pipe was first introduced in North America in the late 1920s and became a common choice for potable water main construction from the 1940s to the early 1970s. The installation of AC pipe was curtailed in North America in the late 1970s but AC pipe is still a significant portion of the water distribution systems in many North American cities. Two prior surveys indicated that about 12 to 15% of water mains in the water distribution systems of the United States and Canada were AC pipes (Kirmeyer et al., 1994; Rajani and MacDonald, 1995). Like pipes made of other materials, AC pipe corrodes as a result of chemical reactions with its environment. Two deterioration processes typically occur in AC pipe:

• Lime leaching: The free lime formed during hydration maintains the strength of the cement matrix, but free lime can be leached from the cement by water in contact with the pipe surface. Soft water with very low ion content (low carbonate and bicarbonate content) is aggressive to free lime and results in the leaching of free lime from AC materials.

The free lime, due to its alkali nature, can also react with acids in conveyed water and groundwater in the surrounding soils. Strong acidic conditions are relatively rare in treated drinking water systems. Carbonate and sulphate are the two main corrosion agents that react with free lime to form calcium carbonate (calcite) and calcium sulphate (gypsum), respectively. However, strong, external acidic environments may exist in wetland soils due to decomposition of plants or in contaminated soils (e.g., due to leaks of petroleum products).

Lime leaching from AC pipes can result in a loss of bonding agents and possibly hydrated products. The loss of the bonding agents and hydrated products may release AC fibers and

*

other chemicals, adversely affecting the quality of conveyed water. It may also reduce pipe strength and, therefore, increase the propensity for the pipes to fail.

• Sulphate attack: Sulphate contained in the conveyed water and in the soil pore water (groundwater) can also react with hydrated calcium aluminate or monosulphate to form calcium sulphoaluminate (ettringite) (Matti and Al-Adeebt, 1985). According to Matti and Al-Adeebt (1985), gypsum and ettringite formed by these reactions occupy considerably more volume (123 to 224%) than the original solids they replace. The formation of these compounds causes swelling, which can ultimately lead to the expansion and destruction of the cementitious portion of AC pipe.

In summary, AC pipes are susceptible to attack by acidic, soft or sulphate-bearing conveyed water and surrounding soils or groundwater. As a result of the attack, AC pipes deteriorate. The deterioration compromises not only water quality, but pipe strength as well. In severe cases, AC pipes may even fail structurally.

Facing public demand for higher levels of service and accountability, and more stringent water quality and environmental requirements, many water utilities are eager to develop short-term plans and/or long-term strategies to manage AC water main assets. The ability to assess and map the present condition of water mains and to forecast future failure is key to the development of such strategies.

To understand the state of AC pipes in North America, a survey was conducted by the National Research Council Canada, in collaboration with the Water Research Foundation (WRF). Responses were obtained from 20 utilities with AC pipes inventories in the United States and Canada. The survey included questions about pipe length, breakage history, pipe working environments, current rehabilitation/replacement and other management practices for AC pipes. This paper presents the current condition assessment practices employed by utilities that responded to the survey. It also describes other currently available condition assessment methods.

2. AC PIPE CONDITION ASSESSMENT

A comprehensive review by Dorn et al. (1996) summarized the techniques for assessing the condition of water pipes or water distribution systems. The techniques that are best suited to AC water mains can be categorized into four groups: internal environment assessment; external environment assessment; pipe inspection; and performance and physical data assessment. Table 1 lists the assessment techniques in these groups and the techniques are described below.

Table 1 Techniques suitable for AC pipe condition assessment

Category Assessment techniques

Internal environment calcium carbonate saturation analysis, water quality testing

Pipe examination and sample testing

visual observation, hardness tests, phenolphthalein test, strength tests, scanning electron microscopy-energy dispersive spectroscopy (SEM/EDS) analysis Performance and

physical data failure record analysis, network modeling

2.1 Internal environment

Calcium carbonate saturation analysis

The Langelier Index (LI) and Aggressive Index (AI) are frequently used to assess the internal environment of AC pipe. The indices are based on a measure of the calcium carbonate content of water relative to its pH and are defined as follows (AWWA, 2003; AwwaRF and DVGW-Technologiezentrum Wasser, 1996):

LI = pH - pHs (1) AI = pH + log([A] * [H]) (2) where pHs is the pH value at which water is saturated with calcium carbonate, pH is the measured pH, [A] is alkalinity expressed as mg/L CaCO3, and [H] is hardness expressed as mg/L

CaCO3.

The indices indicate whether conveyed water has a tendency to form or dissolve calcium carbonate scale. If it tends to dissolve scale, water is considered to be aggressive to AC pipes. AI has been incorporated into standards published by ASTM (1998) and AWWA (2003) to determine whether conveyed water is aggressive to AC pipe. Table 2 summarizes the range of AI and LI values and their aggressiveness to AC pipes.

Table 2 Aggressiveness of water quality conveyed in AC pipes

Highly aggressive water Moderately aggressive water Non-aggressive water LI <-2.0 -2.0 to ∼0 ≥0 AI <10 10 to 11.9 ≥12

Since the indices are based on calcium carbonate saturation, they provide a fairly accurate prediction of “non-aggressiveness” provided by a protective calcium carbonate coating if the water is oversaturated. However, if calcium carbonate is undersaturated, there is no reason to expect the saturation indices to predict with accuracy the dissolution of AC pipes, since calcium carbonate is only a minor constituent of cement. In this case, the aggressiveness of conveyed water to AC pipe will be dictated by other chemical equilibriums (Schock and Buelow, 1981). In addition, the indices fail to account for the protective coating of some of the elements in the water as discussed in following section.

Water quality

The physical and chemical characteristics of water are measured on a routine basis at the system inlet, system outlet and at compliance sampling points as part of the statutory requirements for monitoring drinking water quality, and for the purpose of operation and control. These test

results can be used to predict the condition of water distribution pipes in terms of deposits or corrosion.

An increase in pH value and calcium content after water has passed through AC pipes is an indication of leaching of free lime from the cement matrix. The presence of asbestos fibers in conveyed water may also be used to indicate pipe conditions, since deteriorated AC pipes can release asbestos fibers into conveyed water.

Some elements, such as zinc, iron, manganese, and silica are measured on a routine basis at defined sample points as part of a water utility’s compliance program. These constituents have been observed to form protective deposits on pipe walls, primarily oxide compounds, in many field investigations. The conditions and amount of precipitation of such protective coatings depend on the concentration of the metal and silica ions and the pH and redox condition of the water (Millette et al., 1984).

As sulphate in conveyed water can react with free lime and hydrated calcium aluminate or monosulphate in AC material, high sulphate concentrations may indicate an aggressive environment for AC pipes. The sulphate concentrations for neutral and basic (pH≥7) soluble sulphates in water that may affect the condition of AC pipe are described by AWWA (2003).

2.2 External environment

The aggressiveness of soils is defined in terms of the soil pH and the amount of sulphate present. Sulphates occur naturally in many soil forming materials (e.g. some clay minerals) and soils with significant organic content (e.g., peat soil). The presence of water-soluble sulphates can provide “food” for sulphate reducing bacteria, which increases the acidity of the soil. Contaminated soil may contain acidic or sulphate products that are aggressive to AC material. Soil maps (paper or geographic information systems based) may be used to assess pH and sulphate content in an area where AC pipes are buried and to indicate the external working environments of the AC pipes.

Other soil information that can help to assess pipe conditions includes surrounding soil type. Most surface soils are subject to alternative wetting and drying cycles with progression of the seasons. In soils with a high clay content, the soils can undergo significant swelling as moisture content increases and shrinkage as soils dry out. The changes in soil volume, particularly non-uniform changes in a heterogeneous subsurface environment, can induce differential soil movement that can cause the development of stresses in buried AC pipes. The soil physical properties, coupled with soil moisture change information or meteorological data, can be used to assess the loading imposed on pipes, especially for those with diameters less than 200 mm. Inorganic clays with plastic limits exceeding 50% and plastic index over 30% usually have high inherent swelling capacity and are referred to as expansive clays.

2.3 Pipe examination and sample testing

Pipe testing involves removing sample sections of pipes from a distribution system and examining or testing the pipe samples. The examination and testing can include visual observation, scratch tests, Barcol hardness tests, phenolphthalein tests, elemental/petrographic analysis, and mechanical tests such as crush, hydrostatic, bending, or splitting compression tests.

Visual observation is used to identify gross defects and assess the general condition of a sample. The inspection result is generally documented in the form of a written report and photos.

Hardness tests include scratch tests by fingernail or metal scraper and Barcol hardness tests using Rockwell “L” hardness measurements and modified Shore “D” durometer readings:

• Fingernail scratch tests for evaluating the softening of the AC pipe interior consist simply of determining whether a pipe surface can be scratched with a fingernail (Buelow et al., 1980). Scratch tests can be used in the tentative identification of minerals in the field. New AC pipes cannot be scratched with a fingernail, but a severely attacked AC pipe can. A metal scraper has also been used for scratch tests (AwwaRF and DVGW-Technologiezentrum Wasser, 1996). Although a fingernail/metal scratch test is useful for the tentative identification of pipe condition in the field, this measure cannot quantify the degree of attack for comparison of relative conditions throughout a pipe network.

• For conducting Barcol hardness tests, a Rockwell “L” hardness instrument or a modified Shore “D” durometer is pressed into the pipe wall. By applying a certain force and measuring the penetrated depth, a measure of the hardness is given (Millette et al., 1984). Laboratory tests have indicated that the hardness measurements and the durometer readings can be used to estimate the depth to which calcium had been lost from a pipe exposed to aggressive water when the measurements were compared with the results from a scanning electron microscope (SEM) (Millette et al., 1984).

The phenolphthalein test is particularly suitable for assessing the condition of cementitious materials like asbestos cement (AwwaRF and DVGW-Technologiezentrum Wasser, 1996; Conroy et al., 2005). The test involves spraying phenolphthalein lightly onto a freshly exposed cross section of a pipe sample. This chemical turns pink in contact with alkali (lime) but remains colourless where lime leaching has occurred. Colourless depth indicates the extent to which the wall thickness has softened.

Both elemental and petrographic tests use SEM to examine the microstructure of the cement matrix. Elemental analysis has been used to determine the extent of AC pipe deterioration by analyzing the elemental composition of pipe material as a function of the distance from the inner surface of the pipe. Elemental analysis shows a decrease of calcium content where lime has been leached, whereas a relatively constant percentage of calcium content indicates where no degradation has occurred. In addition, analysis of the chemical composition of the undegraded part of the pipe may indicate other information such as the pipe type (Type I or II).

Pipe is designed with a wall thickness capable of withstanding internal pressure and external loading, and to provide a margin of safety. The minimum requirements for different sizes of pipe to withstand the internal pressure and external loading are specified in C500-98 (ASTM, 1998). AC pipes, like other unreinforced cementitious pipes, are generally weak in bending capacity, especially for small diameter pipe. The minimum bending loading is also stipulated in C500-98 (ASTM, 1998) for pipe diameters smaller than 250 mm (10”). As pipe degrades through lime leaching and/or sulphate attack, its load bearing capability decreases because the degraded part of the pipe wall becomes weaker. Therefore, a pipe strength test result can be used to indicate the residual strength of a degraded pipe. The residual strength can then be compared to the strength

required by C500-98 to rate its current relative condition, or it can be compared with the current loading condition to calculate the residual safety factor.

Non-destructive testing

Pipe sampling and testing are destructive and may disrupt routine services. Recent technology development has introduced the possibility of non-destructive condition assessment of pipe materials. The Georadar technique has been used to determine the degree of deterioration of AC pipe (Slaats et al., 2004). Another recent development is the use of acoustic assessment technology for pipe thickness measurements and the determination of leak location (Bracken, 2009). More extensive tests are needed to evaluate these technologies.

2.4 Performance and physical data analysis Historical failure data analysis

A water distribution system may be comprised of hundreds and even thousands of buried pipes, and direct inspection of all of them is usually prohibitively expensive for utilities. Identifying water main breakage patterns over time based on historical failure data analysis is an effective and comparatively inexpensive way to assess the general condition of pipes in a water distribution system. The basic principle is to use statistical methods to analyze available historical data on past failures to identify pipe breakage patterns and correlate them with factors that may have contributed to pipe failures, such as pipe characteristics, weather, soil, etc.

Various models have been developed to assess deterioration based on pipe breakage data. A comprehensive review of the models was conducted by Kleiner and Rajani (2001). Many factors, including operational, environmental and pipe related factors jointly affect the breakage rate of a water main. These models predict breakage rates using two or more of the factors, based on pipe age and breakage history. In this way, the factors contributing to water main breaks can be identified (Kleiner and Rajani, 2002). Several examples demonstrated that statistical models were successfully applied to predict pipe breakage patterns and identify factors contributing to the breakage patterns of AC pipes in a city with high breakage rate and expansive clay soil (Hu and Hubble, 2007; Hu, 2007).

Network modeling

Network modeling uses numerical methods to simulate the hydraulic behaviour (mainly water velocity and pressure) of water flow in a water distribution system. Models are validated by the adjustment of system parameters such as roughness or demand distribution, until the flow and pressure values described by the model generally agree with measured values occurring in the system. The adjustments necessary to the system parameters for the model to reflect measured flows and pressures provide an indication of system condition. Unduly high calculated pipe roughness values often indicate heavily tuberculated pipes with reduced flow capacity.

3. SURVEY RESULTS

A comprehensive survey questionnaire was sent to 20 participating utilities. The questionnaire included 63 questions that covered five areas: background information; general AC pipe inventory and break information; condition assessment and performance; rehabilitation and

replacement; and safety and health-related AC pipe management information. The survey results for the condition assessment are summarized in the following sections.

Factors contributing to pipe failure

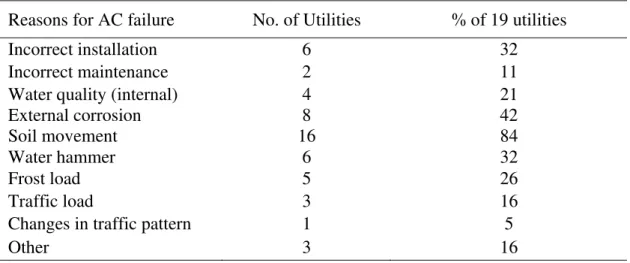

The reasons for pipe failure given by the participating utilities reflected the perceptions of the utilities’ operators and managers. The most likely contributing factors for AC pipe failures perceived by the utilities are shown in Table 3. Most (84%) of utilities indicated that soil movement was the most prevalent factor. The second most perceived factor for AC pipe failure (42% of utilities) was external corrosion, followed by incorrect installation and water hammer (32% each) and frost load (26%). Only 21% of utilities identified water quality as the likely reason. Some utilities also identified construction activities and tree roots as reasons for AC pipe failure.

Table 3 Perceived reasons for AC pipe failure (19 participating utilities)

Reasons for AC failure No. of Utilities % of 19 utilities Incorrect installation 6 32 Incorrect maintenance 2 11 Water quality (internal) 4 21

External corrosion 8 42

Soil movement 16 84

Water hammer 6 32

Frost load 5 26

Traffic load 3 16

Changes in traffic pattern 1 5

Other 3 16

Pipe sample inspection

When a pipe replacement occurs, samples of the section taken out of service can be retrieved for inspection and testing. Table 4 shows the types of sample inspections performed by utilities to assess the condition of AC pipe. Of the 19 utility responses, manual inspection (external and internal surface) was the main means of inspection used. Other methods used included cross-section analysis, chemical composition analysis, and sample strength tests. Many (42%) of the utilities did not do any pipe sample inspections. Of the utilities that performed tests, a very limited number of samples were tested by each utility. When the number of samples tested was compared with the number of pipe breaks of each utility, it is clear that very limited number of these tests were performed on broken pipes.

Table 4 Sample inspection of AC pipe condition (19 participating utilities)

Inspection methods No. of Utilities % of 19 utilities Manual (external surface) 11 58

Pipe cross-section analysis 3 16 Chemical composition

analysis 2 11

Sample strength tests 3 16

None 8 42

Physical techniques

Physical techniques used to assess AC pipe conditions include pressure/flow surveys, leakage level monitoring, and burst frequency analysis. Table 5 shows that burst (leak/failure) frequency (30%) was the most frequently used technique, followed by pressure/flow (20%) and leakage level (5%). However, most utilities (70%) did not use any of these techniques.

Table 5 Physical techniques for AC pipe condition assessment (20 participating utilities)

Physical techniques No. of Utilities % of 20 utilities Pressure/flow survey 4 20

Leakage level 1 5

Burst frequency 6 30

None 14 70

Internal water quality measurement

Table 6 shows the types of internal water quality measurement used for AC pipe condition assessment. The measurement that was used most by utilities was pH, followed by the Langelier index and sulphate content. One utility used fiber content as an indicator of AC pipe condition. A majority of utilities (60%) have not used any internal water quality measures to assess AC pipe conditions. It was noted that utilities have relatively complete data for water quality due to mandatory testing requirements of treated drinking by relevant regulations, so this information can be more fully utilized at a relatively low cost.

Table 6 Internal water quality measurements used for AC pipe condition assessment

Types of measurements No. of Utilities % of 20 utilities

pH measurement 7 35 Langelier index 4 20 Aggressiveness index 0 0 Sulphate content 3 15 None 12 60 Other 1 5

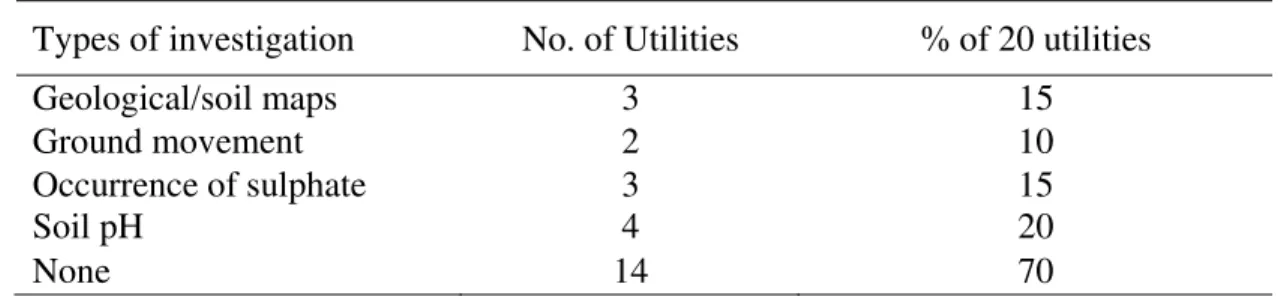

External soil environment investigation/assessment

Table 7 shows the types of external soil environment investigation/assessment used by participating utilities for AC pipe condition assessment. The most common methods used were soil pH (20%), sulphate content and geological/soil map (15% each). Although clay soils are a

common occurrence for many parts of North America and ground movement may be one of the greatest contributing factors causing their AC pipe failure, utilities pay less attention to geological/soil maps and ground movement for assessing AC pipe conditions (15% and 10%, respectively). Most utilities (70%) had never used any of these investigative techniques for AC pipe condition assessment.

Table 7 External soil environment investigation/assessment used

Types of investigation No. of Utilities % of 20 utilities Geological/soil maps 3 15

Ground movement 2 10

Occurrence of sulphate 3 15

Soil pH 4 20

None 14 70

Non-destructive testing technologies

The non-destructive methods currently used for pipe condition assessment include remote field eddy current (RFEC) technology, magnetic flux leakage (MFL) technology, acoustic (ultrasonic) technology, and georadar technology. The former two technologies are for pipes with metal components. Only acoustic (ultrasonic) technology was used by three utilities (of 10 utility responses) to assess AC pipe conditions (Table 8).

Table 8 Non-destructive testing technologies used by utilities (10 participating utilities)

Types of NDT technologies No. of Utilities % of 10 utilities

RFEC – Non-AC 2 20

MFL – Non-AC 1 10

Acoustic (ultrasonic) –AC 3 30 Acoustic (ultrasonic) –

Non-AC 5 50

None 4 40

4. CONCLUSIONS

This paper reviews available condition assessment techniques for AC pipes. It also summarizes the current practices used by several utilities in the United States and Canada to assess the condition of AC pipes in their utilities. These utilities volunteered to contribute to the study and participate in the survey.

Each condition assessment method has advantages and disadvantages. Pipe sampling can accurately assess pipe conditions directly, but it is expensive and also disrupts water delivery services. Internal and external pipe working environmental techniques are indirect, but can use readily available water quality and soil test data. Non-destructive testing methods assess pipe condition without disruption to water delivery, but these techniques are at their early stage of

development. The statistical analysis of pipe network performance data, such as pipe breakage history, is much less costly than the direct condition assessment. It is suitable for lower priority risks caused by breaks of distribution pipes, but its usefulness is highly dependent on data quality and availability. A scarcity of data has hindered the use of this method for many utilities. In many cases, utilities may choose one or more methods over others, depending on their particular situation.

Visual inspection of internal and external surfaces was cited as the principle technique used for AC pipe condition assessment. Phenolphthalein tests, elemental analysis, mechanical tests, pressure/flow survey, leakage level, and burst frequency, were all used, but by only a small percentage of the utilities surveyed. Although utilities have relatively complete water quality information, it has not been fully utilized for condition assessment of AC pipes.

Many AC pipes may be installed in clay soils and ground movement may likely be the causes of AC pipe failure. However, little information was provided in the survey responses that correlated soil type to AC pipe performance. Non-destructive methods are still in their development stage and only ultrasonic techniques have been used for AC pipe condition assessment.

5. ACKNOWLEDGEMENTS

The authors wish to acknowledge the financial support from National Research Council and the Water Research Foundation (WRF). We also thank Dr. Jian Zhang, the project manager of the WRF project, and members of the project advisor committee, Toni Lyons, Steve MacKellar, Showri Nandagiri, and Julie Spacht for their useful suggestions during the questionnaire development. We greatly appreciate the contributions of Karen Cossitt of the City of Regina and the 20 participating utilities that submitted detailed AC pipe information.

6. REFERENCES

ASTM (American Society for Testing and Materials). 1998. Standard test methods for asbestos-cement pipe. ASTM C500-98, Philadelphia, PA.

AWWA (American Water Works Association). 2003. Standard for asbestos cement distribution pipe 4” through 16” for water and other liquids. AWWA C400-03, Denver, CO.

AwwaRF (American Water Works Association Research Foundation) and DVGW-Technologiezentrum Wasser. 1996. Internal corrosion of water distribution system. 2nd Edition, AwwaRF, Denver, CO.

Bracken, M. 2009. Acoustic methods for determining remaining pipe wall thickness in asbestos cement, and ferrous pipes.ASCE Pipeline Conference, San Diego, CA, Aug 24-27, 271-281. Buelow, R.W., Millette, J.R., McFarren, E.F. and Symons, J.M. 1980. The behaviour of asbestos

cement pipe under various water quality conditions. Journal of American Water Works Association, 72: 91-102.

Conroy, P., Cooke, J., Mills, D. Patel, A. and Russell, A. 2005. Managing the risks presented by pipeburst, redundant and live asbestos cement water distribution mains: condition assessment methodology for asbestos cement pipe. UK Water Industry Research, U.K.

Dorn, R., Hyde, R., Houseman, P. and Jarvis, M. 1996. Water mains: guidance on assessment and inspection techniques. Construction Industry Research and Information Association Report #162, London, U.K.

Hu, Y. 2007. Estimated future breaks of asbestos cement (AC) water mains in the City of Regina: Progress report #SIR1001.3. Progress report to the City of Regina, NRC, Regina, SK, Canada, 15p.

Hu, Y. and Hubble, D. 2007. Factors contributing to the failure of AC water mains. Canadian Journal of Civil Engineering, 34:1-14.

Jarvis, B. 1998. Asbestos-cement pipe corrosion – interim report. Customer Services Division, Water Corporation, Western Australia, Australia.

Kirmeyer, G.J., Richards, W. and Smith, C.D. 1994. An assessment of water distribution systems and associated research needs. AwwaRF: Distribution Systems, Denver, CO.

Kleiner, Y. and Rajani, B.B. 2001. Comprehensive review of structural deterioration of water mains: statistical models. Urban Water, 3:131-150.

Kleiner, Y. and Rajani, B.B. 2002. Forecasting variations and trends in water-main breaks. ASCE Journal of Infrastructure Systems, 8:1-14.

Matti, M.A. and Al-Adeebt, A. 1985. Sulfate attack on asbestos pipes. The International Journal of Cement Composites and Lightweight Concrete, 7:169-176.

Millette, J.R., Logsdon, G.S., Clark, P.J. and Kinman, R.N. 1984. Evaluating the condition of asbestos-cement pipe. The International Corrosion Forum Devoted Exclusively to the Protection and Performance of Materials (Corrosion 84), New Orleans, LA, April 2-6, pp152:1-152:16.

Rajani, B.B. and McDonald, S.E. 1995. Water mains break data on different pipe materials for 1992 and 1993. National Research Council Canada, Ottawa, Canada, pp. 11.

Schock, M.R. and Buelow, R.W. 1981. The behaviour of asbestos cement pipe under various water quality conditions. Part 2: theoretical considerations. Journal of American Water Works Association, 73: 636-651.

Slaats, P.G.G., Mesman, G.A.M, Rosenthal, L.P.M. and Brink, H. 2004. Tools to monitor corrosion of cement-containing water mains. Water Science and Technology, 49: pp. 33-39.