HAL Id: hal-01466485

https://hal.archives-ouvertes.fr/hal-01466485

Submitted on 13 Feb 2017

HAL is a multi-disciplinary open access

archive for the deposit and dissemination of

sci-entific research documents, whether they are

pub-lished or not. The documents may come from

teaching and research institutions in France or

abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est

destinée au dépôt et à la diffusion de documents

scientifiques de niveau recherche, publiés ou non,

émanant des établissements d’enseignement et de

recherche français ou étrangers, des laboratoires

publics ou privés.

Graphene-Based Supercapacitors Using Eutectic Ionic

Liquid Mixture Electrolyte

Zifeng Lin, Pierre-Louis Taberna, patrice Simon

To cite this version:

Zifeng Lin, Pierre-Louis Taberna, patrice Simon. Graphene-Based Supercapacitors Using

Eutec-tic Ionic Liquid Mixture Electrolyte. Electrochimica Acta, Elsevier, 2016, vol. 206, pp. 446-451.

�10.1016/j.electacta.2015.12.097�. �hal-01466485�

O

pen

A

rchive

T

OULOUSE

A

rchive

O

uverte (

OATAO

)

OATAO is an open access repository that collects the work of Toulouse researchers and

makes it freely available over the web where possible.

This is an author-deposited version published in :

http://oatao.univ-toulouse.fr/

Eprints ID : 16653

To link to this article : DOI:10.1016/j.electacta.2015.12.097

URL :

http://dx.doi.org/10.1016/j.electacta.2015.12.097

To cite this version :

Lin, Zifeng and Taberna, Pierre-Louis and

Simon, Patrice Graphene-Based Supercapacitors Using Eutectic

Ionic Liquid Mixture Electrolyte. (2016) Electrochimica Acta, vol.

206. pp. 446-451. ISSN 0013-4686

Any correspondence concerning this service should be sent to the repository

Graphene-Based

Supercapacitors

Using

Eutectic

Ionic

Liquid

Mixture

Electrolyte

Zifeng

Lin

a,b,

Pierre-Louis

Taberna

a,b,*

,

Patrice

Simon

a,baUniversitePaulSabatierToulouseIII,CIRIMATUMRCNRS5085,118routedeNarbonne,31062Toulouse,France b

ReseausurleStockageElectrochimiquedel’Energie(RS2E),FRCNRS3459,France

Keywords:

supercapacitors graphenefilm ionicliquideutectic workingtemperaturewindow

ABSTRACT

Compact graphene filmswerepreparedandelectrochemically testedatvarioustemperatures ina eutectic of ionic liquid mixture (1:1 by weight or mole N-methyl-N-propylpiperidinium bis (fluorosulfonyl)imideandN-butyl-N-methylpyrrolidiniumbis(fluorosulfonyl)imide)electrolyte.Alarge temperaturewindowfrom-30!Cto80!Cwasachievedtogetherwithalargepotentialwindowof3.5Vat

room temperature and below. A maximum gravimetric capacitance of 175F.g"1 (85mAh.g"1) was

obtainedat80!C.130F.g"1(63mAh.g"1)and100F.g"1(49mAh.g"1)werestilldeliveredat-20!Cand

-30!Crespectively.Besides,avolumetriccapacitanceof50F.cm"3wasachievedwithathickgraphene

film(60mm).Theoutstandingperformanceofsuchcompactgraphenefilmintheeutecticionicliquid mixtureelectrolytemakesitapromisingalternativetoactivatedcarbonforsupercapacitorapplications, especiallyunderextremetemperatureconditions.

1.Introduction

Thehightheoreticalspecificsurfacearea(upto2630m2g"1)

combined with low resistivity (10"6

V

.cm) as well as highmechanical strength and chemical stability make graphene a

promising active material for supercapacitors [1,2].As a result,

intensive research efforts have been made to characterize

graphene and graphene-based materials in supercapacitors

applications [1,3–5]. Specific capacitance beyond 200F.g"1 has

beenachievedinbothaqueousand organicelectrolytes[4,6–9], which is similaror even betterto many carbon materials like

porous activated carbon [10]. However, the low density of

graphene often comes with a low volumetric capacitance (F.

cm"3),whichisaconcerninmostofapplications,especiallyfor

micro devices [11]. Besides, restacking of graphene film still remainsanissueandblocksthewaytohighercapacitance[12,13].

Accordingly, efforts have been devoted to synthesize more

compactbutun-restackedgraphenefilms.In2013,D.Li'sgroup

[7] proposed a method to develop a dense graphene film by

capillary compressionofgraphenegelfilminthepresenceofa nonvolatile liquid electrolyte,wherethepresence ofelectrolyte betweenthelayerspreventstherestackingofgraphenelayers.

Theenergy densitybeingproportional tothevoltagesquare (E¼1=2$CV2where E is the energy density, C is the

specific capacitanceandVistheworkingpotentialwindow),maximizing thecellvoltageisofhighimportancefordesigning highenergy

devices. Today, most of the graphene and graphene-based

materials have been characterized in aqueous or conventional

organicelectrolytes[11,12].Asaresult,maximumvoltageupto3V werereported[2,14].

Ionic liquid electrolytes provide a large working potential window(morethan4Vinsomecases)[15,16].Inaddition,high chemicalstability,negligiblevaporpressureandnon-flammable propertiesmake ionicliquidsverypromisingaselectrolytesfor bothsupercapacitorsandbatteries[15,17].Oneofthefirstreport

about the use of ionic liquid electrolytes in graphene-based

supercapacitorswasdonebyVivekchandandetal[18],whofound aspecificcapacitanceof75F.g"1withina3.5Vpotentialwindow.

Samegroupreportedareducedgraphenewithenhanced

capaci-tanceof258F.g"1(measuredat5mV/s) bynitrogen-doped[19].

Ruoff's group synthesized activated graphene materials with

extremelyhighspecificsurface area–upto3100m2g"1–able

delivering 200F.g"1 (0.7 Ag"1) in EMIMTFSI ionic liquid [20].

Despite efforts were devoted to improve the performance of

graphene-basedsupercapacitorsin ionicliquidelectrolytes, less attentionwas paid to theoperation temperaturerange

perfor-mance of supercapacitors. Limited by high viscosity and low

meltingpointnearroomtemperature,neationicliquidsarestill

*Correspondingauthor.

E-mailaddress:taberna@chimie.ups-tlse.fr(P.-L.Taberna).

unusableatsub-zerotemperatures[15–22].Therefore,aeutecticof ionicliquidmixturewithlowviscositywasdesignedbyLinetal.as anelectrolyteforsupercapacitors,whichturnedouttopossessa largeworkingtemperaturerangefrom-50!Cto80!Calongsidea widepotential window(up to3.7V)[21,23]. Thiseutecticionic liquidmixtureiscomposedofthesameanion(bis(fluorosulfonyl) imide (FSI)) but two different cations (pyrrolidium (PYR) and

piperidinium (PIP)) with the same molecular formula. The

differenceofmolecularstructure andtheassociatedasymmetry amongthecationswerethoughttohinderlatticeformation,thus

lowers the melting point while maintaining good miscibility

withinalargeworkingtemperaturewindow.Conductivityvalues

of28.9mS/cmand4.9mS/cmweremeasuredat100and20!C,

respectively,asreportedearlier[23].

Inthispaper,weproposetouseadensifiedgrapheneelectrode suchasproposedbyLi’sgroup[7].incombinationwithanionic liquideutecticmixtureaselectrolytetoimproveboththevoltage

window – that is the energy density – and the operating

temperaturerange. 2.Experimental 2.1.Electrodespreparation

Commerciallyavailablegraphitepowder(KS44graphite, pur-chasedfromIMERYSGraphite&CarbonCorporation)wasusedas

the raw material. Graphite oxide was prepared by a modified

Hummersmethod[24].Briefly,amixtureofgraphiteflakes(1.0g,

1wt equiv) and KMnO4 (6.0g, 6wt equiv) was added to a

9:1 mixture of concentrated H2SO4/H3PO4 (120:13mL). The

reaction was then heated to 50!C and stirred for 12hours,

followingbyanaddition of200mLicewith1mL 30wt%H2O2.

Afterwashingbywater,30%HClandethanol,thegraphiteoxide dispersionwasobtained.Grapheneoxidedispersionwasachieved by1hoursonicationand20minutescentrifugationat10,000rpm ofgraphiteoxidewaterdispersion.

Inafirststep,graphenedispersionwasobtainedthroughthe reduction of graphene oxide dispersion by hydrazine solution. 0.2mLhydrazine(35wt%inwater)and0.35mLammonia(28wt%

in water) solution was added into graphene oxide dispersion

(0.5mgmL"1, 100mL)inaglassvialforstirringover1hour(100!C). 60mL 0.5 mgmL"1 reduced graphene dispersion was used for

vacuum filtration, and an Anodiscã membrane (Whatman

company)withan averagepore sizeof 0.1

m

mwas used. Aftervacuum filtration, graphene film was carefully peeled off and

immersedindeionizedwaterovernighttoremovetheremaining hydrazineandammonia[7].

Inasecond step,thegraphenediscfilmswerepunched out

(7mmdiameter)andtransferredintoacetonitrileformorethan 48htototallyreplacethewaterwithacetonitrile.Filmswerethen immersedin10wt%(0.27M)ionicliquidmixtureinacetonitrile formorethan72hours,toexchangetheacetonitrileingraphene filmwiththeionicliquidsolution.Sampleswerethencollected,

clippedbetweentwoglassplatesandmovedtoavacuumoven

under 80!C. After 48hours, the volatile acetonitrile was

completely evaporated and nonvolatile ionic liquids remained

insidethegraphenefilm,whichisexpectedtolimittherestacking ofgraphenelayers.Asaresultofthedensification,thethickness ofthegraphenefilmwasgreatlydecreased(fromaround180

m

mto60

m

m), whilethediameter wasmeasured closeto5.4mm.Herein, the graphene film was well prepared and ready for

electrochemicaltests.

Theweightoftheelectrodeswasmeasuredafter electrochemi-caltests.Specifically,theelectrodeswerewashedbyacetonitrile and ethanol to eliminate the trapped electrolyte and then the

weightwasmeasuredaftervacuumdrying.

2.2.Electrochemicaltests

Graphenefilmswereusedasworkingelectrodesdirectlyafter vacuumdryingwithoutanybinders.Aeutecticionicliquidmixture

composed of (1:1 by weight or molar ratio)

N-methyl-N-propylpiperidinium bis(fluorosulfonyl) imide (PIP13-FSI) and

N-butyl-N-methylpyrrolidinium bis(fluorosulfonyl) imide (PYR14

-FSI) was prepared and used as the electrolyte [21]. Bothionic liquidswereboughtfromSolvionicSA(France).Two25mm-thick porousAl2O3separatorswereusedtogetherwithgold(forRHD

cell)orplatinum(forSwagelokcell)asthecurrentcollector. Forhighandlowtemperaturetests,aRHDcell(Figure.S1)was used,whichenablesfinelyprecisecontrolofthecelltemperature from"40upto100!C[25].Afterreachingeachtesttemperature, thetemperaturewasheldatleasttwohoursbeforemeasurements toensurethecellhasreachedthedesiredtemperature.Testswere

performed by using an Autolab PGSTAT128N (Metrohm,

Switzerland).Besides,three-electrodeSwagelokcellwere assem-bledandtestedatroomtemperature,usingasilverwireas

quasi-reference electrode and tested by using a VMP3 potentiostat

(Biologic, S.A.).All supercapacitorscells mentioned abovewere

assembled in a glovebox under argon atmosphere (waterand

oxygencontentslessthan1ppm).

Electrochemicalimpedancespectroscopy(EIS)measurements

werecarriedoutatopencircuitvoltage(OCV)withanamplitudeof 10mVatthefrequencyrangefrom0.01Hzto200kHz.Capacitance wascalculatedfromcyclicvoltammogramsbymeasuringtheslope oftheintegrateddischargechargeQversusdischargetime(s)plot

and divide by scan rate (V/s). Gravimetric capacitance was

calculated by dividingthe electrode capacitance bythe weight ofgrapheneononeelectrode,accordingtoequation(1)

C¼

D

QD

t$#$m ð1ÞWhereCisthespecificcapacitance(F.g"1);DQ

Dt istheslopeofthe

integrateddischargechargeQversusdischargetimeplot(A);#is thescanrate(V/s)andmisthemassofgrapheneononeelectrode (g).

2.3.Characterization

X-raydiffractionpatternswererecordedbyanX-ray diffrac-tometer(D4ENDEAVOR,Bruker,Germany)usingCuK

a

radiation (l

=0.154nm)withanoperationvoltageof40kVand currentof 40mA.SEMobservationsofthegraphenefilmsweremadeusinga

JSM-6510LV Scanning Electron Microscope after completion of

Fig.1.X-Raydiffractionpatternsofgraphite(GP),graphiteoxide(GO),graphene film(GF)andgraphenefilmfilledwithelectrolyte(GF-IL).Inset:zoominthe8!-35!

electrochemicaltests,forthesakeofaccuracyinthefilmthickness measurement.

3.Resultsanddiscussion

X-Ray diffraction patterns of graphite, graphite oxide and graphenefilmswithorwithoutelectrolytearepresentedinFig.1.

GF stands for graphene films without electrolyte, obtained by

vacuum filtrationthat is containingwater inside. GF-IL arethe graphenefilmsobtainedafterelectrolyteimmersionthatcontain ionic liquid mixture electrolyte after acetonitrile removal. The (002)peakaround26.0!ofpristinegraphite(GP)correspondsto an expected interlayer spacing of 0.336nm. For graphite oxide (GO),thepeakshiftsto9.0!asaresultoftheincreasedinterlayer spacingto0.976nmafteroxidation[26].Nopeakswereobserved for graphenefilmfilledornotwithelectrolyte.It wasexpected sinceforgraphenefilm/GF(withoutelectrolyte),whichcontains morethan90wt%percentofwaterinside,theexfoliatedgraphene

flakes were separated from each other by water, therefore no

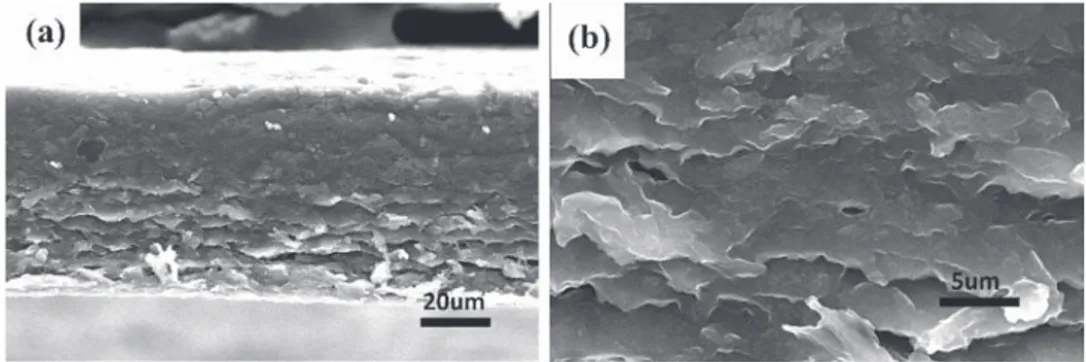

restackinghappens[13].Ontheotherhand,whenelectrolytefilled graphenefilms/GF-IL(waterreplacedbynonvolatileelectrolyte), thepresenceoftheelectrolyteisassumedtopreventrestacking. SEMobservationsofthefilmsareshowninFigs.2.Ascanbe

seen in Fig. 2a graphene films/GF present a homogeneous

thicknessof60

m

mwhichenablesaccuratedeterminationofthe volume(1.374' 10"3cm3)toobtainthevolumetriccapacitance.Alayer-by-layerstructurewas showninFig.2b,asaresultofthe filtrationprocess.Suchalayeredstructureisassumedtobeatthe originofthedensificationofthefilmsascomparedtoconventional

three-dimensional disordered structure, resulting in a high

volumetricenergydensity[7].

Fig.3showsCyclicVoltammograms(CVs)ofanasymmetric 3-electrode Swagelok cell at roomtemperature,ata scan rate of 20mV/s,intheionicliquidmixtureelectrolyte.Therectangular shape of theCVreveals acapacitive behavior. Highgravimetric capacitance (175F.g"1) was achieved, superior to most of the

reducedgrapheneoxidesreportedsofarinionicliquidelectrolytes orconventionalorganicelectrolytes(Table.S1)[7–28].Inaddition, alargepotentialwindowof3.5V(from-2Vto1.5V(vsAgwire)) makethesematerialsmorepromisingfordesigninghighenergy supercapacitors.

Asymmetricaltwo-electrodeSwagelokcellwasassembledand testedatroomtemperature.Thehighfrequencyloopobservedon theNyquistplot(Fig.4a)isassumedtooriginatefromthecontact resistancebetweenthecurrentcollectorsandthefilm[29].The highfrequencyseriesresistancewasmeasuredat40

V

.cm2,whichisinthesamerangeaspreviouslyreportedforthiselectrolyteat roomtemperature[23].Whengoingdowntolowfrequencies,the fastincreaseoftheimaginarypartoftheimpedancerevealsthe capacitive behavior of the electrode. Fig.4b shows theCVs at differentscanrates.Highcapacitanceof170F.g"1wasobtainedata

scanrateof5mV/swithina3.5Vpotentialrange,whichisbeyond mostof theconventional carbons reported sofar [10–31]. The changeofthecapacitancewiththepotentialscanrateisshownin

Fig. 4c. More than 75% of the maximum capacitance was still

preserved at 50mV/s, thus highlighting the decent power

performanceofthecelldespiteusinganeationicliquidelectrolyte.

The associated volumetric capacitance, calculated from the

electrode thickness, was 50F.cm"3 at 5mV.s"1, which is also

comparabletoconventionalactivatedcarbonpowders[10].

Fig. 5 shows the electrochemical characterization at higher temperature,namely40!C,60!Cand80!C.Asexpected,thehigh frequencyseriesresistancedecreaseswithincreasingtemperature (Fig. 5a), due tothe decrease of the electrolyte viscosity. The improvedcapacitivebehavioratelevatedtemperatureascanbe

seen by the sharp increase in the imaginary part at lower

resistance; it is associated withthe increase of theelectrolyte conductivitywiththetemperature[21,23].Theimproved capaci-tive behavior with the temperature is also visible on the CVs (Fig.5b),withcapacitiveelectrochemicalsignatures.However,a limitationinthepotentialwindowfrom3.5Vdownto3.2Vwas observedwhenthetemperaturewasincreasedfrom40!Cto80!C. Such a behavior is associated withtheelectrochemical activity (oxidation) of the ionic liquid electrolyte at high potential, as already reported elsewhere [21]. Specific capacitance was in-creasedfrom160F.g"1upto175F.g"1withincreasingtemperature

becauseoftheviscosityfalloff.

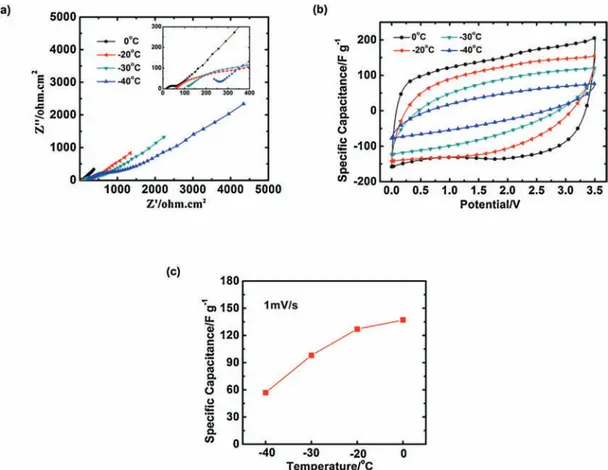

Fig.6showstheelectrochemicalcharacterizationsatlowand

negative (sub-zero) temperature. Owing to the high viscosity

underlowtemperature,aslowscanrateof1mV/swasapplied.The Nyquistplot(Fig.6a)showsanimportantincreaseoftheseries

resistance at negative temperature, in agreement with the

decreaseoftheelectrolyteconductivity[23].Theelectrochemical

Fig.2. SEMimagesofcross-sectionmorphologyofgraphenefilmafterelectrochemicaltests.Scalebar:20mm(a),5mm(b).

Fig.3.CyclicVoltammogramsatroomtemperaturein N-Methyl-N-propylpiper-idiniumbis(fluorosulfonyl)imide(PIP13-FSI):N-Butyl-N-methylpyrrolidiniumbis (fluorosulfonyl)-imide(PYR14-FSI)ionicliquidmixture(1:1byweightormolar ratio).Thepotentialscanratewas20mV/s,withapotentialwindowfrom-2Vto 1.5V/Reference(usingasilverwireaspseudo-referenceelectrode).

Fig.4.Electrochemicalcharacterizationatroomtemperatureofa2-electrodecellassembledwithdensegraphenefilms,ineutecticmixtureelectrolyte:EISNyquistplot(a), CVsatvariousscanrates(b),changeofthespecificcapacitancewiththepotentialscanrate(c).

Fig.5.Electrochemicalcharacterizationat40!C,60!Cand80!Cofa2-electrodecellassembledwithgraphenefilms,ineutecticmixtureelectrolyte.Nyquistplots(a),CVs(b)

signature(Fig.6b)stillshowsacapacitivebehaviordownto-30!C whileitbecomestooresistiveat-40!C.Acapacitanceof135F.g"1

(63mAh.g"1)wasobtainedat0!Cand100F.g"1(49mAh.g"1)at

-30!C.Whenthetemperaturegoesdownto-40!C, the electro-chemicalbehaviorisgovernedbytheohmicdropsinsidethebulk oftheelectrolyte.

These results showthat thecombination ofdensegraphene

filmswithaeutecticionicliquidmixturecanbepromisingasan alternative to conventional porous carbons for supercapacitor applications.Beyondthehighgravimetricandvolumetric capaci-tance obtained at room temperature (165F.g"1 and 50F.cm"3,

respectively),thelargepotentialwindow(3.5V)andtemperature operation range (from -30!C to 80!C) make them suitable for designinghighenergydensitysupercapacitors.

4.Conclusions

Using vacuum filtration, electrolyte immersionand selective evaporation,compactgraphenefilmscharacterizedbya layer-by-layerstructurewaspreparedandusedaselectrodematerialsfor supercapacitorswithoutbinders.Thankstotheuseofaeutectic ionic liquidmixtureaselectrolyte,a largeworkingtemperature

window from -40 to 80!C could be explored. A maximum

gravimetric capacitance of 175F.g"1 (85mAh.g"1) was reached

at80!C.Despitethecapacitanceat-40!Cwaslimitedat60F.g"1

(30mAh.g"1),130F.g"1(63mAh.g"1)and100F.g"1(49mAh.g"1)

werestillachievedat-20!Cand-30!Crespectively.Thepotential windowwasincreasedupto3.5Vatroomtemperatureand3.2Vat 80!C,thusleadingtosubstantialimprovementinthecellenergy density.Additionally, avolumetriccapacitanceof50F.cm"3was

alsoachievedwithathickgraphenefilmof60

m

m.Thesematerials couldbeapromisingalternativetoactivatedcarbonoperatinginconventional electrolytes for supercapacitorapplications, espe-ciallyunderextremetemperatureconditions.

Acknowledgements

ZifengLINissupportedbyChinaScholarshipCouncil(CSC).P.S. acknowledgesthesupportfromEuropeanResearchCouncil(ERC, AdvancedGrant,ERC-2011-AdG,Projectno.291543-IONACES). References

[1]R.Raccichini,A.Varzi,S.Passerini,B.Scrosati,Theroleofgraphenefor electrochemicalenergystorage,NatMater14(2015)271–279. [2]M.D.Stoller,S.J.Park,Y.W.Zhu,J.H.An,R.S.Ruoff,Graphene-Based

Ultracapacitors,NanoLett8(2008)3498–3502.

[3]J.X.Zhu,D.Yang,Z.Y.Yin,Q.Y.Yan,H.Zhang,GrapheneandGraphene-Based MaterialsforEnergyStorageApplications,Small10(2014)3480–3498. [4]Y.Xu,Z.Lin,X.Zhong,X.Huang,N.O.Weiss,Y.Huang,X.Duan,Holeygraphene

frameworksforhighlyefficientcapacitiveenergystorage,NatCommun5 (2014).

[5]R.Raccichini,A.Varzi,S.Passerini,B.Scrosati,Theroleofgraphenefor electrochemicalenergystorage,NatMater(2014)advanceonlinepublication. [6]M.F.El-Kady,V.Strong,S.Dubin,R.B.Kaner,LaserScribingof

High-PerformanceandFlexibleGraphene-BasedElectrochemicalCapacitors, Science335(2012)1326–1330.

[7]X.W.Yang,C.Cheng,Y.F.Wang,L.Qiu,D.Li,Liquid-MediatedDenseIntegration ofGrapheneMaterialsforCompactCapacitiveEnergyStorage,Science341 (2013)534–537.

[8]R.R.Salunkhe,Y.-H.Lee,K.-H.Chang,J.-M.Li,P.Simon,J.Tang,N.L.Torad,C.-C. Hu,Y.Yamauchi,Nanoarchitecturedgraphene-basedsupercapacitorsfor next-generationenergy-storageapplications,Chemistry(Weinheimander Bergstrasse,Germany)20(2014)13838–13852.

[9]C.N.R.Rao,K.Gopalakrishnan,U.Maitra,ComparativeStudyofPotential ApplicationsofGraphene,MoS2,andOtherTwo-DimensionalMaterialsin EnergyDevices,Sensors,andRelatedAreas,ACSAppl.Mater.Interfaces7 (2015)7809–7832.

[10]A.Burke,R&Dconsiderationsfortheperformanceandapplicationof electrochemicalcapacitors,Electrochim.Acta53(2007)1083–1091. Fig.6. Electrochemicalcharacterizationat0!C,-20!C,-30!Cand-40!Cofa2-electrodecellassembledwithgraphenefilms,ineutecticmixtureelectrolyte.Nyquistplots(a),

CVsat1mV.s"1

(b)andchangeofthespecificcapacitancewiththetemperatureatascanrateof1mV.s"1

[11]P.Simon,Y.Gogotsi,CapacitiveEnergyStorageinNanostructured Carbon-ElectrolyteSystems,AccountsChem.Res.46(2013)1094–1103.

[12]J.H.Lee,N.Park,B.G.Kim,D.S.Jung,K.Im,J.Hur,J.W.Choi,Restacking-Inhibited 3DReducedGrapheneOxideforHighPerformanceSupercapacitorElectrodes, AcsNano7(2013)9366–9374.

[13]X.W.Yang,J.W.Zhu,L.Qiu,D.Li,BioinspiredEffectivePreventionofRestacking inMultilayeredGrapheneFilms:TowardstheNextGenerationof High-PerformanceSupercapacitors,AdvancedMaterials23(2011) 2833-+. [14]M.Gali!nski,A.Lewandowski,I.Ste˛pniak,Ionicliquidsaselectrolytes,

Electrochim.Acta51(2006)5567–5580.

[15]M.Armand,F.Endres,D.R.MacFarlane,H.Ohno,B.Scrosati,Ionic-liquid materialsfortheelectrochemicalchallengesofthefuture,NatureMaterials8 (2009)621–629.

[16]M.Galinski,A.Lewandowski,I.Stepniak,Ionicliquidsaselectrolytes, Electrochim.Acta51(2006)5567–5580.

[17]R.D.Rogers,K.R.Seddon,Ionicliquids—Solventsofthefuture?Science302 (2003)792–793.

[18]S.R.C.Vivekchand,C.S.Rout,K.S.Subrahmanyam,A.Govindaraj,C.N.R.Rao, Graphene-basedelectrochemicalsupercapacitors,J.Chem.Sci.120(2008)9– 13.

[19]K.Gopalakrishnan,K.Moses,A.Govindaraj,C.N.R.Rao,Supercapacitorsbased onnitrogen-dopedreducedgrapheneoxideandborocarbonitrides,SolidState Communications175–176(2013)43–50.

[20]Y.W.Zhu,S.Murali,M.D.Stoller,K.J.Ganesh,W.W.Cai,P.J.Ferreira,A.Pirkle,R. M.Wallace,K.A.Cychosz,M.Thommes,D.Su,E.A.Stach,R.S.Ruoff, Carbon-BasedSupercapacitorsProducedbyActivationofGraphene,Science332 (2011)1537–1541.

[21]W.Y.Tsai,R.Y.Lin,S.Murali,L.L.Zhang,J.K.McDonough,R.S.Ruoff,P.L.Taberna, Y.Gogotsi,P.Simon,Outstandingperformanceofactivatedgraphenebased supercapacitorsinionicliquidelectrolytefrom-50to80degreesC,Nano Energy2(2013)403–411.

[22]K.Hayamizu,Y.Aihara,H.Nakagawa,T.Nukuda,W.S.Price,Ionicconduction andiondiffusioninbinaryroom-temperatureionicliquidscomposedofemim BF4andLiBF4,J.Phys.Chem.B108(2004)19527–19532.

[23]R.Y.Lin,P.L.Taberna,S.Fantini,V.Presser,C.R.Perez,F.Malbosc,N.L. Rupesinghe,K.B.K.Teo,Y.Gogotsi,P.Simon,CapacitiveEnergyStoragefrom -50to100degreesCUsinganIonicLiquidElectrolyte,JournalofPhysical ChemistryLetters2(2011)2396–2401.

[24]D.C.Marcano,D.V.Kosynkin,J.M.Berlin,A.Sinitskii,Z.Z.Sun,A.Slesarev,L.B. Alemany,W.Lu,J.M.Tour,ImprovedSynthesisofGrapheneOxide,AcsNano4 (2010)4806–4814.

[25]L.Negre,B.Daffos,P.L.Taberna,P.Simon,Solvent-FreeElectrolytesfor ElectricalDoubleLayerCapacitors,JournaloftheElectrochemicalSociety162 (2015)A5037–A5040.

[26]A.M.Dimiev,J.M.Tour,MechanismofGrapheneOxideFormation,ACSNano (2014).

[27]Y.Chen,X.O.Zhang,D.C.Zhang,P.Yu,Y.W.Ma,Highperformance supercapacitorsbasedonreducedgrapheneoxideinaqueousandionicliquid electrolytes,Carbon49(2011)573–580.

[28]T.Kim,G.Jung,S.Yoo,K.S.Suh,R.S.Ruoff,ActivatedGraphene-BasedCarbons asSupercapacitorElectrodeswithMacro-andMesopores,AcsNano7(2013) 6899–6905.

[29]C.Portet,P.L.Taberna,P.Simon,C.Laberty-Robert,ModificationofAlcurrent collectorsurfacebysol–geldepositforcarbon–carbonsupercapacitor applications,Electrochim.Acta49(2004)905–912.

[30]G.P.Wang,L.Zhang,J.J.Zhang,Areviewofelectrodematerialsfor electrochemicalsupercapacitors,Chem.Soc.Rev.41(2012)797–828. [31]C.Largeot,C.Portet,J.Chmiola,P.-L.Taberna,Y.Gogotsi,P.Simon,Relation

betweentheIonSizeandPoreSizeforanElectricDouble-LayerCapacitor, JournaloftheAmericanChemicalSociety130(2008)2730–2731.