Publisher’s version / Version de l'éditeur:

Proceedings of the BioPlastics 2006, 2006-09-27

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Processing and Properties of Biaxially Oriented Poly(Lactic

Acid)/Thermoplastic Starch Blends

Chapleau, Nathalie; Huneault, Michel A.; Li, Hongbo

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=6260c260-979a-4d60-bdc7-050bb4243b1c https://publications-cnrc.canada.ca/fra/voir/objet/?id=6260c260-979a-4d60-bdc7-050bb4243b1cBioPlastics 2006, September 27-29, 2006, Montreal, Canada

PROPERTIES OF BIAXIALLY ORIENTED PLA/STARCH BLENDS

Nathalie Chapleau*, Michel A. Huneault and Hongbo Li

Industrial Materials Institute – National Research Council of Canada 75, de Mortagne, Boucherville, QC, J4B 6Y4, Canada

Abstract - PLA and thermoplastic starch were blended in various proportions via a twin screw extrusion process; wheat starch was used in all blends and plasticized with glycerol and water. The blends were subsequently cast into sheets and biaxially drawn. The addition of starch did not affect significantly the stretchability of the pure PLA. Even at high starch content (60 wt.%), the biaxial draw ratio at which the sample breaks is very similar to that of the pure PLA. At higher temperatures (above 90oC), all blends could be stretched at significant biaxial draw ratios and very thin films could be obtained. The starch content and processing variables affected the films morphology and mechanical properties.

Introduction

Biaxial orientation processes are commonly used to enhance the performance of polymeric materials. The development of molecular orientation during biaxial forming processes enables to produce materials that can be used in demanding structural applications or with enhanced optical or barrier properties. In these processes, deformation of a sheet or film takes place in both machine (MD) and transverse (TD) directions in the semi-solid state. Typical processes include the double-bubble, thermoforming and tenter frame processes, which are very widespread especially in the packaging industry. Poly(lactic acid) (PLA) is one of the biodegradable polymer available from renewable resources that has received a lot of attention recently, especially for food packaging applications. Adding starch to PLA also enables to reduce cost and maintain biodegradability. However, in its dry native form, starch acts as a filler and increases the inherent brittleness of PLA. In order to favor the ductility of the blends, starch can be plasticized using water and glycerol to form an immiscible polymer blend in which the thermoplastic starch (TPS) is the dispersed phase. Processability using conventional polymer processing equipment is enhanced and better-quality morphologies can be obtained.

In this work, a laboratory biaxial stretcher was used to simulate typical industrial processes often encountered in polymer film processing and evaluate PLA/TPS blends processability. The influence of processing conditions on the structure development, maximum stretchability and mechanical performance was addressed. Also, the effect of compatibilization on the biaxial drawability has been investigated by modifying the PLA.

Experimental

Compounding and extrusion. PLA (PLA 2002D from

NatureWorks) and plasticized starch were blended in

using a twin-screw extrusion process. Wheat starch (Supergel 1203 from ADM-Ogilvy) was used in all blends and plasticized with glycerol and water. PLA was incorporated in the molten form at mid extruder to produce a PLA/TPS blend in the form of pellets. The formulation comprised 36 wt.% glycerol within the TPS phase and the TPS contents studied were 27, 42 and 60 wt.%. For interface modified samples, the PLA was grafted using 2 wt.% maleic anhydride and 0.25 wt.% peroxide initiator. These pellets were then extruded into 0.5 mm sheets on a Randcastle cast film line.

Biaxial stretching. In order to evaluate the effect of the

addition of starch on the processability of PLA, some biaxial stretching experiments were performed on the cast sheets. A Bruckner laboratory biaxial stretcher was used for simultaneous equibiaxial drawing at constant speed (1 m/min). Tests were conducted at 70, 80 and 90oC. The load vs. time curves were recorded; the maximum stress and biaxial draw ratio at break was determined at each temperature.

Blends characterization. The morphology of the

pellets and cast sheets was investigated using scanning electron microscopy on surfaces microtomed under cryogenic conditions after selective removal of the plasticized starch phase. The tensile mechanical properties were measured at room temperature at 50 mm/min according to ASTM D-638 in both MD and TD directions, on rectangular strips cut from cast and stretched films. The elastic modulus, the yield stress and the elongation at break were evaluated. The reported values are the average of five tests.

Results and Discussion

The morphology of the unmodified and compatibilized blends was investigated. The micrographs for the 60 wt.% blend are given in Figure 1 as an example. All blends consisted of a two-phase system where starch is the minor phase. In the unmodified pellets, the

BioPlastics 2006, September 27-29, 2006, Montreal, Canada morphology is quite coarse and the minor phase size

increases from 15 to 30 microns when the starch content is increased from 27 to 60 wt.%. After casting into sheets, coalescence occurs and a near co-continuity morphology is observed for the 60 wt.% blend. In the compatibilized case, the minor phase is nearly spherical, well dispersed and its size is significantly reduced. The deformation during cast extrusion is also favored, with highly oriented domains observed in the machine direction. This is evidence that the grafting of PLA/TPS blends with maleic anhydride is efficient in reducing the interfacial tension and generating finer morphologies.

The mechanical properties of the initial cast sheets were evaluated. Similar properties were observed in both machine and transverse directions, indicating the isotropy of the sheets, which is recommended prior to performing biaxial stretching. The tensile modulus and strength of the cast sheets decreased with TPS content, while the elongation at break remained similar to that of pure PLA. In the compatibilized case, the tensile modulus and strength again decreased with TPS content but a significant increase of the elongation at break was observed in the machine direction.

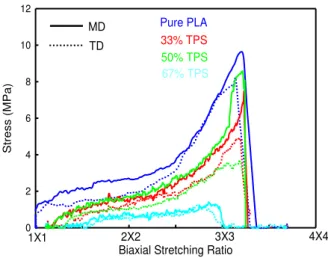

Pure PLA and PLA/TPS blends were biaxially drawn. Typical stress vs. biaxial draw ratio curves are shown in Figure 2 for the biaxial drawing of unmodified PLA/TPS blends at 70oC. It was observed that the addition of starch does not affect significantly the stretchability of the pure PLA. Even at high starch content (60 wt.%), the biaxial draw ratio at which the sample breaks is very similar to that of the pure PLA. At the highest temperature studied (90oC), all blends could be stretched at draw ratios as high as 6X6 and 9X9 for the unmodified and compatibilized blends, respectively. In most cases, the maximum biaxial draw ratio exceeded significantly that of pure PLA.

As in the case of the cast sheets, increasing the starch content was found to decrease the elastic modulus and yield stress of the blends. Upon drawing, these properties increase as a function of draw ratio, especially at the lowest temperature studied (70oC). At higher temperatures, the tensile modulus and tensile strength remain similar to those of pure PLA; at high temperature the stress developed is lower, relaxation is favored and less orientation can be achieved. In general, the elongation at break for the unmodified blends increases with biaxial draw ratio and sometimes exceeds that of pure PLA, depending on the drawing temperature. In order to investigate the effect of interfacial modification, the compatibilized blend containing 27 wt.% starch was also biaxially drawn. Similar results to the unmodified case were obtained; a slight increase of modulus and strength with biaxial draw ratio and similar increase of the elongation at break.

Conclusion

The properties and processability of PLA/thermoplastic starch (TPS) blends were investigated. Compatibilizing

the blends with maleic anhydride reduced the TPS minor phase size and coalescence, and favored deformation in the machine direction during cast extrusion. The tensile modulus and strength of cast sheets decreased with TPS content, while the elongation at break remained similar to that of pure PLA. In the compatibilized case, these properties also decreased with TPS content but a significant increase of the elongation at break was observed in the machine direction.

The biaxial processability of the PLA/TPS blends was assessed. A significant effect of drawing temperature was observed. Very high biaxial draw ratios at break could be reached and adding starch did not significantly reduce PLA drawability. The tensile modulus and tensile strength increased as a function of biaxial draw ratio and the elongation at break only increased significantly for the blends having low starch contents. The significant improvement of the elongation at break observed for the cast sheets due to compatibilization was not observed for the biaxially stretched films.

Figure 1. Morphology of PLA/TPS blend containing 60 wt.% starch. Surfaces of pellets and cast films for unmodified and compatibilized blends are shown.

Figure 2. Stress vs. biaxial draw ratio curves for unmodified PLA/TPS blends stretched at 70oC.

Extruded Pellets strands

Cast Sheets Unmodified

Compatibilized

Biaxial Stretching Ratio

Stres s (MPa ) 0 2 4 6 8 10 12 Pure PLA 33% TPS MD TD 50% TPS 67% TPS 1X1 2X2 3X3 4X4