Publisher’s version / Version de l'éditeur:

Solplan Review, 161, pp. 14-15, 2011-11-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Advances in the use of vacuum-insulated panels (VIPs) in buildings

Maref, W.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC: https://nrc-publications.canada.ca/eng/view/object/?id=a6176a99-7d65-41ef-8bf8-af5de4c3b5be https://publications-cnrc.canada.ca/fra/voir/objet/?id=a6176a99-7d65-41ef-8bf8-af5de4c3b5be

N RC • CONSTRUCTION

Advances in the Use of

Vacuum-Insulated Panels (VIPs) in Buildings

By Wahid Maref

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specifi c instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d’auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d’identifi er la source de l’information et, dans certains cas, d’interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

NRCC-54

567

A version of this document is published in / Une version de ce document se trouve dans:

Solplan Review, No. 161, pp. 14-15, November 2011.

N RC • CONSTRUCTION

This article reports results from a recent NRC-IRC research project involving the preliminary testing of

ten wall systems insulated with various confi gurations of vacuum insulated panels (VIPs).

In previous issues of Solplan Review, the National Research Council’s Institute for Research in Construction (NRC-IRC) reviewed the properties of Vacuum Insulated Panels (VIPs) (Figure 1), opportunities for their use in construction, and technical challenges that need to be overcome. With insulating values of R-60 per inch and higher, VIPs have the potential to signifi cantly reduce building heating and cooling costs.

Figure 1. VIP samples

Recently, NRC-IRC hosted an international VIP symposium and completed a research project called Energy Performance of Highly-insulated Wood-frame Wall Systems Using VIPs. The purpose of this research was to develop recommended construction specifi cations and guidelines for assembling next-generation building envelope systems. The ultimate goal is to encourage their use in Canadian buildings, especially in wood-frame construction.

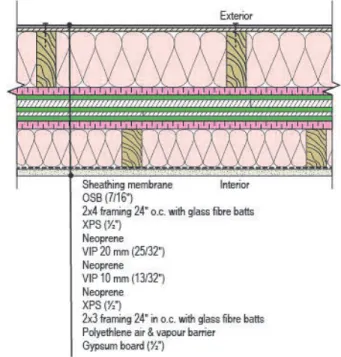

The scope of the project included constructing wall samples, performing thermal and air leakage tests on them and developing recommended details for highly insulated walls incorporating VIPs. Based on consultation with project partners and industry representatives, ten VIP confi gurations were developed based on double-frame walls with 2x4 studs on the exterior and 2x3 studs on the interior. The double wall allowed a number of combinations of VIPs and conventional insulations to be examined. It also provided maximum protection of the VIPs from construction activities (e.g., applying exterior cladding and interior fi nishes) and post-construction activities (e.g., installing shelving, hanging pictures, etc.). Two of the VIP confi gurations are shown in Figures 2 and 3.

Figure 2. Wall Confi guration 1A (two layers of VIPs encased

in XPS insulation on both sides)

Figure 3. Wall Confi guration 1G (two layers of VIPS separated by neoprene and with batt and XPS insulation on both sides)

N RC • CONSTRUCTION

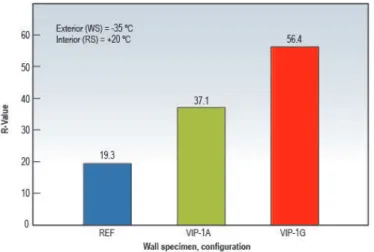

All test walls (2.4 m by 2.4 m) were opaque with no penetrations or windows. Prior to thermal testing, the walls were subjected to cycles of positive and negative pressure to simulate wind conditions in service. Each wall was fi tted with an array of thermocouples on both interior and exterior surfaces to measure surface-to-surface R-values. The R-values of all walls were determined in a guarded hot box facility. The thermal performance of the VIP walls was compared to a conventional 2x6 wall with batt insulation and polyethylene air/vapour barrier (Figure 4).

Figure 4. Thermal Resistance for Reference Wall, Wall VIP-1A, and Wall VIP-1G

The reference wall had an R-value of 19.3 and the ten VIP walls had R-values ranging from 37.1 to 63.0. Although relatively thick (about 250 mm) compared to the 165-mm reference wall, the double walls provide high insulating values. The conventional wall provides an R-value of 0.12 per millimetre of wall thickness, while the best-performing VIP wall provides an R-value of 0.252 per millimetre – twice that of the conventional wall.

The following observations from the project will be taken into account for future research and the move to commercial adaptation of VIPs:

• The choice of VIP sample sizes available from manufacturers was not optimal for typical North American wall construction. This should be addressed to reduce assembly costs.

• VIPs with square-edge insulation sandwiched fi rst in thin neoprene layers and then extruded polystyrene (XPS) layers seemed to be a feasible means for protecting VIPs during fabrication.

• Caulking between abutting VIPs stabilized the panels during installation, reduced air leakage and improved thermal performance.

• The wall panels were completely assembled and insulated in the horizontal position. Work is required to develop installation methods more representative of typical wood-frame wall construction.

This NRC-IRC research was one step in the development of next-generation building envelope systems. It identifi ed VIP confi gurations that have potential for application and issues that require resolution before VIPs can gain greater market acceptance as a construction material. The VIP wall confi gurations are now being tested using the state-of-the-art NRC-IRC fi eld exposure test facility for a one-year cycle of exposure to natural climatic conditions (Figure 5). The results from this testing will be used to benchmark NRC-IRC’s hygrothermal model, hygIRC-C. Thereafter, this model will be used to assess the performance of VIP wall confi gurations subjected to climatic conditions in various regions

of North America.

Figure 5. (L) Preassembly of one VIP confi guration and (R) fi eld

installation of one of the VIP confi gurations covered with exterior rigid insulation

Dr. Wahid Maref is a Senior Research Offi cer in the Building Envelope and Structure Program of the NRC Institute for Research in Construction. He can be reached at 613) 993-5709 or wahid. maref@nrc-cnrc.gc.ca