Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Report (National Research Council of Canada. Division of Building Research), 1953-10-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=4a021028-e68d-4f67-b82d-505b2fdc9b5c https://publications-cnrc.canada.ca/fra/voir/objet/?id=4a021028-e68d-4f67-b82d-505b2fdc9b5c

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20331645

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at Durability Studies of Concrete

NATIONAL RESEARCH coュセcil

CANADA

DURABILITY STUDIES OF CONCRETE

by

E.G. Swenson and V. Cbaly

ANAL YZEO

First Progress Report: Volume Changes of Mortar Bars Made with Some Canadian Cements and Pozzolans on the Reactive U.S. Aggregates

by

E.G. Swenson, E.W. Neumann, and R. Mott

Research Report No.

23

of the

Division of Building Research

L,__

OttawaPREFACE

In its concentration upon building problems peculiar to Canada the Division of Building Research encountered,

very early in its development, vital questions regarding the durability of concrete and masonry materials under Canadian climatic conditions.

This report is the first progress statement on the work which has been started in this field by the Building

Materials Section, under the general direction of E.V. Gibbons,

the Head of that Section. The project is under the general

direction of E.G. Swenson and V. Chaly, Assistant Research Officers.

We are following the unusual course of presenting first a general introductory statement, which will be

repeated when other progress reports are published. The

first progress report itself has been prepared by Mr. Swenson, assisted by E.W. Neumann and R. Mott who assisted him with the laboratory work.

The report is prepared in this form for immediate

distribution to those interested. When the work has developed

sufficiently it is naturally hoped to publish, in scientific journals, research papers which will include the significant information to be presented in these mimeographed progress reports.

Ottawa,

October

1953

R.Fo

Legget,"From the time concrete is first placed in the field it is subjected to the deteriorating influences of

freezing and thawing, wetting and drying, heating and cooling, sulphate waters, and reactions between its component materials"

( 1).

A ャッョァセエ・イュ study has been started in the Materials Section of the Division of Building Research which is intended

to produce useful data on Canadian materials used in concrete,

with particular emphasis on durability. Samples of concrete

and concrete mortar are subjected to freezing and thawing, wetting and drying, and the conventional mortar-bar expansion

test. Volume changes are recorded and compared for each

condition. Strength tests are made and any abnormal behaviour

is studied microscopically.

The cement used is stock material obtained from Canadian plants, with complete analytical data on each.

Reference cements from the U.S. are also usedo The aggregates

are selected from allover Canada, the selection being based on petrographic analyses so that varieties of mineralogical

compositions may be studied. Special aggregates with

performance records and laboratory histories are obtained

from the U.S. and used as reference samples. Canadian

pozzolanic materials are also included in this study (14).

In general, this long-term investigation will deal with the effects of: (a) coarser Canadian cements as compared with U.S. products, (b) high alkali Canadian cements when

used with reactive aggregates, (c) Canadian pozzolanic materials as additives in concrete, Cd) the presence of the so-called

"deleterious" minerals such as chert, opal, chalcedony, and certain other "altered" materials.

The emphasis on petrographic methods in this study

has been dealt with in detail elsewhere (2)0

The destruction of concrete through freezing and thawing is associated with the disruptive action of ice

formation

(3)

and with the hydraUlic pressures developed by thesame action (4). The deterioration processes are accompanied

by excessive expansion, spalling with a reSultant loss in weight, loss in compressive strength, and a reduction in the

modulus of elasticity. The degree of durability of concrete

to freezing and thawing is generally associated with its absorption properties which, in turn, are determined by the original water=cement ratio, the porosity and moisture content

2

-More recent investigations indicate that cycles of wetting and drying of concrete tend to promote destructive actions which have been attributed to some deleterious

aggregates

(7,

8). Temperature changes alone are thought toaffect durability through the difference in thermal coefficients

of aggregate and cement paste (9, 10). The effect of moisture

content on the thermal coefficient of expansion also appears to be a factor (11)0

The reaction between certain deleterious aggregates and high alkali cements, producing excessive expansion in, and ultimate destruction of concrete is attributed to the presence of small quantities of reactive materials such as

chert, opal, cha.l ce dony , and others. The chemistry of this

reaction is not understood. The mortar-bar test is used to

detect this condition in mortars and chemical tests have been developed to .detect the reactive tendencies in aggregates

(11, 12, 13). The early work will be concerned with these

phenomena, but emphasis will be placed on those aspects which promise results of the most practical val.ue ,

It is intended that all phases of this investigation be closely correlated with actual field problems.

Selected References

(1) H.W. Brewer - Durability of Concrete, Proc. of Training

Conferences on Earth and Concrete Control,

UoS o Dept. of Interior9 Bureau of

Reclamation9 Lecture No. 31, November 1948.

(2) V. Chaly - Application of Petrographic Methods to a

StUdy of Canadian Cements and aァァイ・ァ。エ・セ

for Concrete. DoBoRo Report PoCo

6,

Jan 0 1953.

(3) A.Ro Collins - The Destruction of Concrete by Frost,

Journal Insto CeEe, Vol. 23 (1), po29,

Paper Noo 54129 November 19440

(4) T.C. Powers - A Working Hypothesis for Further StUdies

of Frost Resistance of Concrete. Journal

ACI, Vol. 16, No. 4 and Proc. ACI p.245,

Vol. 41, 1944 - 19450

(5) J.B. Blackburn - Freeze and Thaw Durability of Air-entrained

Concrete Using Indiana Aggregates. Rep.

No. 49p Eng 0 Expero Stn., Purdue University

October 19490

(6)

T.M. WhitesideH.S. Sweet - Effect of Mortar Saturation in ConcreteFreezing and ThaWing Tests. Repro No. 12,

Natural Resources Research Insto, University of Wyoming, November 19510

(7) C.H. Scholer - A Wetting-and-Drying Test for Predicting

c・ュ・ョエセaァァイ・ァ。エ・ Reaction. 1949 Preprint, A.SoT.Mo

(8) A.D. Conrow - Cement-Aggregate-Reaction Expansion of

Concretes Containing Kaw River Sand-Gravel

as Aggregate. Research Lab. Rpt., Ash

Grove Lime and Portland Cement Company, Chanute, Kansas, February 1950.

(9) Stanton Walker - Do L. Bloem, W.G. Mullen - Effects of

Temperature Changes on Concrete as

Influenced by Aggregates. Journal ACI

Vol. 23, No.8, April, 1953.

(10) E.J. Callan - Thermal Expansion of Aggregates and Concrete

Durability. Journal ACI, Vol. 23, No.6,

1952. (AoCoI. Proc. Vol. 48).

(11) S.L. Meyers - Thermal Expansion Characteristics of Hardened

Pastes and Concrete - Advance Copy of Paper presented to the 30th Anno Meeting H.R.B., Washington January 9-12, 1952.

(12) T.E. Stanton - Expansion of Concrete Through Reaction

Between Cement and Aggregate. Am. Soc. Civ.

Eng. papers, po1781, December 1940. (13) A.R. Alderman - A Review of the Evidence Concerning

Expansion Reaction between Aggregate and

Cement in Concrete - Bulletin Noo 161, Council for SCo and Indo Res. Australia, 1943.

(14) W.C. Hanna - Unfavorable Chemical Reactions of Aggregates

in Concrete and a Suggested Corrective

Advance Print, Proc. A.SoToMo, Vol. 47, 1947.

(15) R.C. Mielenz - Natural Pozzolans for Concrete. Economic

K.T. Green

&

Geology, Vol o 46, po311, 1951.4

-Progress Report I - Volume cィセャァ・ウ of Mortar Bars Made with

Some Canadian Cements and Pozzolans in Combination with Reactive U.S. Aggregates

by E.G. Swenson, E.W. Neumann, and R. Mott Purpose and Scope

This phase of the investigation was concerned with a preliminary comparison of high and low alkali Canadian cements with respect to their reactivity with deleterious aggregates which have been studied in the laboratory and are

known to be reactive. It was also intended to give preliminary

information on the effectiveness of some Canadian pozzolanic materials which may be useful as admixtures in concrete.

At the time these tests were begun it was not

possible to obtain high and low alkali U.S. cements for direct comparison, but the Bureau of Reclamation results using such cements with the same aggregates provide comparative data.

The mortar-bar expansion test is generally regarded as a sure method of promoting the alkali-aggregate reaction, and the results from it should be studied in this phase of the

work. All series of bars, however, were sub jected to freezing

and thawing and wetting and drying conditions as well, and the data are recorded and discussed.

Data on Materials

Two Canadian cements were used in this series,

(a) a cement with a relatively low alkali content and

which is somewhat finer than most other Canadian cements, manufactured at Exshaw, Alberta.

(b) a cement

somewhat Ontario. given in

with a high alkali content and which is

coarser in grind, manufactured at Belleville, The analytical data on these cements are Table I.

Three reactive U.S. aggregates were used and one Saskatchewan sand, the latter assumed to be non-reactive. Kimball and Republican River sands were obtained from the Bureau of Reclamation, along with laboratory data on their expansion characteristics when used with high and low alkali

U.S. cements. These sands have unsatisfactory field performance

records and have been studied extensively in field and laboratory. The samples obtained by the Division were already sized; the

sizes were re-combined according to specifications. Expansion

data are given in Table II. A Kaw River aggregate from Kansas

was obtained through the courtesy of Mr. A.D. Conrow of the Ash Grove Lime and Cement Manufacturing Company of Chanute,

record and extensive study by

Mr.

Conrow has revealed that it is susceptible to wetting and drying.A number of Saskatchewan volcanic ashes were obtained from the Department of Natural Resources of the

Saskatchewan Government. The raw material s were dried and

ground to moderate fineness by the Bureau of Mines, Ottawa. Further grinding was done in the Divisional laboratory in

an attempt to obtain comparable fineness. This was not

achieved because of the radical difference in the nature of the se asheB •

Two of these ashes were used as a partial substitu-tion for cement 1n order to test their pozzolanic value as a

corrective where alkali-aggregate reactivity occurs. Data on

these materials as well as on the reference material, Chicago

fly ash, are given in Table III. Another pozzolan of proven

performance, California calcined shale, was also used as a reference material.

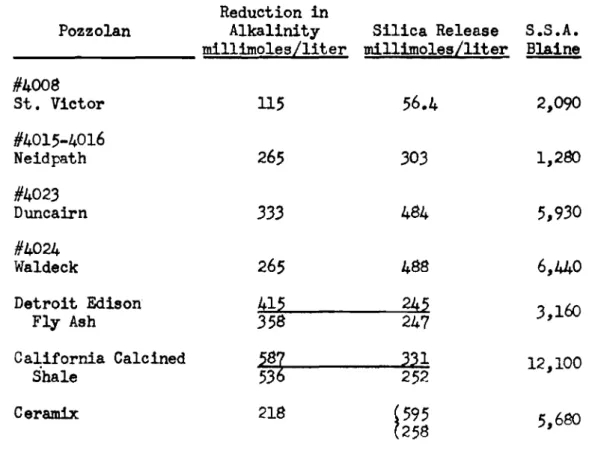

A preliminary evaluation of the volcanic ashes as pozzolanic materials was made according to the chemical

method of the Bureau of Reclamation. This consisted of a

determination of reduction in alkalinity and silica solubility (after digestion of the ash) in a one n9rmal sodium hydroxide

solution. The data are recorded in Table III. Subsequent

fineness tests, using the Blaine air-permeability ,method, indicate that these ashes were not of comparable fineness

(Table III) and that the chemical evaluation data must therefore be interpreted accordingly.

The pyrex glass aggregate used in the reference bars for the mortar bar expansion tests was crushed from used pyrex glassware, separated into five sizes and recombined in equal proportions.

Preparation of Test Specimens

With minor exceptions, the procedure followed in preparing and curing the mortar bars was that outlined in

A.S.T.Mo C227-5lT. These exceptions will be noted in each

instance. They are in nearly every case modifications

practised by the Bureau of Reclamation.

Standard steel moulds were used, fitted with

nickel-chrome alloy inserts. A very thin film of vaseline was used on

the moulds. All mixing was done by hand and by the same person.

The mOUlding and finishing was done by two people. The surface

finishing was somewhat modified, the levelling being done by a combination of rolling and sawing with a 5lB-inch steel tamping

rod. This technique was developed in order to reduce the

extent of the finishing operations.

- 6 =

Curing and Initial Measurements

From 20 to

24

hours after fabrication the bars,which were kept covered with wet cloths g were removed from the moulds, measured in a comparator g weighed and placed in a curing chamber at 76°F. with a relative humidity as close to 100 per cent as possible.

After 7 daysi curingg 3 bars from a given mix were

removed» measured g weighedg and placed in a cabinet conditioned

at 100°F. and 100 per cent relative humidity. This procedure

is in accordance with the mortar-bar test for detection of the

cement-aggregate reaction. A half bar for microscopic work was

also included.

After 28 days' curing four of the remaining bars from

each mix were イ・ュッカ・、セ measured and weighed. Two of these bars

were then subjected to slow cycles of freezing and thawing and

two to corresponding cycles of wetting and drying. In each

case a half bar for microscope examination was subjected to the same treatment.

Conditions of Test

The freeZing-thawing cycling consists of a 7-hour freezing period in a deep-freeze at +IOoF. and a 17-hour

thawing period in water at room temperature (about 75°Fo'.

The bars are held by racks having a capacity of 24 bars. On

week-ends and holidays the bars remain in the deep-freeze. The wetting and drying apparatus alternately cycles

the bars through a wetting cycle of 17 hoursg during which the

bars are completely immersed in water at room temperature g and a drying cycle in which the bars are subjected to heating at

130°F. During the drying cycle the moist air is exhausted.

On week-ends and holidays the bars remain in the wetting cycle. (Method developed by C.H. Scholer.'

The mortar bar expansion cabinet consists of a well

insulated box in which the 。エセッウーィ・イ・ is moisture saturated at

100°F. The bars remain in this cabinet indefinitely and are

removed only for measurement.

In all three of the above conditions the bars are kept upright in specially made racks so that no weight is exerted on

the inserts. Only distilled water is used for wetting the bars

and it is never changed during the test. The materials used

are such as to eliminate the formation of rust. Some small

rusting did occur and some sediment collected which was cleaned out.

Experimental Results

Table I gives the chemical analyses of Belleville and Exshaw cements which were done by the Canada Cement

Company. The values for fineness or surface area are

supplemented by our own results as obtained by the Blaine air-permeability method.

Table II gives the expansion data for bars made with Kimball and Republican sands as carried out by the

Bureau of Reclamation g d・ョカ・イセ Colorado.

Table III gives the chemical analyses of the

Saskatchewan volcanic ashes as done by the Chemistry Department,

University of s。ウォ。エ」ィ・キ。ョセ Saskatoon. It also includes

surface-area determinations carried out in our own laboratory. Specification limits for the Chicago fly ash used are also gi vena

Table IV gives the data on the determination of reduction in alkalinity and the silica solubility for some of

the volcanic ashes. These results were carried out in our

own laboratory.

Table V Haセ bセ C, and D) records the expansion data

for all the bars in this series. The figures are averages of

two or three bars (see Preparation of Test Specimens).

Reproducibility was exceptionally goodg the values being

significant to the last figure given.

The data on the bars in the mortar-bar test are

based on measurements after 7 days' curing. For freezing and

thawing and wetting and drying9 the values given are based on

measurements after 28 days' curing. The times of measurement

correspond for wetting and drying and freezing and thawing but

not for the mortar=bar test. Allowance must be made for this

in interpretation of results.

In some cases it was not possible to make measurements

exactly on a scheduled date. These are noted in each case.

Table VI (A

&

B) records the weight changes in the bars duringfreeZing and thawing and wetting and drying.

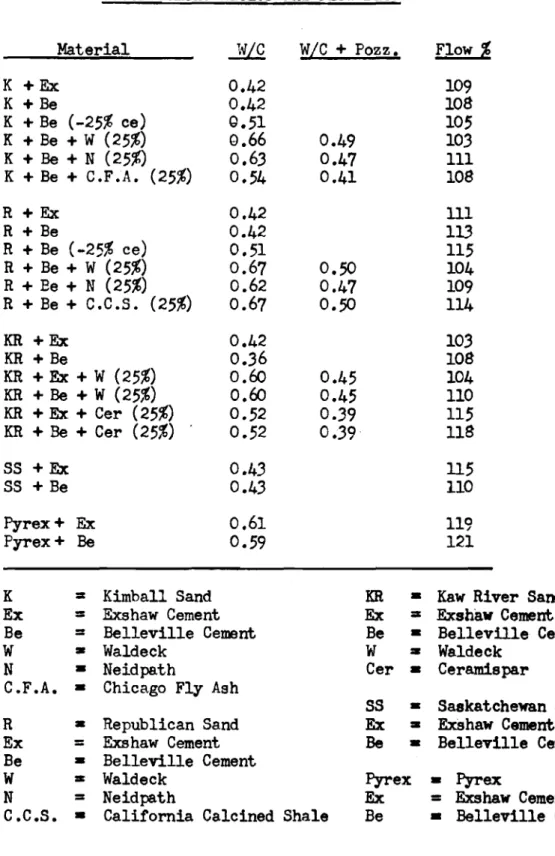

Table VII records the water-cement ratios and flow data.

Discussion and Intarpr-e.tat1.Q"O of ResuI ts

(a) Freezing and Thawing: Examination of Table V A(a)g B (a),

C (a), and D (a) at the end of 20g

32

9 and44

weeks (100, 160,and 220 cycles) shows that no appreciable expansion has occurred in the bars made with either Exshaw or Belleville cements and any of the reactive aggregates.

8

-Kaw River aggregate and Exshaw cement show the highest expansion (0.026%), but this value is still too

small to be taken seriously. Republican River sand shows a

contraction of 0.033% with Belleville cement. The rest show

some intermediate expansion or contraction. Of the small

expansions noted, the larger amount occurs in the first two

weeks (10 cycles). Where contraction occurs, the larger

amount occurs in about

4

weeks (20 cycles). At this periodthere is no evidence of destructive action by frost, so that these conditions do not appear to promote or favour the

cement-aggregate reaction.

Bars made with Kimball and Republican River sand

and with a cement content reduced by

25

per cent showed asomewhat greater expansion, particularly the latter which

showed considerable contraction in the regUlar sample. This

increased expansion may be due, at least in part, to the increased water-cement ratio required in this leaner mix to produce the required flow.

The substitution of

25

per cent of the cement withfinely divided volcanic ashes increases the expansion

considerably in the case of the Republican River sand HPNPWセ

and 0.090%), the highest value being for the Heidpath material. The calcined shale produced a slight reduction in expansion.

For the Kimball sand, the Neidpath ash again

produced a slight increase in expansion, but had no effect on

the bases of equivalent cement content. With the Waldeck

pozzolan and Kimball sand, an actual contraction occurred. It should be noted that a considerably higher water-cement ratio was used with these dry finely divided ashes, and it is surprising that greater expansions did not occur. The maximum expansions are still of a low order.

With Kaw River aggregate the substitution of

25%

ofthe cement with the Waldeck ash produced excessive expansion and ultimate destruction of the bars made with Exshaw cement. A slower but similar expansion occurred with bars made with Belleville cement, probably because of the coarser nature of

the cement. The non-po z aoLand c mineral glacial silt

(Ceramispar or Cera=mix) showed the same tendency. This leads

to the conclusion that the finely divided nature of these

additives are responsible in some way for decreasing durability to freezing and thawing.

The weight change data in Table VI A are included in this report but no attempt is made at this time to interpret them.

(b) Wetting and Drying: Examination of Table V A (b), B (b),

C (b), and D (b) at the end of 20, 32, and

44

weeks (100, 160,and 220 cycles) shows that9 for a

1:2 1/4

mix with Bellevilleand Exshaw cements and reactive aggregates a greater expansion occurs by wetting and drying cycles than by freezing and thawing. The total expansion is still of a relatively minor order but

there is a significant difference in each case.

For the Saskatchewan sand there is

4

to 10 times the・クー。セウゥッョ on wetting and drying than for freezing and thawing, the bars with the finer Exshaw cement showing the greater

difference. For Kaw River sand the expansion is

4

times asgreat, for Kimballg 7 to 27 times as great, the difference

being greatest for the Exshaw cement sample, although the actual expansion is greater for the bars contsining Belleville cement. For the Republican River sand, a considerable difference is apparent since the bars sub je cted to free zing and thawing had shown contraction.

Except for bars made with Republican sand, the greatest difference occurred with the finer Exshaw cement.

Reduction in cement content by

25%

resulted in aslight reduction in expansion with Republican River sand, but trebled the expansion for the bars made with Kimball sand and

Belleville cement. Since the water-cement ratios are the same

(Table IV) this behaviour is difficult to account for.

The substitution of

25%

of the cement by the pozzolanicvolcanic ashes produced varying results for the different mixes. With both Kimball and Republican River sands, the Waldeck ash produced excessive expansion whereas the Neidpath ash produced

no appreciable effect. deither ash had any effect with Kaw

Ri ver aggregate.

It should be noted that the Neidpath ash, al though

dried and ground in the ウ。セ・ manner as the Waldeck material, is

of a granular» crystalline nature when viewed under a microscope, whereas the Waldeck ash has much finer texture and has an

amorphous appearance.

Chicago fly ash had the effect of reducing expansion in the bars made with Kimball sand when based on equivalent cement contents, but only a very slight reduction is apparent when cO"'1lparison is made with the 1:2

1/4

mix.California calcined shale actually promoted excessive expansion with Republican sand under wetting and drying cycles. The weight change data in Table VI B are included here but no attempt is made at this time to interpret them.

10

-(c) Mortar-bar ExtanSion t・ウエセ Comparison of the results in

Table V A (C)1 B

c),

C (c), and D (c) at the end of35

and47

weeks indicate no appreciable or dangerous expansion ofany of the samples made with the reactive aggregates and

either of the low or high alkali Canadian cements usedt This

is remarkable in view of the data given in Table II as reported

by the Bureau of Reclamation, and in view of the comparable

alkali contents of Belleville cement (Table I) and the

corresponding alkali content of the UoSo cement used by the

Bureau of Reclamation (Table II)e The explanation may lie in

the delayed action of the Canadian cements due to the coarser

grind, although this is not likely since Table II indicates

a gradual increase in expansion even at an early age. The

only other apparent reason for the unreactive behaviour of the high alkali Belleville cement must lie in the manner in which the cement is manufactured, that is, in the burning and

grinding processes» which may change the alkali into a form which is not readily available for chemical reaction with the

reactive constituents of these aggregates. The fact that

Belleville 」・セ・ョエ does show reactivity with pyrex glass

(Table V D) may at first sight appear to be anomalous. Pyrex

glass as aggregate is used as a reference material in this, test but there is no real similarity between its reaction with

alkali and that of the reactive components of aggregates. The

expansion data on the bars made with pyrex glass aggregate indicate that the test conditions were right for the

alkali-aggregate reaction. However» these tests are continuing and

it is hoped that they can be repeated on a larger scale in an attempt to confirm these preliminary results.

The reduction in cement content by

25

per cent hadno significant effect on the volume changes nor. did the

substitution of

25

per cent of the cement with Neidpath andWaldeck volcanic ashess California calcined shale, or Chicago

fly ash, make any appreciable difference in expansion results. It is interesting to note, however s that with Republican sand and Belleville cement, the leaner mix produced a lower expansion and the California calcined shale reduced expansion to zero.

With Kimball aggregate and Belleville cement both Waldeck and Neidpath pozzolans reduced expansion to practically

zero, the leaner mix had a somewhat greater expansion trend as did the bars containing Chicago fly ash.

With Kaw River aggregates the Waldeck ash also reduced expansion slightly for both Exshaw and Belleville cements.

Tentative Conclusions

These tests are continuing and no final conclusions

can be drawn. Furthermore the results suggest strongly

that a more elaborate program will be necessary in order to arrive at definite conclusions regarding the behaviour

of some of these mixes. Such a program is being planned.

However, the results to date have already produced some significant results.

The remarkable absence of expansive tendencies in the bars made with high alkali Belleville cement and the Kimball and Republican River aggregates has interesting and

important implications which demand further research. These

experiments will be repeated not only with Belleville and Exshaw cements but with other Canadian cements and also with

U.S. cements. It is hoped that some work can be undertaken

to establish the reason for this apparent contradiction to present concepts on the alkali-aggregate reaction.

The peculiar variation in expansion tendeacies exhibited by the two volcanic ashes and the other admixtures

under different test conditions is also of interest. The

factors responsible for these differences are not apparent, and research work which could finally explain these phenomena would have definite practical value.

Finally, the comparative results between freezing and thawing and wetting and drying suggest that the latter condition is at least as important from a durability point of view and should be developed as a method for evaluating the durability of concrete and concrete mortars.

TABLE I

Chemical Analysis Rnd Fineness of Belleville and Exshaw Cements

Canada Cement Co. Analyses

1. Silica (3i02) (includes insoluble residue 2. Alumina (A1203)

3.

Iron Oxi.de (Fe2C3)4.

Calcium Oxide (CaO) Total5.

Calcium Oxide (CaO) Free6. Eagnesium Oxide Hャセ・oI

7.

Su1rhur Trioxide (S03)

8. Loss on Ignition 9. Insoluble Residue 11. K20 12. S.S.A. B1nine 13• . S.S.A. Wagner ... Determined by D.B.R. Belleville Exshaw Plant £15 Plant #12 21.4% 22.0% 6.4%.5.8%

:?9% 2.4% 63.2% 62.2%0.78%

0.90% 2.2% 4.1% 2.0% 1.9% 0.631 1.3% 0.18% 0.3::'1 O.ffJ% O,J') 0.90% 0.53 2723 (2790)11- HNSQPPセ 1395 Not Available DBR Report R-23Mortar Bar Expansion Results from lvork Done by U.S. Bureau of Reclamation

Cement Soda セョウゥッョ Per Cent セエ Age

Aggregate Equivalent Flow 3 9 12 18 24

d

-.!..

l-1onths Months Months Months Months Months/0

Republican 1.19 128 0.124 0.216 0.247 0.265 0.281 0 •.305

Sand 0.13 121 .013 .013 .013 .017 .020

Kimball 1.19 102 .162 .269 .274 .352 .388 .414

Sand 0.13 97 .002 .007 .009 .011 .019

All mixes were 1:2.0

TABLE III

The Determination of Reduction in Alkalinity and the Silica Release Carried Out by the Division of Building Research

Reduction in

Pozzolan Alkalinity Silica Release S.S.A.

millimoles/liter millimoles/liter Blaine #4008 St. Victor 115 56.4 2,090 #4015-4016 Neidpath 265 303 1,280 #4023 Duncairn 333 484 5,930 #4024 Waldeck 265 488 6,440 Detroit Edison 415 245 3,160 Fly Ash 358 247 California Calcined UXセ 331 12,100 Shale 53 252 Ceramix 218 p95 5,600 258 DBR Report R-23

Chemical Analyses of Pozzolans as Determined by the

Provincial Government of Saskatchwan

St. Victor Neidpath Duncairn Waldeck Chicago

SAMPLE NO. #4008 #4015-4016 #4023 /14024 Fly Ash

Hoisture at 10セc • 2.71 3.68 3.32 10.03 Ignition Loss950°C. 4.23 3.95 5.48 5.08 0.5-5 5i02 68.51 67.39 67.88 59.36 40-50 Fe203 2.44 2.65

2.44

4.05 12-19 Ti02 0.25 0.35 0.14 0.44 a・Rセ 14.00 13.44 12.39 12.55 CaO 1.03 1.53 0.78 1.38 4-8 MgO 0.91 1.64 0.91 1.63 0.2-2 Na20 2.64 2.14 2.90 2.46) ( 3-6 K20 2.45 2.57 _3.70 セQセI 99.17 99.34 99.94 99.10 DBR Report R-23TABLE V

Per Cent Expansion of Mortar-bars Subjected to: (a) Freezing and

Thawing, (b) Uetting and Drying lind (c) Mortar-bar Test

TABLE V A

-

セオ「ャゥ」。ョ River Sand (a) Freezing arn ThawingCycles 5 10 20 40 fJJ 100 I(£) 220

Weeks 1 2 4 8 12 20 32 44 Remarks

R ... Ex 0.00 -.002 -.002 -.006 -.004 -.001 Fliint map cracking

R+ Be +.010 +.008 -.020 -.020 -.036 -.033 Faint map crecking R + Be (-25% ce) +.008 + .007 +.020 + .024 +.032 +NPQセR

R+ Be + '.v (25%) +.014 +.OlS +.034 +.e27 +.037 +.074 Faint surface cracking R + Be + N (25%) +.024 +.036 + .057 +.066 +.076 +.090 Afew small surface cracks R + Be + C.C.S. (25%) -.005 -.C02 セNoo -.004 .:!:O.OO +.005 Faint map cracking

(b) Wetting Pond Drying

R + Ex +.003 + .010 +.008 +.026 +.028 +.036 + .039 Faint map cracking R+ Be +.021 + .036 +.058 +.081 +.078 +.083 + .082 Surface cracking R+ Be (-25% ce) +.019 + .036 +.046 +.056 +.051 +.058 +.O(£) Faint surface cracks R + Be + W (25%) +.007 + .013 +.053 + .136 +.229 +.265 Large cracks on surface R+ Be + N (25%) +.020 + .041 +.047 +.061 +.064 +.078 Large cracks on surface R + Be + C.C.3. (25%) -.001 + .007 +.031 + .120 +.209 +.345 + .459 Excessive map cracking

(c) Mortar-bar Test

Weeks 1 2 3 7 11 15 23 35

R + Ex +.002 +.003 -.008 +.006 +.004 +.003 + .019 +.0226

R+ Be +.007 +.011 +.012 + .020 +.023 +.019 + .029 +.030 R + Be (-25%) +.005 +.005 -.003 + .003 +.002 -.003 + .009 +.0114

R+Be + W (25%) +.021 +.028 +.025 + .015 +.017 +.008 + .022 Faint cracks ゥセ spots on some bars R + Be + N (25%) +.035 +.026 +.023 + .013 +.013 +.006 + .035 Faint cracks in spots on some bars

R + Be + C.C.S. (25%) +.003 +.002 -.006 -.005 -.007 -.012 0.00 +.0024

R = Republican Sand Where a pozzo1an has been used it has been Ex= Exshaw Cement as a substitution for 25% (by wt.) of the cement. Be = Belleville Cement

W= Waldeck

N = Neidpath

C.C.S. = California Calcined Shale

(8) Freezing and Thawing

Cycles 5 10 20 40 W 100 lW 220

Weeks 1 2 4 8 12 20 32 44 Remarks

K + Ex +.005 -.004 -.001 + .006 + .007 +.002 + .003 Faint mapcracking

K+Be +.011 +.008 +.006 + .008 + .• 010 + .0:20 + .014 Faint mapcracking

K + Be (-25% ce ) -.006 -.003 +.003 +.009 + .011 +.018 + .028 Very faint cracking

K + Be+ W(25%) +.007 :!fJ.OO -.005 -.004 -.008 -.007 -.006 Very faint signe of map cracking

K + Be+ N (25%) +.007 +.034 + .017 + .022 + .017 + .022 +.027 Faint map cracking

K + Be+ C.F .A. (25%) +.001 +.008 +.018 + .026 + .023 + .024 +.022 Very faint crpcking (b) Wetting and Drying

K + Ex +.018 +.OJ4 + .033 + .055 +.058 +.067 +.066 Map cracking over entire surface

K +Be +.028 +.057 +.078 + .107 +.105 + .107 +.097 Map cracking over entire surface

K + Be(-25% ce ) +.023 +-.e15 +.043 + .096 +.140 + .226 +.300 Excessive mapcracking

K + Be + W (25%) +.011 +.016 +.029 + .090' +.169 + .295 +.406 Excessive mapcracking and surface cracks

K + Be+ N (25%) +.009 +.015 +.001 + .012 +.013 + .012 +.014 Excessive map cracking and surface cracks

K + Be + C.F•A. (25%) +.038 +.039 +.063 + .067 +.064 +.064 +.067 Excessive mapcracking (c) Mortar-bar Test Weeks· 1 2 3 7 11 15 23 35 K + Ex +.016 +.021 +.003 +.027 +.025 +.026 +.023 + .029 K+Be +.021 +.023 +.014 +.026 +.027 +.022 +.022 + .026 K +Be + W (25%) +.003 +.002 +.001 +.010 +.011 +.009 +.001 +.005 K + Be+ N (25%) +.007 • +.005 +.006 +.010 +.008 + .007 +.001 +.001 Weeks 1 2 3 4 8 12 19 31 K + Be(-25% ce) +.073 +.065 +.064 + .061 +.069 + .057 +.055 +.067 K + Be+ C.F.A. (25%) +.075 +.069 +.067 + .063 +.070 + .061 +.056 + .070 K

=

Kimball Sand Ex=

Exshaw CementBe = Belleville Cement vlbere a pozzolan has been used it has

W

=

Waldeck been as a SUbstitution for 25%(by wt.) of the cement. N=

Neidpa.thC.F.A.

=

Chicago Fly AspTftBLE V C

-

Kllw River Sand(a) Freedng and Thawing

Cycles 5 10 20 40 fIJ 100 IfIJ 220

":eeks 1 2 4 8 12 20 32 44 Remarks

KR + Ex +.007 + .015 ....007 +.024 + .028 +0025 +.031 + .026

KR + Be +.005 + .013 +.003 +.014 + .018 ....012 +.018 + .013

KR+Ex + lJ (25%) 0.00 + .013 +.016 +.157 + .481 Fell apart completely.

KR + Be + IV (25%) +.005 + .012 -.007 +.025 + .055 ... 139 +.238 + .333 Cracks appearing • Falling apart at ends. Ex+ KR +Cer (25%) .000 + .0095 +.0265 +.124 + .164 +.2525 +.266 + .2725 Faint map cracking. Bars カセイケ weak. Be + KR + Cer (25%) +.003 + .009 +.0035 +.024 + .041 +.090 +.1015 + .102 Faint map cracking.

(b) 1,'I'etting and DrrlI1&

KR + Ex + .022 + .036 +.047 +.077 + .087 + .087 +.095 + .099 Faint map cracking in spots.

KR + Be + .021 + .033 +.042 +.053 + .062 + .050 +.050 + .051 Fqint map cracking ir: s]:'ots.

KR + Ex+ セN[ (25%) -.012 -.003 +.018 +.037 + .056 + .071 +.084 + .093 Map cracking in spots. End5 .:.:f t:\rs falling apart slightly.

KR + Be + 1;1 (25%) -.017 -.012 +.006 +.020 + .028 + .026 +.039 + .067

Ex + KR + Cer (25%) +.0065 + .0265 +.038 +.0505 + .072 + .0705 +.0795 + .084 fセゥョエ surface cracks.

Be + KR + Cer (25%) +.003 + .0215 +.0325 +.037 + .Ol185 + .0425 +.047 + .051 Faint surface 」イセ」ォウN Scaly surface. (c) Mortar-bar Teet :'leeks 1 2 3 7 11 15 23 35 47 KR + Ex 0.00 + .001 +.003 +.017 + .036 + .040 +.034 + .029 +.032 KR + Be + .002 + .003 +.004 +.016 + .034 + .034 +.030 + .024 +.023 KR + Ex + \'1 (25%) + .001 ! 0.00 KセoPS +.013 + .030 + .034 + .030 + .025 +.023 KR + Be +

I'

(25%) + .002 + .002 +.004 +.011 + .023 + .027 + .023 + .014 +.011Ex + KR + Cer (25%) -.001 -.0003 +.0023 + .0123 + .0213 + .036 +.0197 + .0217 +.0213 Slight cracking on surface. Be + KR + Cer (25%) -.001 + .001 +.0027 + .0143 + .021 + .034 + .0133 + .015 +.0123 Slight cracking on surface.

KR =Kaw River sセョ、 Where' a pozzolan has been used it has been

Ex =Exshaw Cement as a substitution for 25% (by wt.) of the cement.

Be=Belleville Cement

W =Waldeck Cer =Ceramispar

(a)

Weeks 1 2 4 S 12 20 32 44

5S + Ex + .004 + .007 + .005 +.005 +.005 + .COS +.004

SS + Be + .COS + .010 + .006 +.003 +.004 +.ooS +.006

( b) Wetting and Drying

S5 + Ex -.002 +.004 +.020 +.029 +.041 +.045 +.041 +.045 SS + Be +.002 +.007 +.018 +.0.33 +.027 +.025 +.OlS +.024 (c) Mortar-bar Test Weeks 1 2 3 S 11 15 23 35 47 5S + Ex 0.00 -.005 0.00 +.017 +.023 + .028 +.027 +.027 + .040 S3 + Be +.003 -.002 +.004 +.014 +.016 +.018 +.014 +.011 +.022 Weeks 1 2 3 7 11 15 23 35 47 Exshaw + Pyrex +.004 +.006 +.005 +.015 +.028 + .034 +.023 +.024 +.027 Belleville + Pyrex +.136 +.235 +.244 +.252 +.26S + .272 + .2f:IJ +.258 + .268

55

...

sセウォ。エ」ィ・キ。ョ Sand Ex=

Exshaw Cement Be=

Belleville CementTABLE VI (A)

Percentage Change in Weight of Concrete Mortar-bars During Cycles of Freezing and Thawing Freezing and Thawing

No. ot Cycles 1 10 20 40 100 160 220 R + Ex -.06 -.OS -.14 -.2S -.40 R + Be -.12 - .02 -.04 -.12 -.26 R + Be (-25%) -.04 .02 .06 -.06 -.18 R + Be + W(25%) .04 -.12 -.14 -.25 -.16 R + Be+ N (25%) .15 .10 .24 .10 .04 R + Be + C.C.S. (25%) -.08 -.27 -.33 -.46 -.50 K + Ex -.24 -.22 -.34 -.32 -.42 K+ Be - .35 -.31 -.27 - .35 -.48

*

K+ Be (-25%) 0 -.lS -.18 -.31 K+ Be+ W(25%) .04 -.19 -.75 -.96 -1.13 K + Be + N (25%) .21 -.14 -.56 -.68 -.87oOK+ Be+ C.F.A. (25%) .14 -.43 -.51 -.70

KR + Ex -.67 -.33 -.39 -.29 -.38 -.45 KR + Be -1.09 -.27 -.35 -.23 -.33 -.39 KH + Ex+ W(25%) -1.15 -.29 -.54 KR+ Be+

lv

(25%) -1.12 -.33 -.52 -.01 .07 .16 KR + Ex+ Cer (25%) -.29 -.25 -.29 .32 .35 .29 KR+ Be+ Cer (25%) -.39 -.66 -.67 - .36 -.42 -.49 SS + Ex .07 .03 .06 .20 -.09 -.25ss

+ Be -.06 -.3$ -.43 - .36 -.54 -.64Percentage weight chCJnge is based on weight at 28-day age.

*

I\eight change in t!1is case is based on weight 8t 36-0B.y age.R

•

Rerub1ican Sand K=

Kimball SandE.x

=

Exshaw Cement Ex :I Exshaw CementBe

•

Belleville Cement Be=

Belleville CementW : I Waldeck t'l

=

:ialdeckN : I Neidpath N

=

!Jeidr-athC.C.S. : I California Calcined Shale C.F.A•

=

Chf.cago Fly fl_shKR • Ka'l-r River Sand

Ex :I Exshaw Cement Be : I Belleville Cement W :I Ha.ldeck Cer

=

Cerarnispar SS • Saskat-chewan Sand Ex = Exshaw Cement Be=

Belleville Cement DBR Report R-23R = Ex

=

Be=

1:1 = N = C.C.S. • Republican Sand Exshaw Cement Belleville Cement ivaldeck NeidpathCalifornia Calcined Shale

K

=

Kimball SandEx :I: Exshaw Cement

Be = Belleville Cement

W

=

WaldeckN

=

NeidpathC.F .A. • Chicago Fly Ash KR ,. Kaw River Sand

Ex

=

Exshaw Cement Be :& Belleville CementW' :& Waldeck Cer = Ceramis par

SS • Saskatchewan Sand Ex = Exshaw Cement Be • Belleville Cement

TABLE VII

Water-Cement Ratios and Flow Data

Material 1'1/C K+Ex 0.42 K + Be 0.42 K + Be (-25% ce) G.5l K + Be + W(2.5%) 0.66 K + Be + N (25%) 0.63 K + Be + C.F.A. (25%) 0.54 R + Ex 0.42 R + Be 0.42 R + Be (-25% ce) 0.51 R + Be + W (25%) 0.67 R + Be + N (25%) 0.62 R + Be + C.C.S. (25%) 0.67 KR+Ex 0.42 KR + Be 0.36 KR + Ex + W (25%) 0.60 KR + Be + W(25%) 0.60 KR + Ex + Cer (25%) 0.52 KR + Be + Cer (2.5%) 0 •.52 SS + Ex 0.43 SS + Be 0.43 Pyrex+ Ex 0.61 Pyrex + Be 0 •.59 W/C + Pozz. 0.49 0.47 0.41 0.50 0.47 0.50 0.4.5 0.4.5 0.39 0.39· Flow % 109 108 105 103 111 108 111 113 11.5 104 109 114 103 108 104 110 115 11S

115

110 119 121 R • Republican Sand Ex=

Exshaw Cement Be • Belleville Cement W=

Waldeck N = NeidpathC.C.S. • California Calcined Shale

K Ex Be W N C.F.A.

=

Kimball Sand=

Exshaw Cement=

Belleville Cement • Waldeck • Neidpath• Chicago Fly Ash

KR • Kaw River Sand

Ex