= ==

=

!Jill

by

J. Antonio Rodri ez

-Sublitted in partial fullfill.ment of the requirerients for the degree

of

BACHELOR OF SCIENCE in CIVIL ENGINEERING at the

Massachusetts Institute of Technology June 1959

,, /

.

.

Signature of Author:

Signature redacted

~.

.

ez

vil Engineering

Signature of Supervisor:

Signature of the Head of the Department:

__

,

.

<

Signature redacted

) I ,, I" V " " '- ""V Prof. Eug:ne Mirabelli 1 / / l • , •Signature redacted

/ John B. Wilbur '1440 Beacon St •

Brookline 46, .Massachusetts May, 1959

Mr.

Secretary of th FacultyMassachusetts Institute of Technology

CUlbridge 49. Massachusetts

Dear Sir:

Sutmitted herewith is a thesis, ntitl d "COMPARATIVE

STUDY OF STRUCTURAL

A.LUMillUM A!IDSTEEL",

in partial!ullfillaent of the requir nts for the degree of Bachelor

of Science frCD the Massachusetts Institute of T chnology.

Respectfully yours,

-Signature redacted

-

rr~ -

..

C??'ae=

=

{ / ., • Anf;onio hodr ezTw author wishos to expesos his gratitud. to Professor Eugene Nirabelli, of the Civil Eugineering Department at the

assaaustts Institute of Technology, for his generous help and encouragmeat in the work ooiectsd with this study.

He wishes also to thank, for their cooperative aid, the

staffs of the AI I Im Cempany of AMerica, aM United States

Steel Corporation. Specially Mr. Cook of Alcoa, and Mr. Oraywork

compare eeenemially has arisen.

The object of this thesis is to owipare the oast of similarly

leaded steel and alimnm uwmbers, designed without any speotfic structure in mind, so as to achieve as much generality as possible.

The results of this study show, that from an ecenomic point

ML MD ... R f ... VL .... VI .... VD .... Aw A 1 ... 00 r ... 00 rxx .... * ryy ... * Ixx .... Iyy ... , PL ... 0.0 Cs ... 0 YO ... c cc. CCC ccc.ececc. . . cecece*c . . ececec*c . .... *.. . ...

madim live moment maxim= impact moment

maid=m dead moment

uniform load reaction

allowable stress maximum live shear maxdmm impact shear maximu dead shear

area of web gross area

unsupported length radius of gyration

radius of gyration about x axis radius of gyration about y axis moment of inertia about x axis momnt of inertia about y axis plate

torsion bending constant

distance from extreme bottom fiber to

Simbol or Abbreviation J ... e... k in2 ...

$

ft. req~d ... O.K. d bt

... Axis x-x .... Q W/T torsion constantfactor representing end condition kips inches square inches pounds dollars feet required an

sheer

stress actualshear

stress acceptabletotal aaxiu= m.ment total Maximum shear

depth

width thickness

horisontal axis quantity

Procndus:

Floor systems of varying span and trmsses of two, four, and six panels, have been designed and compared. Each of the ammbers in a steel trass, has been compared separately with the corres. pending member in the aluminum truss.

Loads caused by a two lane highway, with a standard H20S-16 truck loading, have been used throughout; however, for the purposes of this thesis, any other type of loading could have been used.

The design of the members complies with the specifications of the American Institute of Steel Construction, and the Specifi-cations for Structures of Aluminum Alloy 6061-T6 of the ASCE Proceedings, paper No.970. The AISC Handook (1957) and the

ALCOA Structural Handbook (1958), have been used.

In the design of the members, special care was taken to arrive at the most economical section for each metal, without much atten-tion being paid to the economies brought about by the use, in a

truss, of as many similar members as possible. Due to their variable nature, I have not included fabrication costs.

All members have been designed as welded members. In addition

after welded, in order to regain the strength lest in the welding

process.

The sope of this thesis is to design similarly loaded

ala-mium and steel aembers ad to opare their est. flor systins

of varying span and umners of 3 different trusses haVe been mpared.

The results of this study shew, that frm an 0e4go.ia point

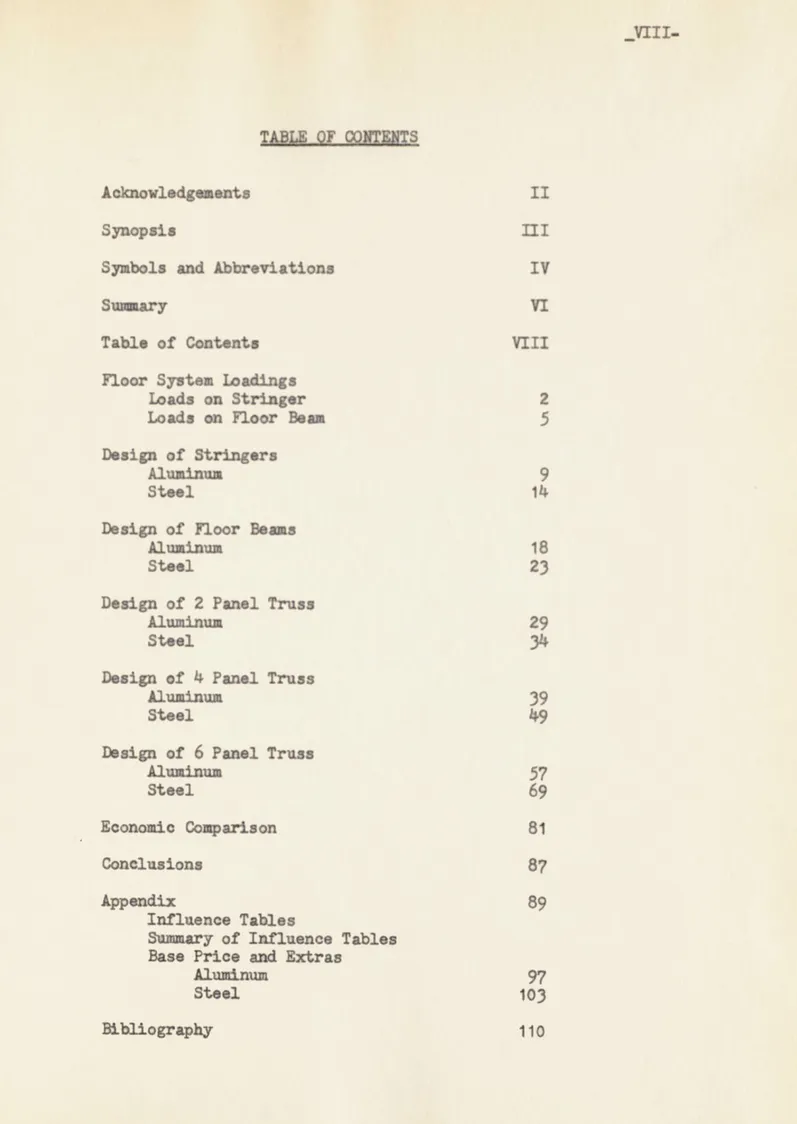

TABLE OF gNMETS

Acknowledgments II

Synopsis III

Symbols and Abbreviations IV

Suawry VI

Table of Contents VIII

Flor Systen loadings

Loads on Stringer 2

Loads anFloor Bean

S

Design of Stringers

AlumInum 9

Steel 14

Design of Floor Beas

Aluminum 18

Steel 23

Design of 2 Panel Truss

Aluminum 29

Steel 34

Design of 4 Panel Truss

Aluminum 39

Steel 49

Design of 6 Panel Truss

Aluminum 57 Steel 69 Econamio Comparison 81 Conclusions 87 Appendix 89 Influence Tables

Summary of Influence Tables Base Price and Extras

Aluminum 97

Steel 103

40* .'6 _ _1.1

As4Mr'g a:

H20-S16 Track Loading.

Thickness of Concrete Slab u 10"

Stringers 0 7 ft. Center to Center.

Leads on Stringers (20 ft. Span)

Maxim= Irinzer LoAdng: (Wheel load on support)

R w 16 (1 + 3/7 + 1/7) a 25.2 k

rincerc L n: (Wheel load not on support)

R = P x K = P

jjg_'

= 20.45 5.5

(b = Spaoing Between Stringers)

ao-.

2.V

VL - 25.2 + 20.4 x La6 31.3 k 2 VI W(31.3)(0.3)

n 9.4

YD-a a) Slab: ( (?)'

8.75 k b) Stringer: Ear AluWMnu:Assume weight of Auminum Stringer = 34 #/ft.

Then, VD I x2g..- 0.35k

2 x 1,000

Assume weight of Steel Stringer - 62 #/ft.

Then, VD n 62 x-2Lu 0.62 k

2 x 1,000

Waim LU12 bamnl:

.q4 K

X = P x L = 20. = 20 102 k -ft.

Ma

(4 g

2 a 1.70 k - ft.8 8

M a W a 6 2 - 3.1 k - ft.

8 8

THEN . FOR ALMI

ML n 102.0 k - ft. MI =

30.6

k -

ft.

MD w.I

k - ft. MT = 178.0 k - ft. VL = 31.3 k Vi = 9.4 k YD = 2@9 k VT a 49.8 k THEN. FOR STlL 102.0 k - ft. 30.6 k - ft. J.la.2 k - ft. 179.5 k - ft. VL =31.3

k Vi a 9.4 kVD*

A

k

VT = 50.1 kA similar procedure has been used for the longer spans. ML

-MD =

FOR 20 ft. STRIN0GER SPAN p= 16 + 16 (A) + 4 (.) * 22 k (20) (20) Mb 0 u 22 (9 + 15 + 24 + 30) - 34 Ra R& = 50.5 k Dgad Lgoa: Ra a W & 2

Due Slab: R& 1&5 x 42.6 k 2 x 1,000

For AuINNIM:

Due Stringer: Ra 34 x 20 3 + 10 +17 + 24 + 31) - 1.70 k

314

Ne Beam: Assume weight a 100 #/ft.

Ra 1 a -. 1.7 k

2 x 1,000

Due Stringer: Ran 64 x 20 = (3 + 10 + 17 + 24 + 31)- 3.1 k 34

Dae Beam: Assume Weight = 200 #/ft.

Ra = 202 x#L = 3.4 k 2 x 1,000

I

9.I

.

~1 ' It

P = 22 k Therefore, Ra a 4 k ML u 44 x 17 - 22 x 8 - 22 x 2 a 527 k - ft. Mi a 527 x 0.30 = 158 k - ft. DeA Lgad: Dae Slab: (2Q)(125)(2!.)(7) - (201)(25) (17)(J2) a 361 k - ft. 1,000 2 1,000 2lor A" I=u:

Due Stringer: x (2.5 x 17) - 3 x-20 (7 + 14) a 14.7 k - ft. 1,000 100 Due Boamt (12 ( 14.6 k - ft. 8 x 1,000 Duo Stringer: 2t2 (2.5 x 17) - A 0(7 + 1) 26.6 k - ft. 1,000 100 Due Beam: 0(])2 a 29 k - ft. 1,000 THEN, FM ALUMM ML a MI a MD = MT = 527.0 k - ft. 158.0 k - ft. .2390, k - ft.

1,075.3

k - ft. VL = VI = VD = VT W 50.5 k 15.2 k 111.7 kMI a 158.0 k - ft. Vi a 15.2 k

ND w _A4 k - ft. VD = 31: k

MT a 1,101.6 k - ft. VT a 114.8 k

A similar procedure has been used for Floor Beaus carrying the longer stringer spans.

Q"Its A imN,4

YL a 31.3 k

VI = 9.A k

VD

a.

k

VT a 49*8 k

3 rAq'd = A 178 & I 132 in3f 14 - 4,v Chec Shart Va =8.5 k/in2 (1)

V

-

L..

. a 4.13

k/in

hwtv 24

x

.5

ML = ND = XT = 278.0 k83.5

k

J&L.1 k550.0 k

ft. ft. ft. ft.i-x

376

+4.3

(12.25)2]2

a1.926

in4

Su u u 154 in3 0.z o 12.5 0. 1. YL = 38.5 k

VI

-11.5 k VD - k I VT - 68,8 k 8roq*d 12 = 472 in' 14(1) ASCE, AS E Procedintgs (May, 1956) Paper No. 970, p.14. ML-M, = ND- NT-102.00 k

30.60

k

178.00 k - ft. -aft - ft. - ft. ""--lChack Shejkri va n 8.5 k/in2 (2) T UgA a 2.87 k/in2

32 x

.75

XL 0 NJ = MD u r=

600 k - ft. 180 k - ft. .. Ujm k - ft. 1,250 k - ft.Ixx n 2,048 + 2 1ii (16.5)21 a 8.o3 in4

3 n LgE 472in3

.

.

17 0. K. VL a VI.= VD w VT.53.8

k

16.2 k3

mR

k

100.0 kSreq'd = I A.U 2 1,070 in'

v. 5 k/in2 (3)

V 100 = 3.14 k/in

2

(2) ASCE, op. cit., p. 14.

(3) ASCE,

op.

cit.,p.

14.I

69909+2L(16z1 )

(26)2

=

28,509

ik

s - 28.-a 1,075 in3 O.K .

938 k - ft. 282 k - ft. _ k - ft. 2,055 k - ft. VL = 64.0 k VI n 19.2 k VD 0 k VT n 125.0 k

Sreqtd = &.55 X. a 1,760 iW3

14 8 Chogk SharX: a a 3.5 k/in2 (4) VS 15 U 3.4 k/ia2

60x .625

I *x a 11,250 + 2 (iB x 1.375)(30.69)2] Ixx - 57,850 in4 0. K.S

n

.1ji

1,1oin3 0. K.31.375

0. K.120

ft. kPa ML = 1,544 k M 1 = 464 k MD = 1.,3Q4 k MT = 3,312 k - ft. - ft. - ft. - ft. Vt = VD = VT = 77.5 k 23.2 k .2a k 152.9 k Sreq'd = 2,440 in3(4) ASCE, op. cit., p. 14.

ML n

MD =

p*-4 9hek Shma Ta g k/lnZ (5) S-

l

- 3.1 k/iU2 Ixxu 17969 + 2 [(22 x 1.375)(33.69)21Ixx =

86*6,5 inW

X

Y ..

37&2

2 520 O

.

,

34-375

MSIGN 07 STINGES

9D-k10 O TRIGOERS N* n 102.0 k -Mi

= 30.6 k

-ND

U.-jJ k -X? - 179.5 k -ft. ft. ft. ft. VL n 31.3 kVI a

9.

k

VDnL

k

VT = 30.1 kSroqtd

a

19..2x

12 a

107.6

a3

20Znz:

18 W 60 s u 107.8 ia3Oak 1or OaL (

va n 13 k/ijt? (6) 13 k/lm2 0. K.

Jl=zil

XL m 278.0 k - ft. NI a 83.5 k - ft. MD = ?JaQQ k - ft.MT

= 561.5 k - ft.VL

U38.5 k

Vi a 11.5 k VD .aUQ k T 7.0 k Sreq'd w 561.5 x 12 a 337 in2 26 30 W 124 (6) AISC, Lc Handbgk (1957) p. 286. 0. K.S

a

354.6 Sn3

gihok for Shuarsva - 13 k/in2 (7) V

iE

70

13

k/ina

2.x .58X n 600.0 k

-NI

180.0 k -ND u.-AIU k -NT = 1278.0 k -ft. ft. ft. ft. Srsq'd 0 1278 _& I& 766 i3 2036

W

230

3 n

835

iW3

hk

for

mshar

va n 13 k/ia

2Sa

313.1

33.36 x .76513 k/ia&

2-_ft sA

ML = NJ = MD = XT =938.0

282.0 2,180.0 k.k k k -ft. ft. ft. ft.(7) AISC, op. cit., p.286.

0. K.

0. K. VL a VI a VD a VT n53.8

k

16.2 k33al. k

103.1 k 0. K. 0. K. VYL VI. VD VT= 64.0 k 19.2 k -ALQ k 131*2 k--- S4

I= a 6, 61 + 2 C(22 x 0.935)(27.47)21

I= a

37,761

in

4S ua =1,350in3 0. .

28 Chegk rar amar-2

va n 4.85 k/in2 v n 1 '.2 ig 4,.85 k/in2

54 x 0.5

-100 ims AR 195"4 k -ft.

.60 k ft. . k - ft.3.043

k - ft. VI U YDU VT77.5 k

23.2 k

1-07 k 160.7 k Sroqd 3.243 x *2 1,825 n3 20 G-egk f - Sher:V

1.7 k/jU26f x .5

I - 9,157 + 2 [(1 x 25) (31)21IME

n57,457 in4

S a =7d 1,825in3

31.5

0. K. ML XTU 0. K. 0. K.1E3IQN OF flO BEAMS

I~E$IGN 07 ~WOR B&&M FOBZOftaSTRIIQUSPAI XL ND -XT = 527.0 k - ft. 158.0 k - ft* _.3ja k - ft.

1,075.3

k - ft.

TL a VI.= VD = VT = 50.5 k 15.2 k .11.7k 111.97 kUsupported lateral lumgth a 7 ft. a*

As a trial s .. 6 8.4 (a) Therefore, f a 14 k/in2 (9) Srsqfd .5 S -1 0 i92 I= 5,760 + 2 1 u 24,960 in 4 S n Z 955 9"ekfa Shoar:

va a

5.7 k/in

2(10)

St 111. - 3.72 k/in2 48 x .625Ckgok for Aullwable S.aA In FlnM: (ii)

so * 955 n j4 1/3

[

2 x 16 (1)3 + 49 (.625)3] . 14.6 nj B Ii d .7 + J (P)I1 d LO16 x 1)(24.5)21 -w3 0 O.K. op. cit., p. 9. op. cit., p. 14. op. cit,, p. 14. op.cit.,

p.9.

.K. (8) (9) (10) (1) ASCE, ASCE, ASCE, ASCE,F V3.58

50&

i7.55Therefore,

Allowable

roa e ft. saiuo SAN

ML

a934.0

k -

ft.

Xi = 280.0 k -f t. ND = .,023. k - ft.XT n

2,023.3 k

-

to.

Stress = 14 k/in2 (12) YL W YV a VD w VT a 0. t. 88.6 k 27.6 k.211..

k

211 .i kSines unsupported length for all Floor bans is the sae as that previous mue, and sin.. this and the following beans are heavier

than the preceding e, w need not wry about bukling.

Therefore, we wifl use f a 14 k/ia2 (13)

3req'd = .023 1 1,730 i3

'1

Check for Ser

Va - 5.25 k/im2 (14) V = a..i - 4.85 k/in2 58 x .73 (12) (13) (14) I = 12,195 + 2

[(18

x 1.375)(29.69)2j

= 53,000

in4

S a ,mRo = 1,820 in330.375

ASCE, op. cit., p. 9. ASCE, op. cit., p. 9.

FS

60

ft.Mrn

SPAN 1,220 k - ft. 366k - ft ja k - ft. 2,826 k - ft. VL = 116.2 k yI a 34.9 k yD = I4k T 294.7 kSroq'd

&o826 &2,20 In

I49hwk

o

m ha

a 6o2 k/in2 (15) - n a 5.27 k/iR2 0 80 ft. SmiG SPI ML . RD w XT a 1,870 k - ft.560

k - ft*i4afk

Ik - ft.4,074

k - ft.xxx

a 19.115 + 2 ((22 x1.375)3.69)2

I=8 3815 184 S 31J a 2,52 n3 O. K33.'3"

0. K. yL a 175.0 k VI n 52.5 k YD = 3 k VT = 421.2 k 3reqtd = 4.074 1xJ&

3,2690 in 14(15) ASCG, op. cit., p. 14. L

-RD *

fta/ -- 70 * / Y& n 6.7 k/in2 (16) v N jLiaLm. 6.02 k/ia2

70 x I

Fm 129 im. 1TNG APA XL u 2,287 k - ft.XN n 696 k - ft.

XDLa.

k - ft.NT

a 5.392 k - ft. rq*d = LI21

- 4,620in3

14Zrz'

27-Z S72w / va = 6.5 k/in2 (17) VMa

= 6.5 k/iA2 72 I z = 28,583 + 2 1(24 x 1.625)(35.81)2) I= n 128,583 in3

-2 3.510 in

0.

K.

0. K.

Y1 D VT = 219.0 k65.0 k

468.2 k I==

31,104 + 2 E(27 x 2)(37) 271=

=

179,000 in4

S= 1229.& 38,720 1n338

0. K. 0* K.(16) ASCE, op. cit., p. 14. (17) ASCE, op. cit., p. 14.

SIGN OF

rLcx

BEAMS IMLlESION OF FLOOR EA1

FOR 20 ft. STRINGER SPAN

ML n 527.0 k - ft. MI- 18.0 k - ft. MD = 416. k - ft. mT 1,101.6 k - ft. Sroq'd

a

1.lL.i.6 x 12 62: 20 In:t33

WF

200

S a 669.6 in 3 Cheak for V: 14

xda--84 &

33

L153

b x t 15.75 x 1.15 Check for Shar:V- 1-1 6 5.2 k/in2

30.70 x .715

FOR 40 ft. STRINGER SPAN

VL = 50.5 k VI - 15.2 k VD = Ad

j

k VT n 114.8 k In3 0. 1. (18) 0. 1. 0. K. ML w 934 k - ft. MI = 280 k - ft. MD = . k - ft. NT = 2,075 k - ft. sreq'd 2.225 x 12 20 88.6 k VI . 27.6 k VD = j4k VT = 218.6 k 1,240 in3L- -an 2.

n

JAII b xt 22 x873 I= a 8,201 + 2 (21 x 7/8)(27.*4)2I= n

35,900 in

4 S a 3,.Lm9 n 1,285 in3 27.875 243 (19) 0. K. 0. 1.Check for Shear:

V. 218.6 .6.5 k/in2

54 x .625

Intrvediate stiffners are needed if v

L

oxceeds MA (20)Au (hvftv)Z

V

a - 8.6 k/in2Therefore, no stiffners required. FOR 60 ft. STRIUKR SPAN

ML n 1,220 k - ft. MI = 366 k - ft. MD.

1=3&

k - ft. XT * 3,018 k - ft. Sreq'd n 3.91 X 1U 20 141T4

(19) (20) VL u 116.2 k Vi = 34.9 k VD a . k VT n 317.8 k 1,810 in3 Ixx a 14,200 + 2 ((1 x 24)(31)2 Ixx = 58,300 in4 S = * =.30Q 1,850 in3 31.5AISC, op. cit., p. 286.

AISC, op. cit., p. 298.

0. K.

l~xn-w 600 (21) b x it 24 x 1

Check for Shear:

T=

31.81

.

n6.95

k/in21 x .75

0. K.

Intermediate stiffners are neoded if v Y. exceeds f (22)

f

9.Ak/in

2Therfore, no stffners required.

FPO 80 ft. STRfI SPAN

HL * 1,870 k - ft.

MI 560 k - ft.

MD w k - ft. T n 4,317 k - ft.

Sreq'd 4.312 &

J&

-20 VL - 175.0 k VI a 52.5 k VD n

ZZLI

k VT = 449.5 k2,59o

in3

Zw

I=a 27,200 + 2 [(1 x 26)(36.5)2]I= a 96,600 in

1 --- 8 S * = 37 2,610 in3LL&

= (84)(74) a 207 (23) b x t (30(0) (21) AISC, (22) AISC, (23) AISC, op. cit., p. 286. op. cit., p. 298. op. cit., p. 286. 0. K. 0. K.Check for Shear:

0. K. V = 449. n 7.13 k/in2

72 x .875

Intermediate stiffners are needed if v

L

excoeds # mw% (24)Av

(hvltv)Z'

( 4,' 2 9.45 k/in

2

Therefore, no stiffners required. FOR 100 ft. STRINGER SPAN

ML n 2,287 k - ft. MI a 696

k -

ft.ND

= k - ft.HT - 5,437

k -

ft.

Sreq'd = 5.-37 x I& 20 VL n 219.0 k VI m 65.5 k VD = k VT - 572.3 k 3,260 in3 -- Z v/ Check for ft L L4 Q 6 =600 (25) b x t 26 x 1Check for Shear

v - 3 6.92 k/in2 84 x I (24) (25) Ixx w 49,400 + 2 [(1 x IXX a 143,200 in 26)(42.5)21 S n 1tt.20

43

0. K. 0. K.AISC, op. cit., p. 298.

AISC, op. cit., p. 286.

Therefore, no stiffners required.

DESIGN OF 2 PANEL TRUSS

TRU53LADN

Uniforu Load- 6u W #/ft. Cao stratod Leads:

a) Chords: 18,000 #/Lan

b) Diagonals and Vertisals: 26,000 #/Lan

Impact w .ni__ but less than 0.30 Live Lead 125 + L

Load Facter = 1.147

Live:

Uniform 29.4 k

Cone. Chord 20.6 k Cone. Diag. and Vert. 29.8 k Dead Leads:

Slab 85.0 k

Stringer 5.4 k

Floor BeaM

Total 92.3 k

AssuMe weight of truss = 0.20 k/ft.

L. L. stress

D. L. Iap-. I + L Total

Stress Uni. Cono. Total Frac. I+I+D

Bar k k k k k k t4LI 0 0 0 0 0 0 L1L2 0 0 0 0 0 0 U0 U1 -50 -14.7 -10.3 -25.0 0.24 -31.0 -82.5 U1U2 -50 -14.7 -10.3 -25.0 0.24 -31.0 -82.5 L 0U0 -50 -14.7 -14.9 -29.6 0.24 -36.8 -88.5 LjU1 0 0 0 0 0 0 L2U2 -50 -14.7 -14.9 -29.6 0.24 -36.8 -88.5 UOLI 70.7 20.8 21.1 41.9 0.24 52.1 124.1 L1U2 70.7 20.8 21.1 41.9 0.24 52.1 124.1

Erx:

'-a 2.3? 10 A2

14.98

3.9

2.23 Area a 2 x 1.97 + 2.23 a 6.19 in2 1 n (1.9)(2.5) + (2.25)(5.125) 6.19 T a 3*46w L0.96

1.66

2

0.92 2.78 '13.62

6.25

18.60 6.25 Total I a 24.85 0. K. rm.= rxe / 2 DRSIGN OF , AND !I UnDesign Load = 124.1 k (Tension)

Area = (3.01)(2) + 2.3 . 8.52 in2 To (3.)(6.02) + 2.5 (7.125) 8.52 To 54.6 in. A L L2 Ij 6.02 1.06 1.12 6.75 K ~/ Z 10

50.45

10 A 2.30 L

2.69

Ij7.25

18.10118 Total I n68.53

rin = r 2.84 Arsq'd n 15 a 8.26 ia2 13DESIGN OF UU1, -1U2,

4OU.,

AND 2P2 Design Load a 88.5 k (Cqmpr..aion)K/2

j l -2 " 7-4/ A10

2- 263.68 12.60 1.17 PL3.0

4.96

ruin n rn w -4.78" Therefore, 7 k/in2 (27) AreqId = a 12.5 in27

0. 1. 0. 1. Area a 12.60 + 3 n 15.60 T (12.60)(6) + 3(12.1z5) u 7.17' 13.60 L1.37

17.3

24,.60

73.8

Total I a 281.0354.8

0. K.(27) ASCE, op. cit., p. 6.

IT

Unifora Lead 0 6,40.0

f/ft.

Coamemtrated loads:

a) chords: 18,000 #/Lanw

b) Diagonals and Vertioalss 26,000 #/Lane

Impat a 50 but los" thas 0.30 Live Toad

Lead Factor a 1.147

TLve s

Uniform 29.4 k

Con.. Mord 20.6 k

Cono. Diag. and Vert. 29.8 k

Dead:

Slab 83.0 k

String 12.4 k

Floor Bea

.3

k

Total 101.2 k

Assume weight of truss n 0.30 k/ft.

Bar D. L. L LA IMp. Total

Stress Uni. Con. Total Fract. I + L I+L+D

LOL1 0.0 0.0 0.0 0.0 0.0 0.0 LjL2 0.0 0.0 0.0 0.0 0.0 0.0 U0 U1

-56.6

-14.7 '-10.3 -25.0 0.24 -31.0 - 87.6 U1U2 -56.6 -14.7 -10.3 -25.0 0.24 -31.0 - 87.6 LOUQ-56.6

-14.7 -14.9 -29.6 0.24 -36.8 - 93.4 LIU1 0.0 0.0 0.0 0.0 0.0 0.0 L2U2 -56.6 -14.7 -14.9 -29.6 0.24 -36.8 - 93.4 U0L1 80.0 20.8 21.1 41.9 0.24 52.1 132.1 LiU2 80.0 20.8 21.1 41.9 0.24 52.1 132.1at

ANL TRMSZn:t

,- ~,g ~ 4LI}4

~.j '.7 AIs a-

all

10 2 - 24.8 PL ---A3.90

2.25 Area a 2 (1.95) + 2.25 - 6.151n

T* .9 x 2.5 + 2.25 & 51T.13

I. L0.96

1.67 02 0.92 2.78 Total 3.60 6.25 In IT 18.4024.63

r *in a rxz E s 2.0D dIN OF L1. *92.k (C. AeND sLo)

Desigm Load = 93.4 k (Couprossim)

L I. Io 133.8 A 8.94

Area

a 2 x #.47 + 2.75 = 11.69 ia2 * 8.9* 1 1 +.7 1 10.125 11. 63To a 6.37"

L1.37

L2 1.88 Ii 16.8 IT l5o.6 0. 1.Total I=

-ai rxz = .- "

Therefore, fall 10.13 k/in? (28) Areqd n 10l a 9.2 in2

10.13

DNOUN AO F UdLi., AND-LizU2

Design Load a 132.1 k (Tension)

Z Area a 2 x 3.36 + 2.5 n 9.22 in2 S- 6.72 x J + 2.5 x 8.13 9.22 To 5.12"

Ku

!p-5

AxLA x - zE I0 PL A 6.72 2.50 L 1.12 3.00 L2- I1 1.25 8.43 9.00 22.30 Total I = - rxx /9 a 3.220 v 9.22(28) AISC, op. cit., p. 209.

0. K. 0. K. 0. K. IT

73.0

'2.3

9305 0. K.q,/ r7 I-'7

@21

0-n

0K.

If)on

I

Panel Leads as in page 30, mopt for the dead load of the truss which we will assme: Wt. of truss n 0.30 k/ft.

D.

L. L.L. Stress IXp. TotalBar Stress Uni. Cone. Total Fract. I+L+D

LOL1 L1L2 L2L3 L3L4 U1 U2 U2U3 U3U4 Uo U1L1 U2L2 U3L3 U4L4 UOL1 UiL2 0.0 156.5

156.5

0.0-156.5

-208.6

-208.6 -156.5 -156.5 - 52.2 0.0 - 52.2 -156.5 222.0 73.6 0.0 4.0 44.o 0.0 -.440 -58.8 -58.8 -44.o -44.0 7.3 -22.0 0.0 7.3 -22.0 -44.0 62*4 31.2 -10.8 0.0 15.4 15.4 0.0 -15.4 -20.6 -20.6-15.4

-22.47.45

-14.90 0.07.45

-14.90 -22.4 31.6 21.1 -10.6 o .o59.4

59.4

0.0-59.4

.79.4-59.4

-66.4 14.75-36.90

0.014.75

-36.90-66.4

94.052.3

0.175

0.175

0*175 0.1750.175

0.1750.175

0.280 0.216 0. 000 0.280 0.216 0.175 0.175 0.216 0.280 0.0 69.8 69.8 0.0. 69.8

-93.3

-93.3

- 69.8 - 78.0 18.9 -44.9

0.0 18.9 - 44.9 - 78.0 110.5 63.6 - 27.4 0.0 226.3 226.3 0.0 ..226.3 -301.9 -301.9 -226.3 -234.5 - 97.1 0.0 -97.1

-234.5

332.5

137.2 * I I I. I ________ I3 2

-10.8 -10.6 -21.4 0.280 - 27.4

Lf Area n 2 x 1.97 + 2.25 - 6.19 ii2 To a (3.941)(2.5) + (2.25)(5.125) 6.19 Tow3- 6 AAS ;& - : I0 2 L-A 14.98 PL 2.25 L

0.96

1.66

0.92 2.78 Ii3.62

6.25

Total I -rain z rxx 9 2DESIGN OF ulhz. AND L2U3

Design Load = 137 k (Tension)

IT 18.60 24.85 7- 354 10 A Area = 6.02 + 3.13 a 9.15 To = (6.01)(3.5) + 3.13 (7.125) 9.15

To

= 4.7" L Ii IT 6.02 1.23 1.51 2 L 43.4 9.10 52.80rain a rxx 0 = 2.83'

Areq'd = = a 9.12 in2

15

DESIGN OF LjI2, AND L2L3

Design Load = 226.3 k (Tension)

Area = 2 x 5.88 + 3.44 = 15.2 in2 - 94 I0 A yo a 11.76 x 4.5 + 3.44 X 9.16 15.2 To a 5.56' L 121.84 11.76 1.06

3.#4

3.60

I1 1.12 14.2 12.95 44.5 IT 136.0 Total I a rain a rxx n 2.4" Areq'd w 15.05 in2DESIGN OF UoLi, AND L3U4

Design load = 332.5 k (Tension)

0. K.

0. K.

180*5

0. K.

/4 12t

AgLw

&W-2 PL 10359.3

A 20.58 3.00 23.5. Yo 6.78* L 0.785.3453

L2 L 0.61 12.3 28.50 85.3 Total I a IT 371.8457.3

0. K. 0. K. rmina rax n 3.4" Argeqd 04314

13

* 22.2 1*2=SIG OF UjLi, AND U.1L1

Design Load = 97.1 k (Cpression)

IZz

Area a 12.60 + 3 n 13.0 102o a

12.60 x 6 + 3x

1.125 T- 7.17" ALga

4 S L2 I 1.37 17.324.6

73.8

Total I = IT 281.0334.8

/2 /Ar- 74 1 2-10 263.7 A 12.603.00

L1.17

4.96

Aroq'd 2l,1 n 13.9 in2

7

Check for local Buckling (30)

(29) ASCE, op. cit., p. 6.

(30) ASCE, op. cit., pp. 11, 12, 13.

B

j /f /.7/ A 19.92 10 629.5 Area - 2 x 9.96 + 3.25 - 23.17 in2 TO = 19.92 x 7.5 + 3.25 x 15.125 23.17 To = 8.58" L 1.08 L1 1.17 IT 23.2 652.73.25

6.55

42.80 139.0 19,. Total I -rain = rxx 5.88" 1 23.17 Therefore, f a 10.2 k/in2 (31) Areq'd a 1092 = 23 in2 (32) 10.*2Check for Local Buckling

IESIGN OF UjU2, AND U2U3

Design Load = 301.9 k (Compression)

Laz:

F

A 7 Area = 19.92 + 10.31 = 30.23 in2 To = 19.92 x 7.5 + 10.31 x 15.28 30*23 YO = 10.2" op. cit., p. 6. op. cit., pp. 11, 12, 13. 791.7 0. K. 0. K. 0. K. (31) (32) ASCE, ASCE,A4iLx - s 10 A 19.92 2.70 10.31

5.18

rain wrxx

=,

a

1w

/30.23

Therefore, f a 10.2 k/in2 (33) Areq'd = 3Qa a 29.6 in2 10.2Check for Local kuokling (34)

3)

Asci, op. cit., p. 6.)

ASCE, op. cit., pp. 11, 12, 13.26.8 Total I = 1,052.0 2"

629.5

L Ii 145.07.3

IT774.5

277.5

&27.5

0. K. 0. K. 0. K.(3

(3

Panel Loads as In page 35, exsept for the dead load of the truss which we will asam: Wt. of truss a 0.30 k/ft.

D. L.. L. . Stress Imp. Imp. Total

Stress. Uni. Conc. _Total Frac. Stress I+L+D

0.0 170.0 170.0 0.0 -170.0 -226.0 -226.0 -170.0 -170.0 LOL1 LiL2 L2L,

L

3L4 UQUl U1U2U

2U

3U

3t

4 UL2 L3U3 L4U4 U0L1 U1L2 U3L2 U4L3 0.0 44.0 44.0 0.0 -44.0 -58.8 -58 .8 -44.0 -44.0 7.3 -22.0 0.0 7.3 -22.0 -44.0 62.4 31.2 -10.8 31.2 -10.8 62.o4 0.0 15.4 15.4 0.0 -15.4 -20.6 -20.6 -15.4 -22.4 7.4 -14.8 0.0 7.4 -14.8 -22.4 31.6 21.1 -10.6 21.1 -10.6 31.6 0.059.4A

59.4

0.0-59.4

-79.4-79.4

-59.4

-66.4

14.7 -36.9 0.0 14.7-36.9

-66.4 94.0 52.3 -21.4 52.3 -21.4 94.00

175

0

175

0.175

0*1750

*175

0.175 0.175 0.280 0.216 0.280 0.216 0*175 0*175 0.216 0*280 0.216 0.280 0.175 0.0 10.4 10.4 0.0 -10.4 -13.9 -13.9 -10.4 11.6 4.1 8.0 0.0 4.1 8.0 11.6 16.5 11.3- 6.0

11.3 - 6.0 16.5 0.069.8

69.8

0.0- 69.8

-

93.3

-93.3

- 69.8 - 78.0 18.1 -44.9

0.0 18.1- 44.9

- 78.0 110.5 63.6 -27.4

63.6 - 27.4 110*5 0.0 239.8239.8

0.0 -239.8 -319.3 -319.3 -239.8 -248.0 -101.5 0.0 -101.5 -248.0 350.5 143.6 143.6 350.5 - 56.6 0.0 - 56.6 -170.0 240.0 80.0 80.0 240 .0 4 PAU& TRU i p -- - -- - - iDESIGN OF tol1, L9LI, AND

!JUj

Design Lad a 0B7

LxIUa l -IV

I0 2&4 14.8 PL A3.90

2.25 Area - 2 (1.95) + 2.25 - 6.15 In2 To a 9 x 2A + 2.25 x 5.11 6.15 To a-*6 L0.96

1.67 L2 0.92 2.6 Total 113.60

6.25

I ' IT 18.40 24.63 0. K. idia = rxz n 20DESIGN OF V1La, AND U1L

Desigp Lead n 143.6 k (Tensica)

-IS 4 8~1 10

6*.6

A 6.72 Area n 2 x 3.36 + 2.5 a 9.22 za2 Te 62x +2.ix 1259.22

To m 5.12" L 1.12 1.25 Ii8.*43

IT73.0

2 " Azin-' . xi10 A 2.50 L

3.00

9.00 Total I = rain a rxx == 9.22 Areqtd = 20%6 7.18 20 DEINOF L1L, AND L U3 3.22' in2Design Load w 101.5 k (Compression)

1UZt Area a 2 x 4.47 + 2.75 - 11.69 in2 o a 9.94 x 5 + .75 x 10.11 11.69 I0 A

133.8

2.75 L 1.373.76

IF I 1.88 16.8 14.10 38.8 Total I = rtin a rxx 4: = 4.04"0 Therefore, f u 10.13 k/in2 (35) Areq'd = 11.,5 = 10 in2 10.13 DESIGN OF L1L2, AND L2L3Design Load m 239.8 k (Tension)

(35) AISC, op. cit., p. 209.

IT 22.5 22.5

95.5

0. K. 0. K.L

f

I1150.6

189.4 0. K. 0. K.-I

//IfL~-

N Ar.aa 2 x 4.39 + 3.44 12.22 1*2 T w8.78 x

j.5 + 3.4x

9.156

12.22 O 5.8' A 8.78 3.4 L 1.y 3.36 L21.069

11.30 Totalraji

a rz 1 2.0" / 12.22 Areq'd a - 12 1,a2 20Deaia Lod n 350.5 k (Tmsoan)

L

-- -/2 M Area n 2 x 7.32 + 3.

17.64 i 2 To= 11.64 z6 + A x- 12,1.3 17.64To

7.05"

L2 I1 1.10 16. 25.8 76.*4 Total I -2 Li 2 " 10 101.4 Ii 14.838.I

I.= IT 116.2 155.1 0. t. 0. K. 10 287 A 14.643.00

L 1.05 5.08 IT 303. 1 isA379.5

20

DESIGN OF ofl. o UOU40 I. AID UIU4

Design lead a 248 k (Cimpression)

=14

K

30 A 10 Area a 2 x 849 + 3 a 20.58 iN2 a= 17.A x + x 12.13 2-L 17.58 0.89 3.00 5.240.79

27.40 1 IT13.9

35.3

82.3 Teta I u r -in a ra. Therefore, f * 11.55 k/iWAreq'd a . 21.A i*2

11.55

Use PL 12 x 5/16

DESIGN OF 192, AND U2U3

0. K.

(36)

Design Lead a 319.3 k (Compression)

(36) AISC, op. cit., p. 209.

TO a 8.?" II

625.2

19.8 1.203.0

rja" - rxx a F 5.860 Thwrfor., f n 13.74 k/in2 (37) Areq'd a a 23.2 in2 Use PL 12 x 5/16 1.486.o

41.010 124.0 Total I a(37) AISC, op. cit., p. 209.

10 A L IT

653.8

777.8

0. K.

'7 c 7 I '7 ~ ' 7____________________

gnm

of)on

an

in

'In

Panel Loads as in page 30 9 eept for the dead load of the truess

whikh we will assme: Wt. of truss a 0.15 k/ft.

Bar II + L

Stress UDI. Cone. Total Frac. Stress I+LD

______ I ______I J .1 _____ r f a LOL1 0.0 0.0 0.0 0.0 0.0 0.0 0.0 L1L2 246.0 73.5 17.1 90.6 0.137 12.3 102.9 348.9

L2L3

393.0

117.6

27.4

145.0

0.137

19.9

164.9

558.0

L

3L

4393.0

117.6

27.4

145.0

0.137

19.9

164.9

558.0

L4L5 246.0 73.5 17.1 90.6 0.137 12.3 102.9 348.9 L5L6 0.0 0.0 0.0 0.0 0.0 0.0 0.0U

0U1

-246.0

-73.5

-17.1

-

90.6

0.137

-12.3

-102.9

-348.9

UiUz

-393.0

-117.6

-27.4

-145.0

0.137

-19.9

-164.9

-558.0

U2U

3-442.8

-132.0

-30.9

-162.9

0.137

-22.3

-185.2

-628.0

U

3U4

-442.8

-132.0

-30.9

-162.0

0.137

-22.3

-185.2

-628.0

U405 -393.0 -117.6 -27.4 -145.0 0.137 -19.9 -164.9 -558.0U5U6

-246.0

-73.5

-17.1

-90.6

0.137

-12.3

-102.9

-348.9

LoUO -246.0 -73.5

-17.1 -90.6

0.137 -12.3 -102.9 -348.9 5.0 5.1 10.1 0.288 2.9 13.0-147.5

- 49.2 -20.0 - 69.20.158

-10.9 - 80.1 -227.6 L2U2 14.7 9.9 24.6 0.226 5.5 30.1 13.4 - 16.7-19.7

-14.9 -34.6

0.186

-6.4

- 41.0-

57.7 L3U3 0.0 0.0 0.0 0.0 0.0 0.0 0.0L. L. Stress Imp. Imp. Total

Bar -I + L

Stress Uni. Cone. Total Frae. Stress I+L+D

L4U4

1

6U6

L3U3 L1 U L2U1 L3U 2 L3U4 L5U6 -16.7

-147*5

-246.0 0.0 W4.0 208* 1 69.869.8

208.1 348.0 14.7 19.7 5.0 -49.2

- 73.5 0.0 104.069.5

7.0 41.2 . 21.0 41.2 - 21.0 69.5 7.0 104.0 9.9 -14.9 5.1 -"20.0 -17.1 0.0 35.2 28.0 -7.1

21.2 -14.0 21.1 -14.0 28.0 - 7.1 35.2 24.6 - 34.6 10.1 - 69.2 - 90.6 0.0 139.297.5

- 14.1 62.4 35.0 62.4 - 35.0 97.5 - 14.1 139.2 0.226 0.186 0.2880.158

0.137

0.137 0.158 0.288 0.186 0.226 o.186 0.226 0.158 0.288 0.1375.5

-6.4

2.9 -10.9 -12.3 0.0 19.1 15.4 - 4.111.6

- 7.9 11.6 -7.9

15.4 4.1 19.130.1

- 41.0 13.0 - 80.1 -102.9 0.0 158.3 112.9 - 18.2 74.0 - 42.9 74.0 - 42.9 112.9 - 18.2 158.3 A I I a I I 13.4 -57.7

-227.6

-348.9

0.0506.3

321.0143.8

143.8 321.o506.3

Area - 2 x 1.97 + 2.25 - 6.19 in2 Y* a (1.91)(2.s) + (2.25)(s.125) 6.19 4 3,416" AAA x - : I0 14.98 A

3.94

2.25

L0.96

1.66

0.92 2.78 Total I n rAn a rxx=9.

9

IZSIGN OF LU2,a AND L3L4

2'0

Design Load = 143.8 k (Tension)

a "4.25 A 10 Area a 2 x 3.62 + 2.5 = 9.74 in2 Y0 - 7.24 x 4 + 2.5 x 8.13 9.74 To a 5.06" L I1 IT 7.24 1.06 1.12 K 2 %. Ij 3.62 6.25 IT 18.60 24.85 0. 1. 2

L-

67.7

8.1 75.810 A 2.5 L 3.07 Total I = ran = r= u 2.8r Aroqtd * .5a* 9.60

L

t 15 DESION OF L114, AND !1LsDesiga Lead n 318.9 k (Tomsisa)

-I/

-r-M

71-Arsa

m19*92

+

3.31 = 23.23 in2

To-

19.92

x.27A+31ta15O

23.23

To=

8.57"

&AM I

wZI 10 2 &. A L19.92

1.07

I1 1.14 22.8 IT652.3

3.31

6.59

43.50

143.7

Total I = rmin mrzz = 2.4 / 23.23 A *d = na1 23.2 in2 15DESIGN OF L2U1 AD 4IE5

)0"

Design Load = 321 k (Temion)

23.5

".3

0. K. 0. K.796.0

O.K . 0. K. II ITI0 A 1! u 7.14' L

324.16

17.64

1.114

3.9

IT 1.30 22.9 24.80 97.0 Total I = rgin = rm n Aroqtd = M 15 11 2.83' u 21. 4 j&2 ESIJ OF -LzL, AnDesign Load = 558 k (Tension)

Area u 2 x 14.70 + 7.88 u 37.28 in2 TO 29.4 x 7.5 + 7.88 x 15.28 37.28 To * 9.120

K

]./5LJ

/f

A L 29.40 1.62 7.88 6.16 I1 2.62 77.0 38.00 299.5 Total I u rain u r= = l37.28 884.322.al

1,183.8 2.0" PL 0. K. 0. K. I0807.3

0. K.Areq#d 0 = = 37.2 jn2

15

DM M OF Lirt. AND L56

W -. 3

Design Lad * 506.3 k (TensiaM) tZ

Area- 29A +

.88

a 34.28 iD2L. j

Areq'd n u 33.8 I 2

rain a rxy S 2.830

DZSIG OF L1 9 AID TT~

Design Toad n 227.6 k (Campression)

ZMS /E & //71 I0 A Area = 19.92 + 3.25 - 23.17 iu2 To 19.92 x 7. + 1.25 1 5.11 23.17

TO

a

8.58 L L2 19.92 1.083.25

6.55

1.17 23.2 652.742.80

139.0

.139.0

0. K. 0.K.

629.5

11 IT Total I=

791.7

rain = rxx

-

I

u.37"

t a 10.2 k/in2H

Areq'd 1 a 22.30 32

10.2

Cheek for local Bholung (39) DESIGN OF flo1. USU2. VA *. AID161

Design Lead n 34.89 k (Comprssioea)

Area = 29.4 +

5.69

-35.09

. + 5.I6935.09

To a 8.741" AELJ'a 10 2 -PL 807.3 1.2.5.69

6.48

1.004

45.2

852.50

42.00239.00

3a. Total I a 1,091.50 * rx 109141 /35.*09 Theroere, f n 9.4 k/la2 (40) Aroq'd - JL1- 37.1U32

9.14Ckwok for local Bakilg (1)

DFSIGN OF 102, AND UOU5

Design Load = 558 k (Comression)

Designed for an unsuprted length of 20 ft.

ASCE, op. cit., ASCE, op. cit., ASCE, op. cit., ASCE, op. cit.,

p. 6. pp. 11, 12, 13. p. 6. pp. Il, 12, IN. 0. K. 0. K. 0. K. -- ? /7418 A L It IT 0. K. 0.K. 0. K. (38) (39) (40) (41) 29.A x 7 5.6w

-r~s

/

/ 807.3 Area a 29.4 + 14 a 43.4 in2 TO - 29.4 x 7.5 +,14 x 15.5 4314 To a 10.00 A 29.4 14.0 L 2.55.5

L2 11 6.25 184.0 30.20 424.7 Total I a a rxx5.75"

Therefore, f a 12.75 k/in2 (42) Areq'd 12.75 - 43,.5 in2Check for Local Buckling (43)

DESIGN OF U2U3, AND U3U4

Design Load = 628 k (Compression)

Designed for an unsupported length of 20 ft.

LEM: -/1-/L- rI.Z8 Area = 29.4 + 14 + 5.25 = 48.65 in2 To = 29.4 x 7.5 + 14 x 15.5 + 5.25 x 16.1 48.65 To = 10.7"

(42) ASCE, op. cit., p. 6.

(43) ASCE, op. cit., pp. 11, 12, 13.

IT

991.30

1,416.00 0. K. 0. K. 0. K.PL 5.25 5.5 30.2 139.0 152 Total I * 1.368

rZa a

r=

5.7

0. K.

Th*rfor., f n 12.8 k/an2 (44) 0. K.

Aroq'd n A 48.5 In2

Cheek for Lmal Baokling (45) 0. K.

DISIGN OF I AND L-U& L"ada 13.4 k (Tension)

57.7 k (Co.prosliAn) Comprasin Load is Critioa

Digp Load n

37.7

+ 13.4 (.3) n 64.4 k (Compression) *Zng:

Area a 4.49 x 2 + 3.73.

12.73 in2To

8.98 x 5 + 3.75 x 10.19 12.73 -/o 6 -a 54* 6.W'*

10

A L L2 II IT 2 134.75 8.98 1.*3 2.37 21.3 156.05* See ASCE Proceedings, Paper #970, pg. 20, &..

(44) ASCE, op. cit., p. 6.

I0 A

3.75

(46) (47) raina

rxa/

au 4.02" 12.73Therofr., fall a 5.05 k/in; (46)

hroqsd a 5a n 12.75 Iu2

5.05

Mc k for Local hakling (47)

ASCE, op. cit., p. 6.

ASCE, op. cit., pp. 11, 12, 13.

L L2 11

13.3

30.0

Total I a IT 206.0 0. K. 0. K. 0. K.-I'E

Pam]1 Load as in page 35 , eoept for the dea load of tb. trass 1hiek wo will assue: W. of truss a 0.0 k/ft-.

D. L. L. L. Stress IMp. Imp. Total

Bar iTI + L

Stress Uni. *

Con.ITotal

Frac.Stress

I+tMDLOL, L1L2 L2L 3 L3L4 L4L5 L5L6 U0U1 U1 U2 U2U3

U34

U4U5 U5U6 LOU0 L1Uj L2U2 L3U 3 0.0 304.0 485.0 485.0 304.0 0.0 -304.0 .485.0 -.546.0 -.546.0-485.0

-304.0 -.304.0 -182.0 - 20.6 0.0 - 20.6 0.073.5

117.6 117.673.5

0.0 -73.5

-117.6 -'132.0 -132.0 -117.6 -73.5

-73.5

5.0

-.49.2 14.7 - 19.7 0.0 14.7 - 19.7 0.0 17.1 27.4 27.4 17.1 0.0 -17.1 -27.4 '30.9-30.9

-27.4 -17.1 -17.1 5.1 -20.0 9.9 -614.9 0.0 9.9 -14.9 0.0 90.6 145.0 145.0 90.6 0.0-

90.6

-145.0

-162.9 -162.0-145.0

-90.6

- 90.6 10.1 - 69.2 24.6 -34.6

0.0 24.6 34.60

*137

0,1370.137

0.1370.137

0.1370.137

0*137 0.1370*137

0,137

0.288 0.158 0.226 0.186 0.226 0.186 0.0 12.3 19.9 19.9 12.3 0.0 '.12.3 -19.9 .22.3 '.22.3 -19.9 -12.3 -12.3 2.9 -010.9 5.5 -6.4

0.0 5.5 - 6.4 0.0 102.9 164.9 164.9 102.9 0.0 -102.9 -164.9 -185.2 -185.2 '164.9 -102.9 -.102.9 2.9 - 80.1 30.1 - 41.0 0.0 30.1 - 41.0 U' J I I I 0.0 406.9 649.9649.9

406.9

0.0 -.406.9-649.9

00731.2 -'731.2-649.9

-406.9 -.406 .9 -262.19.5

- 61.6 0.09.5

- 61.65.0 5.1 10.1 0.288 2.9 13.0 L5U5 .182.0 - 49.2 - 20.0 - 69.2 0.158 .10.9 80.1 .262.1 6U6 -304.0 - 73.5 - 17.1 90.6 0.137 -12.3 -102.9 -406.9

L

1UO

430.0

104.0

35.2

139.2

0.137

19.1

158.3

588.3

258.0

69.5

28.0

97.5

1.158

15.4

112.9

370.9

L2U2 -7.0

- 7.1 - 14.1 0.288 - 4.1 -18.2

86.0 41.2 21.2 62.4 0.186 11.6 74.0160.0

L

3U-

21.0

-14.0

-35.0

0.226

-

7.9

-

42.9

86.0 41.2 21.2 62.4 0.186 11.6 74.0 160.0 L3U4 - 21.0 14.0 - 35.0 0.226 -7.9

- 42.9L4L

5258.0

69.5

28.0

97.5

1.158

15.4

112.9

370.9

- 7.0 - 7.1 - 14.1 0.288 - 4.1 - 18.2L

5U6

430.0

104.0

35.2

139.2

0.137

19.1

158.3

588.3

DISIGI OF 1oLl. LsL6. AND LIU2 Duliga Lad a 0 3Zn 10 A 2 14.8 3.90 PL 2.25 Areas 2 x 1.95 + 2.253 6.13 1n2 Ye

32.9

X2.5

+2.25

15.11

6.13 10. n3o6'

L0.96

1.67 L20.92

2.78 Total 11 3.60 6.23 1 = IT 24.65zAft

= rxx Z " 2.0MINSI OF LIU2. AND EAUS

Daign Load = 160.0 k (Temasin)

, I| ~~ ~~4

~K8L-a1.

I0 A 6.72 Area u 2 x 3.36 + 2.5 n 9.22 ia2 T n 6.72 1 1 + 2.5 x 8.11 9.22 To a 5.120 L 1.12 1.23 118.43

IT73.0

0. K.A 2.50 L

3."

9.oo Toal I ar-ain

rxx

L

2U11'

3.21'

V

9.22Ar.qed 0 *& 8.o iS2 20

DESIGN 01 L291. AN JM0

Design Lead * 370.9 k (TeaiA)

Area u ?.32 x 2 + 4.13 n 18.77 in2

yo

a

1.64 A 6 .11 x 13.188 18.70? Am a=.&:

10 A L 287.01.88

27.5

314.5

23.00

96.0

96.

Tota I rzin a rx. U/- 1 2.83r Areql*d ma! = 18.3 Inj20

DESIGN OF L1L2, AND L5

Design Load = 406.9 k (Tension)

11 I? 22. 5 a1

95.5

0.

K. 0. K. KAY 2 Li Ii IT 410.3 0. lo0.

K. Io L2 14.64 1 *34 4.13 4.82[1

/2.--. 50 Aroa - 2 x 8.79 + 3 a 20.56 Lz2 T n 17. x 6 + x 12.125 20.58 To a6.890

A 17.58 3.00 L 0.89 5.*U L2 110.79

13.9

27.40 82.3 Total I n ZU zn a / arxz 4.5" Areq*d n 0. 20.3 1n2 20 DSION OF L122. AND Ls4D*sinP Load a 568.3 k (Toa.1un)

mmz: