Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Internal Report (National Research Council of Canada. Division of Building Research), 1961-01-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=b642a343-ded4-497e-be58-ecc82f6f2214 https://publications-cnrc.canada.ca/fra/voir/objet/?id=b642a343-ded4-497e-be58-ecc82f6f2214

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20358941

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at Determination of outside surface temperature of a chimney with an analogue computer

NATIONAL RESEARCH COUNCIL CANADA

DIVISION OF BUILDING RESEARCH

DETERMINATION OF OUTSIDE SURFACE TEMPERATURE OF A CHIMNEY WITH AN ANALOGUE COMPUTER

by

G. T. Tamura and G. P. Mitalas

t\セLj t'\L'{ ZE0

Internal Report No. 238

of the

Division of Building Research

OTTAWA

This report represents a further small advance in knowledge of the temperature and heat flow characteristics

of masonry chimneys. It deals with the influence of cycling

furnace operation on the chimney surface temperature which

is of concern primarily from a safety point of view. This

study represents a further use also of the analogue computer which is often of great assistance in the solution of heat flow problems arising in buildings.

The authors are research officers with the Building

Services Section of the Division. The first author is

responsible for the work being carried out on the thermal and safety aspects of chimneys; the second author is engaged in studies of heat transfer through various bUilding elements and of bUilding heat losses and gains using analogue and

computer techniques.

ottawa

DETERMINATION OF OUTSIDE SURFACE rrEIVLPERATURE OF A CHIMNEY WITH AN ANAI,OGUE COMPUTER

by

G. T. Tamura and G. P. Mitalas

To provide for the safe discharge of flue gas, a chimney must have sufficient thermal resistance to prevent

overheating of the surrounding construction. The resistance

of the walls of a chimney to heat flow should be such that the outside surface temperature does not exceed a safe value. Therefore to evaluate the fire safety of a chimney, informa-tion on its outside surface temperature at anticipated

operating conditions is required.

Information on outside surface temperatures of residential masonry chiw1eys was obtained in fire hazard

tests conducted in the DBR chimney laboratory

(1).

Thesechimneys were fired at steady inlet temperatures based on the maximum flue gas temperature at the outlet of the various heating appliances.

Over most 'of the range of flue gas input tempera-tures used in the tests, the outside surface temperatempera-tures of the chimneys were in excess of values normally considered

maximum for combustible materials. Since these chimneys

appear to provide safe conditions in the field, it is

necessary to look critically at both the generally accepted safe temperature limits for combustibles and the test

conditions. This report deals with one aspect of the latter,

the assumption of a constant flue gas input temperature to steady state.

Under normal operations the flue gas temperature outlet from the heating appliance is seldom at a steady level. With a hand-fired solid fuel unit, the temperature of the

flue gas depends on the rate of firing by the operator to

meet the house heating requirement. In gas and oil-fired

units controlled by a room thermostat, there is an on-off firing cycle with the flue gas temperature at maximum value

during the on cycle. Only in extrremeLy cold weather or with

an under-size unit is firing likely to be steady at the

maximum flue gas temperature. The effect of a variable flue

gas input temperature on the outside surface temperature of masonry chimneys was studied with an analogue computer; the results are given in this report.

Analytical determination of the outside surface temperature is complicated by the fact thatihe inside and

outside film conductances, 。」」ッqセエゥョァ for both convection

and radiation, are in part dependent on the surface tempera-tures which are not Imown; a tedious iterative calculation

is required. This is further complicated by the shape of a chimney and the variable nature of the flue gas temperature. With an analogue computer the heat transfer mechanism in a

chi@ley is represented by an electrical circuit; the thermal characteristics of a chimney may now be obtained readily.

Heat transfer in a square masonry chimney was

represented by a two-dimensional analogue network. Because

of its symmetry it was necessary to simulate only a 1/8

section of the chimney with the analogue network. The inlet

flue gas temperature was represented by a periodic voltage input to the network supplied by a relay amplifier circuit. This simulation of the heat transfer problem with an analogue

computer (Race) provided means of dealing with the physical system directly, and means of rapidly investigating the effect of parameters.

Surface temperature readings obtained from the analogue computer with steady voltage input were compared with those obtained during chimney tests conducted in the

laboratory. This comparison gave means of evaluating the

basis for determining the film resistance. DESCRIPrION OF ANALOGUE NETWORK

Consider Fourier's equation for two-dimensional heat flow (1) where 9 = temperature, of 0(

=

thermal diffusivity, ft2/hr t=

time, hr.From equation (1), temperature relationship of the lumped

system may be obtained. Consider Taylor's series expansion:

1'''(

x0 ) (x - x0 )2 f(x)=

f(x o) + f' (xo) (x-x o) +2!

+ + fn-l (x o) (x - xo)n-l (n - I)! (2)...

where - 3 -let f(x)=

G f(x )=

G 0 0 セg f(x)=

G_ 1 f' (xo) _ 0 -1-d-X

c3

2G f(x)+l=

G+1 f" (x ) _- S""""20 0d

xThen, considering temperature in the x

d

2G + 0セ

d

G d2G G+1=

Go + セ セ x + 0d

Xa7

Add (3) and (4), direction, G_ 1 + G+1 - 2Go=

(.A x)2similarly in the y direction,

G_ 2 + G+2 - 2Go

sUbstituting equations (5) and (6) in (1),

d

Go =0«9_1 + 9+1- 29 9_2 + 9 -290) 0 + +2d

t (Ll x)2 (,6 y)2 if .6 x = boy = L thend

90 0( (9_ 1 + 91 + 9_2

+"9+2 - 49 )J

t =12

0.

(8)The analogue circuit for equation

(8)

is shovm in Fig.1.

Temperatures are represented by voltages and the integrator (dc amplifier with a feedback capacitance) sums the quantities

on the right hand side of equation (8) and then integrates.

A sign inversion occurs across the dc amplifier. Temperature

coefficients are represented by the potentiometers that carry

out multiplication by a constant. Initial condition of

temperature or voltage is placed on the integrator. The

analogue representation of the outside film heat transfer is obtained by considering the heat flow equation at the surface.

h (9 - 9 ) o s a = tK (9) where 9 a = 9 s = 9 i = h o

=

air temperature, ofoutside surface temperature, of

temperature of a point inside the surface

adjacent to 9 s ' of

outside heat transfer coefficient,

(Btu) / (hr ft2 of).

The outside film heat transfer coefficient h depends on heat

transfer by convection and radiation. 0

=

(9 - 9

a) 0.25

5

-hr = 0.171 xc..(g - g J{Hセ

-

Hセj

(11) s a h o = hc + hr wheret.

= emissivity of the outside surfacehc

=

convection coefficient, (Btu)/(hr ft 2 OF)hr

=

radiation coefficient, . (Btu)/(hr ft 2 OF)If outside air temperature is assumed constant, the outside heat transfer coefficient varies in an approximate linear relationship with the surface temperature in the

operating temperature range of a chimney (Fig. 2).

i.e.,

= A Q.

s + B

(12)

The values of Q and Q. were plotted in Fig. 3 and

s 1

approximated their relationship by a straight line equation:

=

The analogue representation is shown in Fig. 4. To determine the inside film coefficient, heat transfer due to forced convection was considered and gas radiation neglected.

Film heat transfer due to forced convection is

= 0.023 (Re)0.8 (p )0.4

where

D = equivalent inside diameter, ft

He = Reynolds number

Pr = Prandtl number

hi = inside film heat transfer coefficient,

(Btu)/(hr ft 2 OF).

Knowing the temperature a nd quantity of flow of the flue gas and the inside dioension of the passage, the inside heat transfer coefficient may be approximated as a linear

function of the gas temperature (Fig.

5).

=

EQ + Fg

Then obtaining an equation for heat transfer at the inside surface h. (Q - Q .) 1 g S = K - (Q. - Q ) L 1 S

(14)

L (EQ + F) (g - Q ) = Q. QIe

g g S 1 s with G = E!!

K and H = F LK then (GQg + H) (Qg - Qs) = Q. Q (15) 1 sAnalogue representation of equation (15) is shown in Fig. 6. The periodic flue gas temperature or voltage input is obtained with a relay amplifier circuit using an integrator

and two potentiometers to control the on and off time. The

magnitude of the input voltage is controlled by a potentiometer. The voltage or temperature readings in any part of the circuit may be read on a digital voltmeter or plotted on a graph with

the xy plotter. For parameter investigation the potentiometers

in the circuit are adjusted to the required values. The entire

P"

7

-The analoGue cireuit was assembled on a patchboard and the potentiometers were set to represent a sinele-course

clay-brick masonry chimney with a clay liner. Thermal

performance of this type of chimney at steady inlet flue gas temperature was obtained in the DBR chimney laboratory. The following conditions were selected for the analogue simulation:

Dimensions:

inside 7 by 7 in.

outside QVセ by 16i in.

Properties: K

=

0.60 (Btu)/(hr ft OF)P

=

112 Ib/ft3 Cp=

0.20 (Btu)/(lb OF)0(

= 0.0268 ft2/hr Computer:time scaling

=

(1 sec computer time = 1 hr actualtime)

magnitude scaling

=

1 volt=

lOoPSimulating outside air temperature of 70°F and flue gas temperatures of 400, 600 and 800°F and 100 cfm flue gas flow, time temperature curves of the outside surface tempera-tures were obtained for both steady and periodic flue gas temperature input.

COMPUTER RESULTS

With steady flue gas temperatures of 400, 600 and 800°F, maximum inside and outside surface temperatures at steady state were compared. with those obtained during chimney

tests in the laboratory. Surface temperatures obtained with

the computer were much lower (Fig.8). This was thought to

be due partly to the low' inside film heat transfer coefficient arrived at by using the forced convection heat transfer equation

(13). This inside heat transfer coefficient was adjusted by

increasing the values on the potentiometers II and G of Fig. 6 until the computer inside surface temperature equalled the

chimney test inside surface temperature. It was found that

with the computer increased and equalled that of the chimney test outside surface temperature.

Inside film heat transfer coefficients were re-calculated from readings of the potentiometers adjusted to give surface temperatures identical with those obtained

experimentally. These values are compared with the heat

transfer coefficient obtained from equation (13).

hi

Flue Gas Temp, of Calculated Computer

Btu/hr ft

2

of Btu/hr ft2

of400 / 1.43 5.05

600 1.52 5.21

800 1.61 5.53

With surface temperatures adjusted to test temperatures, inside film coefficients determined by the computer are much

higher than the calculated values. As only forced convection

was considered in calculating the inside film coefficient, the radiation heat transfer coefficient was calculated.

To determine the gas radiation due to carbon dioxide and water vapour content in the flue gas, the flue gas was analyzed for volumetric composition and the dew point tempera-ture measured to obtain the emissivity and absorptivity values.

Volumetric content of carbon dioxide was Rセ per cent and the

dew point temperature was 64°F corresponding to 0.025 and

.0201 atmosphere partial pressures respectively. Then the

gas radiation equation (2) for gray wall surroundings was applied. .9-

- C1+l)

(E G T 4 4 (16) A- () --r

G -o(GITl) hi = A.1.tg £1 = emissivity of a wall9

-Stefan - Boltzmann constant emissivity of a gas

absorptivity of a gas for radiation from a wall

hi

Radiation Radiation + Convection

Flue Gas Temp, of

Btu/hr f't

2

of Btu/hr ft 2 of400 0.198 1.628

600 0.312 1.832

800 0.645 2.255

The calculated values of the inside film coefficient are still substantially lower than the values obtained with

the computer. It is thought that since the hot flue gas is

f'lowing vertically upwards, the equation for determining the f'ilm coef'f'icient must account for the effect of natural

convection.

With the inside and outside surface temperature adjusted to test temperatures, the effects of a periodic flue gas input on the outside surface temperature were recorded on

the xy plotter. The results for flue gas temperature of 600°F

during on-time and 10°F during off-time are shown in Fig. 9. With equal on- and off'-time and a square wave input, the time temperature curve of the outside surface is of a triangular

wave form. As the period is decreased the amplitude is

decreased until at 10 minutes on- and 10 minutes off-time, the surface temperature curve is similar to the curve obtained

with the stead.y input, but lower in magnitude. During actual

burner operation due to the heat capacity of the appliance, maximum and minimum values of flue gas temperature are not attained instantaneously at burner start-up and shut-down

as assumed. The time temperature curve for a typical

operation of an oil bU1TIer of 10 minutes on 5 minutes off

is also ウィッセュ in Fig. 9. Since the on-time is twice the

off'-time, the surface temperature, as expected, is higher than that obtained with the burner operating at 10 minutes on and 10 minutes off.

Over-all heat transfer coefficients based on the inside surface area were determined for the standard

of heat flow from the flue gas to the inside surface was

calculated based on the inside ヲゥャセ coefficient obtained

from the computer results with the inside surface tempera-ture adjusted to that of the laboratory test chimney surface

temperatures. Flue gas flow rate in the laboratory chimney

was 100 cfm representing a heating device burning 1 imperial

gallon per hour of oil with

4

per cent CO2 volume composition

in the flue gas. The calculated over-all heat transfer

coefficients at steady state are as follows:

Flue セウ Temp, C of Btu/h; ft 2 of 400 1.210 600 1.240 800 1.260 DISCUSSION AND sュセセry

The analogue computer provided a means of studying tvro-dimensional transient heat flow in a chimney section with

a periodic input. Although three-dimensional heat transfer

occurs in a chimney, the assumption of two-dimensional heat flow should not lead to any serious error since the tempera-ture gradient is much greater in the horizontal than in the

vertical direction. The chimney section was simulated with

an analogue computer assuming a homogeneous chimney material. Since a chimney section consists of liners, unit masonry, and mortar, all with different physical properties, the heat flow pattern of the actual chimney section differs from that of

the analogue chimney section. It is thought, however, that

for purposes of evaluating the effect of the periodic input on the outside surface temperature, the computer results obtained with this simplification are sUfficiently accurate.

The inside film coefficients obtained with the

forced convection and gas radiation formulae are substantially lower than those obtained with the analogue computer by

adjusting the inside film coefficient to obtain chimney test

surface temperatures (Fig. 10). This discrepancy is due in

part to the use of the forced convection formula equation (13)

often used in chimney heat transfer calculation. This equation

is based on data for Reynolds numbers from 10,000 to 120,000

and for a length diameter ratio of over 60. Since the length

diameter ratio of residential masonry chimney is seldom above 60, it should be accounted for in the determination of the

film coefficient. Data are available for a 90° angle bend

entrance for Reynolds numbers from 26,000 to 56,000 (2). The

11

-10,000. Since the heating fluid is flowing upwards in a

chimney, it is thought that the heat transfer film coefficient is dependent on natural convection as well as forced convection. Recent data on inside film coefficient for heating fluid (water)

flowing vertically upwards (3) indicate the "film coefficient

to be a function of Grashof and Prandtl numbers and the critical Reynolds number to be much lower than 2,100 for non-isothermal

vertical flow. The data were obtained for Reynolds numbers

up to 1,000. For flow of higher Reynolds numbers it is thought

that the film coefficient is a function of Reynolds and Grashof numbers.

There are no available data that permit calculation of the inside film coefficient in the operating region of a

chimney. Both the entrance and the natural convection effect

not considered in the forced convection formula materially

increase the rate of heat transfer. Although the inside film

coefficient determined with the computer is subject to errors

due to the assumptions and approximations made in setting up

the analogue circuit, it does point out the need for a more precise method of determining the inside film coefficient.

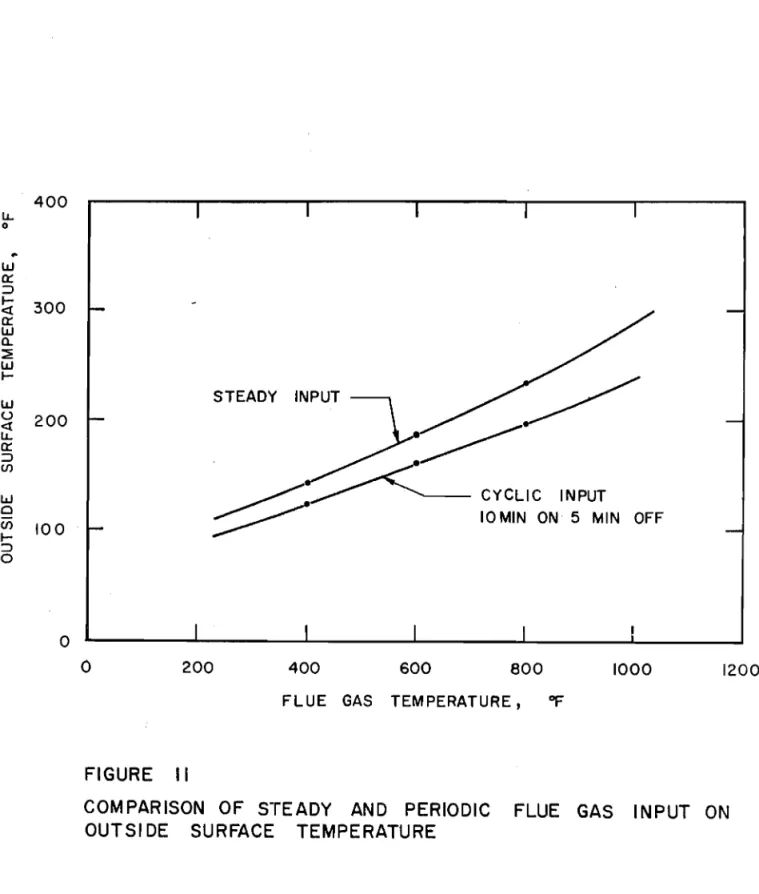

The results obtained from the computer operation with periodic input indicated. that with rapid cycling to

simulate the operation of an automatic heating appliance, the outside surface temperature reaches a constant value. At equal maximum flue gas temperature the surface temperature

obtained with a periodic input is lower than that obtained

with

a

steady input as expected. Maximum surface temperaturesobtained with a periodic flue gas input of 10 minutes on and

5

minutes off are compared with those obtained with a steadyflue gas input in Fig. 11. From this graph the periodic flue

gas input temperatures reqUired to produce the same outside surface temperature as steady flue gas input temperatures can be determined.

ACKNOWLEDGMENT

The authors grateful13r acJmowledge the advice and assistance given to this project by Dr. D. G. Stephenson and Mr. A. G. Wilson, Building Services Section, Division of Building Research, National Research Council.

REFERENCES

1. Tamura,

G.

T. andA.

G. Wilson. Fire hazard tests onsmall masonry chimneys. National Research Council,

Division of Building Research, Intenlal Report No. 202, 1960.

12

-2. McAdams, William H. Heat transmissi.on. 3rd Edi.tion,

McGraw-Hill,

1954.

"

3.

Brown, W. G. Die Uberlagerung von erzwungener undnatfirlicher kOllvektion bei niedrigen dオイ」ィウセエコ・ョ

in einem lotrechten rohr. (The superposition of

forced and free convection at low flow rates in a

vertical tube). VDI, Forschungsheft 480, Ausgabe B,

..

INTEGRATOR

O)[i

POTENTIOMETER SETTINGal.

c.FIGURE

UNIT - LUMP COMPUTER DIAGRAM OF A CHIMNEY

u,

4·0

NATURAL CONVECTION + RADIATION - -...

380 340

セNMM

• 300 260 ho = ·00675 Ts + 1·03 (APPROXIMATED) 220 180 140BASED ON AIR TEMPERATURE OF 70° F

EMISSIVITY OF WALL ·90

OUTSIDE WALL DIMENSION 16·75" x 16'75"

100

.i->:

»->

60 ... 5· 0 セ z w U u, u, W o o a: w u, C/) 3'0 z « 0::: セ セ « w 2· 0 J: a: 6·0 I <, ::::> セ CD w o C/)S

1'0 o o..c Ts OUTSIDE SURFACE TEMPERATURE, of

FIGURE 2

OUTSIDE HEAT TRANSFER COEFFI CIENT VS OUTSIDE SURFACE

FIGURE 3

OUTSIDE SURFACE TEMPERATURE VS CHIMNEY SECTION TEMPERATURE

ADJACENT TO SURFACE. 900 800 700 600 ADJACENT TO SURFACE, of 400 500 TEMPERATURE

CALCULATED FROM HEAT FLOW

EQUATION AT SURFACE - as = ·758 Gj + 17 (APPROXIMATED) 300 SECTION -? -7' -:? ,p -7' セ 100 200 aj =CHIMNEY BASED ON AI R TEMPERATURE OF 70 OF EMISSIVITY OF WALL' 90

OUTSIDE WALL DIMENSIONS -16·75"x 16·75"

K OF MATERIAL· 60 BTU /HR FT of

o

o 100 200 600 300 500 400 w o en I-::J o u, o l/I (J) w uIt

cr ::J en w cr ::J I-<f cr W CL ::2: wI-FIGURE 4

ANALOG REPRESEI\JTATION OF A CHI MNEY OUTSIDE SURFACE 1000 900 800 700 600

---.-;::::.::::::.. セNMZZZZZMMNセ

.;o.-:o-r

.

セ - hi • 4-5 x10'Tg +'-250 (APPROXIMATED) 500Tg FLUE GAS TEMPERATURE, of

W

-...

SUMMERL

POTENTIOMETER400

FLUE GAS FLOW - 100 C FM

FLUE SIZE 7"x 7"

FIGURE 5

INSIDE HEAT TRANSFER COEFFICIENT VS FLUE GAS TEMPERATURE 1·0 300 w o U) z u, 0 N l-u, 2·0 Q:: セ ::> I-CD i-e セ I-z w U u, u, 1·6 w 0 U Q:: W u, 1-4 U) z <t Q:: l- I-<t 1·2 w J:

POTENTIOM ETER

SUMMER MULTI PliER

(G 8g +1-1) 8j - 8s - 100 V - 8g FROM RELAY AMPLIFIER - 8g CIRCUIT 8g - 8S +8 5 -ej +eS FIGURE 6

ANALOG REPRESENTATION OF A CHIMNEY

セL I') I I..r---r\ r -イMiセo 11&-I 16 I

I

+100 • 1\.JI

I

7

1iHセi

セ

L - - ---".rr _ _=.J / +'00 """ r-, セ / セ +I.C. SEL セ /1 • uP )(1 / OOWN MiセO セセO / VP - VARIPLOTTER / x, - Xcoセrdinate / Y, - Y CO-ORDINATE / / ANALOG NETWORK Of / セ CHIMNEY SECTION / - ". / <, /-.

/Y

セ/

// .

: FIGURE 7ANALOG CIRCUIT OF セ SECTION OF CHIMNEY

-'M

,

ャMイセ

76 CON rFolOL..:i MAGNiTl.:CEcr INPL:TA.\4PLlTl:QE

77 」ッイセtrolセZ[ MAGNITUDE ("F INPUT I.C.

78 CONTROLS TIME ON INP'JT AMP:"ITJOE 79 CONTROL.5i TIME ON エイセpuZ r c

1000 セ 800 ui a: :J I-<t: a: 600 ui o, セ w I-OJ 400 0

It

cr :J en 200CHIMNEY TEST TEMP.

--- COMPUTER UNADJUSTED TEMP. INSIDE SURFACE MMMセ OUTSIDE SURFACE o o 200 400 600 800 1000 1200 1400

FLUE GAS TEMPERATURE, of

FIGURE 8

COMPARISON OF TEST AND COMPUTER (UNADJUSTED)

FIGURE 9

OUTSIDE SURFACE TEMPERATURE VS TIME FOR CYCLIC FLUE GAS TEMPERATURE INPUT

22 ...

-'

20 18 16.--",,-/

/-

/ /"

/'

.../ 1410 MIN ON 5 MIN OFF 10 MIN ON 10 MIN OFF I HR ON I HR OFF 2 HR ON 2 HR OFF 4 HR ON 4 HR OFF 8 10 12 TIME, HOURS 6 4 2 u, ° 180 w 160 a: :::::> I-140 c:[ a: w a. 120 セ w I-100 w o c:[ 80 u, a: :::> If) 60 w 0 40 If) I-:::::> 20 0 0 0

セ 6·0 セ u, a:: :x: <, 5·0 セ I--m

FLUE GAS FLOW - 100 CFM

.--- .---

セ

COMPUTER400 600 800 1000

FLUE GAS TEMPERATUREt of

1400 1200 GAS RADIATION FORCED CONVECTION •

----セMMMMMM

CALCULATED ---.... 200..

I--Z 4·0 w U LL u, W 0 u 3·0 a:: w u, (f) Z <r a:: 2·0 l- I--<r w :x: 1·0 w 0 (f) z 0 0 FIGURE 101

r

J セ 400 LL 0 W Q: => I-300 <t Q: W Q. セ W I-STEADY INPUT w u 200 <t LL Q: => Cfl w INPUT 010MIN ON 5 MIN OFF

Cfl 100 l-=> 0 o

o

200 400 600 800 1000 1200FLUE GAS TEMPERATURE, "F

FIGURE II

COMPARISON OF STEADY AND PERIODIC FLUE GAS INPUT ON

OUTSI DE SURFACE TEMPERATURE

¥. .セG

- MセMセセ

セZセ

,