Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Internal Report (National Research Council of Canada. Division of Building

Research), 1968-10-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=c123c0c3-a6db-4e56-937b-a15f12251db2 https://publications-cnrc.canada.ca/fra/voir/objet/?id=c123c0c3-a6db-4e56-937b-a15f12251db2

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20337895

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Exterior exposures of coatings on wood substrates

NATIONAL RESEARCH COUNCIL OF CANADA DIVISION OF BUILDING RESEARCH

EXTERIOR EXPOSURES OF COATINGS ON WOOD SUBSTRATES

by

H. E. Ashton

Internal Report No. 365 of the

Division of Building Research

OTTAWA October 1968

PREFACE

Application of organic coatings to exterior wood surfaces is an important aspect of Canadian building practice, especially on both coasts where timber is plentiful. Consequently, studies that would help the Division to give advice on problems that arise in this field have been part of the program of the Building Materials Section. Mr. J. Harris, who was the officer-in-charge of the Paint

Laboratory for some years, carried out much research on coatings applied to wood.

Laboratory studies on the properties of coatings indicated which types should give good performance. In the absence of re-liable or accepted accelerated tests it was necessary to confirm the laboratory results by natural exposure of the coatings. This report records the results of the different exposure tests.

Ottawa

October 1968

R. F. Legget Director

EXTERIOR EXPOSURES OF eOA TINGS ON WOOD SUBSTRATES

by

H. E. Ashton

In conjunction with laboratory studies on coating systems for wood, Mr. J. Harris (1) had many of the same materials exposed out-door s on various wood substrates. This report records the results of the different exposure tests.

MATERIALS

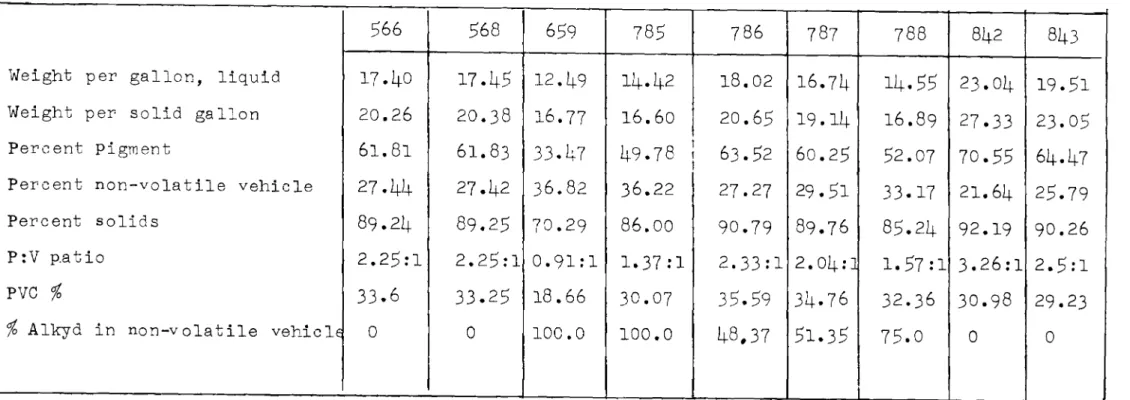

The generalized composition of the coatings which were ex-posed is given in Table I and, except for the commercial latex paints, their chief parameters are compared i.n Table II. Complete formu-lations of materials prepared in the DBR Paint Laboratory, including primers and a sealer, are given in Appendix A. The acrylic latex was purchased over a period of

zi

years so it is not known if the com-position had been changed between batches.The substrates used were white pine and red cedar siding, birch exterior grade plywood, tempered hardboard (masonite) and red cedar shingles. In most tests on siding the long dimension was in the horizontal direction and the siding was in the drop or cove shape. One year, siding was also exposed with grain arranged vertically and for this test tongue and groove siding was used. Most tests were conducted at the Division's Montreal Road exposure site, but three duplicate panels of one series were exposed in Halifax at the York Redoubt site. All panels were mounted vertically facing south.

Because the exposures were begun in different years and the program was modified as time progressed as the result of laboratory and exposure tests, all the different coatings were not exposed on all substrates. This procedure reduces the number of individual samples but makes analysis of the results much more complex. There were al-so differences in the application procedures with time. In most of the early tests the wood was sealed with two coats of clear alkyd sealer. In the later tests three coats of the finishes, regardless of type, were applied to bare wood. While this procedure may be regarded as placing

2

-all coatings on the same footing, it may have been unfair to those that were specifically designed for use over a primer. Except for the last exposure series in 1963, the first coat of the three coat system was generally reduced with 10-15 per cent thinner. The first coat of latex paints was not reduced because thinning cannot aid penetration of the binder which is dispersed, not dissolved, in water. Thinning would only reduce the already low dry film thickness of latex paints. The coatings exposed and their substrates are arranged in Table III in chro-nological order. Details of application such as primer used or amount of thinning are also given.

From 1956 to 1959 the white pine and red cedar siding was coat-ed before being fastencoat-ed to the exposure frame. Aluminum paint was applied to the backs and ends of the boards after application of the test material to the face. The boards were screwed to H-frames so that the backs were open to the weather.

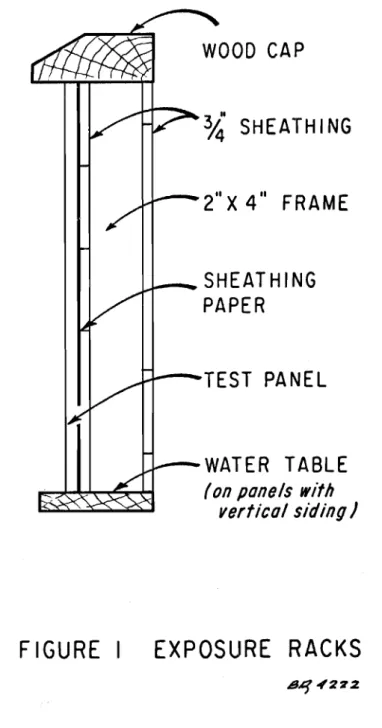

After 1959, the siding was mounted before painting. The backs of the boards were not sealed but the ends were. The siding was nail-ed to 3/4 inch sheathing covernail-ed with sheathing paper. There was also wood sheathing on the back of the assembly and, for vertical siding, a water table at the bottom as shown in the diagram (Figure 1). Shingles, plywood and masonite were also applied over sheathing paper. The

sides of the frames and the sheathing on the back were coated with alumi-num paint. Except where noted, panels were coated in the laboratory. RESULTS

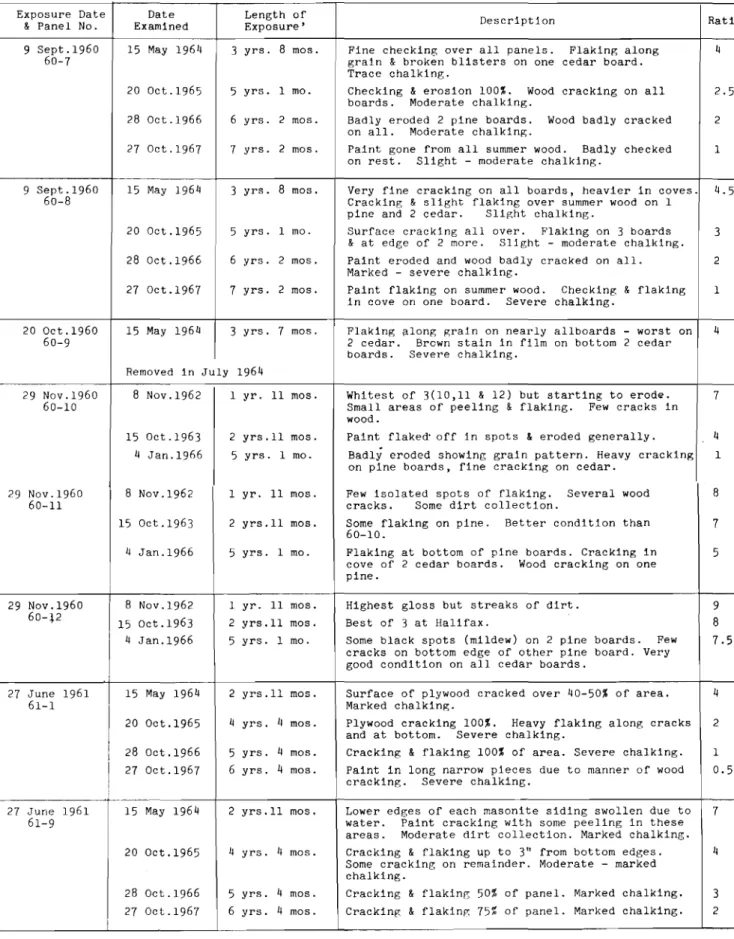

The exposure panels were rated periodically by various

ob-servers. The descriptions and ratings are given in Table IV in the same order as their exposure. Unfortunately, in many cases it has not been possible to find the earlier results in the records. For the final ex-amination in 1967 two observers rated the panels independently and then reviewed the results together to resolve disagreements. Ratings were made on the conventional scale of 10 to 0, where 10 is perfect condition and

°

is complete failure.It is diffic ult to present exposure results in a manner that readily enables comparisons to be made or meaningful conclusions to be reached. At any single observation time there may be reversals in ratings of different coatings. In the analysis of these exposure studies the ratings were first

3

-plotted against time. From the general trend, the times at which each system reached ratings of 8, 5 and 2 were determined and are given in Table V. The first moderate drop in appearance or the first isolated failures in protection are reflected in a rating of 8. Five represents the condition when most coatings require repainting but without extensive preparation of the substrate. Two indicates severe failure either of the coating or the underlying surface. With coatings that had long durability or which had been exposed for only a relatively short time it was necessary to extrapolate to the time required to reach the lower ratings. In some cases, therefore, the estimate is not very precise, especially for the rating of 2.

The graphs of performance v s , time in Appendix B show that some coatings quickly drop to a fairly low rating but then do not exhibit much change for some time. Straight white lead paint had this type of ex-posure history. Other coatings have a high rating for several years and then fail rapidly. In the third case, the rating decreases fairly uni-fonnly with time. In order to accommodate these three types of failure, the time to reach a rating of 5 was selected as being most representative of the performance of a coating.

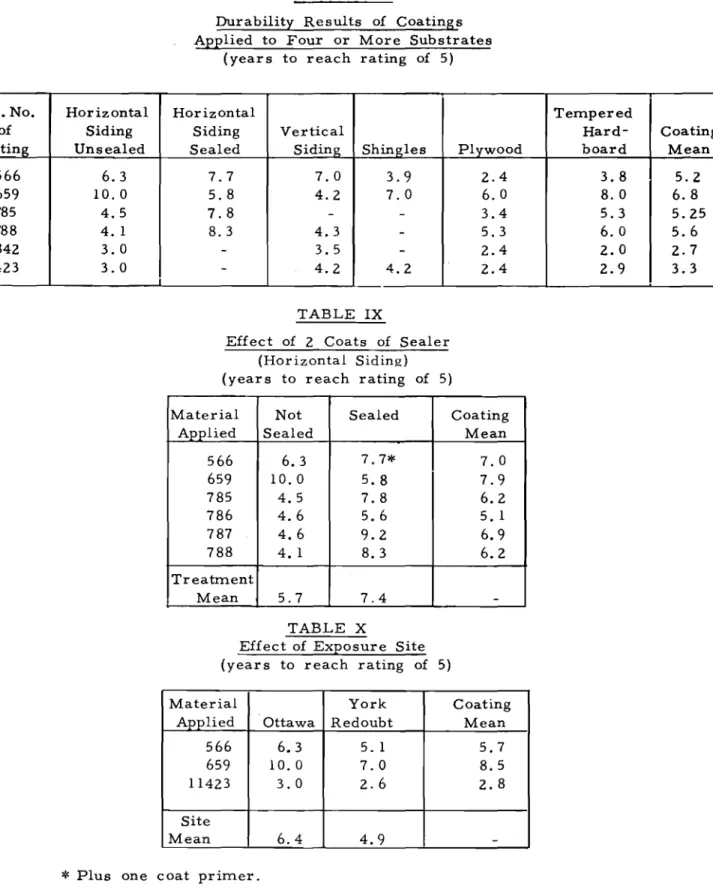

Effect of Substrate

The years required for several finishes applied in 3 coats to hare substrates to reach the repaint condition are shown in Table VI. Based on these results, horizontal siding is one of the better wood sub-strates. Cedar shingles also have a high rating, but this conclusion is more tentative because only 3 coatings were tested on them. The rn ean for the same three materials on horizontal siding was 6.4 years, but

this is influenced by the high rating of the alkyd enamel. Naturally, more definite conclusions can be reached when there are several ex-posures which can compensate for an occasional erratic result.

As expected from enquiries received from the field, plywood had the lowest mean rating of the different wood substrates. The alkyd enamel, however, lasted 6 years on it and the isophthalic finish had a higher rating on plywood than on other substrates except for tempered hardboard and sealed horizontal siding.

Plywood might be expected to be a good substrate for painting because the perpendicular arrangement of the plies increases its sta-bility to dimensional changes caused by variations in moisture content.

4

-However, when care is not taken in cutting the veneers or when the face veneer is not oriented so that the side that was originally towards the outside of the tree is on the outside of the sheet (referred to in the trade as bark- side out or loose face in), plywood on exterior exposure is very prone to develop cracks known as checks. The means for preventing this have been known for some years (2-4). Nevertheless, because most plywood is used where appearance is not a factor, it is evidently considered not economically feasible to take the necessary steps to produce plywood that will not check.

When the face ply has the bark-side out, the outer layer of wood is in compression. When the loose side is out, the small cracks pro-duced in rotary cutting of the veneer are exposed under tension and are likely to crack even more when stressed from shrinking and swelling. Since the laying up of plywood occurs randomly, about half should have the preferred arrangement which may account for the variations in per-formance of coatings on plywood. In addition, because veneers are edge jointed to provide the necessary panel width, this variation in dura-bility commonly occurs on the same panel (Figure 2).

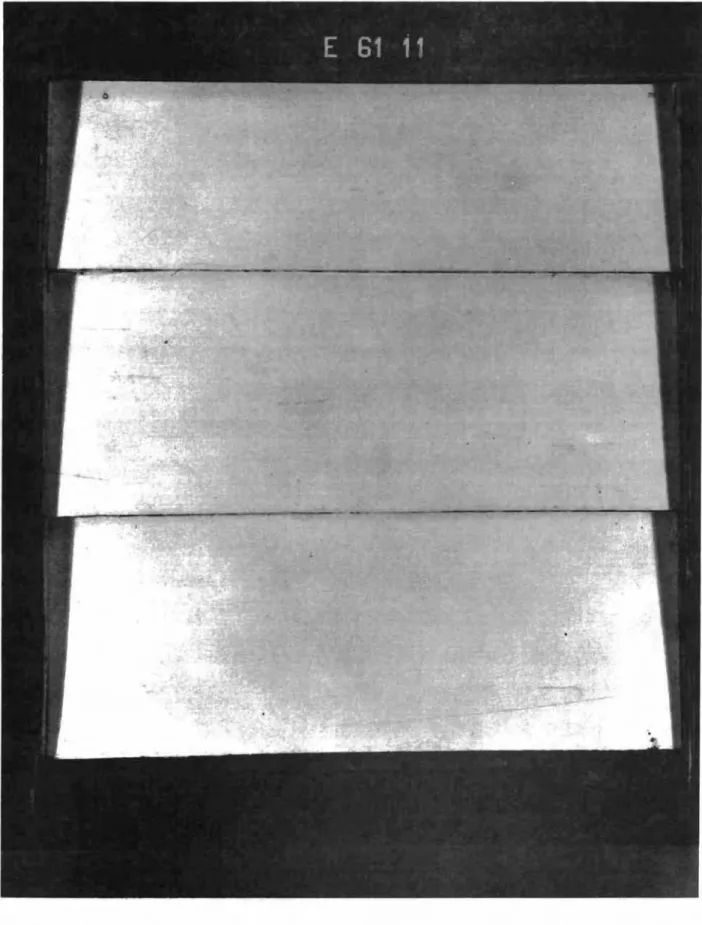

Tempered hardboard showed poorer results than expected, chiefly because the lower edge of the siding swelled and disrupted most coatings. Studies by the U. S. Forest Products Laboratory (5) have shown that in-creasing the resin content is one way to overcome the "edge flare" de-fect in particleboards. This may also be true for fiberboards. The more water resistant alkyd enamel gave very good service on this surface, as shown in Table VI and Figure 3.

The effect of mounting the siding in the horizontal or the vertical direction is shown in Table VII. With 6 different coatings applied to wood erected in both directions the mean for horizontal is higher than for vertical siding. The analysis of these results is complicated by two factors: the reversal in durability results of the alkyd compared to those for the other 5 finishes and the different methods of preparation used in the two series. If the alkyd results are deleted, then the vertical siding mean is higher. Finishes applied to the horizontal panels in the field had the first coat reduced 10 - 15 per cent with solvent, however, where-as they were unreduced when applied to vertical siding in the laboratory. Browne (6) showed in 1930 that reduction of oil paints was not beneficial to exterior performance and DBR work on clear finishes has shown that thinning the first coat merely reduces film thickness and subsequent

5

-durability. It is therefore difficult to conclude definitely that :mounting siding in any particular direction is a :more severe exposure of coatings. Differences Between Coatings

The results fro:m coatings that were applied to 4 or :more sub-strates are given in Table VIII. It can be seen that where there was a sufficient nu:mber of exposures to :make a reasonable co:mparison, the alkyd ena:mel gave the best over-all results. Comparison of the alkyd perfor:mance on other surfaces with other :materials indicates that the durability rating is higher on horizontal and lower on vertical siding than :might logically be expected.

The i s ophthalic alkyd finish ranked second in over -all perfor-:mance on 6 different surfaces. In s orn e cases because of :mildew growth it received a lower rating than it :might have fro:m the point of view of protection alone. The :mildewcide reco:m:mended in the original for:mula was not incorporated in the batch :made in the DBR Paint Laboratory SO

the :material :may be capable of better perfor:mance. For:mula 785, an alkyd finish, and 566, the standard oil paint, were si:milar in durability. The hiding pig:ment in the alkyd was anatase titaniu:m dioxide which chalks :much :more than the rutile used in the oil paint. The severe chalking lead-ing to :marked erosion of the fil:m probably contributed to the lower dura-bility of 785 co:mpared to that of the alkyd ena:mel.

The white lead in oil paint was quite inferior to rn o st of the other coatings, generally failing by checking. Even on plywood where the sub-strate failed leaving long thin strips, the re:maining paint was checked. Inclusion of zinc oxide in for:mula 843 did not noticeably i:mprove the per-for:mance. It is thus evident that the industry has produced coatings that are superior to those in co:m:mon use at the beginning of this century. The reputation for good durability that these old-ti:me paints still possess is apparently due more to fond recollection than to actual perfor:mance.

Latex paint, which is the other coating com:monly applied to wood siding in North America, was inferior to the oil paint. This result is contrary to rn o s t field experience and is probably due to application of the latex paint to unprimed wood. Acrylic latices at the ti:me these ex-posures began were not :made for use on bare wood. In recent years such ernul s ions have been introduced and better perfor:mance might be expected. In general, a latex paint should be used precisely as directed by the

6

-The PYA latex paint was not exposed long enough or under enough con-ditions to rnak e a valid c ornpa r i s on , It is understood, however, that rn o st coating rnariufa c tu r e r s in Canada prefer acrylics for use on ex-terior wood.

In the series 785, 786, 787, c ornpa r ing p igm ent and vehicle rnodific a ti.on s , it is again difficult to reach any conclusions because rn o r e than one factor was varied at a tirn e , Also, the numbe r of ex-posures of all three coatings was Lirrri te d, On bare wood the three were a lrn o st identical in pe rf o r maric e but on sealed wood there was a rria r k ad difference. It cannot be concluded on the basis of one ex-posure whether this difference was real or fortuitous. The r erria.r k . able irnp r ov erne nt in p e rf'o r rnaric e on sealed wood of the lead-free zinc-t.i.tan iurn oil-alkyd finish, 787, will be checked again.

The effect of sealing the wood before coating is shown in Table IX. Most coatings had iITlproved durability over sealed wood as m ight

be expected f r orn a s ornewhat higher total f i lrn thickness. Again the alkyd enamel exhibited a reversal of the general trend and this will also be rechecked on exposures that commence at the same time.

In the fir st exposure series oil paints 1- GP-2 8a, Types A and B, were applied to siding over primer l-GP-55b. The resultant durabilities were unexpectedly higher than in any subsequent exposures of Type B over white lead p r irn.e r or s e lfvp r irn ed, Although a single result is not conclusive evidence, there is a strong indication that superior performance is obtained if oil paint is applied over a properly formulated p r irn e r , Comparable results obtained by industry probably ledtothe adoption of special primers for house paints instead of self-priming.

Effect of Sites

Table X shows that in this very limited test, three coatings failed rn o r e rapidly at York Redoubt than at Ottawa. Most of our more extensive exposure studies have not shown this difference in severity between these two sites. Part of the discrepancy ITlay result f r orn the use of different ob servers except for the final examination.

SUMMARY

7

-a difficult m-ateri-al to p-aint s-atisf-actorily. An alkyd enamel and an isophthalic alkyd finish gave reasonable performance on this sub-strate.

Cedar shingles were somewhat less demanding on the three coatings applied to them than was hardboard. The latter swelled at the lower edges, cracking most systems except the alkyd enamel.

The alkyd enamel was best on most surfaces although it had poor durability on vertical siding. An isophthalic alkyd was next in over -all performance. The latex was generally poor, probably because it was applied to bare wood. The usual type of oil paint was intermediate to the enamel and the latex except on vertical siding, where it was best due to the unexplained low rating of the alkyd. Use of an oil primer markedly improved the performance of this oil paint on horizontal siding. Straight white lead was very poor on most sur-faces; on hardboard it had an unsatisfactory appearance in a few months and deteriorated to a rating of 5 in only two years (Figure 4). Application of two coats of sealer to siding appeared to improve the durability of most finishes but the exposures with and without sealer were started in different years.

On the basis of these exposures and previously reported labo-ratory tests (1), it is concluded that the use of alkyds on wood siding should receive more consideration than it has in the past. Many paint chemists have cautioned against blind acceptance of test fence

exposure results because there is no temperature or moisture gradient across the panels. In laboratory tests, however, alkyds have demon-strated good wet adhesion and have been reportedly used on houses in Norway where the climate is wet and in Australia where it is dry. It is thought, therefore, that their use for this purpose should be

re-examined in Canada. ACKNOWLEDGEMENT

These exposure studies were commenced by Mr. J. Harris, formerly Research Officer in charge of the Paint Laboratory. Thanks are due to Mr. R. C. Seeley who rated the panels and kept accurate records over the last 4 years. Mr. Seeley also prepared the exposure panels for the last 3 series.

8

-REFERENCES:

1. Harris, J. A Study of House Paint Properties. Canadian Paint

and Varnish, Vol. 37, No.2, p.22, No.3, p.42, 1963.

2. Batey, T. E. Minimizing Face Checking of Plywood. Forest

Products J., VoL V, No.5, p.277, 1955.

3. Yan, M.M. and W. G. Lang. Veneer Checking and Warping.

Canadian Woodworker, November 1958, p.20.

4. Keith, C. T. Surface Checking in Veneered Panels. Forest

Products J., Vol. XIV, No. 10, p.481, 1964.

5. Heebink, B. G. A Look at Degradation in Particleboards for

Exterior Use. Forest Products J. ,Vol. 17, No.1,

p.59, 1967.

6. Browne, F. L. Effect of Primer Reduction and Special Primers

Upon Paint Service, Ind. and Eng. Chemistry, Vol. 22,

TABLE I

Materials SUbjected to Exterior Exposure on Wood Substrates

Labora tory

Number

Type of vehicle

Main pigments

Classification of

coating

566

Linseed Oil

Lead, Zinc, Titanium

Oil Paint l-GP-28a Type

B568

Linseed Oil

Lead,

Zinc, Titanium

Oil Paint l-GP-28a Type

A659

Alkyd Resin

Titanium Dioxide

Alkyd Enamel

785

Alkyd Resin

Titanium, Talc

Alkyd Finish

786

Oil-Alkyd

Lead,

Zinc, Titanium

Alkyd Modified Oil Paint

787

Oil-Alkyd

Zinc, Titanium

Alkyd Modified Oil Paint

788

Isophthalic Alkyd

Titanium, Talc

Alkyd Finish

842

Linseed Oil

White Lead Carbonate

Lead in Oil Paint

843

Linseed Oil

White Lead, Zinc Oxide

Lead-Zinc

Oil Paint

11374

PVA Latex

Unknown

Latex Paint

11423 )

Acrylic Latex

Unknown

Latex Paint

TABLE II

Comparison of Coating Properties

I

566

568

659

785

786

787

788

842

843

Weight per gallon, liquid

17.40

17.45

12.49

14.42

18.02

16.74

14.55

23.04

19.51

Weight per solid ga 110n

20.26

20.38

16.77

16.60

20.65

19.14

16.89

27.33

23.05

Percent Pigment

61. 81

61.83

33.47

49.78

\I63.52

60.25

52.07

70.55

64.47

I

Percent non-volatile vehicle

27·44

27.42

36.82

36.22

27.27

29.51

33.17

21.64

25.79

Percent solids

89.24

89.25

70.29

86.00

90.79

89.76

85.24

92.19

90.26

P:V p.atio

2.25:1

2.25:1 0.91:1

1.37:1

2.33:1 2.04: ]

1. 57 : 1 3.26:1 2.5:1

PVC

%

33.6

33.25

18.66

30.07

35.59

34.76

32.36

30.98

29.23

TABLE III Coating Systnms ExposAo

Year PanelNo. MMMMMセゥdゥセ「 _

No. Type Subs tra te 1st Coat 2nd Coat 3rd 4th 5th 6th

"

1956 56-27 & 28 56-25 & 26 566 568 Oil Paint " nCedar &Pine Siding It n 578 Primer

"

"

566 thin. 51t 568 566 568 566 566 566 659 659 659 659 11374 11374 11374 -494 pro"

"

718"

""

"

718 Sealer"

""

"

Cedar & Pine Siding Oil Paint

566 58-41 &

42

58-39 & 659 Alkyd Enamel 40

58-37 & 1374 PVA Latex 38

1958

195959-41 &

42 785 Alkyd Finish Cedar &Pine

Sid ing 718 Sea ler 59-43 & 44 59-45 & 46 59-47 & 48 786 787 788 Oil-Alkyd " II Isophtha lie

"

"

" ""

"

""

"

"

"

718"

"

"

785 786 787 788 785 786 787 788 785 786 787 788 5661 Oil Paint 659 Alkyd EnamelI

785 Alkyd Finish 786 Oil-Alkyd 787" "I

788 Isophthalic 842 Lead in Oil 566 thin.101t 659 " " 843 thin.10-15% 11423"

1960 60-5 60-6 60-1 60-2 60-3 60-4 60-7 60-8 60-9 60-10 60-11 60-12 843 11423"

566 659 Oil Paint Acrylic Latex It " Oil Paint Alkyd EnamelPine & Cedar

"

"

" rt"

"

"

"

""

""

Pine &Cedar"

"

I, If"

"

It ft 566 659 785 786 787 788 842 エィゥョNQoMQUセ tt " tr n ft " thin. 10-15"1. " It 566 659 785 786 787 788 842 843 11423"

566 659 566 659 785 786 787 788 842 843 11423"

566 659 Panels 60-1 to 60-8 were prepared on the fence in Sept. Panels 9 to 60-12 were prepared in the lab in October.Panels 60-1 to 60-8 were prepared on the fence in Sept. Panela 9 to 60-12 were prepared in the lab in October. The laat 3 were exposed in Halifax. 842 Lead in Oil 566 Oil Paint

"

"

"

785 Alkyd Finish " II II 11423 Acrylic Latex " " 11 788"

"

842"

785"

566"

659 11423"

566 659"

785 " 788 842"

11423"

"

"

"

"

"

"

"

"

""

"

"

"

"

"

"

""

"

11423"

566 thin.lO% f1 " " 842 659 785"

788 Plywood Masonite Plywood Masonite Plywood Masonite Plywood Masonite Plywood Masonite Plywood Masonite ""

"

788 Isophthalic " n 659 Alkyd Enamel " n " 61-1 61-9 61-2 61-11 61-6 61-8 61-5 61-7 61-3 61-10 61-4 61-12 1961 1963 63-1 63-2 63-3 63-4 63-5 63-6 63-7 63-8 63-9 566 659 788 842 843 11423"

659 566 Oil Paint Alkyd Enamel Isophthalic Lead in Oil Oil Paint Acrylic Latex " It Alkyd Enamel Oil Paint Vertical pine Siding"

"

"

"

"

" t1 ""

"

n " 566 659 788 842 843 11423"

659 566 566 659 788 842 843 11423"

659 566 566 659 788 842 843 11423"

659 566 Panels 1 to 63-6 were exposed in April. Panels 63-7 to 63-9 were ex-posed in December.TABLE IV

Exposure Results

Exposure Date Date

&Panel No. Examined 28 Sept.1956 15 May 1964 56-27 & 28 20 Oct.1965 28 Oct.1966 27 Oct.1967 Length of Exposure 7 yrs. 8 mos. 9 yrs. 1 mo. 10 yrs. 1 mo. 11 yrs. 1 mo. Description

Some cracks at ends and bottom edges of some boards. Marked chalking.

Up to 2" cracks on all boards. Peeling at ends of 3 boards, cracking in cove of one and at bottom of another board. Marked chalking. End cracks as before. 2 boards with cracking on bottom. Marked chalking.

End cracks as before. 3 boards with cracking in cove. One board cracking &peeling 25%. 4 with mildew. Chalking moderate - marked.

Rating 7 6 5 28 Sept.1956 56-25 &26 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967 7 yrs. 8 mos. 9 yrs. 1 mo. 10 yrs. 1 mo. 11 yrs. 1 mo.

Fine cracks in coves and over most of sur-face. Slight dirt collection. Marked chalking.

1-1/2" cracks at ends. One board cracking in cove &one at bottom. Marked chalking. Cracking in all coves. Two boards cracking at bottom. Erosion and severe chalking. Cracking &peeling in coves &at edges. 3 boards cracking at bottom, 2 others fine crack-ing at bottom. Erosion and severe chalking.

6 5 3 + + + + -1 Aug.-1958 58-41 &42 1 Aug.1958 58-39 &40 6 Aug.1959 9 Nov.1959 9 Aug.1960 12 Sept.1961 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct .1967 6 Aug.1959 9 Nov.1959 9 Aug.1960 12 Sep.1961 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967 1 yr. 1 yr. 3 mos. 2 yrs. 3 yrs. 1 mo. 5 yrs. 9 mos. 7 yrs. 3 mos. 8 yrs. 3 mos. 9 yrs. 3 mos. 1 yr. 1 yr. 3 mos. 2 yrs. 3 yrs. 1 mo. 5 yrs. 9 m05. 7 yrs. 3 mos. 8 yrs. 3 mos. 9 yrs. 3 mos. Moderate chalking.

Moderate chalking &trace of dirt collection. Moderate chalking &slight dirt collection. Cracking on one board. Moderate dirt· collection. Chalking moderate - marked. Slight cracks at edge of cove. Flaking one pine panel. Slight dirt collection. Marked chalking.

Cracking at cove edge 4 boards. Severe chalking.

Cracking in all coves and on face of 3 boards. Severe chalking.

Paint cracking &peeling in all coves. Cracking & peeling badly on face of one pine board. On one cedar board cracking to primer only. Severe chalking.

Trace chalking.

Trace chalking and slight dirt. Slight chalking &dirt collection. Chalking moderate - marked. Marked dirt collection.

Cracking in all coves. All faces good except one board. Marked chalking.

Cracking in coves - cedar few, pine 100%. Flaking on 2 boards. Darkening at bottom edge. Marked chalking.

Cracking in all coves &on face of 2 boards. Some mildew. Severe chalking.

Fine cracking in all coves. Cracking and flaking face and coves of 2 boards. Ckalking severe. 9.5 9 9 8.5 7.5 6 4 3 10 10 9.5 8 5 4 3.5 3

Exposure Date

&Panel No. ExaminedDate

Length of Exposure TABLE IV (Cont'd) Description ( 2) Rating 1 Aug.1958 58-37 &38 13 July 1959 59-41 &42 8 Aug.1959 9 Nov.1959 9 Aug.1960 12 Sep.1961 15 May 1964 9 Aug.1960 12 Sep.1961 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967 1 yr. 1 yr. 3 mos. 2 yrs. 3 yrs. 1 mo. 5 yrs. 9 mos. 1 yr. 1 mo. 2 yrs. 2 mos. 4 yrs.lO mos. 6 yrs. 3 mos. 7 yrs. 3 mos. 8 yrs. 3 mos. Slight chalking. Moderate chalking.

Moderate - marked chalking. Cracking on 2 pine

and 1 cedar. Fine cracks on 2 cedar.

Cracking on 5 boards, fine cracks on other.

Peeling on one board. Marked chalking.

Marked cracking of wood. Flaking on one board

along grain. Heavy erosion and marked chalking.

Slight - moderate chalking.Marked dirt colI. Moderate chalking. Marked dirt collection. Few small cracks in wood at ends. Slight dirt

collection. Severe chalking.

Cracking at edge of cove on 4 board. Few cracks

on bottom edge of 2 boards. Severe chalking.

Wood cracking at cove edge except top board. Cracking and erosion bottom corners. Severe chalking.

Wood cracking in cove and at edge. Erosion on

face and heavy erosion at edges.

,10 9.5 7 4.5 2 9 8 8 7 6 4 13 July 1959 59-43 &44 9 Aug.1960 12 Sep.1961 15 May 1964 20 Oct.1965 1 yr. 1 mo. 2 yrs. 2 mos , 4 yrs.lO mos. 6 yrs. 3 mos.

Trace cracking on bottom end of lower board. 9

Slight - moderate chalking.

Marked cracking at end,of bottom board. Moder- 8

ate chalking. No dirt.

Cedar boards fine cracks in cove. Pine boards 6.5'

wood cracks at ends. No dirt. Moderate chalking.

Paint cracking &flaking in cove &on surface 4

of pine boards. Also end cracks in wood.

Marked chalking. 28 Oct.1966

27 Oct .1967

7 yrs. 3 mos. 8 yrs. 3 mos.

Cracking in all coves. Flaking on pine.

Marked chalking.

Cracking in all coves. Fine cracks on face of

pine boards. Marked chalking.

3 2 13 July 1959 59-45 &46 13 July 1959 59-47 &48 9 Aug.1960 12 Sep.1961 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967 9 Aug.1960 12 Sep.1961 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967 1 yr. 1 mo. 2 yrs. 2 mos. 4 yrs.lO mos. 6 yrs. 3 mos. 7 yrs. 3 mos. 8 yrs. 3 mos. 1 yr. 1 mo. 2 yrs. 2 mos. 4 yrs.lO mos. 6 yrs. 3 mos. 7 yrs. 3 mos. 8 yrs. 3 mos.

Slight - moderate chalking. 9.5

Moderate chalking. No dirt collection. 9.5

Moderate - marked chalking. No dirt collection. 9.5

Bright appearance.

Bottom board wood cracks one end. Marked chalking. 9

Few cracks in coves of 4 boards. Wood cracks at 8

end of bottom board. Marked chalking.

Cracking in all coves and cove edges of 2 boards. 6.5

Wood cracking at ends of bottom 2 boards. Bright

appearance. Marked chalking.

Moderate chalking. Marked dirt collection. 8.5

Moderate chalking. Marked - severe dirt colI. 8

Mildew on surface. Bottom board wood cracks at 7

end and minute blisters on bottom. Marked chalking

Mildew on all panels. Wood cracks at end of bottom 6.5

cedar &pine boards. Marked chalking.

Mildew slightly worse on bottom cedar &pine 6

boards. Marked chalking.

Mildew very dense on cedar, dense on pine. 5

Bottom cedar board badly cracked on bottom and fine paint cracks in cove. Moderate - marked chalking.

TABLE IV (Cont'd) (3)

Exposure Date

&Panel No.

Date Examined

Length of

Exposure Description Rating

9 Sept.1960 60-5 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967 3 yrs. 8 mos. 5 yrs. 1 mo. 6 yrs. 2 mos. 7 :frs. 2 mos.

Few brown spots on bottom of pine board. Marked chalking.

Small cracks in coves of 3 boards. Wood crack-ing on one cedar board. Moderate chalking. Cracking on half of boards with few on rest. Marked chalking.

Fine cracking on all boards. 2 with flaking on summer wood. Severe chalking.

9 7.5 5.5 3 9 Sept.1960 60-6 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967 3 yrs. 8 mos. 5 yrs. 1 mo. 6 yrs':' 2 mos. 7 yrs. 2 mos.

Panel in very good condition.

Mildew on 2 pine boards on bottom edge. Marked chalking.

Trace greying (mildew) on bottom 1/2" of boards. Severe chalking.

2 pine boards have mildew, other has cracking at bottom. Severe chalking.

10 8.5 8 7 9 Sept.1960 60-1 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967 3 yrs. 8 mos. 5 yrs. 1 mo. 6 yrs. 2 mos. 7 yrs. 2 mos.

Small broken blisters on bottom of one pine board. Flaking from summer wood on another pine board. Marked chalking.

Erosion on all panels. Small cracks on 3 boards. Marked chalking.

Badly eroded. Marked chalking.

Badly eroded. Yellow stain on 2 cedar boards. Wood cracking on 2 pine boards. Moderate - marked chalking. 6.5 4 2 1 3 2 4 7 i f = -- -- -- -- -- -- -- -- --

--Bottom pine &cedar boards cracking &flaking at lower corners. Slight stain at cracks. Marked chalking.

Cracking &flaking at bottom edges of cedar. Cracking on surface of all boards. Wood cracking on one cedar board. Erosion on cove edge of another cedar. Marked chalking.

Cracking and flaking 100%. Marked chalking. Paint eroded on all panels, also flaking from summer wood. Two pine boards stained. Marked chalking. 3 yrs. 8 mos. 5 yrs. 1 mo. 6 yrs. 2 mos. 7 YrS' 2 mos. 28 Oct.1966 27 Oct.1967 20 Oct.1965 15 May 1964 9 Sept.1960 60-2 9 Sept.1960 60-3 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967 3 yrs. 8 mos. 5 yrs. 1 mo. 6 yrs. 2 mos. 7 yrs. 2 mos.

Paint cracking at edges &ends of pine boards. Very good on cedar. Marked chalking.

Cracking on pine boards with flaking on 2. Some cracking in all coves. Wood cracking on bottom of one cedar board & end of one pine board. Marked chalking.

Cracking &flaking on pine. Erosion &wood crack-ing on cedar. Moderate - marked chalking.

Cracking, severe flaking & yellow stain on pine. Erosion with cracking on cedar. Moderate chalking.

7.5 4 2 1 9 Sept.1960 60-4 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967 3 yrs. 8 mos. 5 yrs. 1 mo. 6 yrs. 2.mos. 7 yrs. 2 mos.

Small broken blisters on bottom & cove edge on pine. Cracking & flaking along grain. Mica evident. Marked chalking.

Erosion on all panels. Fine cracks in wood. Severe chalking.

Cracking &erosion on all boards. Marked chalking. Paint badly eroded. Wood cracking. Yellow stain on 2 pine boards. Moderate - marked chalking.

6

3

2 1

Flaking along grain on nearly allboards - worst on 4

2 cedar. Brcwn stain in film on bottom 2 cedar

boards. Severe chalking.

Whitest of 3(10,11 & 12) but starting to erode. 7

Small areas of peeling &flaking. Few cracks in wood.

Paint flake& off in spots & eroded generally. 4

Badly eroded showing grain pattern. Heavy cracking 1

on pine boards, fine cracking on cedar.

Very fine cracking on all boards, heavier in coves. 4.5

Cracking & slight flaking over summer wood on 1

pine and 2 cedar. Slight chalking.

Surface cracking allover. Flaking on 3 boards 3

&at edge of 2 more. Slight - moderate chalking.

Paint eroded and wood badly cracked on all. 2

Marked - severe chalking.

Paint flaking on summer wood. Checking & flaking 1

in cove on one board. Severe chalking.

Exposure Date Date Length of

&Panel No. Examined Exposure'

9 Sept.1960 15 May 1964 3 yrs. 8 mos.

60-7

20 Oct.1965 5 yrs. 1 mo.

28 Oct.1966 6 yrs. 2 mos.

27 Oct.1967 7 yrs. 2 mos.

9 Sept.1960 15 May 1964 3 yrs. 8 mos.

60-8

20 Oct.1965 5 yrs. 1 mo.

28 Oct.1966 6 yrs. 2 mos.

27 Oct.1967 7 yrs. 2 mos.

20 Oct.1960 15 May 1964 3 yrs. 7 mos.

60-9

Removed in July 1964

29 Nov.1960 8 Nov.1962 1 yr. 11 mos.

60-10

15 Oct.1963 2 yrs.ll mos.

4 Jan.1966 5 yrs. 1 mo.

TABLE IV (Cont'd)

Description

Fine checking over all panels. Flaking along

grain & broken blisters on one cedar board. Trace chalking.

Checking &erosion 100%. Wood cracking on all

boards. Moderate chalking.

Badly eroded 2 pine boards. Wood badly cracked

on all. Moderate chalking.

Paint gone from all summer wood. Badly checked

on rest. Slight - moderate chalking.

Rating 4

2.5

2

1

29 Nov.1960 8 Nov.1962 1 yr. 11 mos. Few isolated spots of flaking. Several wood

60-11 cracks. Some dirt collection.

15 Oct.1963 2 yrs .11 mos. Some flaking on pine. Better condition than

60-10.

4 Jan.1966 5 yrs. 1 mo. Flaking at bottom of pine boards. Cracking in

cove of 2 cedar boards. Wood cracking on one

pine. 8 7 5 29 Nov.1960 VPMセR 27 June 1961 61-1 27 June 1961 61-9 8 Nov.1962 15 Oct.1963 4 Jan.1966 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967

r

15 May 1964I

20 Oct.1965 28 Oct.1966 27 Oct.1967 1 yr. 11 mos. 2 yrs.11 mos. 5 yrs. 1 mo. 2 yrs.ll mos. 4 yrs. 4 mos. 5 yrs. 4 mos. 6 yrs. 4 mos. 2 yrs.ll mos. 4 yrs. 4 mos. 5 yrs. 4 mos. 6 yrs. 4 mos.Highest gloss but streaks of dirt. Best of 3 at Halifax.

Some black spots (mildew) on 2 pine boards. Few

cracks on bottom edge of other pine board. Very good condition on all cedar boards.

Surface of plywood cracked over 40-50% of area. Marked chalking.

Plywood cracking 100%. Heavy flaking along cracks

and at bottom. Severe chalking.

Cracking &flaking 100% of area. Severe chalking. Paint in long narrow pieces due to manner of wood

cracking. Severe chalking.

Lower edges of each masonite siding swollen due to

water. Paint cracking with some peeling in these

areas. Moderate dirt collection. Marked chalking.

Cracking &flaking up to 3" from bottom edges. Some cracking on remainder. Moderate - marked chalking.

Cracking &flaking 50% of panel. Marked chalking. Cracking &flaking 75% of panel. Marked chalking.

9 8 7.5 4 2 1 0.5 7 4 3 2

Exposure Date & Panel No.

Date Examined Length of Exposure TABLE IV (Cont'd) Description (5 ) Rating 27 .June 1961 61-2 27 .June 1961 61-11 27 .Iu ne 1961 61-6 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967 2 yrs.11 mos. 4 yrs. 4mos. 5 yrs. 4 mos. 6 yrs. 4 mos. 2 yrs.ll mos. Ij yrs. 4 mos. 5 yrs. 4 mos. 6 yrs. 4 mos. 2 yrs.ll mos. 4 yrs. 4 mos. 5 yrs. 4 mos. 6 yrs. 4 mos.

Few cracks at bottom of panel with discoloration

there. Marked chalking.

Bottom cracks up to 2" long. Several small cracks

on remainder. Marked chalking.

Cracks at bottom up to 3". Fine cracks in center

and at right bottom. Marked chalking.

Cracks at bottom up to 3" long. Fine cracks on

right 40% of panel. Film adhering well and good

gloss. Marked chalking.

Two panels 1/2" swelling of board & slight dis-coloration. Slight dirt collection &moderate chalking.

Swelling at bottom 3/4" with some cracking and

darkening there. Marked chalking.

Bottom edges swollen up to 1". Grey and wrinkled

in this area. Marked chalking.

Bottom edges swollen, dirty and wrinkled up to 1". Marked chalking but good gloss under chalk.

Fine cracks in center 1/3 of panel. Larger cracks

at bottom and along sides. Severe chalking.

Paint eroding. Cracking over 80% of panel. Black

areas near bottom. Marked chalking.

Paint eroded. Wood badly cracked. Black area

50%. Marked chalking.

Film badly eroded. Wood badly cracked.

9 7 6 4.5 9 8.5 8 7.5 6 3 2 1 , r -27 .June 1961 15 May 1964 61-8 20 Oct.1965 28 Oct.1966 27 Oct.1967 27 .June 1961 15 May 1964 61-5 20 Oct.1965 28 Oct.1966 27 Oct.1967 27 .June 1961 15 May 1964 61-7 20 Oct.1965 28 Oct.1966 27 Oct.1967 2 yrs.ll mos. 4 yrs. 4 mos. 5 yrs. 4 mos. 6 yrs. 4 mos. 2 yrs.ll mos. 4 yrs. 4 mos. 5 yrs. 4 mos. 6 yrs. 4 mos. 2 yrs. 11 mos. 4 yrs. 4 mos. 5 yrs. 4 mos. 6 yrs. 4 mos.

Lower edges of boards swollen up to 1" with

dis-coloration. Marked chalking.

Bottom edges swollen up to 1" with film cracking

and slight discoloration. Marked chalking.

Paint eroding at ends &bottom of each board. Marked chalking.

Film eroded at ends &bottom and some in center .

.Also yellow stain in center. Marked chalking.

Film cracks at bottom 2". Good condition. Moderate chalking.

Cracks at bottom up to 3" long. 4 cracked areas

scattered over panel. Moderate chalking.

Cracks at bottom up to 4". 10 patches of fine

cracks. Mica evident. Marked chalking.

Cracks at bottom up to 4" long. 15 patches of fine

cracks. These areas appear dark. Severe chalking.

Bottom edges swollen up to 1". Grey &wrinkled in

this area. Mica evident. Slight chalking.

Bottom edges swollen &grey up to 1-1/2". Moderate chalking.

Bottom edges swollen, grey &wrinkled up to 2" and 1" on one side. Mica evident. Marked chalking. Bottom areas swolle'n, grey & wrinkled up to 2-1/2".

Dense セイ・ケ specks (mildew). Severe chalking.

B 7.5 5 3 9 6 5 4 8 7 6 4.5

Exposure Date

&Panel No. 27 June 1961 61-3 Date Examined 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967 Length of Exposure 2 yrs.ll mos. 4 yr s . 4 mos. 5 yrs. 4 mos. 6 yrs. 4 mos. TABLE IV (Cont'd) Description

Plywood cracking 100% of panel. Film checking

between cracks 100%. Marked erosion but only slight

chalking.

Paint eroded to show grain. Fine surface cracking

of wood 100%. Slibht - moderate chalking.

Paint badly eroded. Plywood cracked over all area.

Paint almost completely gone. Fine cracks over all

wood. ( 6) Rating 4 2 1 o

Completely eroded except as above. Last areas of paint checked. Marked chalking. overlaps. Dark 27 June 19(.1 61-10 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967 2 yrs.ll mcs . 4 yrs. 4 mos. 5 yrs. 4 mos. 6 yrs. 4 mos. Paint der. Paint Paint areas

eroding off 80% of boards; 」ィ・」ォゥョセ on

remain-Slight chalking.

eroded along brush marks. badly eroded except under on grey substrate. 3 2 1 o 27 June 1961 15 May 1964 61-4 20 Oct.1965 28 Oct.1966 27 Oct.1967 2 yrs.ll mos. 4 yrs. 4 mos. 5 yrs. 4 mos. 6 yrs. 4 mos.

Heavy wood cracking on one side of panel. Fine film 4

cracking on rest of panel. Marked chalking.

Cracking over all panel. Erosion over 75%, flaking 2

over badly cracked wood. Marked chalking.

Panel warped. Wood cracking worse on one side. 1.5

Flaking on 40%. Severe chalking.

One-third of paDel badly cracked &peeling. Remainder 1 fine cracks and badly eroded.

' 1 / + , , -27 June 1961 61-12 22 April 1963 63-1 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967 15 May 1964 20 Oct.1965 28 Oct.1966 Oct.1967 2 yrs.ll mos. 4 yrs. 4 mos. 5 yrs. 4 mos. 6 yrs. 4 mos. 1 yr. 1 mo. 2 yrs. 6 mos. 3 yrs. 6 mos. 4 yrs. 6 mos.

Mottled effect over panel. Fine cracks ovei fibres.

Marked chaIkinI';.

Erosion over much of panel. Film cracking over

fibers. Severe chalking.

Erosion and cracking 100%. Severe chalking.

Paint badly eroded. Flaking along brush marks.

Stain over 3 knots. Slight dirt collection and

chalking.

3 knots showing. Few cracks at bottom up to 2". One board 5" cracks &stain at bottom. Marked chalking. 3 knots showing &purple stain from mildew near water table. Marked chalking.

Cracking over 3 knots. Some erosion. Few dark

patches may be mildew. Marked chalking.

5 3 2 1 9.5 8 7.5 7 22 April 1963 15 May 1964 63-2 20 Oct.1965 28 Oct.1966 27 Oct.1967 1 yr. 1 mo. 2 yrs. 6 mos. 3 yrs. 6 mos. II yrs. 6 mos.

Stain over 3 knots. Few cracks at bottom up to 3". Moderate dirt collection and trace chalking. Cracks at bottom from 1/2 to 5". Two boards grey

areas at bottom (mildew). Slight - moderate chalking.

All boards cracked at bottom. Two boards dark area

under film. Good gloss under dirt and chalk.

Marked chalking.

Black around cracks at bottom. Two areas cracking &

micro flaking. Two areas dark under rilm. Good

gloss, severe chalking.

8.5 7 6 4.5 MMMMセMMMKMMMMM⦅⦅⦅KMMMMMM⦅KMMMMMMMMMMMMMMMMMMMMMMMエMMMM 22 April 1963 15 May 1964 63-3 20 Oct.1965 1 yr. 1 mos. 2 yrs. 6 mos. 1 knot showing. 1 knot showing. Severe chaIkinf';.

One crack at bottom. Severe chalking. 9

Exposure Date Date & Panel No. Examined

63-3 (Contd) 28 Oct.1966 27 Oct.1967 Length of Exposure 3 yrs. 6 mos. 4 yrs. 6 mos. TABLE IV (Cont'd) Description

Mica evident. Purple-grey scains bottom of 2

boards and top of third. Severe chalking.

Paint eroding at sides and ends. Mildew present.

One board cracked. Severe chalking.

( 7) Rating 6.5 5 22 April 1963 15 May 1964 63-4 20 Oct.1965 28 Oct.1966 27 Oct.1967 1 yr. 1 mo. 2 yrs. 6 mos. 3 yrs. 6 mos. 4 yrs. 6 mos.

Stain over 2 knots. Slight discoloration at bottom.

Slight chalking.

One board badly cracked; others few cracks at bottom.

Fine checking of paint. Slight chalking.

One board badly cracked. Paint has checked and is

eroding. Slight chalking.

Paint has checked - not any worse over knots. Fine

cracks in wood except 2 boards with heavy cracking. Slight chalking. 8 6 5 MMセセセMセ⦅⦅⦅エセセセセセKMセセセセセセエMMセセセセMセMMMセMセセMセMセセMMKMMM 200ct.1965 28 Oct.1966 27 Oct.1967 1 yr. 1 mo. 2 yrs. 6 mos. 3 yrs. 6 mos. 4 yrs. 6 mos.

Knots showing. 2 boards cracking at bottom. Slight 8.5

erosion but no chalking evident.

Flaking at 3 knots. Some erosion at bottom. Slight 7

surface cracking and chalking.

Paint eroding &.cracking on edges of 3 boards. Wood 6

cracking at bottom of 2 boards. Flaking around knots.

Slight chaLk l ng .

Paint eroded from 3 boards leaving fine cracks in

wood. 2 boards heavy crackinc at bottom, one with

stain. Slight chalking.

MMMMMセMセMMM _ . _ + 1 + -22 April 1963 15 May 1964 63-6 20 Oct.1965 Oct.1966 27 Oct.1967 1 yr. 1 mo. 2 yrs. 6 mos. 3 yrs. 6 mos. 4 yrs. 6 mos.

Stain over 3 knots. One board cracked at bottom

Moderate chalking.

3 knots showing. Cracks at bottom up to 3". Severe chalking.

One board split full length with mildew along

edges. 3 boards cracked at both ends. Severe

chalking.

Boards cracked at top & bottom, one full length.

Heavy mildew one board, some on 2 others. Some

erosion. Severe chalking.

9 8 6 4.5 3 Dec. 1963 63-7 15 May 1964 200ct.1965 28 Oct.1966 27 Oct.1967 5 mos. 1 yr. 11 mos. 2 yrs.ll mos. 3 yrs.ll mos.

Slight stain especially at side and bottom of each

shingle. No chalking.

Brown stain showing at edges of shingles. Severe

chalking.

Slight stain still evident. Rough peaks of shingles

evident. Severe chalking.

Heavy brown stain from shingles. Severe chalking.

9 8.5 8 6 MMMMMMKMMMMMMMKMMMMMMKMMMMMMMMMセMMMMMMMMMMMM⦅⦅⦅エMM 3 Dec.1963 63-8 15 May 1964 20 Oct.1965 28 Oct.1966 27 Oct.1967 5 mos. 1 yr. 11 mos. 2 yrs.ll mos. 3 yrs.llmos.

Very good gloss. Panel excellent.

Good gloss. Knots appear darker. Trace chalking.

Good gloss. Rough peaks of shingles evident.

slight chalking. Panel excellent.

Wood grain evident. One knot has cracked film.

Moderate chalking. 10 9 9 8 5 mos. 3 Dec.1963 63-9 15 May 1964 ,20 Oct.1965 28 Oct.1966 27 Oct.1967 1 yr. 11 I 2 yrs.ll 3 yrs.11 I mos. mos. mos. Trace chalking. Slight chalking.

Stain over 5 knots. Marked chalking.

Cracks over 5 knots. Film cracking on most shingles.

Fairly bright appearance from severe chalking.

10 10

9 5

TABLE V

Years to Attain Given Rating

I

Horizontal Vertical Cedar Birch Tempered

NRP

Coating System Siding Siding Shingles Plywood Hardboard

No.

- -

- - --

- - セMMMMMMM - - - - - - - --8

5

2

8

5

2

8

5

2

8

5

2

8

5

2

566

3

coats4.

e

6.3

7.5

2.5

I

>8

3.3

3.9

4.3

1.0

2.4

4.3

1.9

3.8

6.3

3

coats+

primer4.5

7.7

9.4

+ 2

coats sealer-

-

-

-

-

-

-

-

-

-

-

-2

coats+ 1

primer5.7 10.1

12.4

-

-

-

-

-

-

-

-

-

-

-

-3

coats,exp.Halifax1.9

5.1

----g--

-

-

-

-

-

-

-

-

-

-

-

-

-568

2

coats+ 1

primer4.3

9.0

- -11. 8

--

-

-

-

-

-

-

-

-

-

-659

3

coats6.1 10

>11

1.5

4.2

6.5

3.9

I

->8

3.6

6.0

-

8

5.3

-8

>9

3

coats+ 2

sealer3.1

5.8

11

-

-

-

-

-

-

-

-

-

-

-

-3

coats,exp.Halifax2.9

I

->8

-

-

-

-

-

-

-

-

-

-

-

-785

3

coat s2.1

4.5

6.1

-

-

-

-

-

-

1.4

3.4

5.3

2.9

5.3

--

6.8

3

coats+ 2

sealer2.2

7.8

2-

-

-

-

-

-

-

-

-

-

-

-

-786

3

coats2.4

4.6

7.1

-

-

-

-

-

-

-

-

-

-

-

-3

coats+ 2

sealer2.2

5.6

8.3

-

-

-

-

-

-

-

-

-

-

-

-787

3

coats3.0

4.6

6.1

-

-

-

-

-

-

-

-

-

-

-

-3

coats+ 2

sealer7.3

9.2

>10

-

-

-

-

-

-

-

-

-

-

-

-788

3

coats1.8

4.1

6.1

2.0

4.3

6

-

-

-

3.4

5.3

8

2.9

6.0

8

3

coats+

2

sealer2.2

8.3

-10

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-842

3

coats1.2

3.0

6.1

1.0

3.5

-

6

-

-

-

1.0

2.4

4.3

0.8

2.0

4.3

843

3

coats1.3

3.3

6.1

1.5

4.0

-

6

-

-

-

-

-

-

-

-

-11374 3

coats+ 2

sealer1.7

2.9

5.8

-

- --

-

-

- --

-

-

-11423 3

coats1.2

3.0

5

2.5

4.2

6

2.9

4.2

5

1.0

2.4

4.3

1.2

2.9

5.3

3

coats,exp.Halifax1.3

2.6

"If.

4

-

-

-

-

-

- --

-

-

-

-

-

-

TABLE VI

3 Coats on Unsealed Substrate (years to reach rating of 5)

Wood Substrate Substrate

Substrate 566 659 788 842 11423 Mean 785 Mean

Horiz. Siding 6.3 10 4. 1 3.0 3.0 5.3 4.5 5.2 Vertical

"

7 4.2 4.3' 3.5 4.2 4.6-

4.6 Plywood 2.4 6.0 5.3 2.4 2.4 3.7 3.4 3.6 Hardboard 3.8 8 6.0 2.0 2.9 4.5 5.3 4.7 Coating Mean 4.9 7. 1 4.9 2.7 3. 1-

4.4 -Shingles 3.9 7-

-

4.2 5.0-

5.0 Coating Mean 4.7 7.0 4.9 2.7 3.3-

4.4 -TABLE VIIEffect of Siding Direction (years to reach rating of 5)

Material Coating

Applied Horizontal Vertical Mean

566 6.3 7 6.7 659 10 4.2 7. 1 788 4. 1 4.3 4.2 842 3.0 3.5 3.3 843 3.3 4.0 3.7 11423 3.0 4.2 3.6 Direction Mean 5.0 4.5

-Mean with 3.9 4.6 -out 659-TABLE VIII

Durability Results of Coatings Applied to Four or More Substrates

(years to reach rating of 5)

Lab. No. Horizontal Horizontal Tempered

of Siding Siding Vertical Hard- Coating

Coating Unsealed Sealed Siding Shingles Plywood board Mean

566 6.3 7.7 7.0 3.9 2.4 3.8 5.2 659 10.0 5.8 4.2 7.0 6.0 8.0 6.8 785 4.5 7.8

-

- 3.4 5.3 5.25 788 4. 1 8.3 4.3-

5.3 6.0 5.6 842 3.0-

3.5-

2.4 2.0 2.7 11423 3.0-

4.2 4.2 2.4 2.9 3.3 TABLE IXEffect of 2 Coats of Sealer (Horizontal Siding) (years to reach rating of 5)

Material Not Sealed Coating

Applied Sealed Mean

566 6.3 7.7* 7.0 659 10.0 5.8 7.9 785 4.5 7.8 6.2 786 4.6 5.6 5. 1 787 4.6 9.2 6.9 788 4. 1 8.3 6.2 Treatment Mean 5.7 7.4

-TABLE XEffect of Exposure Site (years to reach rating of 5)

Material York Coating

Applied Ottawa Redoubt Mean

566 6.3 5. 1 5.7

659 10.0 7.0 8.5

11423 3.0 2.6 2.8

Site

Mean 6.4 4.9

%

SHEATHING

セMRGQX 4" FRAME

u -__SHEATHING

PAPER

TEST PANEL

.--WATER TABLE

(on panels with

vertical siding

J

&.;IIiIo. , - •

-o

Figure 2 . - Different performance of latex paint on same plywood panel. C r a c k i n g and peeling on left quarter; erosion on centre; cracking and erosion on strip at right . (4 years ' exposure)

Figur e 3 . Alk yd enamel on tempered hardboard, a ft e r 6 ye a r s ' e x posu re. (Stre ak s are bru sh hair s l e ft in c oa t ing ).

Figu r e 4. White l e ad in o il o n t emper ed h ardbo ard a ft e r 6 year s' e x pos u re . (Paint r e m a in s only u nder l ap s and few i s ola t ed s pots ).

APPENDIX

AFORMULATION OF COATINGS SUBJECTED TO NATURAL WEATHERING

NRP Number:

566

568

Type:

Oil Paint

Oil Paint

Ingredients

Ib.per

parts by

Ib.per

parts by

100 gal.

*

wt.

100 gal.

wt.

Anatase Titanium Dioxide

-

-

107

6.15

Rutile Titanium Dioxide

200

11. 50

-

-Extended Titanium Dioxide

-

-

321

18.45

White Lead Carbonate

268

15.42

268

15.41

Zinc Oxide

268

15.42

268

15.41

Talc - Asbestine 3X

334

19.21

107

6.15

Bentone 34

4.5

0.26

-

-Aluminum Stearate

-

-

4.5

0.26

Alkali RefinedLinseed Oil

334

19.21

334

19.20

Z-3 Bodied Linseed Oil

143

8.22

143

8.22

Mineral Spirits

175

10.07

175

10.06

24% Lead Naphthenate

6.5

0.37

6.5'

0.37

6% Cobalt Naphthenate

5.5

0.32

-

-6% Manganese Naphthenate

-

-

5.5

0.32

1738.5

100.00

1739.5

100.00

NRP Number:

659

785

Type:

Alkyd Enamel

Alkyd Finish

Anatase Titanium Dioxide

-

-

290

20.06

Rutile Titanium Dioxide

420

33.47

-

-Talc - Ny tal 300

-

-

429.5

29.72

100% Alkyd Resin Aroplaz 1271

-

-

523.5

36.22

70% Alkyd Resin Durap1ex D65A

660

52.59

-

-Mineral Spirits

161

12.83

194.5

13.46

24% Lead Naphthenate

9.6

0.77

4.5

0.31

6% Cobalt Naphthenate

2.8

0.22

0.17

0.01

6% Manganese Naphthenate

-

-

1. 78

0.12

Anti-Skinning Agent

1.5

0.12

1.5

0.10

1254.9

100.00

1445.45

100.00

NRP Number:

842

843

Type:

Lead in Oil

Lead-Zinc in Oil

White Lead Carbonate

1630

70.55

756

38.68

Zinc Oxide

-

-

378

19.34

Talc - Ny tal 300

-

-

126

6.45

Alkali Refined Linseed Oil

500

21. 64

504

25.79

Mineral Spirits

166.5

7.21

176.5

9.03

24% LeadNaphthenate

10.1

0.44

10.1

0.52

6% Cobalt Naphthenate

3.9

0.17

3.8

0.19

2310.5

100.01

1954.4

100.00

A - 2

NRP Number:·f 786 787

Type: Alkyd Modified Pnt Alkyd Modified Paint

Ingredients lb.per 100 gal. parts by lb.per wt. 100 gal. parts by wt. Anatase Titanium Dioxide

Zinc Oxide

Leaded Zinc Oxide Talc - Nytal 300

100% Alkyd Resin - Aroplaz 1271 Alkali Refined LinseedOil

Mineral Spirits 24% LeadNaphthenate 6% Cobalt Naphthenate 6% Manganese Naphthenate Anti-Skinning Agent 171 575 400 238 254 158.5 4.15 0.16 1. 65 1.8 9.48 31. 87 22.17 13.19 14.08 8.78 0.23 0.01 0.09 0.10

175

380 465 256.5 243 165.5 4.25 0.17 1.71 1.7 10.34 22.45 27.47 15.15 14.35 9.78 0.25 0.01 0.10 0.10 1804.26 100.00 1692;83 100.00 NRP Number: Type: 578 Oil Primer 788Isopthalic Alkyd Fin. Anatase Titanium Dioxide

Rutile Titanium Dioxide White Lead Carbonate Talc - Nytal 300 325 Mica

Bentone 34'

100% Isophthalic Alkyd Raw Linseed Oil

Q

Bodied Linseed Oil Z-3 Bodied Linseed Oil Mineral Spirits 24% Lead Naphthenate 6% Cobalt Naphthenate 6% Manganese Naphthenate 4% Calcium Naphthenate 142.5 475 332 501 216 15.2 3.8 1685.5 8.45 28.18 19.70 29.72 12.82 0.90 0.23 100.00 240 60 390 60 3.6 360 120 192 9.6 4.8 2.4 4.8 1447.2 16.58 4.15 26.95 4.15 0.25 24.87 8.29 13.27 0.66 0.33 0.17 0.33 100.00 I + + H l . . . -NRP Number:Type: White Lead Primer

718

Clear Alkyd Sealer White Lead Carbonate

Raw Linseed Oil

60% Alkyd Resin Glyptal G2475 Mineral Spirits 24% Lead Naphthenate 6% Cobalt Naphthenate 960 785 24.4 1769.4 54.26 44.36 1. 38 100.00 350 490 3.5 1.4 844.9 41. 43 57.99 0.41 0.17 100.00

8

Nセ

セN

6 c 4 2 E Posu r es Siding x ts Sealer 2 Coa 3 Coats Over din Ottawa 3 Coats Exposed in Halifaxo Expose 'd'ng • 3 Coats Vertical SI I c 3 Coats on S rf aces Other u on Plywood • 3 Coats Masonite 6 3 Coats on Shingles 6 3 Coats on 2 YEA RS EXPOSURE,

2 Coats Over I-GP-SS Primer • 3 Coats Over White Lead Primer

and 2 Coats Sealer

o 3 Coats I-GP-28 Type B

n 3 Coats on Vertical Siding • 2 Coats 1- GP-28 Type A Over

1- GP-55 Primer 2 3 1 8 9 10 7

Nセ

r..:> z 6 I-セN

« 0:: >-l - S ...J a:> « c:: => 4•

Clo

o

2 4 6 EXPOSURE, YEARS 8 10 1210 9 8 7 セ 6 cc <I: セ 4 o 3 2 1

PVA Over 2 Coats Sealer

.l Acrylic 3 Coats on Siding,Ottawa o Acrylic 3 Coats on Siding,Halifax n Acrylic 3 Coats Vertical Siding

x Acrylic 3 Coats on Shingles

10 8 4 2

o

セッ--:-

セMMMMMMNNNlMMMMMMMNNャNNNMMMMMMMャMMMMMMMMMNj 1212 10 566 Oil Paint • 659 Alkyd Enamel o 785 Alkyd Finish [J 7881sophthalic • 842 Lead in Oil

& 11423 Acrylic Latex

8 6 EXPOSURE, YEARS 4

.---< ;

Nセ

. .

セN

• 0 2 L - ---l - L MlセNMMMMMMMlNMMMMMMMMMMMiMMMMMMMMMMMjo

o

7 2 3 9 8 10 ...l >-f - 5 t.? Z 6566 Oil Paint • 659 Alkyd Enamel o 785 Alkyd Finish n 788 I sophthalic "l 1$42 Lead in Oil • 11423 Acrylic Latex 3 2

セ

0 fJ 0 2 4 6 8 10 12 EXPOSURE, YEARS 1 0 . . . . " . . . - - - , r - - - , - - - . - - - . - - - , - - - , 9 7 8 I -<l: Ct: >-I - 5 <.::> z 6566 Oil Paint • 659 Alkyd Enamel • 786 Oil-Alkyd .842 Lead in Oil

a 843 Lead-Zinc Oil Paint

-.

•

7 9 8 10 c:.::> 6 z l -e:( a::: >-... 5 ....J a::l e:( a::: ;:) 4•

Q-.

3セセ

2-,

o

o

2 4 6 EXPOSURE, YEARS 8 10 1210 Vertical NRP Cedar 9 Si di n g NO. Shingles 566

•

•

659•

0 11423 x 8 0 843 7 <.:l 6 z l --c 0::: >-I - 5 セ co e( 0::: :::l 4 0 Q 3 2o

o

2 4 6 EXPOSURE, YEARS 8 10 1212 10 8 6 EXPOSURE, YEA RS 4 2 8 Horizontal NRP

•

NO. Verticalセ

•

566•

•

c 659 .t.-.

0 788 x 842•

....J10

0

With NRP Without

9 Sealer NO. Sealer

785

•

•

786 ... 0 787 8 0 788 x 7 セ Z I - 6 co::: IX: >l -S ...J co co::: IX: セ 4 0 3 2 12 10 8 6 EXPOSURE, YEARS 4 2ol-

--.l..- ---l ..l.- ----L ----lL- ---'o

8I1U47-IO 2 1 8 6 4 EXPOSURE, YEARS 0 2 0 EFFECT OF SITE FIGURE 6-10 3 NRP HaIi fax Ottawa NO. 566