HAL Id: hal-01726061

https://hal.archives-ouvertes.fr/hal-01726061

Submitted on 7 Mar 2018

HAL is a multi-disciplinary open access

archive for the deposit and dissemination of

sci-entific research documents, whether they are

pub-lished or not. The documents may come from

teaching and research institutions in France or

abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est

destinée au dépôt et à la diffusion de documents

scientifiques de niveau recherche, publiés ou non,

émanant des établissements d’enseignement et de

recherche français ou étrangers, des laboratoires

publics ou privés.

In-situ infrared thermography measurements to master

transmission laser welding process parameters of PEKK

Miguel Villar, Christian Garnier, France Chabert, Valérie Nassiet, Diane

Samélor, Juan Carlos Diez, Andres Sotelo, Maria A. Madre

To cite this version:

Miguel Villar, Christian Garnier, France Chabert, Valérie Nassiet, Diane Samélor, et al..

In-situ infrared thermography measurements to master transmission laser welding process

param-eters of PEKK. Optics and Lasers in Engineering, Elsevier, 2018, vol.

106, pp.

94-104.

To cite this version :

Villar, Miguel

and Garnier, Christian

and Chabert, France

and

Nassiet, Valérie

and Samélor, Diane

and Diez, Juan Carlos and

Sotelo, Andres and Madre, Maria A. In-situ infrared thermography

measurements to master transmission laser welding process parameters of

PEKK. (2018) Optics and Lasers in Engineering, vol. 106. pp. 94-104.

ISSN 0143-8166

Open Archive TOULOUSE Archive Ouverte (OATAO)

OATAO is an open access repository that collects the work of some Toulouse researchers

and makes it freely available over the web where possible.

This is an author’s version published in :

http://oatao.univ-toulouse.fr/19615

Official URL :

https://dx.doi.org/10.1016/j.optlaseng.2018.02.016

Any correspondence concerning this service should be sent to the repository administrator :

tech-oatao@listes-diff.inp-toulouse.fr

In-situ

infrared

thermography

measurements

to

master

transmission

laser

welding

process

parameters

of

PEKK

M.

Villar

a,

C.

Garnier

a,∗,

F.

Chabert

a,

V.

Nassiet

a,

D.

Samélor

b,

J.C.

Diez

c,

A.

Sotelo

c,

M.A.

Madre

ca LGP-ENIT-INPT, Université de Toulouse, 47 Avenue d’Azereix, Tarbes cedex BP1629-65016, France

b CIRIMAT, Université de Toulouse, CNRS, INPT, UPS, ENSIACET-4 allée Emile Monso, Toulouse cedex 4 BP44362-31030, France c Institute of materials science of Aragon, CSIC-University of Zaragoza, Calle de Pedro Cerbuna, 12, Zaragoza 50009, Spain

a

r

t

i

c

l

e

i

n

f

o

Keywords: Assembling process Transmission laser welding Polymeric material PEKK

Infrared thermography Variability test

a

b

s

t

r

a

c

t

Thetemperaturefieldalongthethicknessofthespecimenshasbeenmeasuredduringtransmissionlaserwelding. Polyetherketoneketone(PEKK)isaveryhighperformancethermoplasticwithtunableproperties.Wehaveshown thatthisgradeofPEKKcanbeturnedtoquasi-amorphousorsemi-crystallinematerial,duetoitsslowkinetics ofcrystallization.Itsglasstransitiontemperatureis150°C.Theeffectofitscrystallineratedirectlyimpacts itsopticalproperties:thetransmittanceofquasi-amorphousPEKKisabout60%intheNIRregion(wavelength rangefrom0.4to1.2µm)whereasitislessthan3%forthesemi-crystallinematerial.Theweldingtestshavebeen carriedoutwithan808nmlaserdiodeapparatus.Theheatfieldisrecordedduringtheweldingexperimentby infraredthermographywiththecamerasensorperpendiculartothelasersheetandtothesample’slengthtofocus ontheweldedinterface.Thestudyisdividedintwosteps:firstly,asinglespecimenisirradiatedwithanenergy densityof22J.mm−2:thewholesamplethicknessisheatedup,themaximumtemperaturereaches222±7°C. ThistemperaturecorrespondstoaboutTg+70°C,butthepolymerdoesnotreachitsmeltingtemperature.After that,weldingtestswereperformed:atransparent(quasi-amorphous)sampleastheupperpartandanopaque (semi-crystalline)oneasthelowerpartwereassembledinstaticconditions.Themaximumtemperaturereached attheweldedinterfaceisabout295°Cwhentheupperspecimenisirradiatedfor16swithanenergydensity of28J.mm−2.ThetemperatureattheweldedinterfacestaysaboveT

gduring55sandreachedthemelting temperatureduring5sbeforerapidcooling.Theseparametersaresuitabletoassemblebothpolymericpartsina strongweld.Thisworkshowsthatinfraredthermographyisanappropriatetechniquetoimprovethereliability oflaserweldingprocessofhighperformancethermoplastics.

© 2018ElsevierLtd.Allrightsreserved.

1. Introduction

Highperformancethermoplasticsgraduallyreplacemetallicalloys insomeindustrialfields,suchasaerospaceandpowerelectronics. In-deed,theyattesthighmechanicalstrengthcombinedtoheatresistance higherthan200°Caswellasresistancetocorrosion,withthe advan-tageoflightness.Thelatterresultsinprogresstowardssustainability. Amongthem,thepolyaryletherketone(PAEK)familyhasbeen demon-stratedtobethemostresistanttothermo-oxidativedegradation[1].In particular,polyetherketoneketone(PEKK)withanEther/Ketoneratioof

1

2,keepsaconservativemodulushigherthan1GPauptoitsglass

tran-sition(Tg)atabout150°C.TheadvantageofPEKKisitsslower

crystal-lization,allowingtoeasilyturnPEKKintoamorphousorsemi-crystalline polymer,comparedtowell-knownpolyetheretherketone(PEEK).More

∗ Correspondingauthor.

E-mailaddress:c.garnier@enit.fr(C.Garnier).

knowledgeandknow-howaboutassemblingprocessesofPAEKwould seeminglyleadtowidespreadindustrialuses.

Among assembling processes for thermoplastics, laserwelding is anenvironmentally-friendly,fast,reliableandnon-contactprocess[2]. Weldingbytransmissionrequirestheupperparttobetransparentto thelaserwavelengthwhereastheinferiorpartabsorbsthesame wave-length.Thus,theenergyofthebeamisstoppedattheinterface, allow-ingbothpolymericpartstoheatup.Earlytheoriesonweldingstrength werebasedon diffusion[2].Upon temperature,theinterdiffusionof polymericchainstakesplaceattheinterface,creatingmacromolecular entanglementsbetweenbothparts,resultinginastrongassembly.Laser weldingisinprincipleapplicabletoanythermoplastic,providedthat theupperpartistransparenttothelaserwavelength.Thisprocessis alreadyappliedintheindustrywithcommonpolymerssuchas polycar-bonateandPMMA[3].

Sinceamorphouspolymersarecommonlytransparenttolaserbeam, lasertransmissionweldingisfeasible.Thus,thebeamgoesthroughthe materialwithoutinducingmajorchangesinitschemicalstructure.From aphysical pointof view,a theory todescribetheadhesion of simi-larpolymers,alsocalledautohesion,basedonthediffusionof macro-moleculesaboveTgwasproposedin1960sbyVoyutskii[4]andVanenin

[5].Then,thetheoryofreptationexposedbyDeGennes[6,7]described themotionof polymericchainsandwas successfulin predictingthe molecularweightdependencyoftheself-diffusion.Fromthesetheories, anumberofattemptshavebeenmadeinordertolinktheprocess pa-rameterstotheinterfacialstrengthinweldingprocesses.Amongthem, Wool’smodel[8],predictingthemechanicalenergyrequiredtoseparate twoweldedpolymericpartsasafunctionoftime,pressure,temperature andmolecularweight,appearstobestfittheexperimentaldata.

Weldingasemi-crystallinepolymerisachallenge:mostofthe theo-riespredictingtheinterfacialstrengthdonottakeintoaccounttherole ofcrystallinityonself-diffusionandtheroleofthekineticsof crystal-lization.Moreover,lasertransmissionweldingrequirestheupperpart tobetransparentandtostaytransparenttothelaserbeamallalongthe process.Semi-crystallinepolymerssuchasPAEKareopaqueto visible-nearinfraredlight.Nevertheless,somestudiesgoinsidemore knowl-edgeabouttransmissionlaserweldingofPEEK:Amanatetal.[9]give theparametersrangestogetstrongweldsof250µmthickfilmswith aninfraredabsorbingmediumattheinterface,withapulsedfiberlaser withawavelengthof1060nm.Asaresult,somebubblesaretrappedat theinterface:theexplanationgivenbytheauthorsisthepresenceof wa-terinthespecimens.Potenteetal.[10]weldedundriedandpre-dried PEEK,theynoticedbubblesintheundriedPEEKweldsonly.Sometimes, heatdamagesarereported[9]onamorphousPEEKatapowerof20W withafocalplanespeedof4mm.s−1.Despitethefactthatauthorsagree

abouttheeffectofwater,theprocessparameters,suchaspowerand samplespeed,arenotwelldefinedyet.Additionally,theexperimental studiesoflaserweldingprocesslackconclusivelinksbetweenprocess parametersandtheireffect onassemblies.Forinstance,theeffectof laserpoweronthetemperatureofspecimensisindefiniteuntilnow.

Measuringthetemperaturesinvolvedduringthelaserwelding pro-cessismeaningfulformanyreasons:(a)checkingthatthetemperature reachedishighenoughtoinsureself-diffusionaccordingtoautohesion theoriestogetinterfacialstrength(b)checkingthatthetemperature in-sidethepolymericpartsstayslowenoughtoavoidthermaldegradation ofthematerial,and(c)locatingtheHeat-AffectedZone(HAZ),thelatter haspossiblyundergonemorphologicalchangesandthus,modification ofpropertiesanddimensions.In-situtemperaturemeasurementswould allowgettinginsightthetransmissionlaserweldingprocesstomakeit morereliable.

Measuringthetemperatureattheinterfaceisademandingtask be-causebothpolymericpartsareinclosedcontactallalongtheprocess. So,contact-freetemperaturemeasurementtechniquessuchasinfrared (IR)thermographyhavebeenimplementedtothelaserweldingprocess insomestudies[11–14].Inparalleltotheexperimentalwork,these au-thorshavedevelopedanumericalsimulationtopredictthetemperature attheinterface.Tovalidatetheirmodel,thechosenmaterialsareeither PMMAassemi-transparentelementandABS/PCasabsorbentpartor, inanotherstudy,polycarbonatebasedFRP(fiberreinforcedpolymer). Bothareamorphouspolymers,withwell-knowntransmission,reflection andabsorptionfactorsatnear-andmedium-IRspectrum.Todate,the laserweldingofPEKKhasnotbeenreported,duetothenoveltyofthis high-performancethermoplastic.Also,theoriginalityofthisworkisto weldtwosamplesofthesamepolymertunedintoamorphous(A-PEKK, transparent)andsemi-crystalline(C-PEKK,opaque)state.

AlthoughIRthermographyseemstobesuitedtothetransmission laserweldingprocess,nostudyusesitasatechniqueforcontrolling tem-peraturesdistributionalongthesample’sthickness.Intheexisting stud-ies,measurementswereperformedwiththecamerasensorparallelto theweldedinterface.Withsuchanexperimentalsetup,thetemperature ismeasuredattheupperorlowersurfaceofthepolymericparts.These

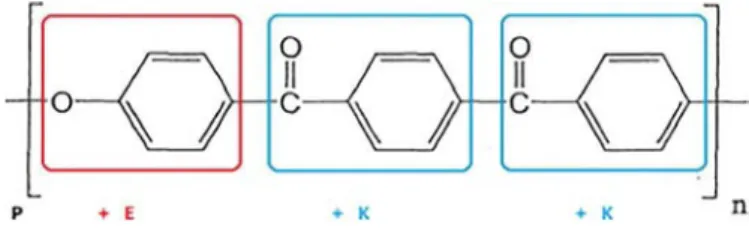

Fig.1. ChemicalstructureofPEKK.

calculated/experimentalresultswereimplementedtonumerical simu-lation,usingahybridcodethatcombinesMietheory[15,16]andthe MonteCarlomethod[17]toquantifythescatteringphenomena.The ex-perimentalandnumericalresultsmatchforthetemperaturesmeasured attheupperandlowersurfaces,nevertheless,thetemperatureatthe interfaceisforecastfromthesemeasurementsbutnotreallymeasured. Withthecamerasensorperpendiculartothelasersheetand perpendic-ulartothesample’slength,thetemperatureattheinterfaceofwelded assemblyisreportedforthefirsttime.

Inthiswork,thefeasibilityofdeterminingthetemperature distri-butionattheinterfacealongthesample’sthicknessduringthewelding processofPEKKisoutlined.Toachievethis,theheatfieldisrecorded byinfraredthermographywiththecamerasensorperpendiculartothe lasersheetandperpendiculartheweldedinterface.Thisstudyisdivided intwosteps:Firstly,atestoflaserbeam/specimeninteractionwas per-formedinordertobringabetterunderstandingoffastheatingeffects duetohighconcentratedpowerlaserspotonasemi-crystallinePEKK. Then,fortheweldingtest,anassemblymadeofamorphousPEKKasthe upperpartandsemi-crystallinePEKKasthelowerpartwasused.The effectsofprocessparametersonthepropertiesofPEKKareexplained.

2. Materialsandmethods

AhighperformancePAEK,thepolyetherketoneketone(PEKK) Kep-stan6002byArkema waschosen.Itschemicalstructureis shownin

Fig.1,itismadeofetherandketonecopolymersin1 2 ratio.

Quasi-amorphousandsemi-crystallinePEKKspecimenswereused fortheweldingtest.Inthefollowing,quasi-amorphousPEKKwillbe re-ferredasA-PEKKandsemi-crystallinePEKKasC-PEKK.Bothspecimens wereprocessedbycompressionmoldingfromdriedpellets.An800kN PinetteEmidecauLAB800Photplatespresswasused;withcontrolled heatingandcoolingtemperaturesfrom2to10°C.min−1.Forcontrolling

thecrystallinerateandplatedimensions,thesamplesweremadeintwo steps.Inthefirststep,thepelletsweremeltedat340°C,slightly com-pressedandcooleddowntoroomtemperature.Thecoolingratewas 2°C.min−1forthecrystallizedsample;andliquidnitrogenwasusedfor

afastcoolingratetogetthequasi-amorphoussample.Inthesecondstep, thesampleswereflattenedupto2mmthickwhileheatingat2°C.min−1

untilglasstransitioninordertoremoveanyresidualstress.The com-pressionmoldedspecimensweredriedduring24hat140°Ctoremove waterbeforewelding.

Transmissionfactorsandreflectionfactorsinthewavelengthrange of400–1100nmhavebeenmeasuredwithaPerkinElmerLambda19 spectrophotometerequippedwithanintegratingsphere.Theincidence beamanglewas8° withrespecttotheperpendiculardirectionofthe samplesurface.Beforetheexperiments,thedevicewascalibratedwith aBaSbackground.Testswereperformedat20°C.

Transmissionfactorsinthewavelengthrangeof3–5µmhavebeen measuredwithaPerkinElmerSpectrumOnespectrophotometerinthe transmissionmode.Theincidencebeamangleis0° withrespecttothe perpendiculardirectionofthesamplesurface.Testswereperformedat 20°C.

DifferentialScanningCalorimetry(DSC)scanswerecarriedoutwith aDSCQ200fromTAInstrumentscalibratedwithindium,startingat roomtemperatureto400°Cwitharampof5°C.min−1.Sampleswere

M. Villar et al. Optics and Lasers in Engineering 106 (2018) 94–104

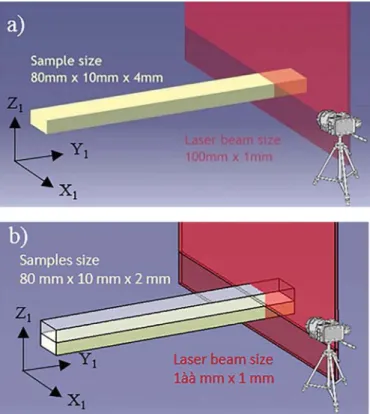

Fig.2. Schemeoftheprojectedlaserbeamonthespecimen,a)singlespecimen, b)assembly.

studiedasprocessed,bykeepingtheirthermomechanicalhistoryof com-pressionmoldingprocess,tobeascloseaspossibletoindustrial condi-tions.Glasstransitiontemperature(Tg),coldcrystallizationtemperature (Tcc)andmeltingtemperature(Tm)wereobtained.Coolingrampswere

performedat2°C.min−1and10°C.min−1from400to20°C.

Crystalliza-tionenthalpyandmeltingenthalpywerecalculatedbyintegrationof theareaoftheexothermicandendothermicpeaksrespectively.

Experimental near infrared laser device performs a continuous 808nmbeam,projectingasingle100×1mm2lasersheet,asrepresented inFig.2.Lasersourceisfedby90diodesbranchedon6stacksof15 diodes.Laserpower issetbydiode feedingintensity,starting power emissionat13Aandreaching230Wfor40A.Nonetheless,poweris spreadoutallalongthelasersheet,soonlyactualirradiatedzonemust beconsideredininteractionforenergycalculations.Eventhoughlaser weldingisusuallyperformedindynamicsetup,statictestswerecarried outforamoreaccurateinterfacialmeasurement,andtosuppress para-siteaccumulativethermaleffectsappearingfordynamiclaserwelding. Infraredtemperaturefieldsmeasurementswereperformedwithan IRcameraCEDIP©JadeIIIMWIRretrofittedFLIR©titaniumSC7200

withathermalresolutionof20mKat30°C.Theuseddetectorisa mid-waveIndiumAntimonide(InSb)oneandthesensoris aclose-upx1 coveringaspectralrangefrom3.70to5.15µmwithafocalplanearray (FPA)windowingof7.6×9.9mm2.Basedonliterature,weassumethe

reflectivityofthematerialsismuchlessthan1[11]andso,thereflection factorisassumedtobe lessthan15%foramorphousspecimens.The detectorresolution is320×256 pixelsandthepitchof thesensoris 30µm.Soon,thepixelsizeonbothdirectionsis0.03mm.Calibration anddatarecordingweremanagedbyAltairsoftware.

Specimenswerelaidout300mmfarfromthecloseupx1sensorto havethebestsharpness.Inordertomeasuretheinterfacialtemperature andthedistributionofthermalfieldalongbothdirections(thicknessand lengthofthesample),side-byrecordingswereperformedscopingthe regionofinterest(Fig.3).Thewholeexperimentsweredoneina25°C inathermoregulateddarkroomtoreduce theeffectofenvironment onIRmeasurement.Withregardtomeasuretherapidtemperaturerise

Fig.3. Infraredareaofinterestofthesamples,a)singlespecimen,b)assembly.

Fig.4. Experimentallaserdevice.

duringlaserirradiation,integrationtimewassetupat16µs,obtaining atemperaturerangefrom140to300°C.IRMovieswererecordedat 125Hzwith5imagesaveragingconducivetominimizingtherandom noise.Soon,theeffectivefrequencywas25Hz.Thewholeexperimental setupisshowninFigs.4and5.

3. Resultsanddiscussion

UnlessthetechniqueofDSCiscontrovertedfortheanalysisofthe crystallinityof PAEKbecauseofthenearnessofmelting and crystal-lization[18],wechooseittocomparethethermaltransitionsofthe quasi-amorphousandcrystallized materialsbecauseof thesimplicity of use.ThethermaltransitionsatthefirstheatingofA-PEKKand

Fig.5. Layoutofinfraredrecordingscene. 50 100 150 200 250 300 350 −1.5 −1 −0.5 Temperature (°C) Heat Flow (mW)

C−PEKK−Annealed at 250°C − Heating 2°C/min A−PEKK−Heating 2°C/min

Fig.6. DSCthermogramofA-PEKKandC-PEKK:firstheatingat2°C.min−1of moldedsamples.

PEKK are seen in Fig. 6. For both materials, the thermograms dis-playaglasstransitionat150°C,whenthemacromolecularchainshave gained enough mobility tomove slightly. Then, for A-PEKK, a cold crystallizationpeakis observed withamaximum at220°C followed byadoublemeltingpeakcenteredat300°C.Theenthalpyof crystal-lization(ΔHc=18.6±0.5J.g−1)islowerthantheenthalpyofmelting

(ΔHmA=20.0±0.5J.g−1) indicating thatthespecimens wereslightly

crystallinebeforetesting,duetothecompressionmoldingprocess.The crystallinerateisusuallygivenby:ΔHm/ΔH100%,assumingΔH100%is 122J.g−1 likefor PEEK [19],itgives aninsignificant rateof 0.01%

foramorphousA-PEKK.ForC-PEKK,nocold-crystallizationoccurs,the coolingrateappliedduringthecompressionprocessisslowenoughto al-lowthemacromoleculestoself-organizedintocrystallinephaseatmost astheycan.TheenthalpyofmeltingisΔHmC=25.6±0.5J.g−1,

corre-spondingto20.9%of crystallinitystillassumingΔH100%=122J.g−1.

SincetheC-PEKKisprocessedwithalongannealingtime,thismelting enthalpyapproachesthemaximumcrystallinityreachedbythisgrade ofPEKK.

Weldingasemi-crystallinepolymerisachallenge,sincetheupper partastostaytransparenttothelaserbeamallalongtheprocess.As soonasthecrystallinerateincreases,anysemi-crystallinepolymerturns transparenttosemi-transparenttoopaqueforhighestcrystallinerates. Itiswellknownthatitispossibletocontrolthecrystallinityby apply-ingacoolingratefasterthanthekineticsofcrystallization.Thisway, PEKKcanbeobtainedastransparentoropaquematerial.Thekineticsof crystallizationisslowforthisgradeofPEKKcomparedtootherPAEK

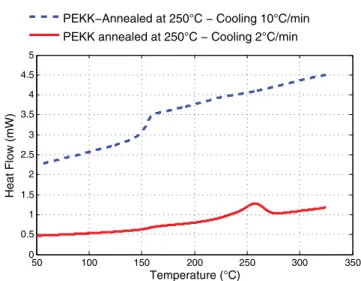

50 100 150 200 250 300 350 0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 Temperature (°C) Heat Flow (mW)

PEKK−Annealed at 250°C − Cooling 10°C/min PEKK annealed at 250°C − Cooling 2°C/min

Fig.7. DSCthermogramofPEKK:coolingrampsfrommeltingstateat380°C.

400 500 600 700 800 900 1000 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 Wavelength (nm) Transmission

C−PEKK

A−PEKK

Fig.8. TransmissionfactorforA-PEKKandC-PEKKmeasuredby spectropho-tometry.

[16],allowingthoroughlycontrollingthecrystallinityalong the pro-cessingsteps.Togofurtherthekineticsofcrystallizationofthisgrade ofPEKK,coolingrampsatvariousrateshavebeenperformed,asseenin

Fig.7.Fromthemeltingstate,nocrystallizationoccurswhenthecooling rateis10°C.min−1orfaster.Theglasstransitionisbroadat150°C.At

M. Villar et al. Optics and Lasers in Engineering 106 (2018) 94–104 400 500 600 700 800 900 1000 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 Wavelength (nm)

Specular + Diffuse Reflection

C−PEKK

A−PEKK

Fig.9. ReflectionfactorforA-PEKKandC-PEKKmeasuredby spectrophotom-etrywithanintegratingsphere.

400 500 600 700 800 900 1000 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 Wavelength (nm) Calculated Absorption

C−PEKK

A−PEKK

Fig.10. Absorbancefactor(𝛼)forA-PEKKandC-PEKK,calculatedwithEq.(1).

3.4 3.6 3.8 4 4.2 4.4 4.6 4.8 5 5.2 5.4 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 Wavelength (µm) Transmission

C−PEKK

A−PEKK

Fig.11. TransmissionfactorforA-PEKKandC-PEKKmeasuredby spectropho-tometry. 0 5 10 15 20 25 140 150 160 170 180 190 200 210 220 230 240 Time (s) Temperature (°C)

0,98

0,96

0,91

0,85

0,80

Fig.12. Impactoftheemissivityratevariabilityonmaximumtemperature.

Table1

Impactoftheemissivityvariabilityontemperaturemeasurements.

Emissivity𝜺 0.80 0.85 0.91 0.96 0.98

Maxtemperature(°C) 232.25 227.55 222.35 218.34 216.81

𝚫T(°C) +9.9 +5.2 – −4.01 −5.54

2°C.min−1,anexothermicpeakindicatesthecrystallization:itcouldbe

interpretedastheorganizationoftheshortestchains,thelatterhaving moremobilitythanthelongestones.Theglasstransition,stillat150°C islessobviouswhenthecoolingrateislower.Asacomparison,the crys-tallinityofPEEKismaximumevenwithacoolingrateof25°C.min−1

[16].

Forthetransmissionlaserweldingprocess,thepolymericmaterial usedastopelementhastobetransparentenoughforthelaserbeamto gothrough.Inthesameidea,thelowerelementoftheassemblyhastobe absorbenttothewavelength.TheopticalpropertiesofbothA-PEKKand C-PEKKhavebeendeterminedinthevisible-nearinfraredrange,from 400to1100nm.Anythermoplasticistransparentwhenamorphousand itturnstoopaquewhenitissemi-crystalline.

TheabsorbanceA𝜆,transmittanceT𝜆andreflectanceR𝜆arelinkedto

theintensityofthelightflux𝜑𝛾

𝜆byEq.(1),where??istfortransmitted

flux,iforincidentfluxandrforreflectedflux: 𝐴𝜆+𝑇𝜆+𝑅𝜆=1 𝑇𝜆= 𝜑𝑡 𝜆 𝜑𝑖 𝜆 𝑅𝜆= 𝜑𝑟 𝜆 𝜑𝑖 𝜆 (1)

Thetransmissivitycoefficientandthereflectivity coefficienthave beenmeasuredusingaspectrophotometerwithanintegratingsphere. Forthesametemperature,thetransmissionfactorisinfluencedbythe surfaceroughness,thelightincidenceangleandthesamplethickness. The results of transmission andreflection are shown in Figs. 8 and

9respectively.ThetransmissionoftheamorphousPEKKisnegligible between 200 and400nm,then, thetransmission factorincreases to reach65±5%atmaximumfor1100nm.Atthewavelengthof inter-est(808nm),thetransmissionfactoris60±5%at20°Cforthe2mm thicksamples.Forthesemi-crystallinesample,thetransmissionisabout 3%alloverthestudiedwavelengthrange.

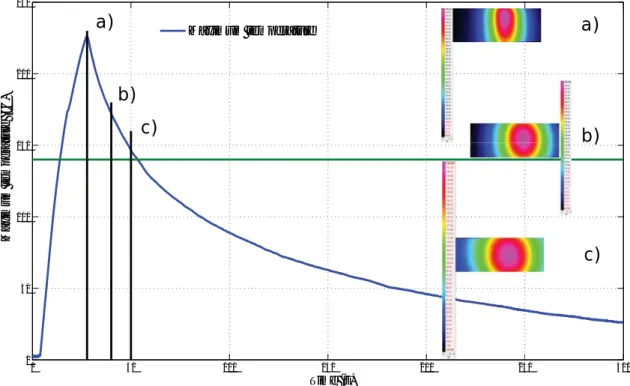

0 50 100 150 200 250 300 0 50 100 150 200 250 Time (s) Maximum temperature (°C) Maximum temperature

a)

b)

c)

a)

b)

c)

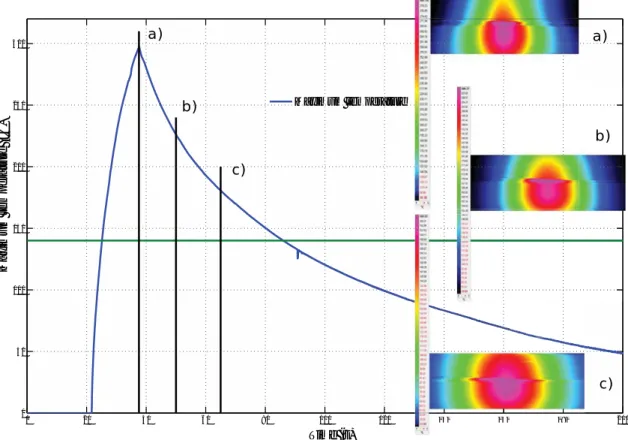

Fig.13. IRthermogramduringandafterirradiation:temperature(°C)versustime(s).Theverticalboldblacklinesindicatethetimewhentheimageswererecorded.

0 2 4 6 8 10 80 100 120 140 160 180 200 220 Distance (mm) Temperature (°C) a) 0 0.5 1 1.5 2 2.5 3 3.5 4 80 100 120 140 160 180 200 220 Distance (mm) Temperature (°C) b)

Fig.14. IRprofilesoftheHAZ– a)AlongYaxis(lengthwise)– b)AlongZaxis(thickness).

Fig.15. Opticalphotographyofthesampleafterlaserbeam/specimen interac-tionexperiments:ontheleft:topview,ontheright:sideview.

Globalreflectionistheadditionofthespecularreflectionanddiffuse reflection.Fortheamorphoussample(A-PEKK),theglobalreflection factorisatmost12%at1000nm.

From the transmission factor and the reflection factor, the ab-sorbancefactor(𝛼)hasbeencalculated.TheresultsareshowninFig.10.

Theabsorbanceiscloseto100%forthelowestwavelengthanddecrease withwavelength.At808nm,theabsorbanceisabout25%.

Tosum up,at 808nm, the transmissionfactor is about 60%for thequasi-amorphoussample, A-PEKKreferred astransparentsample, whereasthetransmissionfactorofthesemi-crystallineC-PEKKisless than3%.Thelatterisconsideredasopaquematerialinthefollowing. Theseresultsconfirmwhatissupposedinotherstudies[21],the reflec-tionfactorisverylow(lessthan12%)comparedtotransmissionand absorptionfactor.

Theblackbodyisoftenusedasareferencefordeterminingthe emis-sivitycoefficientofmaterials.Theblackbodyabsorbslightinthe visi-blewavelengthrangeandtransmitsintheinfraredrange.Despite poly-meremissivitymeasurementshavebeenshowntobehighlyimprecise

[20,21],polymersareusuallyconsideredtohavehighemissivity coef-ficients[12,22],theirbehaviorwithinvisibleandIRrangearecloseto thoseoftheblackbody.DuetothenoveltyofthepolymersofthePAEK family,afewopticalpropertiesareavailableintheliterature. Never-theless,theiropticalpropertiesareexpectedtobethesameasanyhigh performancepolymerinthiswavelengthrange.Toconfirmthis assump-tion,thetransmissionfactorhasbeenmeasured.Thesensorusedfor IRthermographymeasurementscoversaspectralrangefrom3.70to

M. Villar et al. Optics and Lasers in Engineering 106 (2018) 94–104 0 20 40 60 80 100 120 140 160 180 200 0 50 100 150 200 250 300 Time (s) Maximum temperature (°C) Maximum temperature

a)

b)

c)

a)

b)

c)

b)

140 160 180Fig.16. IRthermogramforweldingtest:duringandafterirradiationoftheassembly:temperature(°C)versustime(s).Theverticalboldblacklinesindicatethe timewhentheimageswererecorded.

Fig.17. Photographyoftheweldedsamples:Ontheleft:topviewofthe as-sembly,onthemiddle:sideview,ontheright:bottomviewoftheassembly– dimensionsgiveninmm.

5.15µm.Inthisrange,thetransmissionislessthan5%forA-PEKKand C-PEKK,asseeninFig.11.

Assuminglikeotherauthors[13]thatthereflectionfactorislow,we concludethatthePEKKabsorbsalmostthewholeincidentradiationin the3.70to5.15µmrange.

Thetemperaturecalculatedfromtheinfrared thermography mea-surementsdependsontheemissivityofthematerials.Toestimatethe impact of temperature variation due to theemissivity, a variability testwasundertaken. Theemissivitywassetup as0.91forthe semi-transparentPEKKand0.96fortheopaqueone;thesevaluesarein agree-mentwithpreviousstudies[12,23].Forourvariabilitytest,the emissiv-ityfactorvariesfrom0.8to0.98.Theeffectontheresultingmaximum temperatureisplottedinFig.12.TheresultsarereportedinTable1, where𝜀=0.91ischosenasareference:variationsofthemaximum tem-peraturearewithintherangeof−5.5°C–+9.9°C.Standarddeviation𝜎

andaverageµ ofthisdatasetarerespectively6.44°Cand223.46°C. ThecoefficientofvariationCv,canbecalculatedasfollow:

𝐶𝑣 = (1+ 1 4𝑛

) ×σ

μ (2)

wherenisthepopulation,𝜎isthestandarddeviationandµ isthe av-erage.Withexperimentaldata,Cv is0.03.Duetotheverylowvalue ofCv,thefollowingemissivitycoefficientsarefinallyused:0.91forthe

transparentmaterialand0.96foropaqueone. 3.1. Laserbeam/specimeninteraction

Inordertosetupalltheinfraredmeasurements,experimentswere performedonasinglesample.Laserpower,measuredinWatt,isset dur-ingagiventime(s)uponthespottedarea(mm2)bringsenergydensityin

J.mm−2.Energydensitywas22J.mm−2forthelaserbeam/specimen

in-teractiontests.AnIRmoviewasrecordedusingtheparametersdefined intheexperimentalsection.Alltheimageswereprocessedseekingto matchmeasuredareatothespecimensize.Aplotofthemaximum tem-peratureandthreeimagesatdifferentstepsareprovidedinFig.13to showaqualitativedistributionofthethermalfieldsinthesample thick-ness.

Duetotheintegrationtimeapplied,onlytemperatureabove140°C isconsidered.Thisthermogramconfirmsthatrealirradiationtimelasts about20s.Theheatingrateisveryfast;itiscalculatedat600°C.min−1

inaverage.

Attheendoftheirradiationat22J.mm−2,themaximum

tempera-turereachedis222±7°C.Thistemperatureisabout70°Chigherthan theglasstransitionofthepolymer.Thewholethickness(2mm)ofthe sampleisaffecteduniformlybythetemperaturerise.Theheat-affected zone(HAZ)iswiderinthedirectionparalleltothelaserbeamatthe endoftheirradiation.Assoonastheirradiationisstopped,theHAZ be-comeswiderandwiderduetoheatconduction.Afterirradiation, ther-malwavespropagateperpendicularlytoleadtoahomogeneouscircular

shapeHAZintheobservedplane,attheendoftheexperiment.The cool-ingrateofthesampleis270°C.min−1inthefirst10sanddecreasesto

150°C.min−1 inthefollowing20s.Accordingtotheresultsobtained

byDSC,thetemperaturealongthesample’sthicknesswashigherthan theglasstransition(150°C)during34sforanirradiationof21s.The polymerdoesnotreachitsmeltingpointwiththistimeandpowerof exposure.

ThedimensionsoftheHAZisdeterminedusingprofileonboth di-rectionsfortemperatureabove150°C.InFig.14, bothprofilesbring HAZsize:4mmlengthwiseand4mmallalongthesample’sthickness. Thewholethicknessisthermallyaffected,thatmatcheswithvisual ob-servationinFig.15:theHAZappearsonbothsurfacesofthesample, wheretheaffectedzoneslookbrighterandsmootherthantherestofthe sample.Thesameisobservedontheuppersurfaceofthesample. 3.2. Weldingtests

Afterthetestoflaserbeam/specimeninteraction,IRmeasurements wereperformedduringweldingofacoupleof2mmthickspecimens. A-PEKKwasusedastopelement,C-PEKKforthebottom.Theenergy densitywasdeterminedpreviouslyandfixedat28J.mm−2forthistest.

Theevolutionof themaximum temperatureof theassemblywas recordedduringwelding,stillwiththecamerasensorperpendicularto thelasersheetandperpendiculartothesample’slength.Theresultsare plottedinFig.16,aswellasimagesatdifferentstepsoftheprocessto haveaqualitativedistributionofthethermalfields.

Aspreviously,onlytemperatureabove140°Cisconsidereddueto theintegrationtimeapplied.Realirradiationtimeisabout16s.As ex-pectedintransmissionlaserwelding,theenergyofthebeamisstopped attheinterfacesincethelowerpartisabsorbentat808nm.The max-imumtemperatureduringtheprocessis295±7°Cforanirradiation at28J.mm−2.Thistemperatureisabout140°Chigherthantheglass

transition,andabout20°Chigherthanthebeginningofthemeltingof PEKKoccurringat275°C.Theheatingrateduringirradiationismore than600°C.min−1.Unlikeforthelaserbeam/specimeninteraction

pre-sentedinFig.13,theheat-affectedzoneinthelowersampleis symmet-ricalinbothdirections,alongsideandperpendicularlytothelasersheet, whereastheHAZisstretchedoutintheupperpart.

Whentheirradiationisstopped,thetemperatureinthelowerpart graduallydecreases.Thecoolingrateisabout300°C.min−1thefirst10s

justaftertheirradiationisstopped.ThetimeneededtoreachTgon cool-ingfromthemaximumtemperature(295°C)is42s.Theaveragecooling ratebetweentheirradiationisstoppedandtheTgisabout200°C.min−1.

FromDSCresults,weexpectnocrystallizationofA-PEKKuponcooling, thecoolingrateistoofast.

Uponcooling,theHAZintheupperpartincreases,andmore,the HAZinthelowerparttremendouslystretchesout.Inall,thetemperature attheinterfaceof bothsampleswashigherthantheglass transition during55sandhigherthanthemeltingtemperatureduring5sforan irradiationtimeof16s.

ThephotographyoftheresultingassemblyispresentedinFig.17. ThedimensionsoftheHAZmeasuredfromthesepicturesarein agree-mentwiththedimensionsobtainedbyinfraredimages.

4.Conclusion

Thetemperaturedistributiononthesurfacealongthesample’s thick-nesshasbeenmeasuredduringtransmissionlaserwelding.The origi-nalityofthisworkistoplacethecamerasensorperpendiculartothe lasersheetandperpendiculartotheweldedinterface.Withsuchan ex-perimentalsetup,thetemperaturesattheweldedinterfaceandalong thethicknessofthespecimenshavebeenmeasured.Weareawarethat thetemperaturesmeasuredarenotrepresentativeoftheonesinsidethe sample(xaxis),duetothedifferenceofpropagationofheatwaves in-sidethematerialandinair.Nevertheless,thetemperaturemeasuredon

thesurfaceofassembliesishelpfultolinktheprocessparameters(laser powerandlaserspeed)tothemechanicalstrengthofweldedinterfaces. Forthisstudy,ahigh-performancethermoplastic,PEKKwaschosen, itsglasstransitionwasmeasuredat150°Canditsmeltingrangebetween 275and320°C.Thematerialwasprocessedbycompressionmoldingto getquasi-amorphoussamples,referredasA-PEKKandfullycrystallized, referredasC-PEKK.Theiropticalpropertiesaswellaskineticsof crys-tallizationhavebeenoutlined.Itisthefirsttimethelaserweldingof PEKKisreported.

Thelaser beam/specimeninteractiontestwas performedwith C-PEKKirradiatedat22J.mm−2.Themaximumtemperaturereachedby

thesampleisabout220°Candthetemperaturealongthesample’s thick-nessstaysaboveTgduring34swhentheirradiationsteplasts21s.When

theirradiationisstopped,theheat-affectedzone(HAZ)hasinitiallya longitudinalshapealongthewholethicknessofthesample.Theshape oftheHAZbecomessymmetricalintheobservedplanefor20safterthe irradiationisstopped.

Forthe welding test, anassembly made of a transparent (quasi-amorphous)sampleastheupperpartandopaque (fullycrystallized) sampleasthelowerpartwasused.Themaximumtemperaturereached attheinterfaceisabout295°Cwhentheupperspecimenisirradiated for16swithanenergydensityof28J.mm−2.Thetemperaturealong

thesample’sthicknessstaysaboveTgduring55sandabovethemelting

temperatureduring5s.Thistimeisobviouslyenoughtoallow macro-moleculestoself-diffuseandtocreateentanglements.Indeed,the ob-tainedassemblylooksstrong,althoughnomechanicaltesthasbeen per-formeduntilnow.

ThisgradeofPEKK,withaslowkineticsofcrystallizationissuitable forlasertransmissionwelding.Withtheenergybeamandirradiation timestudied,themaximumtemperatureinsidethesampleiskeptfar fromthedegradationofPEKK.Finally,thelocationandsizeofthe heat-affectedzone(HAZ)havebeendetermined.Thisworkisasteptowards morereliabilityofthelaserweldingprocess.Infutureworks,the in-terfacialstrengthofweldedassemblieswillbestudiedbymechanical tests.

Acknowledgment

TheauthorswouldliketothanktheFrenchMinistryofHigher Edu-cationandResearchforFinancialsupportthroughaPhDfunding.

References

[1] Tarrieu J . Etude et durabilité de solutions de packaging polymère d’un composant diamant pour l ’électronique de puissance haute température PhD Thesis. Institut National Polytechnique de Toulouse; 2012 .

[2] Wise RJ . Thermal welding of polymers. Abington Publishing; 1999. p. 21 . [3] Klein R . Laser welding of plastics. Wiley-VCH; 2012 .

[4] Voyutskii SS . Autohesion and adhesion of high polymers. Wiley; 1963 .

[5] Vasenin RM . Adhesion pressure in the diffusion theory of the adhesion of polymers. Polym Sci U.S.S.R 1962;3(4):608–15 .

[6] De Gennes PG . Comptes Rendus de l’Académie des Sciences 1980;B291:219–21 Paris (in French) .

[7] De Gennes PG . Reptation of a polymer chain in a presence of fixed obstacles. J Chem Phys 1971;55(2):572–9 .

[8] Wool RP , Yuan BL , McGarel OJ . Welding of polymer interfaces. Polym Eng Sci 1989;29(19):1340–67 .

[9] Amanat N , et al. Transmission laser welding of amorphous and semi-crystalline polyetheretherketone for applications in the medical device industry. Mater Des 2010;31:4823–30 .

[10] Potente H , et al. Investigations towards application of a new technique on laser transmission welding. Weld World 2001;45(5-6):15–20 .

[11] Ilie M , et al. Through-transmission laser welding of polymers – field modeling and infrared investigation. Infrared Phys Technol 2007;51:73–9 .

[12] Speka M , et al. The infrared thermography control of the laser welding of amorphous polymers. NDT&E Int 2008;41:178–83 .

[13] Akué Asséko A , et al. Laser transmission welding of composites-part A: thermo-phys- ical and optical characterization of materials. Inf Phys Techol 2015;72:293–9 . [14] Akué Asséko A , et al. Laser transmission welding of composites-part B: experimental

validation of numerical model. Inf Phys Techol 2015;73:304–11 .

[15] Gouesbet G , Gréhan G . Generalized Lorenz–Mie theories, from past to future. Atomic Sprays 2000;10(3–5):277–334 .

[16] Gouesbet G , Gréhan G . Generalized Lorenz–Mie theories for assemblies of spheres and aggregates. J Opt 1999;1:706–12 .

M. Villar et al. Optics and Lasers in Engineering 106 (2018) 94–104 [17] Blanca CM , Saloma C . Monte Carlo analysis of two-photon fluorescence imaging

through a scattering medium. Appl Opt 1998;37(34):8092–102 .

[18] Jonas A , Legras R , Issi JP . Differential scanning calorimetry and infrared crystallinity determinations of poly(aryletheretherketone). Polymer 1991;32(18):3364–70 . [19] Mehmet-Alkan AA , Hay JN . The crystallinity of poly(ether ether ketone). Polymer

1992;33(16):3527–30 .

[20] Becker F . A step towards understanding the heating phase of laser transmission weld- ing in polymers. Polym Eng Sci 2002;42(2):365–74 .

[21] Van de Ven J , Erdman A . Laser transmission welding of thermoplastics – part II: experimental model validation. Manuf Sci Eng 2007;129:859–67 .

[22] Ilie M , et al. Laser beam scattering effects in non-absorbent inhomogenous polymers. Opt Lasers Eng 2007;45:405–12 .

[23] Cosson B , et al. Infrared heating stage simulation of semi-transparent media (PET) using ray tracing method. Int J Mater Form 2011;4(1):1–10 .

M. Villar is a mechanical engineer with a specialization in materials science, thermal and energy technologies. After being involved in some industrial projects, he went on to develop his scientific profile with a PhD thesis in Polymer Physics. His PhD thesis topics apply the transmission laser welding to assemble a new kind of polymer of the PAEK family. For the time being, the works he has accomplished covers the thermal, optical and mechanical characterization of materials and processes.

C. Garnier has been graduated by the National Engineering School of Tarbes. In 2011, he defended his PhD thesis untitled “Dynamic Behavior of LRI’s composite structures: application to impact and fatigue ”. In 2013, he joined the Laboratory of Manufacturing Engineering in Tarbes, part of the University of Toulouse, France, as associate professor. His research interests include all aspects of composite materials (manufacturing, behavior, FEM, inspection, tests). His research specially focuses on composite material behavior in static, fatigue and multiaxial fatigue, on experimental mechanics and on thermal fields measurements.

F. Chabert obtained a PhD degree in Materials and Process Engineering in 2004 at the Institut National Polytechnique of Grenoble – France in the field of materials for fuel cells. She worked as postdoctoral fellow successively at the Chemical Engineering Department at the University of Melbourne, Australia and ESPCI Paristech, France. Since 2010, she is a teacher-researcher at the Interface and Functional Materials group of the Laboratory of Manufacturing Engineering in Tarbes, part of the University of Toulouse. Her research focuses on polymer processing, assembling processes for thermoplastics as well as nano and micro-composites with controlled properties. She has co-authored 4 patents and 15 scientific articles.

V. Nassiet is Professor of materials engineering at the National Engineering School of Tarbes (ENIT) since 2012. She graduated with a Ph.D. in Physics from the UPPA University, France, in 1995. Associate Professor from 1997 to 2012 at the Laboratory of Manufacturing Engineering in Tarbes, part of the University of Toulouse, she holds a habilitation thesis (HDR) at the Institut National Polytechnique of Toulouse, France. Her research interests focus on the physical, chemical and mechanical properties of adhesive interfaces in multi-materials and on interface durability. The main aim is the establishment of reliable relationships between the polymeric (adhesive or resin matrix) structure and its properties such as mechanical, rheological, thermal and adhesives into the interface.

D. Samélor has been graduated in Materials Engineering by Evry-Val-d’Essonne University in 2001. She completed her Masters with specialization on methods of preparation and characterization of thin films in the same university in 2002. In 2003, she joined the CIRIMAT laboratory in Toulouse as an engineer. Her activities are focused on preparation of ceramics, metals and composites by Metal Organic Chemical Vapor Deposition (MOCVD) and characterization of the coatings by conventional or more specific techniques.

J. C. Diez teaches at the University of Zaragoza ’s School of Engineering and Architecture (Department of Materials Science). He holds a Physics Degree and Ph.D. from the University of Zaragoza. Since 1989 he teaches in this University, in subjects mainly related with General Physics, Materials Science, Technology of Ceramics and Materials Laser Processes. He is mainly interested on the use of laser technology to improve the properties of functional ceramics (HTc superconductors and thermoelectric oxides). He has also experience in the use of laser radiation on metals, polymers, and composite materials, especially on the mold sector and in aeronautic applications.

M. Villar et al. Optics and Lasers in Engineering 106 (2018) 94–104

A. Sotelo had his Doctoral degree in Chemistry at the Universidad de Zaragoza in 1994. He has got a two ‐years postdoctoral position at Max ‐Planck Institute for Metals Research in Stuttgart (Germany) in 1995. In 1997 he got two years Marie Curie grant in CRISMAT Laboratoire, Caen (France). From 2000 he is Professor at the Universidad de Zaragoza in the Department of Materials Science. He has published more than 135 scientific articles and book chapters, most of them related to thermoelectric and superconducting ceramics with emphasis on laser processing techniques.

M. A. Madre has been graduated in Chemistry by the University of Zaragoza. She has got Ph.D. in Engineering by the Universidad de Zaragoza with qualification: Cum Laude with Extraordinary Doctorate Award. Since 1991 she is University Professor at the Dpt. Materials Science in the School of Engineering and Architecture. Her research interests include aspects of: Thermoelectric and superconducting ceramics. Texturing of ceramics by laser techniques, laser appliances in other fields, solution chemical synthesis techniques, and mechanical properties. She has published more than 110 scientific articles and book chapters.