Computational Improvements to Predict Propeller Performance at Off Design

Conditions

by

William E. Duncan

B.S., Naval Architecture and Marine Engineering, U.S. Coast Guard Academy, 1996

Submitted to the Departments of Ocean Engineering and Mechanical Engineering in partial fulfillment of the requirements for the degrees of

Master of Science in Naval Architecture and Marine Engineering and

Master of Science in Mechanical Engineering at the

Massachussets Institute of Technology JUNE 2002

C 2002 William E. Duncan. All rights reserved.

The author hereby grants to MIT permission to reproduce and to distribute publicly paper and electronic copies of this thesis document in whole or in part.

Signature of A uthor... .... .... Department of Ocean Engineering and Mechanical Engineering

May 10, 2002 Certified by ... ... ...

David V. Burke Senior Lecturer, epartment of Ocean Engineering Thesis Supervisor Read by... Ain A. Sonin anical Engineering Thesis Reader A ccepted by ... ... . ... ... Henrik Schmidt ssor of Ocean Engineering Chairman, Committee on Grad ts for Ocean Engineering Accepted by ...

Ain A. Sonin Professor of Mechanical Engineering Chairman, Committee on Graduate Studies for Mechanical Engineering

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

Computational Improvements to Predict Propeller Performance at Off Design Conditions

by

William E. Duncan

Submitted to the Department of Ocean Engineering and the Department of Mechanical Engineering in partial fulfillment of the requirements for the degrees of Master of Science in Naval Architecture and Marine Engineering and Master of Science in Mechanical Engineering.

Abstract

The purpose of this thesis is to modify an existing computational method to predict performance for the 4119 propeller at off design conditions. The 4119 propeller is a conventional three bladed propeller without skew. The existing computational method used is an Euler/Integrated Boundary Layer Theory (IBLT) axisymmetric flow solver coupled with a propeller lifting

surface design and analysis program. Presently, the coupling will converge to realistic thrust and torque coefficients at advance coefficients between 0.7 and 1.1. The modified procedure

outlined in this thesis can predict thrust and torque coefficients down to an advance coefficient of 0.3, however, the results are lower than expected from model tests. An error analysis is included to identify reasons for the low thrust and torque coefficients.

Thesis Supervisor: David V. Burke

Acknowledgments

Table of Contents

1 Introduction 12

1.1 Overview 12

1.2 Propeller Blade Design (PBD) Theory 12

1.3 MTFLOW 15

1.4 Coupling PBD with MTFLOW 15

1.5 Purpose 16

2 Identifying the Problem at Low Advance Coefficients 17

2.1 Overview 17

2.2 MTFLOW Grid 18

2.3 PBD Wake 18

2.4 Input Swirl to MTFLOW 19

2.5 Results 21

3 Concentrating the streamlines with a Foil 22

3.1 Overview 22

3.2 Guidelines to an Optimum MTFLOW Grid 22

3.3 Examples 23

3.4 Using a Longer Chord 25

3.5 Axial Velocity Around Foil 26

4 Case I, Blade Grid is Fixed 27

4.1 Overview 27

4.2 Grid 27

4.3 Artificial Modifications 28

4.4 Effective Velocity 30

5 Case II, Blade Tip Follows Trailing Edge 31

5.1 Overview 31 5.2 Grid 31 5.3 Procedure 32 5.4 Swirl Input 33 5.5 Verification 34 6 Error Analysis 35 6.1 Overview 35 6.2 PBD Error 35 7 Conclusion 37 7.1 Summary of Results 37

7.2 Recommendations for Future Work 37

A Input Files to PBD/MTFLOW Coupling 38

A. 1 Walls File without Foil and Hub 38

A.2 Walls File with Foil and Hub 39

A.3 Batchfile 40

A.4 Vel.in 41

A.5 Mtcouple.inp 42

A.6 PBD Admin file 42

A.7 MTFLO 43

A.8 MTSOL 43

C Changes made to PBD2MT Source Code 47

D PBD Admin. File for PSF-2 Convection Velocities 50

List of Figures

Page

1.1 B-Spline Grid 13

1.2 Horseshoe Element 14

2.1 Kt, 1OKq Vs. Advance Coefficient 17

2.2 Blade and MTFLOW Grid, J=0.4 18

2.3 Blade and MTFLOW Grid, J=0.833 18

2.4 Blade and Transition Wake, J=0.833 19

2.5 Blade and Transition, J=0.4 19

2.6 PBD Input Swirl Contour Lines, J=0.4 19

2.7 PBD Input Swirl Contour Lines, J=0.833 19

2.8 Blade and MTFLOW Grid, J=0.833 20

2.9 Blade Boundary and MTFLOW Grid, J=0.4, Ifix=1 20

3.1 MTFLOW Grid x-0.001 24

3.2 MTSOL grid E = 0.900 24

3.3 MTSOL grid E = 0.600 24

3.4 MTFLOW Grid e=0.4 24

3.5 Blade and MTFLOW Grid 25

3.6 Blade and MTFLOW Grid 25

3.7 Hub and Blade in MTFLOW Grid 25

3.8 MTSOL Grid E=0.900 25

3.9 Foil in MTFLOW Grid 26

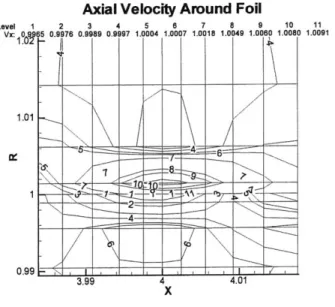

3.10 Axial Velocity Around Foil 26

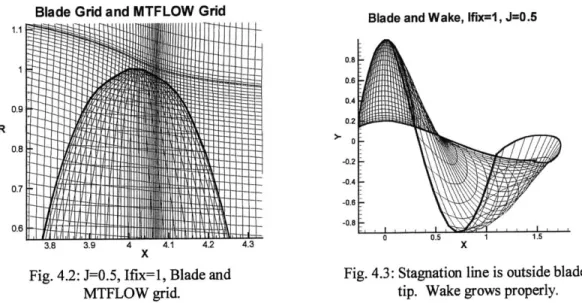

4.2 Blade Grid and MTFLOW Grid 28

4.3 Blade and Wake, Ifix=l, J=0.5 28

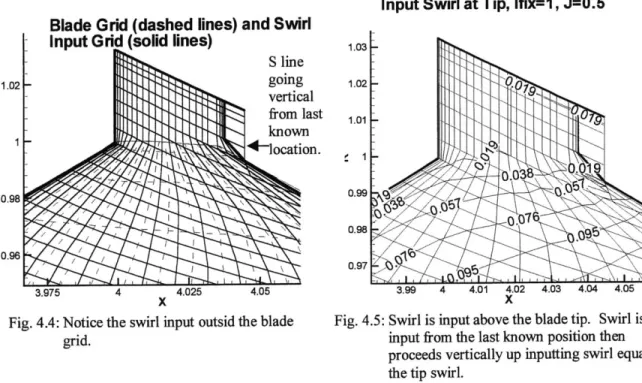

4.4 Blade Grid and Swirl Input Grid 29

4.5 Input Swirl at Tip, Ifix=1, J=0.5 29

4.6 Effective Velocity, Ifix=1, J=0.5 30

5.1 Kt, lOKq Vs. J, Ifix = 0 31

5.2 Blade and MTFLOW Grid, Ifix=O, J=0.4 32

5.3 Blade and MTFLOW Grid, Ifix=0, J=0.4 33

5.4 Swirl Input, Ifix=O, J=0.4 33

5.5 Swirl Input Locations to Blade, Ifix=0, J=0.4 33

5.6 Blade and Wake, Ifix=0, J=0.4 34

Page

22 24 25 36List of Tables

3.1 Guidelines to Concentrate Streamlines 3.2 Foil and MTSET values

3.3 X and R values for Foil

Nomenclature

A B D h Vs nD T Kt T pn2D4 Kq 2 pn2 D5 m n n p q R S To V r V o (Veffective) (Vinsced)cross sectional area field parameter propeller diameter enthalpy advance coefficient thrust coefficient torque coefficient

mass flow rate

surface normal vector

propeller rotation rate rev sec pressure meridional speed radial coordinate entropy field parameter velocity

swirl, tangential velocity effective velocity

VS ship velocity

(Vtotal) total velocity

AH enthalpy addition AS entropy addition AW work addition IF circulation p fluid density Yf free vorticity rad

blade rotation rate ---Ssec)

Chapter 1

Introduction

1.1 Overview

The purpose of this research was to use computational techniques to predict propeller

performance at low advance coefficients. The computational techniques used is a propeller blade design (PBD) lifting surface code (developed by Kerwin' et al) coupled with an axisymmetric through flow solver called MTFLOW (developed by Drela2). The history of this type of an

analysis started with a Reynolds Average Navier Stokes (RANS) method coupled with a lifting surface code. The RANS coupling proved to be computationally inefficient and required significant user experience. The coupling with PBD and MTFLOW proved to be robust and efficient but only for advance coefficients near design.

1.2 Propeller Blade Design (PBD) Theory

PBD is a lifting surface method to determine the resultant distribution of force on a propeller blade, hub and duct. The mathematics used to determine the force starts with identifying the kinematic boundary condition which states that the flow normal to a surface is zero (1.1).

1Justin E. Kerwin, Professor Emeritus of Naval Architecture, Ocean Engineering Department, MIT.

V-n=O (1.1) Next step is to identify the types of flow around a propeller. There are four types:

Total flow (Vot&a): total velocity with the propeller operating.

Effective flow (Veffective): "total time-averaged velocity in the presence of the propeller minus the

time-average potential flow velocity field induced by the propeller itself." [5]

Induced flow (Vinduced): induced velocity by the propeller and trailing wake vortex

distributions.

Nominal flow: velocity in the region of the propeller with the propeller not operating. The effective flow and the induced flow are not physical velocities that may be measured. The total flow is divided into effective and induced flow for computational purposes. PBD analyzes

the forces using the effective flow. The total velocity equals the effective plus the induced velocity (1.2).

(Vtota) =(Veective) + (Vinduced (1.2)

For inviscid flow there is zero vorticity in the inflow. Therefore, the induced velocity from the propeller can not interact with zero vorticity in the inflow. This results in the unique case when the effective velocity equals the nominal velocity. The cases analyzed in this thesis are inviscid, thus, the relationship between nominal and effective flow is used to verify the accuracy in the MTFLOW/PBD coupling.

The propeller blade, hub and duct are identified using B-Spline surfaces. B-Spline B-Spline Grid

surfaces are ideal due to the normal vector from the surface and the curvature can be uniquely defined everywhere on

0.7

the surface. In defining the surface, the user can choose an 6 0.5:

appropriate grid density to accurately capture the forces. 0.4 0.3

0.2 -0.2 0 0.2 0.4 0.6

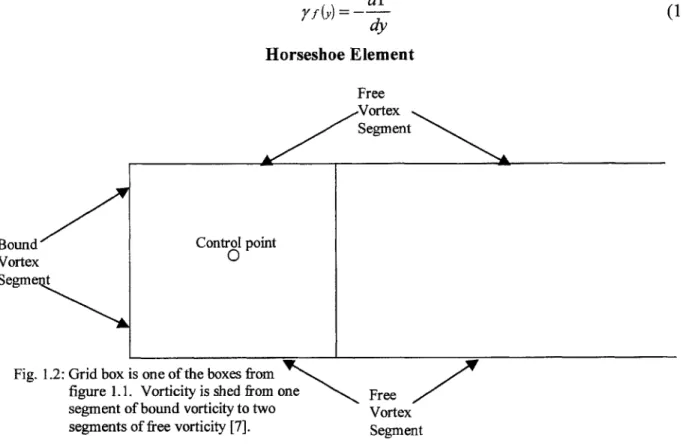

Figure 1.1 uses a blade grid density of 10 X 10, but the cases analyzed in this thesis use a density of 25 X 25. Contained within each grid box PBD calculates the position of a control point. Along each grid segment PBD assigns a constant-strength bound vortex. Also, PBD assigns a coincident line source to account for thickness. From each bound vortex segment vorticity must be shed in the flow (then to the wake) as free vorticity to stay consistent with Kelvin's Theorem (1.3). The bound vorticity shedding to free vorticity can be visualized as a horseshoe element (figure 1.2). dF rf(y) - (1.3) dy Horseshoe Element Free Vortex Segment

Bound Control point

Vortex 0

Segme t

Fig. 1.2: Grid box is one of the boxes from

figure 1.1. Vorticity is shed from one Free segment of bound vorticity to two Vortex segments of free vorticity [7]. Segment

An influence matrix is developed by calculating the distance from every control point to every bound and free vortex segment. The induced velocity at every control point is then calculated by multiplying the influence matrix by the vortex segment strength matrix (1.4).

[ INF] [I-] =Vi.uced (1.4)

[[INF] i] +Veecte -n =0 (1.5)

From equation 1.5, the resultant distribution of force on the blade can be calculated using Kutta-Joukowski's and Lagally's theorems [1].

1.3 MTFLOW

MTFLOW consists of three programs; MTSET, MTSOL and MTFLO. MTSET reads a geometry or walls file and generates an initial grid (Appendix A. 1, A.2). MTSOL then solves the Euler equations. MTFLO manages the input and output data from MTSOL (data in this thesis is location and magnitude of tangential velocity or swirl and drag). The programs provide an inviscid/viscous analysis and design capability for axisymmetric bodies. The theory is based on the conservation of mass, energy and momentum to solve for the total velocity everywhere in the flow field [2].

1.4 Coupling PBD with MTFLOW

PBD by itself is limited to inviscid open propeller cases because the user can assume the effective velocity is equal to the nominal velocity. To expand PBD's capability, it is usually coupled with a through flow solver. The MTFLOW/PBD coupling procedure used in this thesis was completed in reference [4] and [11]. It uses an iterative process between MTFLOW and PBD to converge to the correct thrust coefficient, Kt, and torque coefficient, 1 OKq, for a

particular advance coefficient. Essentially, MTFLOW passes the total velocity field to PBD, and PBD inputs the tangential velocity and drag due to the blade, hub and duct. MTFLOW, then, re-computes the total velocity field. This process is repeated until convergence. Appendix A outlines the input files for the PBD/MTFLOW couplings used in this thesis.

In addition to the MTFLOW and PBD programs, this thesis focuses on the coupling code PBD2MT. PBD2MT inputs the swirl and drag from PBD to MTFLOW.

1.5 Purpose

The following thesis presents two methods of how to converge the PBD and MTFLOW coupling at low advance coefficients for the 4119 propeller. The 4119 propeller is a three bladed propeller without skew. Data about the 4119 propeller has been extensively documented, therefore, it is used to validate the PBD/MTFLOW coupling. The converged solutions at low advance

coefficients resulted in the thrust and torque coefficients being lower than expected from model tests. An error analysis is included to identify reasons for the low thrust and torque coefficients.

Chapter 2

Identifying the Problem at Low Advance

Coefficients

2.1 Overview

The coupling between PBD and MTFLOW will converge to the correct Kt and 1 OKQ for advance coefficients near design.

Kt, I OKq Vs. Advance Coefficient

Figure 2.1 shows the close

0.5

-correlation of Kt and IOKq results 5Model Test

10 10Kq,Model Test

Kt 0.4 IL KtCoupled no fbil

for advance coefficients between 0.7 K 1 Oq,Coupled nofoit

10Kq _

and 1.1 [4,11]. There are two Kt

problems at low J. First, the grid in 0.2

MTFLOW is too coarse to accurately

model the flow around the tip. %.3 0 0 0 0 0 0 2 Advance Coefficient J

Second, PBD2MT does not accurately input Fig. 2.1: Kt/IOKq results for

existing coupling routine. swirl and drag from PBD coordinates to

MTFLOW coordinates. The streamlines moving when running MTSOL also presents a problem with swirl and drag input.

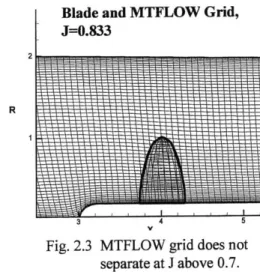

2.2 MTFLOW Grid

The coarse MTFLOW grid results in three types of program failures. First, the grid separates as shown in figure 2.2. In this case, the streamlines are not able to adjust sufficiently to follow the flow. As a comparison, figure 2.3 shows the grid uniformity required for MTSOL to converge. Second, MTSOL will crash when the streamlines cross. The streamlines usually cross at a J well below design (J<0.4). The streamlines try to go more vertical to follow the flow and

subsequently cross. A final way MTSOL crashes is when the grid is over-constrained. An indication of an over-constrained grid is the addition of artificial entropy added to MTSOL to converge the Euler equations. MTSOL will converge if the artificial entropy approaches zero.

Blade and MTFLOW Grid,

Blade and MTFLOW Grid, J=0.4 J=a.833

1.5 R

R

0.5

3 4 5 3 V4 5

xV

Fig: 2.2: MTFLOW grid Fig. 2.3 MTFLOW grid does not

separates at low J. separate at J above 0.7.

MTSOL crashes if the artificial entropy approaches infinity. 2.3 PBD Wake

The wake is unable to grow properly downstream as a result of the MTFLOW grid separating. Figure 2.5 shows the resulting wake when the grid separates. As a comparison, Figure 2.4 shows a wake growing properly downstream.

Blade and Transition J=0.4

Blade and Transition Wake, J=0.833 0.a5 1 1 0.5 Y 0 -0.25 -0.5 -0.75 x Fig. 2.4 Wake follows the

streamlines.

x

Fig. 2.5 Wake can not follow the streamlines.

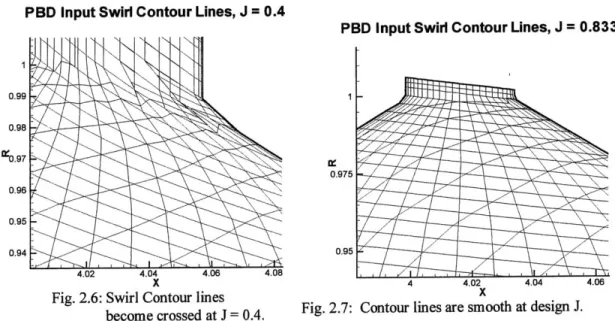

2.4 Input Swirl to MTFLOW

The second problem that causes the coupling not to converge at low J is the program PBD2MT

PBD Input Swirl Contour Lines, J = 0.4

PBD Input Swirl Contour Lines, J = 0.833

0.975

0.95

4.02 4.04

X

Fig. 2.6: Swirl Contour lines become crossed at J= 0.4.

4.02

Fig. 2.7: Contour lines are smooth at design J.

not accurately inputting swirl and drag from PBD coordinates to MTFLOW coordinates. Figure 2.6 illustrates how the contour lines become scrambled at low J. As a comparison, figure 2.7

illustrate the smooth contour lines at design J. The method that PBD2MT inputs swirl to

MTFLOW is not robust. PBD2MT labels the horizontal MTFLOW streamlines as t lines and the vertical blade grid lines as s lines (figure 2.8). It inputs swirl by following a constant s line until

US 0.5 025 1 0.99 0.98 50.97 0.96 0.95 0.94 Y I 1-5 4.06 4.08 4.04 4.06

1 .

R

0

0

Blade and MTFLOW Grid, J = 0.833

Notice the jump in streamlines

between inside and outside the

blade

9

Streamlines Vertical blade

.8 in M TFL OW lines are s

are t lines lines

.7

3.7 3.8 3.9 4 4.1 4.2 4.3

x Fig. 2.8: Blade grid and MTFLOW grid

it finds a t line within the blade grid. When it finds a t line it inputs the given swirl from PBD to that location in MTFLOW. This process is repeated until all the t lines within the blade have inputted swirl. If following an s line and not finding a t line within the blade, the program jumps to the next t line above the blade (figure 2.8). At that location the swirl is input equal to the swirl at the blade tip. This process would work Blade Boundary and MTFLOW Grid, J= 0.4

Ifix

=I

fine if the streamlines stayed perfectlyhorizontal and the MTFLOW grid had dense streamlines at the tip. Two

R-problems develop when the streamlines

The constant s

line crosses a t are not horizontal and the MTFLOW grid 0.95 line twice. is coarse at the tip. First, at low J

the streamlines become more vertical. 4 4.05 4.1

x

This causes streamlines (t lines) to cross s Fig. 2.9: Blade grid boundary and MTFLOW grid. lines twice (Figure 2.9). The program can

only input one value of swirl for every s and t coordinate, therefore, the second crossing of the s line does not receive an input swirl value. This causes the swirl contour lines to cross. The second problem is the jump from inside the blade to outside the blade. A coarse MTFLOW grid near the blade tip will cause the swirl contour lines to jump because the space between t lines is too great.

The movement of streamlines with each iteration also presents a problem with swirl and drag input. After PBD2MT inputs the swirl and drag, MTSOL converges the total velocity field. During the MTSOL convergence the streamlines contract, therefore, the original input from PBD2MT changes with the contracting streamlines. This results in PBD obtaining a skewed inflow, and PBD will output a skewed distribution of swirl and drag.

2.5

Results

The result of the MTFLOW grid separating, the wake not able to follow the streamlines, the method that PBD2MT inputs swirl and drag to MTFLOW and the streamlines contracting after receiving swirl and drag from PBD2MT is the PBD/MTFLOW coupling not converging.

Chapter 3

Concentrating the Streamlines with a Foil

3.1 Overview

A small, artificial foil is used to concentrate the streamlines at the blade tip to keep the

streamlines from separating. The foil allows the user to test the ability of MTFLOW to converge with concentrated streamlines without re-writing the MTFLOW source code. The foil is created

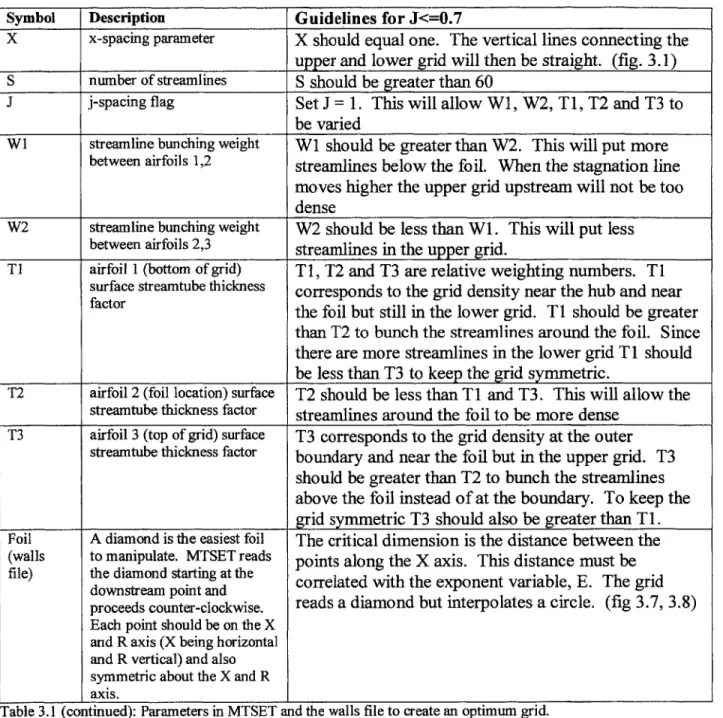

such that MTFLOW only identifies the leading and trailing edge. During convergence at low J, the leading and trailing edge move to stay inline with the flow. Table 3.1 outlines the parameters

in MTSET and the walls file to create an optimum MTFLOW grid. MTFLOW source code was modified to output the grid above the foil (Appendix B).

3.2 Guidelines to an Optimum MTFLOW Grid Symbol Description Guidelines for J<=0.7 N number of streamwise grid N should be greater than 150

points

E exponent for airfoil side E must be correlated with the size of the foil. For a

points: n = N*chord given foil if:

(fig. 3.2, 3.3, 3.4) E is too large - mtsol will only grid the leading edge E is too small - mtsol output grid includes the foil E just right - mtsol will grid the leading and trailing

edges and the output file will not grid the foil Table 3.1: Parameters in MTSET and the walls file to create an optimum grid.

Symbol Description Guidelines for J<=0.7

X x-spacing parameter X should equal one. The vertical lines connecting the upper and lower grid will then be straight. (fig. 3.1) S number of streamlines S should be greater than 60

J j-spacing flag Set J = 1. This will allow WI, W2, T1, T2 and T3 to

be varied

W1 streamline bunching weight Wi should be greater than W2. This will put more between airfoils 1,2 streamlines below the foil. When the stagnation line

moves higher the upper grid upstream will not be too dense

W2 streamline bunching weight W2 should be less than Wi. This will put less between airfoils 2,3 streamlines in the upper grid.

TI airfoil 1 (bottom of grid) TI, T2 and T3 are relative weighting numbers. TI surface streamtube thickness corresponds to the grid density near the hub and near factor the foil but still in the lower grid. TI should be greater

than T2 to bunch the streamlines around the foil. Since there are more streamlines in the lower grid Ti should be less than T3 to keep the grid symmetric.

T2 airfoil 2 (foil location) surface T2 should be less than TI and T3. This will allow the streamtube thickness factor streamlines around the foil to be more dense

T3 airfoil 3 (top of grid) surface T3 corresponds to the grid density at the outer

streamtube thickness factor boundary and near the foil but in the upper grid. T3 should be greater than T2 to bunch the streamlines above the foil instead of at the boundary. To keep the grid symmetric T3 should also be greater than TI. Foil A diamond is the easiest foil The critical dimension is the distance between the (walls to manipulate. MTSET reads points along the X axis. This distance must be file) the diamond starting at the correlated with the exponent variable, E. The grid

downstream point and

proceeds counter-clockwise. reads a diamond but interpolates a circle. (fig 3.7, 3.8)

Each point should be on the X and R axis (X being horizontal and R vertical) and also symmetric about the X and R

axis.

Table 3.1 (continued): Parameters in MTSET and the walls file to create an optimum grid.

3.3 Examples

The following Tables and Graphs illustrate the guidelines outlined in Table 3.1. All graphs use values identified in Table 3.2 unless otherwise noted.

X R Symbol Value 4.001 1.0 N 200 4.0 1.001 E 0.900 3.999 1.0 X 1.000 4.0 0.999 S 60 4.001 1.0 J 1 W1 0.700 W2 0.500 TI 0.500 T2 0.050 T3 0.700 Table 3.2 Foil

MTSOL

Grid

E

=

0.900

Fig. 3.2: MTSOL will crash because the trailing edge does not

cross a grid line. E needs to

be smaller. Foil

Fig. 3.3: MTSOL will converge. Trailing edge does cross a grid line.

w Grd e=0.4

Fig. 3.4: E is too low. MTSOL output file is gridding a portion of the foil.

1.01 Streamlines will cross as flow goes

around foil to blade D~an -&06 4 4.005 Foil

MTSOL

Grid

E

=0.600

MTSET I I 2.5[

MTFLOW Grid x=0.001 R t. o 0.5Fig. 3. 1: MTSOL will crash. Upper and lower grid do not meet at right angles. X

Blade and MTFLOW Grid I | | | | | | | | | || | | | | 0 | | | | | | | I I I I I I I I I I I

Blade and MTFLOW Grid 16 14-4 -1.2 R 0.8 0.6 0.4 3.9 4 x 4.1 4.2 x

Fig. 3.5: Same graph as Fig. 3.6 Fig. 3.6: Illustration of dense gridding in

but zoomed in. MTSOL X and R directions. MTSOL

will converge will converge.

3.4 Using a Longer Chord

The following graphs use the same MTSET parameters as outlined in Table 3.2 but the foil is identified in Table 3.3. The foil in Table 3.3 has a longer chord.

X R 4.01 1.0 4.0 1.01 3.99 1.0 4.0 0.99 4.01 1.0 Table 3.3

Hub and Blade in

MTFLOW Grid R 3 Fig. 3.7: 4 5 x

Hub and blade with longer chord. Grid is not as dense in the X direction.

Foil

MTSOL

-- - - Grid

E = 0.900

Fig. 3.8: The longer chord set in the walls file allows the trailing edge to cross a grid

line even with the higher E. 1.15 1.1 Ros 1 0.95 0.9 0.85

Figure 3.9 illustrates a chord set in the walls file for a foil that is too long even at an exponent equal to 0.9. The streamlines would cross as the flow goes across the foil to the blade.

1.3

1.2

Foil in MTFLOW Grid

1.1 R 0.9 0.8 0.7 3.6 3.8 x 4 4.2 Fig. 3.9: Chord length for this

foil is 0.2.

3.5

Axial Velocity Around Foil

As a final check, the foil must not significantly disturb the velocity at the blade tip for an

accurate coupling. Plotting the axial velocity in figure 3.10 shows that the influence of the foil is less than 1% of the nominal flow. The impact of the induced velocity will be shown to be

negligible on the final Kt and lOKq in chapter 5.

Axial Velocity Around Foil Level VX: 1'1 1.01 0. 99 - 1 2 3 4 5 0.9976 0.9989 0.9997 1.0004 5 .1.0007 6 1.0018 1.00497 8 1.0060 1.0080 1.00919 10 11 x

Fig. 3.10: Axial velocity around the foil is less than 1%.

-r . ,,, 1,

Chapter 4

Case

I,

Blade Grid is Fixed

4.1 Overview

The first case that will be analyzed at low J is a fixed blade grid lattice (also known as Ifix =1) with the concentrated streamlines at the

blade tip. In this case the blade does not Kt, 1 OKq Vs. Advance Coefficient, Ifix=1 move with the streamlines. There is only - - - - - KtModel Test

1 OKq,Model Test

A Kt,Foil at tipix=1

slight movement to maintain a geometrical 0.4 lI 1OKq,FoIl at tip, fx=1

Cr

relationship with the outer domain '0.3

-AK

boundary. Figure 4.1 shows that the 0.2 'L

coupling converged down to an advance 0.1

coefficient of 0.5, however, there were 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 1.1 1.2

coeficiet of0.5,howeer, hereAdvance Coefficient, J

artificial modifications to the coupling to force Fig. 4.1: Results for Ifix=1 convergence at J=0.5. These modifications

will be discussed in this chapter.

4.2 Grid

Figure 4.2 illustrates the blade and MTFLOW grid for J=0.5 using the MTSET parameters outlined in Table 3.2. The foil parameters are the same as Table 3.2 except that the X location is moved to begin at 4.051 instead of 4.001. It is necessary to move the X location downstream to

avoid the stagnation line from crossing the blade tip. Two problems will develop if the

Blade Grid and MTFLOW Grid Blade and Wake, lfix=1, J=0.5

0.9

R

0.8 3

x

Fig. 4.2: J=O.5, Ifix=1, Blade and Fig. 4.3: Stagnation line is outside blade

MTFLOW grid. tip. Wake grows properly.

stagnation line crosses the blade. First, the tip wake will begin outside the slip stream where the velocities are

just

free stream. This will result in the tip wake pitch not proceeding at the correct angle and will skew the final Kt and 10OKq results. The second problem is that the tangential velocity will not be added above the stagnation line. The PBD2MT code sections the lower grid and upper grid based on the location of the stagnation line. Because the foil tricks the code into thinking it is a ducted case, there is not any tangential velocity input above the foil andstagnation line.

4.3 Artificial Modifications

The solution would not converge at a J=0.5 without modifying the swirl input from PBD. There are two problems that required attention. First problem was the gap of zero swirl between the blade tip and the stagnation line. This gap prevented MTSOL from converging. The PBD2MT

code was modified to input swirl between the blade tip and the stagnation line equal to the blade tip swirl, thus, forcing MTSOL to converge (figure 4.5). The second problem was the t lines were crossing constant s lines at two locations (chapter 2). This resulted in the swirl input contour lines to cross. To fix this problem, the PBD2MT code was modified such that the tip swirl was input between the first crossing of the t line and the stagnation line. After the first

Blade Grid (dashed lines) and Swirl

Input Grid (solid lines)

-- going - vertical from last known 4 location. 3.7F,.05 40 3.975 4 4.025 4.05 x

Fig. 4.4: Notice the swirl input outsid the blade grid.

crossing the s lines went vertically upward to the

Input Swirl at Tip, Ifix=1, J=0.5

3.99 4 4 0 . 4.03 .04 .0 1.03 1.02 1.01 S1 0.99 0.98 0.97 3.99 4 4.01 4.02 4.03 4.04 4.05 X

Fig. 4.5: Swirl is input above the blade tip. Swirl is input from the last known position then proceeds vertically up inputting swirl equal to the tip swirl.

stagnation line (figure 4.4). Essentially the blade tip was cut at the first crossing of a t line and swirl was equal to the tip swirl between the

cut and the stagnation line (figure 4.5). Appendix C outlines the changes to PBD2MT source code.

1.02

R

0.98

4.4 Effective Velocity

Effective Velocity, Ifix=1, J=0.5

The effective velocity ranges +/-12 % which is an indication of poor coupling. The artificial modifications are partly to blame. An in depth error analysis will be conducted in chapter 6.

0.9 0.8 0.7 R 0.6 0.5 0.4 0.3 -T2 Level Ux 14 1.12043 13 1.11338 12 1.10406 11 1. 09558 10 1.08708 9 1.01123 8 0.994208 7 0.977182 6 0.960157 5 0.943132 4 0.:26107 3 0.90982 2 0.892056 1 0.875031

Fig. 4.6: The large range in effective velocity indicates poor coupling. The velocities not shown are concentrated at the blade tip trailing edge.

0.4 0.6

Chapter

5

Case

II,

Blade Follows the Streamlines

5.1 Overview

The difference with case II is that the blade moves with the streamlines (also known as Ifix =0) such that the horizontal blade grid lines are

parallel to the streamlines. Case II resulted Kt I OKq Vs. J, IfIx=O

in converged solutions down to J=0.3 but 0.5 KtFo Downsream

0 1 OKq,Foll Downstream

the solutions were much lower than 04O 0'KqtFoiatTip

aY- - KtModel Test

c - 1Kq,Model Test

expected from model tests (figure 5.1). The T

10Kq

solutions were converged with the foil 0.2

Kt located at the tip and downstream. There 0

were only slight differences in final 3 . 0 0 0 1.2 J, Advance Coefficient

Kt/l0Kq with the two methods. However, Fig. 5.1: Kt/1OKQ Vs. J, Ifix=O the lowest J for the foil downstream was 0.4

and the lowest J for the foil at the tip was 0.3. The MTFLOW grid lines crossed at J=0.3 with the foil downstream which resulted in MTSOL crashing.

The grid used for this case was the MTSET Blade and MTFLOW Grid,

Ifix=O, J=0.4 parameters outlined in Table 3.2 and the foil 2

parameters outlined in Table 3.3. Figure 5.1 1.6 illustrates the resulting blade and MTFLOW

R

grid after converging at J=0.4. The chord length

0.8 of the foil used in this case is longer than in case 0.6

I, thus, the grid density in the X direction is less. 0.2

3.5 4 4.5 5

The dense grid in the X direction used in Fig. 5.2: Blade and MTFLOW grid, Ifix=O, J=0.4.

Chapter 4 proved to increase the chances of the streamlines crossing with this case.

5.3 Procedure

The procedure for this case was aimed at testing the foil. There were two major concerns after completing the Kt/lOKq curve in Chapter 4. First, it was suspected that the foil was significantly constraining the streamlines causing the increase in effective velocity. Second, it was suspected that the induced velocity from the foil was having an impact on the blade's induced velocity near the blade tip. To address both of these concerns the solution was converged with the foil at the tip and with the foil downstream of the tip. Converging solutions downstream requires a strict procedure to keep the MTFLOW streamlines from separating. The foil had to be located

downstream in a position such that the stagnation line was just above the blade tip after convergence. The following procedure was used:

* The solution was converged for a specific advance coefficient with the foil at the blade tip. From this converged solution the vertical location of the stagnation line at X = 5.5 was noted. The X position was determined through an iterative process considering two guidelines. First, the position had to be downstream far enough not to interact with the blade flow.

EJINEW U U ~IJ

Second, the position could not be too far downstream such that it interacted with the downstream boundary.

* The solution was re-converged with the foil downstream and the J from above. This

resulted in the stagnation line being close to the blade tip (figure 5.3).

* Adjust J such that the stagnation line is just above the blade tip. This will allow the swirl to be input at the proper location.

R

If the downstream foil was too high, the

0.95 concentrated streamlines would be above the blade

and MTFLOW would crash. If the foil was too low, the stagnation line would cut through the blade and swirl would not be input above the

Blade and MTFLOW Grid, Iix=O, J=0.4 (Tip Region)

x

Fig. 5.3: Stagnation line does not cross blade tip. Foil is downstream. The foil was placed in the correct location, thus, not requiring J to be adjusted. stagnation line. By first finding the location of the downstream foil with the solution from the foil at the tip saves time by not having to re-compute various foil locations downstream.

5.4

Swirl Input

Following the procedure outlined in section 5.3 will result in zero additional swirl being added Swirl Input, Ifix=0, J=0.4

1.04 1-15 0.362827 14 0.338638 1 0.9261 7 0.169319 2 0.4876 8

Swirl Input Locations to Blade, Ifix=0, J=0.4 1. 04 1-1.02k 1 0.98 i0.96 0.94 0.92 0.9 4.05

Fig. 5.4: Swirl input locations. Notice the contour lines do not cross.

mm

-J

4.05 4.1

4x6

Fig. 5.5: Swirl is input properly along the blade. Dashed lines are the blade grid. Solid lines are the input swirl locations.

artificially to the foil (figure 5.5). However, in order for MTSOL to converge, PBD2MT must 1.02 1 0.98 M 0.96 0.94 0.92 0.9 1 4.1 4.1 4.1

-

U---initially input swirl between the tip and the stagnation line. This swirl is reduced with each iteration until equaling zero as long as the final solution has the stagnation line just above the tip. Additionally, with the blade grid following the MTFLOW streamlines, there are not any jumps in the swirl contour lines (figure 5.4).

5.5

Verification

The blade wake and the effective velocity are used to verify that the MTFLOW grid did not separate and the coupling accuracy respectively. Figure 5.6 shows the wake growing properly downstream. However, figure 6.7, illustrates an error in the coupling with up to 24% increase in effective velocity. The source of this error is explored in Chapter 6.

Blade and Wake, Ifix=O, J=0.4

x

Wake follows streamline.

0.9 0.8 0.7 : 0.6 0.5 0.4 0.3

Effective Velocity, Ifix=O, J=0.4

-Level LIx 1 1 1240( 10 1.220 9 1.201: 8 1.1811 7 1.1611 6 1.122 5 1.083 8 4 1.024C 3 1.004 2 0.984 -71 0.965 6 -4

1 1 1

AI

A .1 -0.2 0 0.2 0.4 XFig. 5.7: The large variance in effective velocity indicates poor coupling. 1 0.5 Y 0 -0.5 0 Fig. 5.6: 0.6 94 27 6 93 58 4 55 73 2 0.6 2

Chapter 6

Error Analysis

6.1 Overview

One obvious source of error for case I and II is the method of inputting swirl and drag into MTFLOW. Case one is artificially inputting swirl between the stagnation line and the first crossing of a t line. Case two is inputting zero swirl and drag above the stagnation line which cuts through the blade tip. Also, both cases are not accounting for the movement in streamlines after PBD2MT inputs swirl and drag at a particular streamline and X position. These errors should, however, only result in a few percent error in the final Kt/l OKq. This chapter explores other sources of error.

6.2 PBD Error

Since both cases were inviscid and with an open propeller, PBD can be used in stand-alone mode. An effective velocity equal to one and a convective wake velocity equal to values obtained from an older lifting surface code called PSF-2 resulted in the stand-alone values outlined in table 6.1 (Appendix D contains the PBD input file). Table 6.1 shows that if PBD uses the correct effective velocity and convective wake velocity it will calculate answers close to answers obtained by model tests. Kt and IOKq is 7.9% and 9.8% respectively less than the

answer obtained by model tests. Part of this error can be accounted for using Polhamus' leading edge suction analogy described in the next paragraph.

Reference [5] predicted Kt and 1 OKq for a DTRC N4118 propeller using the propeller panel method PSF1O. PSF10 was able to predict Kt/lOKq down to a J of 0.4 with minimal variance between PSF10 results and experimental data. However, the solution included a

leading edge suction force correction to increase 1 OKq up to 5% but minimal increase in Kt. The correction was based on Polhamus' leading edge suction analogy. If PBD included this suction loss, the IOKq for stand alone mode would only be lower than model tests by 4.8%. Kt,

however, would still be less than model tests by 7.9%.

Comparison Between Stand-alone, Model Test and Coupled, J=0.4

Test Value % Error from Model test

Kt, model test 0.33 0%

IOKQ, model test 0.53 0%

Kt, Ifix=O, coupled 0.2367 28%

10Kq, Ifix=O, coupled 0.3708 30%

Kt, stand-alone 0.3039 7.9%

1OKq, stand alone 0.4779 9.8%

Table 6.1

Sources of other error include vortex tip formulation and wake roll up. Currently PBD only sheds vorticity from the trailing edge, however, at low J vorticity is also shed from the blade tip. To account for this vortex tip formulation at low J, PBD needs to be modified to shed a wake from the tip chord. Wake roll up relates to the wake influencing itself as it progresses downstream. Currently PBD does not account for wake roll up.

Chapter

7

Conclusion

7.1 Summary of Results

Using a fixed blade grid lattice and concentrated streamlines, the coupling converges down to an advance coefficient of 0.5. Using a blade grid lattice that follows the concentrated streamlines, the coupling converges down to an advance coefficient of 0.3. Both methods result in converged solutions that are lower than expected by model tests. Possible errors include wake generation, leading edge suction losses, swirl and drag input to MTFLOW and wake roll up.

7.2 Recommendations for Future Work

1. Change MTFLOW to facilitate the concentration of streamlines at any point in the flow. The duct in this thesis proves that concentrating streamlines near critical areas enable MTSOL to converge. MTSET should allow users to input a point in the flow domain that requires concentrated streamlines.

2. Create a more robust method of inputting swirl and drag from PBD to MTFLOW.

3. Change PBD to input a weighting function to account for leading edge suction losses at low advance coefficients. Also, change PBD to account for wake roll up.

Appendix A

Input Files to PBD/MTFLOW

Coupling

A.1 Walls File Without Foil and Hub

4119 ITTC walls case

0.0 7.6 0.00 2.000 7.6 0.2 5.449084 0.2 5.340678 0.2 5.234253 0.2 5.130387 0.2 5.029772 0.2 4.933049 0.2 4.840815 0.2 4.753613 0.2 4.671937 0.2 4.596230 0.2 4.526885 0.2 4.464243 0.2 4.408596 0.2 4.360183 0.2 4.319196 0.2 4.285772 0.2 4.260002 0.2 4.240000 0.2 4.22 0.2 4.2 0.2 4.18 0.2 4.16 0.2 4.14 0.2 4.12 0.2 4.1 0.2 4.08 0.2 4.06 0.2 4.04 0.2 4.02 0.2 4.0 0.2 3.2375 0.2 3.2125 0.2 3.2 0.2 3.0 0.2 2.0 0.2 1.0 0.2 0.0 0.2

A.2 Walls File with Foil and Hub

4119 ITTC 0.0 7.6 5.449084 5.340678 5.234253 5.130387 5.029772 4.933049 4.840815 4.753613 4.671937 4.596230 4.526885 4.464243 4.408596 4.360183 4.319196 4.285772 4.260002 4.240000 4.22 4.2 4.18 4.16 4.14 4.12 4.1 4.08 4.06 4.04 4.02 4.0 3.2375 3.2125 3.2 3.188016 3.165110 3.143820 3.124304 3.106635 3.090819 3.076809 3.064515 3.053822 3.044594 3.036688 3.029959 3.024263 3.019467 3.015447 qalls case 7.6 0.00 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.199641 0.196933 0.191947 0.185122 0.176870 0.167569 0.157556 0.147119 0.136499 0.125893 0.115453 0.105290 0.095481 0.086069 0.077072 2.0003.012093 0.068492 3.009314 0.060322 3.007026 0.052547 3.005163 0.045150 3.003665 0.038112 3.002482 0.031414 3.001573 0.025038 3.000901 0.018968 3.000436 0.013194 3.000148 0.007705 3.000016 0.002498 3.000000 0.0 3.000016 -0.002498 3.000148 -0.007705 3.000436 -0.013194 3.000901 -0.018968 3.25 -0.200000 999.0 999.0 4.01 1.0 4.0 1.01 3.99 1.0 4.0 0.99 4.01 1.0

A.3 Batchfile

bl2body=$HOME/MTFLOW.1/MTCouple/bl2bodyhanson velcon9=$HOME/MTFLOW.1/VELCON9/SRC/velcon9hanson pbdl43=$HOME/PBD14.36/SRC/pbdl4 pbd2mt=$HOME/MTFLOW.1/MTCouple/pbd2mt mtflo=$HOME/MTFLOW.test/Mtflow/bin/mtflo mtsol=$HOME/MTFLOW.test/Mtflow/bin/mtsol buildtflow=$HOME/MTFLOW.1/MTCouple/buildtflowhanson rm Batch.log date > Batch.log pwd >> Batch.log MAX=20 COUNT=1echo 'TITLE = "ITTC 4119 PBD/MTFLOW COUPLING"' >> KTQOUT.TOT echo 'VARIABLES = "N", "Kt", "10Kq"' >> KTQOUT.TOT

echo 'ZONE T="Kt / 1OKq", I= ' $MAX >> KTQOUT.TOT

################################################################

#######

do

echo ' ## PBD - MTFLOW ITERATION ' $COUNT >> Batch.log echo ' ####### PBD - MTFLOW ITERATION ' $COUNT' #######'

################################################################

# MTFLOW TO PBD #

################################################################

# Create VELJOIN.tec from Mtflow results $bl2body >> Batch.log

echo ' ## Done with bl2body ##'

# Run velcon

$velcon9 < vel.in >> Batch.log

############################################################ #

# PBD / PBD to MTFLOW #

################################################################

# Run PBD14.3 and create tflow.xxx

$pbdl43 < pbd.in >> Batch.log echo ' ## PBD complete ##'

$pbd2mt >> .. /Batch.log

#cat PBDOUT.CMV >> PBDTOT.CMV #cat PBDOUT.CMF >> PBDTOT.CMF #cat PBDOUT.SGR >> PBDTOT.SGR cat PBDOUT.KTQ >> ktrot.tot tail -1 PBDOUT.KTQ > ktq.in

read wordi word2 word3 word4 < ktq.in echo $COUNT $word3 $word4 >> KTQOUT.TOT

#############################################################

# MTFLOW #

################################################################ # Combine tflow files and run Mtflow

$mtflo 4119 < runMTFLO >> Batch.log $mtsol 4119 < runMTSOL >> Batch.log

####################################################### #########

COUNT='expr $COUNT + 1'

# End of while loop done

#######

################################################################ ################################################################

VELJOIN.tec restart.vel 4.0 1.0 1 1 59 199 0

A.

5 Mtcouple. inp

Mtcouple. inp 5 !5 0.001 1.0093 4.0 1.000 4119 4119.pbd 0 0 1 ! Reynolds number inlet mach number! Vship used in PBD to find J

! x location of LE tip

! r location of LE tip MTFLOW case name

pbd input file name

Blinput toggle (0=no,1=yes)

I Nominal velocity toggle (0=no,1=yes) Number of blade rows

A.6 PBD Admin File

admin file 4119.BSN restart.vel. 3 25 25 1 1 24 1 2 3 4 5 6 7 8 9 10 11 12 13 14 MCTRP 3 0.0 0 0.0 0 0 0 0 0.0 0 0.0 0.0 10 -10 0 0 6 0 0 0 5 0.001 0.02 2.0 1 1 0 0 8

:FILE NAME FOR BLADE B-SPLINE NET :FILE NAME FOR WAKE FIELD

:nblade, nkey, mkey

:ispn (0=uniform,1=cos),iffixlat

15 16 17 18 19 20 21 22 23 24 : MC,

:ihub, hgap, iduct, dgap

IHUBSUBLAY, IDUCSUBLAY HDWAK, NTWAKE Cq, MXITER OVHANG(1), OVHANG(3) nx,ngcoeff,mltype,mthick :IMODE :NWIMAX niter,tweak,bulge,radwgt,nufix

:IBSHAPE, IHUBSL, IDUCSL, NGENLINE

1 0.02 : nplot,hubshk

4 6 : NOPT, NBLK

0.6 1.0 1.500 0.05 :ADVCO XULT XFINAL DTPROP

0.0080 0.0100 0.0200 0.0300 0.0350 0.03500 0.0300 0.0200 .0100 0.0000 :G(design) .2000 .3000 .4000 .5000 .60000 .7000 .8000 .9000 .9500 1.0000 .06576 .05630 .04777 .0396 .03209 .02504 .01828 .0120 .00896 .0000 r/R T/D

0.00814 0.0086 0.0085 0.0084 0.0082 0.0081 0.008 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0079 0.0078 0.0079:Cd 0.0000 0.0000 0.000 :UA 0.0000 0.0000 0.000 :UAU 0.0000 0.0000 0.000 :UT 0.0000 0.0000 0.000 :UTU

A.7

MTFLO

Run MTFLO p r w qA.8 MTSOL

Run MTSOL x 1 1 1 1 1 0 w qAppendix B

Changes made to MTFLOW Source

Code (io. f)

Note: Corrections are required for MTFLOW to plot grid above stagnation line.

.... Start corrections made by Bill Duncan 5MAR02 REAL XAC(II-1,JAIR(3)+1)

REAL YAC (II-1, JAIR (3) +1)

REAL QAXC (II-1, JAIR (3) +1)

REAL QAYC(II-lJAIR(3)+1) REAL RAVTC (II-1, JAIR (3)+1)

REAL dAlbot, dA2bot, dAltop, dA2top

.. .. End corrections made by Bill Duncan 5MAR02

!...CJH 7/24/00...

Output cell info to OUTVEL.tec in TecPlot format

Mtflow velocity info is valid at cell centers only,

but X,Y locations are at cell corners.

So ...

Shift X,Y to cell centers and extrapolate velocity info back to boundary

wall. Thus, array size info:

Original X,Y,Q,RVT array II,JJ but Q,RVTA valid only in

II-1,JJ-1 since already cell centered. For Q,RVTA the IIth column and JJth row are all zero.

New XCYC,Q,RVTA arrays are II-1,JJ+l due to adding streamline at bottom

and top of domain to recover the half cell which drops out in the shift to cell center. The half cell lost at the inlet and outlet is ignored since they do not effect the PBD results.

Current version outputs info from t=0 to t=1.0, should be improved to give up to t=2.0 for the ducted case.

If the extrapolated velocity is < 0 (in case of rapid BL change with

a specific inlet profile), the velocity is "stamped" to zero.

!...

... Shift X & Y to cell center and shift all info up one row to make room for wall streamline to be added later.

DO J=1,JAIR(2)-1

DO I=1,II-1

XC(I, J+l) = 0.25* (X(I,J)+X(I+1,J)+X(I,J+1)+X(I+1, J+1)) YC(I,J+l) = 0.25*(Y(I,J)+Y(I+1,J)+Y(I,J+1)+Y(I+lJ+1))

QXC (I, J+1) =QX (I, J)

QYC (I, J+1) =QY(I, J)

RVTC (I, J+1)=RVT (I, J)

END DO END DO

.... Start corrections made by Bill Duncan 5MAR02

DO J=JAIR(2),JAIR(3)-1 DO I=1,II-1

XAC(I,J+l) = 0.25*(X(IJ)+X(I+1,J)+X(I,J+1)+X(I+1,J+1)) YAC(I,J+l) = 0.25*(Y(I,J)+Y(I+1,J)+Y(I,J+1)+Y(I+1,J+1))

QAXC (I, J+1) =QX (I, J) QAYC (I, J+1) =QY (I, J)

RAVTC (I, J+1) =RVT (I, J)

END DO END DO

.... End corrections made by Bill Duncan 5MAR02

... Now add in the bottom and top streamlines to recover the half cell on

! bottom and top that was lost during cell center shift. Linearly * extrpolate velocity info from two points outward to get

* velocity info. DO I=1,II-1 XC(I,1)=0.5*(X(I,1)+X(I+l,1)) YC(I,1)=0.5* (Y(I,1)+Y(I+l,1)) XC(I,JAIR(2)+1)=0.5*(X(I,JAIR(2))+X(I+1,JAIR(2))) YC(I,JAIR(2)+l)=0.5*(Y(I,JAIR(2))+Y(I+1,JAIR(2))) dlbot=SQRT((XC(I,2)-XC(I,1))**2+(YC(I,2)-YC(I,1))**2)

d2bot=SQRT ((XC (1,3) -XC (1,1)) **2+ (YC (1,3) -YC (1,1) ) **2)

dltop=SQRT((XC(I,JAIR(2))-XC(I,JAIR(2)+l))**2+(YC(I,JAIR(2))

& -YC(IJAIR(2)+1))**2)

d2top=SQRT((XC(I,JAIR(2)-1)-XC(I,JAIR(2)+1))**2+

& (YC(I,JAIR(2)-1)-YC(IJAIR(2)+l))**2)

QXC(I,1)=VelExtrap(QXC(I,2),QXC(I,3),d1bot,d2bot)

IF (QXC(I,1).LT.0) QXC(I,1)=0 ! Velocity "stamping"

QYC(I,1)=VelExtrap(QYC(I,2),QYC(I,3),d1bot,d2bot)

RVTC(I, 1)=VelExtrap(RVTC(I,2),RVTC(I, 3) ,dlbot,d2bot)

QXC(I,JAIR(2)+l)=VelExtrap(QXC(I,JAIR(2)),QXC(I,JAIR(2)-l), & d1top,d2top) QYC(I,JAIR(2)+l)=VelExtrap(QYC(I,JAIR(2)),QYC(IJAIR(2)-l), & dltop,d2top) RVTC(I,JAIR(2)+l)=VelExtrap(RVTC(I,JAIR(2)),RVTC(I,JAIR(2)-l), & dltop,d2top) END DO

.... Start corrections made by Bill Duncan 5MAR02

DO I=1,II-1 XAC(I,JAIR(2))=0.5*(X(I,JAIR(2))+X(I+1,JAIR(2))) YAC(I,JAIR(2))=0.5*(Y(I,JAIR(2))+Y(I+1,JAIR(2))) XAC(I,JAIR(3)+l)=0.5*(X(I,JAIR(3))+X(I+1,JAIR(3))) YAC(IJAIR(3)+l)=0.5*(Y(I,JAIR(3))+Y(I+l,JAIR(3))) dAlbot=SQRT((XAC(I,JAIR(2)+2)-XAC(I,JAIR(2)+l))**2+ & (YAC(I,JAIR(2)+2)-YAC(I,JAIR(2)+1))**2) dA2bot=SQRT((XAC(I,JAIR(2)+3)-XAC(IJAIR(2)+1))**2+ & (YAC(I,JAIR(2)+3)-YAC(IJAIR(2)+l))**2) dAltop=SQRT((XAC(I,JAIR(3))-XAC(I,JAIR(3)+1))**2+ & (YAC(I,JAIR(3)) & -YAC(I,JAIR(3)+1))**2) dA2top=SQRT((XAC(I,JAIR(3)-1)-XAC(IJAIR(3)+l))**2+

& & "stamping & (YAC(IJAIR(3)-1)-YAC(IJAIR(3)+1))**2) QAXC(I,JAIR(2))=VelExtrap(QAXC(I,JAIR(2)+2), QAXC(I,JAIR(2)+3),dAlbot,dA2bot) IF (QAXC(I,JAIR(2)).LT.0) QAXC(IJAIR(2))=0 f QAYC(I,JAIR(2))=VelExtrap(QAYC(I,JAIR(2)+2), QAYC(I,JAIR(2)+3),dAlbot,dA2bot) Velocity RAVTC(I,JAIR(2))=VelExtrap(RAVTC(I,JAIR(2)+2), & RAVTC(I,JAIR(2)+3),dAlbot,dA2bot) QAXC(I,JAIR(3)+l)=VelExtrap(QAXC(I,JAIR(3)),QAXC(I,JAIR(3)-l), dAltop,dA2top) QAYC(I,JAIR(3)+1)=VelExtrap(QAYC(I,JAIR(3)),QAYC(I,JAIR(3)-1), dAltop,dA2top) RAVTC(I,JAIR(3)+1)=VelExtrap(RAVTC(I,JAIR(3)), RAVTC(I,JAIR(3)-1),dAltop,dA2top) END DO

.... End corrections made by Bill Duncan 5MAR02

... .Corrections made by Bill Duncan 5MAR02 - changed OUTVEL.tec

!....JAIR(3) instead of JAIR(2)

OPEN(UNIT=169, WRITE(169,'(A) WRITE(169, '(A) WRITE(169,'('' & FILE='OUTVEL.tec',STATUS='UNKNOWN')

TITLE = "MTFLOW Velocity Output"

VARIABLES = "X", "R", "Vx", "Vr", "Vt", "Cp"

ZONE T="Cell Velocity", I='',I4,'' J='',I4,

'' F=POINT '')') II-1,JAIR(3)+l to read to ' DO J=1,JAIR(2)+l DO I=1,II-1 WRITE (169, 1002) & END DO XC(IJ),YC(IJ),QXC(I,J),QYC(I,J),RVTC(I,J), CP(I,J) END DO

.... Start corrections made by Bill Duncan 5MAR02

DO J=JAIR(2),JAIR(3)+l

DO I=1,II-1

WRITE (169, 1002)

&

XAC(IJ),YAC(I,J),QAXC(IJ),QAYC(IJ),

RAVTC (I, J) ,CP (I, J) END DO

END DO

.... End corrections made by Bill Duncan 5MAR02

CLOSE(169)

46

&

Appendix C

Changes

made

to PBD2MT Source

Code

Note: This code inputs swirl equal to the tip swirl between the first crossing of a t line and the stagnation line. Change Zlast to Zl in the **** section and the program will go to the tip instead of the first crossing. Uncomment the $$$ section and swirl will not be input between the tip and stagnation line.

Subroutine GetZRrVt finds Z,R,rVt where the given t line crosses ! current blade CP line of interest.

Input: t: t value of interest BFGline: t line number

Output: Z,R coordinate and rVt at the coordinate Global Variables used: Blade array, BFG array,MM,JJ

---SUBROUTINE GetZRrVt (BFGline, t, Z,R, rVt, DSdrag, ZLAST,togl) IMPLICIT NONE

REAL, INTENT(IN) :: t

INTEGER, INTENT(IN) :: BFGline

REAL, INTENT(OUT) :: Z,R,rVt,DSdrag REAL

Z1,Z2,RlR2,Zhigh,Rhigh,Zlow,Rlow,rVthigh,rVtlow,Ll,L2,L,tt,ZLAST

INTEGER :: I

REAL, PARAMETER :: Tolerance=1E-7

LOGICAL :: Undershoot,Overshoot,togl Undershoot=.TRUE. Overshoot=.FALSE. DO I=1,MM Zl=BLADE (1, J, I) Rl=BLADE (2, J, I) tt=t Find (Z 1, Rl) IF (tt>t) THEN ZLAST=Zl EXIT END IF

Undershoot=.FALSE. If here, at least one blade CP is below t line

IF (tt<=t) Overshoot=.TRUE. I This can happen above the last blade

CP

... No blade CP above for interpolation ==> extend CP #MM info up IF (Overshoot) THEN

Z=ZLAST I Extend Z info up

DO K=1,II

tLineZ(K)=BFG(1,BFGline*II-II+K)

tLineR(K)=BFG(2,BFGline*II-II+K)

END DO

CALL LININTERP(II,tLineZ,tLineR,Z,R) I Find R given t line and Z rVt=O I For open prop rVt=O

IF ((ISDUCT.OR.INTERNAL).AND.(.NOT.togl)) THEN

rVt=BLADE(3,J,MM)! For ducted/internal extend rVt info up from CP

#MM

togl=.TRUE.

END IF END IF

... No blade CP below for interpolation ==> extend CP #1 info down IF (Undershoot) THEN

Z=Z1 ! Extend Z info down

DO K=1,II

tLineZ(K)=BFG(1,BFGline*II-II+K)

tLineR(K)=BFG(2,BFGline*II-II+K)

END DO

CALL LININTERP(II,tLineZ,tLineR,Z,R) ! Find R given t line and Z rVt= BLADE(3,J,1) ! Extend rVt info down from CP

#1

DSdrag=BLADE (4, J, 1)

END IF

... Have blade CP above and below t line of interest Interpolates info from blade CP above and below

Uses bisection method to get Z,R of blade span and t line intersection IF ((.NOT.Overshoot).AND.(.NOT.Undershoot)) THEN Z2=BLADE(1,.J, I-1) R2=BLADE(2,J, I-1) Zhigh=Zl Rhigh=Rl Zlow=Z2 Rlow=R2 DO Z=0.5*(Zl+Z2) R=0.5*(Rl+R2) tt=tFind (Z, R) IF (tt<=t) THEN Z2=Z R2=R ELSE Zl=Z Rl=R END IF IF (ABS(R2-R1)<Tolerance) EXIT END DO

L1=SQRT ((Zhigh-Z) **2+ (Rhigh-R) **2) L2=SQRT ((Z-Zlow) **2+ (R-Rlow) **2) L=L1+L2

rVthigh=BLADE (3, J, I)

rVtlow=BLADE(3,J,I-1)

rVt=rVthigh*L2/L + rVtlow*L1/L Linear interpolate to get rVt

DSdrag=BLADE(4,J,I)*L2/L + BLADE(4,J,I-1)*L1/L !same fore DSdrag

END IF

Appendix D

PBD Admin. File for PSF-2

Convection Velocities

4119.BSN :FILE NAME FOR BLADE B-SPLINE NET uniform.rotor.vel :FILE NAME FOR WAKE FIELD

3 25 25 :nblade, nkey, mkey

11 :ispn (0=uniform,1=cos),iffixiat 24 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 : MC,

MCTRP

3 0.0 0 0.0 :ihub, hgap, iduct, dgap

0 0 : IHUB SUBLAY, IDUCSUBLAY

0 0 HDWAK, NTWAKE 0.0 0 Cq, MXITER 0.0 0.0 OVHANG(1), OVHANG(3) 10 -10 0 0 nx,ngcoeff,mltype,mthick 4 :IMODE 0 0 0 :NWIMAX 5 0.001 0.02 2.0 1 niter,tweak,bulge,radwgt,nufix

1 0 0 8 :1_BSHAPE, IHUBSL, IDUCSL, NGENLINE

1 0.02 : nplot,hubshk

4 6 : NOPT, NBLK

0.4 1.0 1.500 0.05 :ADVCO XULT XFINAL DTPROP

0.0080 0.0100 0.0200 0.0300 0.0350 0.03500 0.0300 0.0200 .0100 0.0000 :G (design) .2000 .3000 .4000 .5000 .60000 .7000 .8000 .9000 .9500 1.0000 :r/R .06576 .05630 .04777 .0396 .03209 .02504 .01828 .0120 .00896 .0000 :T/D 0.00814 0.0086 0.0085 0.0084 0.0082 0.0081 0.008 0.0079 0.0078 0.0079:Cd 0.178 0.626 0.935 1.158 1.351 1.535 1.612 1.449 1.238 0.918 :UA 1.122 1.266 1.509 1.714 1.738 1.500 1.145 0.875 0.835 0.891 :UAU -0.132 -0.802 -1.071 -1.082 -0.976 -0.864 -0.735 -0.544 -0.412 -0.249 :UT -1.888 -1.218 -0.931 -0.845 -0.775 -0.589 -0.364 -0.226 -0.231 -0.305 :UTU

Bibliography

[1] A. Chrisospathis, J.E. Kerwin and T.E. Taylor. PBD-14.36: A Coupled Lifting-Surface Design/Analysis Program for Marine Propulsors. Technical Report, Department of Ocean Engineering , Massachusetts of Technology, July 2001.

[2] M. Drela. A User's Guide to MTFLOW 1.2. MIT Fluid Dynamics research Laboratory, November 1997.

[3] M. Drela and M. Giles. Conservative Streamtube Solution of Steady-State Euler Equations. Technical Report CFDL-TR-83-6. Department of Aeronautics and Astronautics, Massachusetts Institute of Technology, November 1983.

[4] C.J. Hanson. Integrated Lifting-Surface and Euler/Boundary-Layer Theory Analysis Method for Marine Propulsors. Master's thesis, Department of Ocean Engineering, Massachusetts Institute of Technology, 2000. Also Naval Engineer's thesis.

[5] C. Hsin. Development and Analysis of Panel Methods for Propellers in Unsteady Flow. PHD thesis, Department of Ocean Engineering, Massachusetts Institute of Technology, September 1990.

[6] S.D. Jessup. An Experimental Investigation of Viscous Aspects of Propeller Blade Flow. PHD thesis, School of Engineering and Architecture, The Catholic University of

America, 1989.

[7] J.E. Kerwin. 13.04 Lecture Notes Hydrofoils and Propellers. Department of Ocean Engineering, Massachusetts Institute of Technology, January 2001.

[8] R.W. Kimball, T.E. Taylor and J.E. Kerwin. PBD-14.6: A Coupled Lifting-Surface Design/Analysis Program for Marine Propulsors. Technical Report, Department of

[9] G.P. Mc Huch. Advances in Ducted Propulsor Analysis using Vortex-Lattice Lifting-Surface Techniques. Master's thesis, Department of Ocean Engineering, Massachusetts Institute of Technology, January 2001.

[10] A.M. Polsenberg. An Assessment of the PBD/MTFLOW Coupling: 3 Case Studies. Department of Ocean Engineering, Massachusetts Institute of Technology, 2000. [11] D.H. Renick. An Analysis Procedure for Advanced Propulsor Design. Master's thesis,

Department of Ocean Engineering, Massachusetts Institute of Technology, January 2001. Also Naval Engineer's thesis.

[12] T.E. Taylor. Combined Experimental and Theoretical Determination of Effective Wake For a Marine Propeller. Master's thesis, Department of Ocean Engineering,