Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Internal Report (National Research Council of Canada. Institute for Research in

Construction), 1996-05-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=492abcaa-f1e0-4c5d-b5d4-2f66b81aad02 https://publications-cnrc.canada.ca/fra/voir/objet/?id=492abcaa-f1e0-4c5d-b5d4-2f66b81aad02

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20359052

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

User's manual of a computer program for postflashover burning of

thermoplastic materials

National Research Conseil national

1

R427

,

*

I

Council Canada de recherches CanadaI no.

716

1

e. 2User's Manual of

a

Computer

Program for Postflashover

Burning of Thermoplastic

Materials

by Jennifer Ryan and David Yung

report (Institute

fInternal Report No.

71

6

IDate of Issue: May 1996

CISTI/ICIST NRCiCNRC

IRC Ser

Received on:

06-17-96

Internal report

USER'S M A N U A L O F A COWPUTER PROGRAM FOR POSTFLASHOVER

KURNINC OE"fIIERMOPLAS1'IC MATERIALS

Jennifer Ryan and David Yung

A B S T R A C T

The simplified model for postflashover buning of thermoplastic materials

proposed by Yung

[I]

provides a simple tool for conservative modeling of postflashover

fire behavior. Yung's analysis. through similarity considerations, of the equations

governing postflas60ver fires results 7n two algebraic equations that depend on six

similaritv narameters and three coefficients. The complexity of one of the equations

requircsshumerical procedure to bc employed.

his

b a s ~ccomplished

by creating a

computer program in Visual Basic in which the incremental search method is used to

determine the root of the equation. Solving this, the conservative values for the gas

temperature and burning rate can then be calculated. Values generated by the computer

model are shown to be in good agreement with values

presented

in Ref. 1.

As

an example,

calculated values for the gas temperature, internal and external heat release rates are

tabulated and plotted for the burning of flexible polyurethane foams.

USER'S MANUAI. O F A C O M P U T E R P R O G M M FOR POS'l'F1,ASHOVER

BURNING O F TIIERMOPL.ASTIC MATERIA1,S

by

Jennifer Ryan and David Yung

INTRODUCTION

For conscrvativc modelling of firc behaviour, Yung [ I ] proposed a simplified

mathematical modcl for postflashover burning of thermoplastic materials. The model was

created by analyzing thc equations describing thc fire dynamics of a postflashover firc

through similarity considerations. For conservative modelling, heat loss through the walls

was neglected. The results showed that the fire behavior is governed by two non-

dimensional algebraic equations.

where the dimensionless parameters are defined as:

The two dependent variables, the dimensionless gas temperature and the

dimensionless burning rate, wcrc shown to depend on six similarity parameters and three

coefficients.

In

this model, two of the coefficients, the combustion efficiency and the

considerations. This results in conscrvativc

estimates

of the gas temperature and the

burning rate.

The dimensionless gas temperature can be determined numerically. From this. the

gas temperature. burning rate. mass venting ratc and cxtcrnal heat release rate can be

easily

calculated.

- -NUMERICAL PROCEDURE

Equation (I) is a 5th degree algebraic equation with respect to

0,. The equation

cannot be solved so

0, is explicitly expressed as a function of the other independent

parameters. To solvc Equation (I), a numerical procedure is required. This was

accomplished

by

determining thc root of Equation (I),

0,, using the incremental search

method.

In thc program. thc subroutine "Search" contains the code with the incremental

search method. Thc algorithm is as follows:

I . Given the interval

m i , X 9

in which

0, is sought and

an

increment

Dxi.

2.

The function

F(X)

is evaluated at successive points

Xi, Xi

+

Dxi, Xi

+ 2Dxi,

...,

until

Xf

is reached or until the value of the function changes sign (when

F@i+nDxi).F@i+(n+l)Dxi)

<

0).

3. Once the root has been bounded by

@Old, XNew),

the incremental search is repeated

within the new interval using a reduced increment value. This is done by dividing

Dxi

by

skale.

4.

Steps

1

to

3 arc repeated until the increment or function tolerance is met.

5.

Discontinuities are distinguished from a root by comparing the quantity

F@New)

-

F a o l d )

from one iteration to the next.

N B :

The interval, stepsize, tolerance limits and maximum number of iterations are

declared in the "Search" subroutine. The values are:

Xi

= 0

X f

=

10

Dxi

= 0.01

Tolx

= 0.0001

Tolf

=1.0xl0-~

Skale

= 2

Nmax

=

1000

PROGRAM

Flowchart

Yes-Click0

No-Click5'

Yes-Clickk 5

6 -

No-ClickInterface

Thc interface of the program is the location where the user makes decisions

regarding the running of the program, where the relevant data is entered and where the

output is displayed.

The program starts with the screen

Output.

If No is clicked, no data will be saved. The output will just be displayed on the screen.

If

Yes is clicked, the Save As screen appears and the user can enter the name for the

output file.

File N-:

-

Directories:c:\

Save File as h e : Dkes:

I i S c: ~ t - d o - 6

If

OK

is clicked, the evaporation area,

gas

temperature, mass combustion rate, mass

venting rate, internal heat release rate, external heat release rate and fire duration will be

saved this file.

If Cancel is clicked, the

Output

screen will reappear.

The

next screen that appears is

Properties. All of the information requested in this

screen must he entered to obtain output values.

If OK is clicked. calculations are performed and the output is displayed in the following

mcssagc box (samplc output).

Gas temperature: 1235 K

Mass combustion rate: 0.125 kg/s

Mass venting rate: 0.044

kgls

External heat release rate: 0.7 MW Internal heat release rate: 2.1 MW Fire duration: 0.26 h

If indicated at thc

beginning.

this is thc data. including thc arca of the fuel slab, that will be

savcd in the output filc.

If

Cancel is clickcd. thc program ends.

The ncxt scrcen to appcar is

Again.

If

Yes is clicked. thc Properties scrcen will rcappear and ncw property values can be

entcrcd and the output is rc-calculated.

If

No is clickcd, thc program ends.

Note:

The

data stored in the output filc can bc importcd into Sigmaplot or Excel, or both

for graphing and analysis.

Parameters

Thc following parameters arc used to calculate the output of the program once the

dimensionless gas temperature.

e,,

has been determined.

Gas temperature

(K)

L~

Buming Rate

Combustion limit

Mass venting rate (kgts)

m ,

=Max,

.+

External heat release rate (MW)

HRR,,

= mm,AH,

Mass combustion rate (kgls)

Internal heat release rate

(MW)

HRR,,

= in,AH,

Fire duration (h)

RESULTS

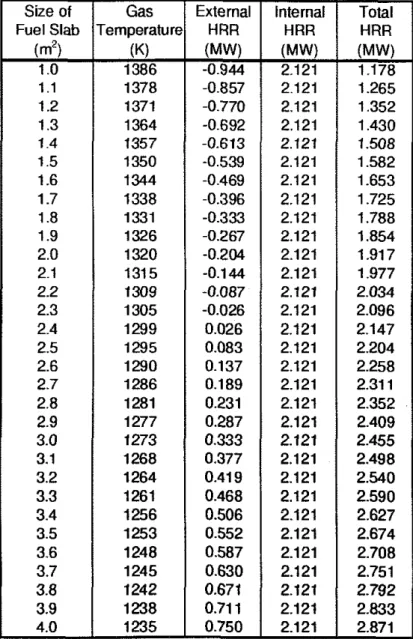

As an example, the results obtained from the program for the combustion of

flexible polyurethane foams are shown in both tabular and graphical form in Table

1

and

Figure 2.

In the calculations. the following values were used:

Ambient temperature

Area of ventilation opening

Density of air

Density of foam

Efficiency of combustion

Efficiency of evaporation

Flow coefficient

Heat of combustion

Hcat of evaporation

Height of ventilation opening

Specific heat of gases

Stoichiometric fuel-tc-air ratio

Temperature of evaporation

Table

1.

Gas temperature and heat release rate for the combustion of polyurethane.

Size of Fuel Slab (m2) 1.O

1.I

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2.0

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

3.0

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

4.0

Gas Temperature (K)1386

1378

1371

1364

1357

1350

1344

1338

1331

1326

1320

1315

1309

1305

1299

1295

1290

1286

1281

1277

1273

1268

1264

1261

1256

1253

1248

1245

1242

1238

1235

External HRR (MW)-0.944

-0.857

-0.770

-0.692

-0.613

-0.539

-0.469

-0.396

-0.333

-0.267

-0.204

-0.144

-0.087

-0.026

0.026

0.083

0.137

0.189

0.231

0.287

0.333

0.377

0.41

9

0.468

0.506

0.552

0.587

0.630

0.671

0.71 1

0.750

Internal HRR (MW)2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

2.121

Total HRR (MW)1

.I78

1.265

1.352

1.430

1.508

1.582

1.653

1.725

1.788

1.854

1.91

7

1.977

2.034

2.096

2.147

2.204

2.258

2.31

12.352

2.409

2.455

2.498

2.540

2.590

2.627

2.674

2.708

2.751

2.792

2.833

2.871

Internal HRR

1

~ 2 .

/I

1350

1

.o

1 I I I1

1000

1

.O

1.5

2.0

2.5

3.0

3.5

4.0

Size

(m2)Figure

2.

Gas temperature and heat release rate as a function of the fuel slab area

for the ventilation-controlted combustion of polyurethane.

To determine whether this program was running properly or not, the output

generated by the program was compared with numerical results presented in Ref.

1

for the

burning of PMMA (polymethyl-methacrylate). This was accomplished using two

methods.

First, the program was

run

using the data from the example Yung presented in his

paper. The results are compared in Table

2.

The comparison shows that the values agree

quite well.

Table 2. Comparison

of

values generated by the computer program and those

obtained from the example in Ref. 1.

Secondly, values for the dimensionless temperature and burning rate, obtained

from the computer program, were compared to the plots in Figures

1

and

2

of Ref.

1.

This was done for different values of the radiation area parameter, a, when the radiative

loss parameter,

6,

and the two efficiencies,

q,

and

q m

were equal to

1.

The values are

compared in Table

3.

Once again the results show good agreement.

Output

Gas temperature

(K)

Mass combustion rate (kg/s)

Mass venting rate (kg/s)

External heat release rate (MW)

Internal heat releasc rate (MW)

Fire duration (hr)

Table

3.

Comparison of values for the dimensionless temperature and burning rate

obtained from the computer and those obtained from the Figures

in

Ref.

1.

Through the comparison of computer-generated values and those presented in

Ref. 1, it can be concluded that the computer program is functioning properly for these

Paper

1320

0.177

0.926

24.1

4.6

1.87

conditions.

Program

1322

0.178

0.928

24. I

4.6

1.86

NOMENCLATURE

radiation area parameter, dimensionless

area of evaporation, m'

area of ventilation opening, m2

flow cocficient

specific heat of gases J k g K

gravitational constant

=

9.8 m/s2

height of ventilation opening, m

heat of combustion, J/kg

heat of evaporation, J k g

mass combustion rate. kg/s

mass evaporation rate, kg/s

mass venting rate, kg/s

stoichiometric air-to-fuel ratio

ambient temperature, K

evaporation temperature,

K

gas temperature, K

Greek Alphabet

radiative loss parameter

heats ratio

efficiency of combustion

efficiency of evaporation

dimensionless ambient temperature

dimensionless evaporation temperature

dimensionless gas temperature

density, kg/m3

Stefan-Boltunann constant

=

5.67~10~'

w / ~ ~ . K ~

ventilation factor

=PA,,

a,

kgfs

REFERENCE

1.

Yung,

D.,

"A Simplified Model for Posfflashover Burning of Thermoplastic

Materials," ASME Winter Annual Meeting, Heat Transfer in Combustion Systems,

San Francisco, USA,

HTD 122, 1989, pp.45-5

1.

CODE

m t

Option Explicit

Sub

cmdYes-Click0

Dim FName

Dim

Area,

Temp, Mass-Comb, Mass-Vent, Ext-HRR, In% Duration, m2,K, MW,

kgs,hr

frmoutputHide

'CANCELERRROR IS TRUE

On Error GoTo Errhandler

'SET FILTERS

SaveAsl.Filter = "All Fila (*.*)lf.*IText Files (*.txt)lf .txt" 'DISPLAYS THE SAVE AS DIALOGUE BOX

SaveAsl Action = 2

'OPENS FILE FOR OUTPUT

Open SaveAsl .Filename For Output As 1

'FLAG TO INDICATE FILE IS OPEN

File-open = 1

TITLES FOR OUTPUT COLUMNS

Area

="AreaW

Temp = "Temp"

Mass-Comb = "Mass

Comb"

Mass-Vent =

"Mass

Vent"Ext-HRR = "Ext

HRR"

In-HRR = "Int

HRR"

Duration = "Fiie Duration"

'UNITS FOR OUTPUT COLUMNS

*

= Wm2"K = " K

kgs = "kgls"

MW = "MW"

hr

= "WWRITE TITLES AND UNITS TO THE FILE

Write # I , Area, Temp, Mass-Comb, Mass-Vent, Ext-HRR, h-wDuration

Write # I ,

m2,

K, kgs, kgs,MW, MW, hr'DISPLAYS THE PROPERTIES FORM frmpropertia.Sbow

Exit Sub Errhandler:

'USER PRESSED CANCEL BUTTON fhnoutput.Show

Exit Sub End Sub

Suh emdNo-Click

0

fmutput.Hide

'DISPLAYS THE PROPERTIES FORM frmproperties.Show

P r o p e m Option Explicit

'INPUT VARIABLES

Dim density. flowcoeff, H, Hc, He, Mass, Cg, r, Ae, Av, Ec, Ee, Ta, Te, Tg 'CALCULATED VARIABLES

Dim ?beta-a, Tbela-e, Thetas, Psi, Del, A, phi, Burnin~rate, M-evap, Comb-limit, Max-vent, Ext-HRR, M-comb, I n t - r n Fire-duration

'CONSTANTS Const Sigma = .0000000567 Const g = 9.8 Sob txtAc-Change

O

Ae = Val(txtAe.Text) End Sub Sob txtAv-ChangeO

Av = Val(txLAv.Text) End Sub Sub t x t C ~ C h a n g cO

Cg = Val(txtCg.Text) End Sub Sob txtDensity-ChangeO

density = Val(txtdensity.Text) End Sub Sub txtEc-ChangeO

Ec = Val(txtEc.Text) End Sub Sub txtEc-ChangeO

Ee = Val(txtEe.Tex1) End Sub Sob txfflowcoeff-Change0

flowcodf = Val(txtflowcoeff.Tex1) End Sub Sob txtH-Change0

H = Val(txW.Text) End Sub Sob &tar-Change0

Hc=

Val(txtHc.Text) End Sub Sob txtHe-ChangeO

He = Val(txtHe.Text) End Sub Sob txtmass-Change0

Mass = Val(txtmass.Texl) End SubSub Txtr-Change

0

r = Vai(txtr.Text) End Sub Sub txtTa-Change0

Ta = Val(txtTa.Text) End Sub Sub htTe-Change0

Te = Val(txtTe.Text) End Sub Sub cmdOK-Click0

fmpropertics.Hide.CALLS SUBROUTINE TO CHECK IF DATA ENTERED IS

v a m

check

End Sub

Sub cmdCanccILClick

0

If File-open = l Then

'CLOSES THE OUTPUT FILE Close #I

End If

'QUITS THE PROGRAM End

End Sub

Sub Check

0

THIS SUBROUTINE ENSURES THAT ALL OF THE INFORMATION HAS 'BEEN ENTERED INTO THE PROPERTIES FORM AND THAT IT IS VALID. 'IF IT HASNT IT WILL INSTRUCT THE USER TO DO SO.

Dim done, donel. done2, done3, done4, done5, done6, done7, done8, done9, donelo, done1 1, donel2, donel3, donel4

THE PROGRAM CHECKS FOR UNINITIALIZED VARIABLES AND VALUES OF ZERO If IsEmpty(Ac) Or Ac = 0 Then donel = False Else done1 = T N ~ End If If IsErnpty(Av) Or Av = 0 Then done2 = False

Else done2 = True End If

If IsEmpty(Cg) Or Cg = 0 Then done3 = False

Else done3 = True End If

If IsEmpty(density) Or dcns~ty = 0 Then done4 = False

Else done4 = Tnle End If

If IsEmpty(Ec) Or Ec = 0 Then done5 = False

End If

If IsEmply(Ee) Or Ec = 0 Then done6 = False

Else done6 = True End If

If IsEmnpty(flowcoc Or flowcoeff = O Then done7 = Falsc

Else done7 = Tnie End If

If IsEmpty(H) Or H = 0 Then done8 = False

Else done8 = True End If

If IsEmpty(Hc) Or Hc = O Thcn done9 = Falsc

Else done9 = True End If

If IsEmpty(Hc) Or He = 0 Thcn done10 = False

Else doncl O = True End If

If IsEmpty(Ma~s) Or Mass = O Then donel 1 = False

Else done1 l = True End If

If lsEmpty(r) Or r = O Then done12 = False

Else done12 = True End If

If IsEmpty(Ta) Or Ta = O Then donel3 = False

Else done13 = True End If

If IsEmpty(Te) Or Tc = O Then done14 = Falsc

Else done14 = True End If

done = done1 And done2 And done3 And done4 And done5 And done6 And done7 And done8 And done9 And done10 And done1 1 And done12 And done13 And done14

'IF NOT ALL THE INFORMATION HAS BEEN ENTERED OR SOME INFORMATION 'IS INVALID THEN

If danc = False Then

'DISPLAYS A MESSAGE BOX AND THEN THE PROPERTIES FORM Ms@ox "Please enter all of the information."

frmproperties.Show Else

'IF OK, CALLS THE SUBROUTINE THAT CALCULATES THE PARAMETERS Parameters

End If End Sub

Suh Paramctcn ()

THIS SUBROUTINE CALCULATES THE PARAMETERS 'CALCULATES THE VENnLATlON FACTOR

phi = dtnsily

*

Av + Sqr(g*

H)'CALCULATES THE DIMENSIONLESS AMBIENT TEMPERATURE Thela-a = (Cg

*

Ta) I Hc'CALCULATES THE DIMENSIONLESS EXHAUST TEMPERATURE Thela-c = (Cg

*

Te) I He'CALCULATES THE RADIATION AREA PARAMETER A = ( A e * S i g r n a * H e " 3 ) l ( p h i * C g " 4 )

'CALCULATES THE HEATS RATIO Psi = Hc I Hc

'CALCULATES THE RADIATIVE LOSS PARAMETER Del = Av I Ae

'CALLS THE SEARCH SUBROUTINE

Search flowcocff, Ec, Ee, Psi, Del, r, A, Thda-a, Theta-e End Sub

S u b Search (flowcoeff, Ec, Ee, Psi, Dd, r, A, Theta-a, Theta-e)

' THIS SUBROUTINE SEARCHES FOR THE ROOT OF A FUNCTION USING INCREMENTAL SEARCH

Dim Xi, Xf, IncRoot, Dxi, Tolx. Tolf, Skale, NMax

' Xi: START POINT FOR SEARCH

' Xf: FINAL POINT FOR SEARCH

INCROOT: ROOT TO WITHIN INCREMENTAL SEARCH TOLERANCE

' Dxi: INITIAL STEPSIZE FOR SEARCH -

' TOLX. STEPSIZE TOLERANCE FOR SEARCH

' TOLF: FUNCTION TOLERANCE FOR SEARCH

' SKALE: SCALE FACTOR FOR SEARCH

' NMAX: MAXIMUM NUMBER OF ITERATIONS FOR SEARCH Dim XOld. XNLW, Fold, FNnu, Dx, D~fOld. D~fNew

Dim N As Integel, Flag As Intcger

' N: NUMBER OF ITERATIONS CARRIED OUT FLAG: WARNING FLAG FOR SEARCH

' IF FLA(i = 0 . NO ROOT FOUND IN THE INTERVAL

' IF FLAG = I. MAXIMUM NUMBER OF ITERATIONS PERFORMED ' IF FLAG = - I , NO ERROR IN SEARCH

N = 0

Flag = -I

'PARAMETERS FOR INCREMENTAL SEARCH Xi = 0 X f = I0 Dxi = .Ill Tolx = .0001 Tolf = .00000001 Skalc = 2 NMax = I000

'CALCULATES INTITAL FUNCTION VALUE XOld = Xi

Fold = F(X0ld. flowcoeff, Ec. Ec, Psi, Dcl, r, A, Thetaa, Theta-c) Dx = Dxi

Do Wh~le N < NMax And XOld < Xf XNew = XOld + Dx

FNew = F(XNew, flowcoeff, Ec, Ec, Psi, Del, r, A, Theta_% Theta-e)

N = N + I

CHECK TO SEE IF FOLD IS THE ROOT If Abs(FO1d)

<

Tolf ThenIncRoot = XOld Exlt Do

' CHECK TO SEE IF FNEW IS THE ROOT ElseIf Abs(F0ld

*

FNew)<

Tolf Then1ncRoot = XNcw Exlt Do

' CHECK TO SEE IF lNTERVAL BOUNDS ROOT ElseIf Fold

*

FNew>

0 ThenXOld =

XNew

Fold = FNew

' REDUCE STEP SIZE ON THE BOUNDING INTERVAL Else

' FIRST, CHECK IF DX IS GREATER THAN DXMIN If

Dx

< Tolx ThenIncRoot = XNew Exlt Do

ElseIf Dx = Dxl Then

' IF THIS IS OUR FIRST BOUNDING INTERVAL, STORE DIFOLD IhfOld = Abs(F0ld

-

FNew)Dx = Dx I Skale Else

' OTHERWISE STORE DIFNEW AND COMPARE TO DIFOLD TO SEE IF WE

' HAVE HIT A DISCONTINUITY Dimew = Abs(F0ld - FNew) If (DifNew

-

DifOld)<

0 ThenDx = Dx l Skale D I ~ O I ~ = DifNew Else

' IF DlFNEW IS GREATER THAN DIFOLD, WE HAVE HIT A DlSCONTINUITY

' AND STEP OVER IT

AND

BEGIN A NEW SEARCH XOld =XNew

Fold = FNew Dx = Dxl End If End If End If Loop'FLAGS TO CHECK IF THE MAXIMUM NUMBER OF INCREMENTS OR THE FINAL VALUE HAS BEEN EXCEEDED

If N >= NMax

Then

Rag = 1If XOld

> Xf Then

Flag = 0'CALLS

THE OUTPUTS SUBROUTINEOutputs IncRoot

Function F (Thetas, flowcoeff, Ec, Ee, Psi, Del, r, A, Theta-a, Theta-e) THIS IS THE FUNCTION FOR WHICH THE ROOT IS BEING DETERMINED Dim Top, Bottom

Top = (flowcoeff

*

((Ec 11) - (Thetag-

Theta-a)))Bottom = ((Ee

*

Psi A 3)*

((I +((Psi*

(Theta2-

Theta-e)) / (1 +Psi*

(Theta-e-

Theta-a))))*

(Thetas 4

-

Theta-c 4) + (Del / Ee)*

(Thetas A 4-

Theta-a 4)))F = (Top / Bottom) - A

End Function

Sob Outputs (Thetas)

THIS SUBROUTINE CALCULATES AND DISPLAYS THE OUTPUT

Dim msg As String, NL As String

NL = Chr(l0)

'CALCULATES THE GAS TEMPERATURE

Tg = (Thetas

*

Hc) / Cg*CALCULATES THE BURNING RATE

Bumingrate = ((Ee

'

A*

Psi A 4*

(Thetag 4-

Theta-e A 4))I

(1 +Psi*

(Theta-e-

Theta-a)))'CACULATES THE COMBUSTION LIMIT

Comb-Iimit = (Ec

*

flowcoeff)I

r

'CALCULATES THE MAXIMUM VENTING OF UNBURNED

FUEL

Max-vent = Bumingrate

-

Comb-limit%ALCULATES THE MASS VENTING RATE

M-evap = Max-vent

*

phi'CALCULATES THE EXTERNAL HEAT RELEASE RATE

Ext-HRR = (M-evap

*

Hc) / 1000000'CALCULATES THE MASS COMBUSTION RATE

M-comb = (Ec

*

flowcoeff*

phi) / r'CALCULATES

THE

INTERNAL HEAT RELEASE RATEInt-HRR = (M-comb

*

Hc)I

1000000'CALCULATES

THE

FIRE DURATIONFire-duration = Mass I (M-mmb

*

3600)'DISPLAYS OUTPUT IN A MESSAGE BOX

msg = "Gas tanperture: " & Formatpg, "######")

msg=msg&"K"&NL

msg = msg & "Mass combustion rate: " & Format(M-comb, "0.000")

msg=msg&"kg/s"&NL

msg = msg & "Mass venting rate: " & Format(M-evap, "#0.000")

msg=msg& "kg/sW&NL

msg = msg & "External heat release

rate:

" & Format(Ext-HRR, "####.On)msg=msgBrWMw"&NL

rnsg = msg & "IIItanal heat release rate: " & Fonnat(I0t-HRR, "W.0")

msg=msg&"Mw"&NL

msg = msg & "Fire duration: " & Format(Fire-dwation. "0.00")

msg=msg&"hr" =gBoxmsg

If File-open = 1 Then OUTPUT TO FILE

Write

#I,

Ae, Tg, M-comb, W a p , Ext-HRR,In-

FiedurationEnd If

'DISPLAYS THE AGAIN FORM

frmagain.Show

&&

Option Explicit

Sub cmdYes_Click 0

'RUNS THE PROGRAM AGAIN frn~aga~n.Hide

'DISPLAYS THE PROPERTIES FORM frmproperties.Sbow

End Sub

Sub cmdNo-Click

0

If File-open = 1 Then

'CLOSES THE OUTPUT HLE Close #1

End If

'QUITS THE PROGRAM limagain.Hide

End End Sub