-Cu

Precipitations

at

the

Surface

of

Crystalline

Cu

—Zr

Alloys

after

Annealing

in

Hydrogen

*Xin-Nan Yu, Laboratorium

fur Festkorperphysik,

ETH Zurich, CH-8093 Zurich andL.Schlapbach,

Institut dePhysique,

Universite deFribourg.

CH-1700Fribourg

Crystalline

Cu-Zralloys

of variouscomposition

were annealed (200-400C) in

ultrahigh

vacuum and inhydrogen,

and their surfacecomposition

wasanalyzed

by

X-ray

photoelectron

spectroscopy.Contrary

to themostly

observed oxygen induced surface segregation of Zr we found strong Cu

segregation

afterannealing

Cu-richsamples

inhydrogen

atmosphere.

Scanning

electronmicrographs

show surface Cuprecipitates,

apparently

formed under the effect of the heat ofchemisorption

ofhydrogen

on Cu. IntroductionAmorphous

and alsocrystalline alloys

of Cu with thed-transition metalsZr,

Niand Pd have been studied

quite

intensively

forthe last fewyears among otherreasons because of their

special

dynamical

and diffusionalproperties

in the bulk and at the surface which results ininteresting

catalytic

andhydrogen

sorption phenomena

[1-15].

Studies of theelectronicstructure of

amorphous

CuxZr-|-x

alloys

reveal that in the middle of theglass forming

range(20

-75 at%

Cu),

i.e. around 50 at%Cu,

the Fermi level

Ef

is situated in the Zr 4d band and there is notendency

forordering.

At Cuconcentrations > 80 at%CuEf

shiftstotheedge

of the Zr 4dband so that the

density

ofstatesN(Ef)

gets

drastically

reduced to s-bandvalues,

inagreement

with asign

reversal of the Hall coefficient[1]

andincreased

tendency

for local order. These drasticchanges

of electronicproperties

are interrelated to total energychanges

and structural instabilitiesand relaxation effects

[2].

Activationenergies

for metal atom diffusion inamorphous

Cu

-Zr

alloys

are rathersmall,

by

far smaller than forrecrystallization,

implying

thatrecrystallization

is limitedby

nucleation rather than surface diffusion[3].

Theenthalpy

variation uponcrystallization

amountsto5 kJ/mol

[4].

As many other intermetallic

compounds

alsoalloys

of Cu with d-transitionmetals show surface

segregation

effects. The ratherhigh mobility

of the metalsurface more

easily

than in otheralloys.

Indeed,

the solid solutionsystem

CuxNh-x

is the best studied surfacesegregation alloy [6-8].

On the cleansurface

segregation

of Cu is observed forcompositions

0 < x < 0.75 and Nisegregation

is observed at the Cu-rich end of thecompositional

range.Electronic

theory

based on atight binding

Hartreeapproximation

iscapable

ofexplaining

this crossoverby preserving charge

neurality [6]

in acomparable

model

by Mukeherjee

et al.[7],

in which crossover is absent. Cu enrichment was also observed in thetopmost

surfacelayers

ofsingle crystalline

Cu3f\li97

and

Cu24Ni76

afterannealing

at700 to 800 K and aftersputtering [8].

Oxygen

chemisorption

leads to the "normal" surfacesegregation by

selectiveoxydation

of the more reactivecomponent

(Zr).

Activated bimetallic Zr-Nicatalysts

thus consist of active Ni metal clustersdispersed

on Zroxidesupport,

both of which are

supported

on theunderlying

bulk intermetallicalloy [9].

Attemperatures

around400°

surface enrichment ofNi intheform of NiO and Ni is found afterannealing

ofZrNi3

inO2

andH2,

resp.[9].

Preferential oxidationof Zr and Zr enrichment at the surface was also observed upon oxygen

exposure of

amorphous

Cu -Zralloys

of variouscompositions [10].

Whereas surface

segregation

effects inducedby

oxygen are known to bestrong

andimportant

e.g. for bimetalliccatalyst,

activation ofhydrogen

storage

materials andgetters

[9,11-13],

surface effects inducedby

theadsorption

orabsorption

ofhydrogen

areusually

rather weak or absent[12,13,14].

In thecaseof Cu-d transition metal

alloys,

however,

the results onhydrogen

induced surfacephenomena

are rather controversial[14]. Hydrogen adsorption

reduces the Cu

segregation

of Cu-Nialloys

ascompared

tocleansurfaces,

inagreement

withtheory [15]. Strong

surface enrichment of Cu and Pd wasfound upon

hydrogen

exposure ofamorphous

Cu-Zr andPd-Zr,

resp., around200C,

but on the Pd and Cu rich sideonly [14,16].

Itwasargued recently

thatthis unusual Cu

segregation

is characteristic ofamorphous alloys

and does not exist oncrystalline alloys.

In view of theimportance

of thesesegregation

effects and their

potential application,e..g.

in thepreparation

of bimetalliccatalyst,

we have studiedhydrogen adsorption phenomena

oncrystalline

Cu-Zr

alloys.

Photoelectron

spectroscopy

was used toinvestigate

the surfacecomposition

after various treatments of thealloys

in anultrahigh

vacuumsystem.

The formation of Cuprecipitates

was observed afterannealing

of Cu richsamples

in

hydrogen.

Scanning

electronmicrographs

show that theprecipitates

reachurn diameter.

Experimental

Cu forms with Zr many intermetallic

compounds.

Thecongruently melting

compounds

areCuZr2

(MoSi2

type

structure[17])

andCu3Zr

orCu5-|Zr-|4

(Ag5-|Gd-|4

type

structure[17]) according

to older[18]

and newer[19] phase

Cu3ZrOn.04. Cu5lZr-|4

andCuZr2

by

RF levitationmelting

in a watercooled Cu crucible at 5.

10"7

mbar the constituants Cu(99.99%, Johnson-Matthey),

Zr

(99,9%,

Johnson-Matthey)

and in the case ofCu3ZrOn.o4

some CuO(99.9%, Merck).

GuinierX-ray

patterns

ofCuZr2

andCu5-|Zr-|4

agree withthose

reported

in the literature[17],

thepatterns

ofCu3Zr

andCu3ZrOo.o4

show additional linesprobably

due to the presence of Zr richercompounds.

The lines of

Zr02

and ofCuareabsent.Heat treatment and surface

analysis

of thesamples

wereperformed

on a VG Escalab 5spectrometer

at basepressurel

.10~1u

mbarusing MgKa

radiationof 1254eV

(Au

4f at 84.0eV,

1.2 eVFWHM).

Thespectrometer

isequipped

with ahigh

pressurecell,

fracturestage,

heating

andsample cleaning

(diamond

file,

Ar+bombardement)

facilities. Thus allsample

treatment wasperformed

inside theultrahigh

vacuum(UHV)

spectrometer

avoiding

thetransfer of the

sample

atair betweentreatment andanalysis.

Micrographs

ofsomesamples

weretakenby

ascanning

electronmicroscope.

Results and Discussion

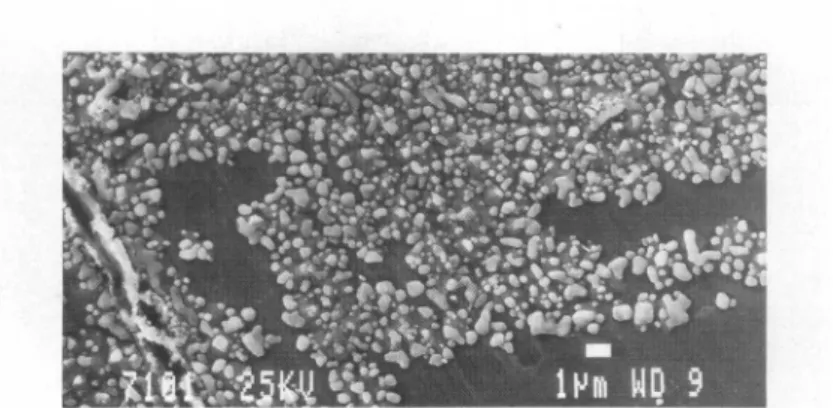

Typical precipitates

observed after 10 to15n

annealing

at200C and 1 barH2

of

previously

UHV-cleanedsamples

ofCu3Zr,

Cu3ZrOrj.04

andCu5-|Zr-|4

areshown in

Fig.

1. Thealloy

surface is coveredto ahigh degree

withprecipitates

of 0.1 to 1 mm diameter.

Analysis

of the characteristicX-rays

by

EDAX andXPS data revealthat the

precipitates

are ofpure Cu. Thosesamples

are Cucoloured,

contrary

to thegrey-metallic

colour of the fracturedsamples.

Fig.1: SEM micrographotaCu3Zr alloy(UHVfractured, 10hoursannealedat200Cat1 bar

H2) showingthespherically shapedsurface Cuprecipitates.

It is

questionable

whetherhydrogen chemisorption

isresponsible

for thisCu

segregation

and it isinteresting

to learn whathappened

to Zr.Surface

Typical

Zr3dphotoelectron spectra

and Cu : Zr ratios are shown inFig.2.

The more bulk orsubsurface(B)

and the moretop

surface(S)

sensitive ratios asevaluated from

Cu3p

andCu2p

core levelpeaks, respectively,

are indicated as well as the colour. Airexposed samples

showheavily

oxidized Zr and a ratherstrong

Cu enrichment at the surface(Cu

: Zr(S)

= 6.22:1).

The Zr3dbinding

energy(BE)

of 182.5 eV is smaller than that ofZrC>2

pointing

to a suboxide.UHV clean surfaces areZr rich.

Annealing

in UHV(200°

for10n)

causessome oxidation of Zr due to oxygen diffusion from bulk to surface and due to thereaction with residual gas. A mixture of Zr suboxide and Zr metal is found. Furthermore

annealing brings along

astrong

Zr enrichment in the nearsurfaceregion

and relativetothe latteroneaCuenrichment ontop

of thesurface.No Cu

precipitates

and no Cu colour were found on the airexposed,

UHVcleaned and UHV annealed

samples, respectively.

I i i i i—i—i—i-1 XPS _* I_^Zrmetal' Zro>ide y UHV I .Oil B 200°C 1.8:1 S 10HOURS _l_I_I_I_I I l_ 188 184 180 176 eV — BINDING ENERGY

Fig

2: Photoelectronspectraof the Zr3dcorelevels ofcrystalline CU51

Zri4aftervarious sampletreatments. The Cu:Zr atomic ratios S and Bwereevaluatedusing

thelargely

topsurface sensitiveCu2p peak

(S)

and thelargely

bulksensitiveCu3p

peak(B),

respectively.

Annealing

inhydrogen (1

barH2, 200C,

10n)

causesfull oxidation ofall surface and nearsurface Zr into

Zr02

aand does notsignificantly

affect the Cu : Zrratio,

although

thesample changes completely

to Cu colour in asurface

layer

of several tenth of a millimeter thickness. On somesamples

asplitting

of the Cu core levelpeaks

was observedapparently

due to theformation ofsome

electrically

isolated Cuprecipitates

whichget

charged

uponphotoelectron

emission.Apparently

annealing

in UHV leads to thenormal, fast,

oxygen induced surfacesegregation

of Zr with the formation ofZr02

at thesurface,

whereasannealing

inhydrogen

ends up in asurfacedisproportionation

of Cu-Zralloys

intoZr02

and Cuprecipitates.

In order toanalyse

the influence of time andtemperature,

hydrogen

and oxygenpartial

pressure as well as of thealloy

composition

on the formation and size of the Cuprecipitates

annealing

ofvarious

samples

attemperatures

upto400C at0..1 to 30 barH2

duringg

0.5to50n

was studied. Detailed results will bepublished

elsewhere;

they

can besummarized as follows:

-nosurface Cu

precipitates

areformed ontheZrrichcompound CuZr2.

-minordifferenceswere

only

observed betweenCu5-|Zr-|4

and

Cu3Zr.

-size and number of

particles

per unit surface areadepend

on theannealing

parameters time, temperature,

andpressure.-the unannealed air

exposed

samples

show a ratherhigh

oxygen contentdown to 100 nmdepth.

-samples

with additional oxygen(Cu3ZrOo.04)

show similar Cuprecipitates.

Based on the above resultswe

suggest

thefollowing

mechanism:The Cu rich

alloys

have a ratherhigh

oxygen content. The oxygen is dissolvedin the metal matrix or

present

in aternary

suboxide. Residual gas andhydrogen

gasare furthersources of oxygen. Elevatedtemperature

favours theformation of the

thermodynamically

more stableZr02

by

adisproportionation

reaction of the

type

Cu-Zr-Ox

+O2

Zr02

+ Cu + Cu-ZrUpon annealing

in UHV Zr isselectively

oxidized andstrongly

enrichedontop

of the

surface,

i.e. Cu is coveredby Zr02-

The presence ofhydrogen

blocksthe Zr enrichment and the free surface Cu forms

precipitates, possibly

favouredby

the heat ofhydrogen

chemisorption

on Cu. Similardisproportionation

of FeTi with the formation of surface Feprecipitates

was observed earlier[20].

We

gratefully acknowledge P.Wagli,

ETHZ,

fortaking

the SEMmicrographs,

S.BOchler,

M. Erbudak and F. Vanini for discussions and the Swiss NationalEnergy

Research Foundation(NEFF)

for financialsupport.

1. D.NguyenMann, D.Pavuna,F.Cyrot-Lackmann, D.Mayou,and A.Pasturel,

Phys.Rev. B33,5920 (1986)

2. AlfredoL.YeyatiandM.Weissmann,Phys. Rev.. B35,2714(1987) 3. E.C.Stelterand D.Lazarus,Phys.Rev. B36,9545(1987)

4. J.Chevrier,SolidState Commun.65, 1461 (1988)

5. W.Wagner,R.Poerschke andH.Wollenberger, Europhys. Lett, 2,379(1986) 6. Yi-Chen

Cheng,

Phys.Rev. B34, 7400(1986)7. S.Mukherjee, J.L.Moran-Lopez,V.Kumar,andK.H.Bennemann, Phys.

Rev.B25, 730(1982)

8. Th.Berghaus,Ch.Lunau,H.NeddermeyerandV.Rogge,Surface Science

182, 133 (1987)

9. R.B.Wright, M.R.Hankins, M.S.Owensand D.LCocke.J.Vac.Sci.Technol.A5,593 (1987)

10. P.Sen, D.D.Sarma, R.C.Budhani,

K.L.Chopra,

andON.R.Rao, J.Phys.F:Met.Phys.

14, 565(1984)11. L.Schlapbach,A.Seiler, F.Stucki, H.C.Siegmann,J.Less-Common Met.73,

145 (1980)

12. L.Schlapbach,NATO ASI B136,397(1986)

13. L.Schlapbach, in Hydrogen In Intermetalllc Compounds II, ed.

L.Schlapbach, Springer

TAP 64. chapt.2,inpress14. F.Vanini, St.Buchler, X.N.Yu, M.Erbudak,L.Schlapbach,andA.Baiker,

Surface Science189, 1117(1987)

15. S.ModakandB.C.Khanra,Phys.Rev.B,34,5909(1986)

16. P.Oelhafen,R.Lapka,U.Gubler,J.Krieg, A.DasGupta,H.J.Guntherodt,

T.Mizoguchi, C.Hague, J.Kubler and S.R.Nagel, Rapidly Quenched Metals IV,eds. T.Masumoto andK.Suzuki(JapanInstitute ofMetals,

Sendai),1259 (1982)

17. P.Villars andL.D.Calvert, Pearson's Handbook ofCrystallographicDate for IntermetallicPhases,Am.Soc.forMetals,1985

18. T.B.Massalski,ed.,Binary AlloyPhaseDiagramsVolI,American Soc. forMetals, Ohio,1986

19. E.Keller, Y.Khan, U.Gorres,Z.Metallkde.77,43(1986)

20. G.Kirch, R.Hampelmann,E.Schwab, H.Zuechner,Z.Physik.ChemieNF, 126,109 (1981)