READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Strength and deformation tests on frozen peat

MacFarlane, I. C.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=22770085-31e5-4e49-a41d-5b18723d5352 https://publications-cnrc.canada.ca/fra/voir/objet/?id=22770085-31e5-4e49-a41d-5b18723d5352

Ser

TH1

N21r2

no.

433

c. 2BLDG

CBNSEIL

NATIONAL

DE

RECHERCHES

DU

CANADA

STRENGTH

AND DEFORMATION TESTS ON FROZEN PEAT

& 2- -..+ * BY

I.

@. MACFARLANE

I C E 10 CENTS R E P R I N T E D F R O MPROCEEDINGS

THIRD INTERNATIONAL PEAT CONGRESS H E L D IN QUEBEC, CANADA, 1 8

-

23 AUGUST 1968P. 143

-

149R E S E A R C H P A P E R N O . 433

O F T H E

DlVlSlON OF BUILDING RESEARCH

OTTAWA

Strength and Deformation Tests on

Frozen Peat

I. C. MacFARLANE

CANADA

ABSTRACT

Very little information is available on the properties of peat in its frozen state. There is considerably more information on the compressive strength and physical properties of ice and of frozen soils in general. Russian studies have shown that the stress-deformation state of frozen soil is dependent upon a time factor and that frozen soil may be regarded as a com- pressible elastic-plastic-viscous body.

Axial compression tests were carried out on frozen fibrous peat samples to test the hypothesis that peat in its frozen state exhibits rheological properties similar to those of frozen inorganic soils. Curves plotted from the results of the tests indicate that a load applied to a frozen peat sample will cause it to react in a time dependent manner, as for inorganic soils.

A series of unconfined compression tests shows that the strength of frozen peat is quite high. The strength varies with temperature; the lower the temperature, the higher the strength. The rate of load application also has an effect on strength, with a higher rate of strain resulting in a higher strength. The highest strengths and lowest strains were found in those peat samples tested parallel to the natural bedding plane of the peat. For a testing temperature of -9.5"C the average unconfined strength of the frozen peat varied from 40 kg/cm2 at 1 per cent per minute strain rate to 47 kg/cm2 at 2 per cent per minute strain rate. At a testing temperature of -1 5.5"C the average unconfined compressive strength at a strain rate of 2 per cent per minute was 55.5 kg/cm2. These results represent values in the order of 350 to 400 times the unconfined compressive strength of the unfrozen peat.

On ne possede que peu de donnees concernant la tourbe

i

1'8tat conge16 mais on a recueilli un nombre considerable de renseignements sur la resistancei

la compression et les propriktks physiques de la glace et des sols congeles. Les etudes effectuees en URSS ont montre que la relation contrainte-deformation des sols congeles etait fonction de la duree, et que le sol conge16 peut etre considere comme un materiau compressible, visco-6lastique et plastique.Afin de verifier I'hypothkse selon laquelle la tourbe

i

1'6tat conge16 possede des proprietes rheologiques semblables

a

celles des sols inorganiques congeles, des essais de compression axiale ont kt6 effectues sur des Bprouvettes de tourbe fibreuse congelee. Les graphiques des resultats des essais revdent que la charge appliquee sur une Bprouvette de tourbe congelee entraine une modification en fonction du temps tout comme celle d'un sol inorganique.Une serie d'essais de compression d'eprouvettes libres d'etreinte montrent que la resistance de la tourbe congelee est tres grande. Sa resistance varie avec la temperature; plus la temperature est basse, plus grande est sa resistance. La vitesse de chargement a aussi un effet sur la resistance. Cette derniere croit en fonction de la vitesse d'application de la contraite. Les plus grandes resistances et les plus faibles deformations ont Bt6 obtenues avec des Bprouvettes de tourbe prelevees parallelement au plan de stratification de la tourbe.

A

une temperature d'essais de -9.5"C, la resistance moyenne d'une Bprouvette libre d'etreinte en tourbe congelee varie de 40 kg/cm2i

une vitesse de deformation de 1 p. 100 par minute jusqu'a 47 kg!cm2a

une vitesse de deformation de2 p. 100 par minute. A une temperature d'essai de -1 5.5"C, la resistance moyenne 21 la compression d'une eprouvette libre d'etreinte a une vitesse de deformation de 2 p. 100 par minute est de 55.5 kg/cm2. Ces resistances atteignent donc de 350

i

400 fois la resistancea

la compression de la tourbe non congelee libre d'etreinte.In the construction of access routes (roads and railways) over the frozen layer in bogs is of engineering significance. Construc- northern peatland areas, as well as in off-road vehicle access, the tion operations in muskeg areas are frequently carried out in depth of freezing and the strength and deformation properties of winter because of the unstable condition and low bearing capa- city of the material in the unfrozen (summer) condition. The maximum load that can be carried by the frozen layer is there- I. C. MacFarlane, Soil Mechanics Section, Division o f Building Research, National

Research Council of Canada, Ottawa, Ontario. fore important.

Information on the properties of peat in the frozen state is meagre. There are, however, considerably more data on the strength and physical properties of ice (Mantis, 1951) and frozen soils in general (Vyalov, 1959). So many variables are involved in the strength properties of ice and frozen soils that generalities are of doubtful value. Nevertheless, for purposes of rough com- parison, Mantis (1951) reports ultimate compressive strengths of ice ranging from 312

-

1,400 psi (22.0-

99.6 kg/cmZ). Khomi- chevskaya (1940) reports compressive strengths for frozen in- organic soils ranging from as low as 278 psi (19.6 kg/cm2), for an artificially frozen light silt loam, to as high as 1,930 psi (135.9 kg/cm2), for a perennially frozen sand.Most of the information available on the ultimate strength of frozen peats comes from the USSR. Khomichevskaya (1940) reports that in a series of tests to determine the compressive strength of peat the strength varied from 390

-

795 psi (27.5-

56.0 kg/cm2), with an average of 551 psi (38.7 kg/cm2). The moisture content of the specimens varied from 300-

900 per cent of dry weight (average of 581.7 per cent), and the test temperature varied from - 1.1 to -1.9"C. Not enough tests were carried out, however, to establish any definite relation between the compressive strength of the frozen peat and the temperature, loading rate, or moisture content. Romanov and Rozhanskaya (1946), reporting on 26 tests of frozen peat specimens, showed shear strengths ranging all the way from 22.7-

594 psi (1.G-

41.8 kg/cm2). They suggest that with such a range of values it is inadmissible to use an average value of shear strength. They indicate also that various physical properties of the test speci- mens (e.g. porosity, density, volume of ice, thermal conductivity and strength) are interrelated, so that by determining one of these it should be possible to estimate the magnitude of the others.Crawford (1954) carried out a few preliminary tests on frozen peat samples and obtained unconfined compressive strengths ranging from 28

-

350 psi (1.97-

24.6 kg/cm2) at 10 per cent strain. H e observed that the strain rate was an important consideration in the strength testing of frozen peat.Rather extensive studies have been carried out in the USSR into the fundamental aspects of stress-deformation properties of frozen soils (Vyalov, 1955; Vyalov and Skibitskiy, 1961; Tsyto- vich, 1957). These studies have shown that the stress-deformation state of frozen soil is dependent upon a time factor and that frozen soil may be regarded as a compressible elastic-plastic- viscous body (Vyalov, 1955).

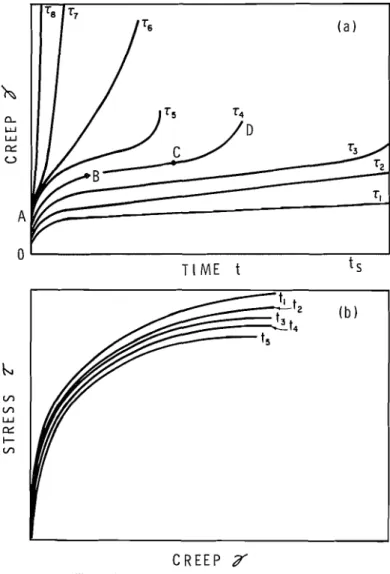

Frozen soils, creep and their strength is reduced with time under sustained loading (Vyalov and Skibitskiy, 1961). The character of the phenomena depends upon the soil properties, but in general the phenomena obey common rheological laws reflected by a family of curves (Figure I), developed experi- mentally by Vyalov (1955).

The process of creep characterized by the curves in Figure l(a) varies with the magnitude of load. If 7

<

7, (where 7, is themaximum long-term strength), the deformations are damped and failure does not occur. If 7

>

re, then non-damping deformationsoccur, including the following stages (Vyalov and Skibhkiy, 1961): OA-shock (i.e., instantaneous) loading, AB-variable, BC-steady (plastic-viscous flow at constant rate), and CD- progressive (at an increasing rate). In frozen soils the progressive stage culminates in brittle failure or in total plastic deformation of the sample (without disrupting continuity).

In the general case, the relation between the stress 7 and

strain

r

is non-linear and is reflected by a family of mutually similar curves, whose parameter is the time during which the load acts (Figure l(b)).In a limited test program at the Division of Building Re- search, National Research Council, several samples of artificially frozen peat were subjected to constant load tests for a limited

I

T I M E

t

t s

C R E E P

Z

Figure 1. Rheological curves for frozen soils.

time in a cold room. It was assumed that frozen peat would exhibit the same rheological pattern as that of inorganic soils; preliminary tests were carried out to verify this hypothesis. In addition, a number of unconfined compressive tests were per- formed on frozen peat samples at different rates of strain and different temperatures to ascertain the effect of the parameters on ultimate strengths.

SAMPLE RETRIEVAL AND PREPARATION

Block peat samples, 10 in. (25.4 c m ) on a side, were obtained from a local bog at the 1- to 2-ft (0.3- to 0.6-m) depth. The peat was non-woody, fine-fibrous Sphagnum peat, with an average water content of 878 per cent, bulk density of 58 pcf (0.93 t/cu m), specific gravity of soil solids of 1.4, and organic content of 97.9 per cent.

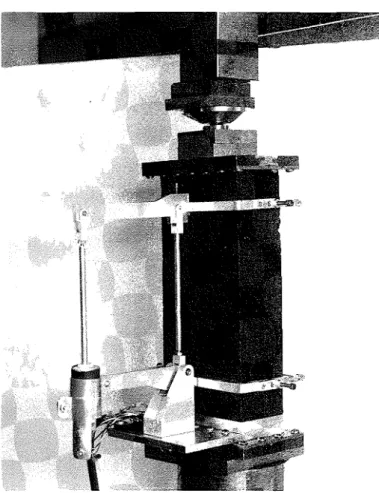

In the laboratory one peat block was sliced vertically and another horizontally into four equal sections. These smaller blocks were then placed in a cold room for three days at a temperature of -9.5"C. The frozen samples were cut lengthwise into two bricks that were trimmed to final dimensions of 2 by 4 by 8.5 in. (5 by 10 by 21.5 cm) with a lathe set up in the cold room. Small pieces from the ends of the samples were retained for water content determinations. A typical brick section is shown in Figure 2. T o prevent sublimation of the ice, the speci- mens were immersed in a kerosene bath until tested. Following

Figure 2. Frozen peat specimen ready for controlled stress tests.

constant load tests, some of the samples were trimmed with a band-saw into smaller blocks 2 by 2 by 4 in. (5 by 5 by 10 cm) for unconfined compressive strength tests.

TEST PROCEDURES Constant Load (Creep) Tests

The equipment used in the creep test program was the apparatus normally used for carrying out such tests on ice samples (Gold, 1965). Compressive loads were applied to the 2- by 4-in. face of the specimen with a simple lever system having a load magni- fication of 10.2:l. The loading plates in contact with the frozen peat were made of steel with surfaces ground to a flat "mirror" finish.

The weights used for applying load, which could be applied or removed within about 2 seconds, were supported on a jack. Just prior to application of the load, the specimen supported the lever arm. This preload of about 25.6 psi (1.8 kg/cm2) was ap- plied between 2 and 4 seconds before the full load.

Creep was measured over a 6-in. (15.25-cm) gauge length with an extensometer of adjustable working range from 0

-

4 per cent strain. The extensometer was supported on the lower load- ing plate and attached by thumb screws to two metal collars frozen to the specimen (Figure 2). Design of the extensometer and its mounting was such that the measured deformation was not influenced by possible slight bending of the specimen during creep. A linear differential transformer was used to transform creep strain into an electrical signal for recording.The experiments were conducted in a cold room maintained at a temperature of -9.S°C

*

0.5"C. Constant compressive stresses of between 85 and 285 psi (6 and 20 kg/cmF) were ap-plied. Creep strain was recorded on a strip chart recorder located outside the cold room. As a double check, strain was also measured by a digital voltmeter with recording tape.

Ten single-load tests were carried out, load in all cases being applied for at least one hour and in some cases for as long as 20 hours (Table I). One specinlen was loaded four times with a series of increasing loads.

TABLE I

Duration of Load for Creep Tests Sample

Number

Stress Duration of Load kg/cm2 min

1-1A 10 Immediate failure

1 -3A 14 1275 1-38 6 375 2-TI A 14 400 2-TI B 10 400 2-T2A 10 1290 2-T2 B 6 600 2-B1 A 6 60 2-B1 A 10 120 2-B1 A 14 11 86 2-B1 A 20 240 2-B1 B 20 106 2-B2A 20 145 2-B2B 14 1204

Constant Strain Rate Tests

A series of 37 unconfined compressive tests on small 2- by 2- by 4-in. ( 5 by 5 by 10-cm) samples was carried out in the cold room. Test specimens were placed in a 5-ton capacity unconfined com- pression machine, and an axial compressive load was applied until the sample failed. A special guide was used to prevent the specimens from bending over during the test. Load was applied to some samples normal to the natural bedding plane of the fibres (i.e., in the in situ vertical direction); to others, parallel to the natural bedding plane.

The frozen peat sample was placed between two bearing plates; the upper bearing plate acted against a dynamometer ring, the deflection of which was measured by a stress dial indicator and gave the load on the sample. The lower bearing plate was mounted on a hydraulic jack activated by an electric motor. A strain dial indicator was mounted on the lower plate, bearing against the upper one so as to measure directly the deformation of the sample. As the load was applied, stress and strain dials were read at specified intervals. Tests were per- formed at two different strain rates: 1 per cent per minute and 2 per cent per minute.

The majority of tests were carried out at a temperature of -9.S°C, but a few tests were carried out at -15.5"C to illustrate the effect of temperature on ultimate strength. Available facili- ties did not permit the carrying out of tests at temperatures near 0°C.

TEST RESULTS

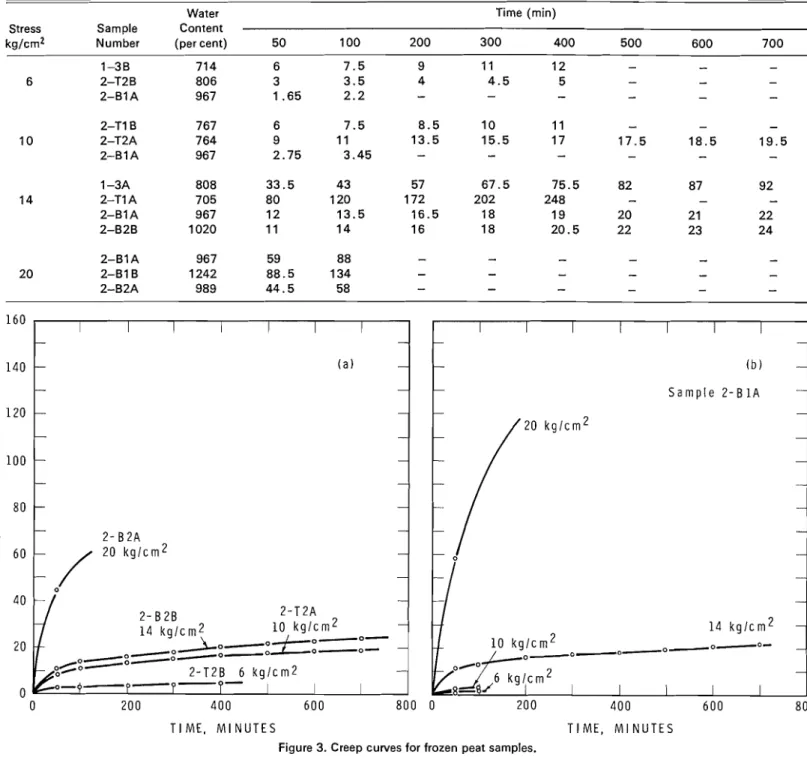

Table I1 summarizes the creep at various intervals for the specified stresses of 85, 142, 199 and 285 psi (6, 10, 14 and 20 kg/cm2) in the constant load tests. The Table also gives the water content of the various samples. Figure 3(a) shows the plots of the creep curves for various samples with different loads; and Figure 3(b) the creep curve for the single sample, which was loaded with a series of increasing loads. The similarity of these

TABLE II

Creep for Various Loads

-

(in./in.) x 1o4

Water Time (min) . .

Stress Sample Content

kg/crn2 Number (per cent) 50 100 200 300 400 500 600 700

I I I - - - ( a ) -

-

- - - - - - - - - - - - 2 - B 2 A - - - - 2 - B 2B 2 - T 2 A 1 4 k g l c rn2 1 0 k g l c m 2 L o - o j - : : ~ - s -" , , : -o -O 2 - T 2 B 6 k g l c m 2 - I 1 I I I - - ( b ) - S a m p l e Z - B ~ A - - - - - - --

- - - 1 4 k g l c m 2 - O O . o L - O - o - O - - I I I I T I M E , M I N U T E S T I M E , M I N U T E SFigure 3. Creep curves for frozen peat samples.

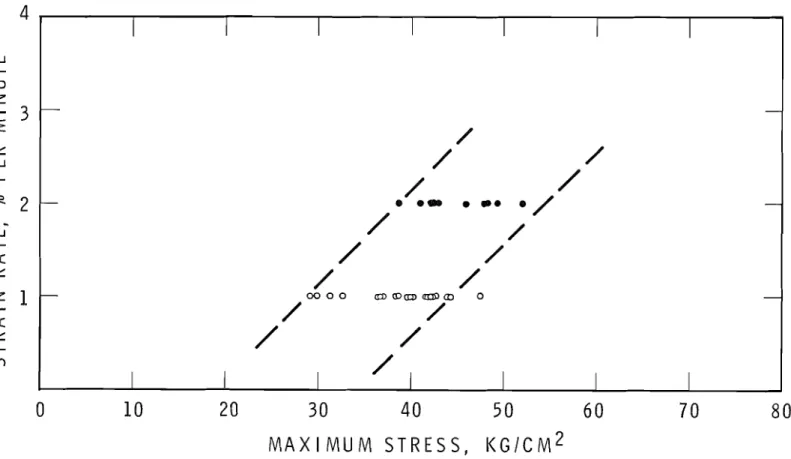

TABLE I l l

Summary of Strength Test Results

Test Strain Avg. Max. Avg. Ult.

Temp. Rate Strain Strength No. of

"C per cent/min per cent kg/cm2 Samples Remarks

-9.5 1 3.06 40.0 15 Load par'l. to nat. bedding plane

-9.5 2 3.04 47.0 7 Load par'l. to nat. bedding plane

-9.5 1 13.2 36.6 4 Load normal to nat. bedding plane

-9.5 2 11.5 40.8 3 Load normal to nat. bedding plane

-15.5 2 3.3 55.5 7 Load par'l. to nat. bedding plane 146

M A X I

M U M S T R E S S ,

KGICM'

Figure 6. Maximum stress vs strain rate.

The direction of load relative to natural bedding plane had a great effect on maximum strain at failure, strain being about 305 per cent greater, on the average, for samples loaded normal t o the bedding plane than for those loaded parallel to the bed- ding plane.

APPRAISAL AND DISCUSSION

In practical field problems involving frozen soils it is essential to know the long-term strength of a frozen soil under a structure, and to know also the maximum temperature to which the frozen soil can be subjected before failure occurs. The theory and techniques developed by Vyalov and Skibitskiy (Vyalov, 1955; Vyalov and Skibitskiy, 1961) can be utilized to estimate the ultimate long-term strength of frozen inorganic soils.

The shape of the curves of Figures 3 and 4 indicates that frozen peat reacts in a time dependent manner similar to that of frozen inorganic soils. Consequently, it may be inferred that the ultimate long-term strength of peat can be evaluated like that of other soils. In frozen veats (varticularlv the more fibrous types), however, the quantity of ice is much greater than that in frozen inorganic soils. Frozen peats with an extremely high water (or ice) content tend to act rather more like ice than soil. The rigorous assessment of the strength of a frozen soil is a complicated problem. The temperature of the sample during test is rather critical, as is the frozen and unfrozen water content; the rate of strain has been shown to be important; and thermo- dynamic processes (such as pressure induced thawing) while the sample is stressed are of significance. These factors are at present extremely difficult to evaluate, for both organic and inorganic soils. Consequently, the results obtained from this test program of the ultimate strength of frozen peat are but an approximation, although they do provide a general quantitative value for the

frozen strength of one particular peat type. Further testing must be carried out with other peat types over a much longer period of time, with greater control of sample freezing temperature and test temperature, and with a wider range of strain rates.

As is indicated in Table 111, the unconfined compressive strength of one type of frozen peat, measured at a temperature of -9.5"C, averaged 570 psi (40 kg/cm? at the 1 per cent per minute strain rate and 670 psi (47 kg/cm2) at the 2 per cent per minute strain rate. These values agree very favourably with frozen peat strengths reported by Khomichevskaya (1940) and Romanov and Rozhanskaya (1946), but they are somewhat higher than those reported by Crawford (1954). The latter result may arise from the fact that the tests performed by Crawford were carried out at strain rates much lower than those reported herein.

The unconfined compressive strength of an unfrozen peat of the same general physical characteristics as the frozen samples averaged 1.75 psi (0.123 kg/ cm'). Consequently, the ultimate compressive strength of a frozen fibrous peat (at -9.5"C) is of the order of 350 times as great as that of the unfrozen peat.

ACKNOWLEDGMENT

The author gratefully acknowledges the assistance of J. A. 0.

Guibord, who carried out the experimental work. This paper is a contribution from the Division of Building Research, National Research Council of Canada, and is published with the approval of the Director of the Division.

REFERENCES

Crawford, C. B. 1954. Some engineering properties of muskeg. Unpublished report.

Gold, L. W. 1965. The initial creep of columnar-grained ice. Part I: Observed behaviour. Can. J. Physics, 43:1414-1422.

Khomichevskaya, L. S. 1940. The compressive strength of perma- frost and ice in their natural states. Trans. Permafrost Committee, USSR, vol. X, p. 37-83. Translation issued by U.S. Corps of Engineers, Office of Chief of Engineers, Airfields Branch, Engineering Division, ~ i l i t a r ~ Construction. October 1951. Mantis, H. T. (ed.) 1951. Review of the properties of snow and

ice. U.S. Corps of Engineers, SIPRE Report 4.

Romanov, V. V., and 0. D. Rozhanskaya. 1946. The physical properties of the frozen layers of marshes. (In Russian.) Priroda. No. 3, p. 57.

Tsytovich, N. A. 1957. The fundamentals of frozen ground mechanics (new investigations). Proc., Fourth Inter. Conf. on Soil Mech. and Found. Engng., 1 : 116-1 19.

Vyalov, S. S. 1955. Creep and long-term strength of frozen soils. Dok. Akad. Nauk, 104:6:850-853.

-

1959. Rheological properties and bearing capacity of frozen soils. Izdatel'stvo Akad. S.S.S.R., Moscow. U.S. Army Corps of Engineers, Army Material Command, C.R.R.E.L., Transl. 74, Hanover, N.H., 1965. 219 p.and A. M. Skibitskiy. 1961. Problems of the rheology of soils. Proc.. Fifth Inter. Conf. on Soil Mech. and Found. Engng.,