Magnesium

Insertion in Vanadium Oxides:

A Structural

Study

By

Petr NóvákPaul ScherrerInstitute, ElectrochemistrySection,CH-5232Villigen PSI,Switzerland

Valéry

Shklover and ReinhardNesper

Institute of

Crystallography

andPetrography,and LaboratoryforInorganic

Chemistry,-Zentrum,CH-8092Zürich,Switzerland

Dedicatedto

Professor

Dr.Wolf

Vielstichontheoccasionof

his 70thbirthday

(Received July7, 1993;acceptedAugust 30, 1993)

Magnesium battery

/

Vanadium oxides/

Mg2

+ ion insertion/

X-ray diffraction / Electrochemistry

X-ray powderdiffraction patterns ofV205-related electrode materials

[V205,

NaV308 and Mg(V308)2] as well asofpoly(tetrafluoroethylene)-bonded composite

electrodes,containing chemically andelectrochemicallyinserted

Mg2

+,

wereanalysed

before andafter

Mg2+

insertion. Transmission electronmicroscopyandbothwavelengthand energydispersiveelectronprobe microanalysiswereappliedfor thedetermination of the

compo-sition andstructureofdifferenttypesofmicroparticlesfoundinthe electrodemass.

Röntgen-Pulverdiffraktogramme

einiger V205-verwandtenMg2

+-einlagernden

Elektro-denmaterialien[V205,NaV308und Mg(V308)2]sowie derPolytetrafluoroethylen-halti-genVerbundelektroden wurdenvorund nachderchemischen sowie elektrochemischen

Einlagerungvon

Mg2+

ausgewertet. Transmissions-ElektronenmikroskopiesowieWel-lenlängen- und energieaufgelöste

Elektronen-Mikroprobenanalyse

wurden für dieBe-stimmungvon Zusammensetzungund Struktur derinder Elektrodenmassegefundenen

verschiedenen Mikroteilchen

eingesetzt.

1.

Introduction

High

energydensity rechargeable

iontransferbatteriesarecurrently

underdevelopment

in manylaboratories.They

consistofanalkali metalnegative

electrode,

anaprotic (nonaqueous) electrolyte,

and apositive

insertionValéry Nesper

generated

at one of the electrodes is at the same time consumed at theopposite

electrode.Thus,

incontrasttocustomary

batteries there isnoneed forcomparatively large electrolyte

volumes.Due to its natural

abundance,

lowequivalent

weight,

and lowprice,

metallicmagnesium might

beanalternativetolithiumorsodium inafuture ion transferbattery [1 —4].

Unfortunately,

themagnesium

electrochemistry

at ambienttemperatures

is far frombeing

wellunderstood,

andonly

fewcompounds containing

insertedmagnesium

ions have been mentioned in the literature[1-14].

We

regard

V205

and other related vanadium oxides aspromising

electroactive materials for thepositive

insertion electrode ofasecondary

Mg-battery [3, 4].

Mg2+

ions can be inserted in the oxidechemically

orelectrochemically.

An overall scheme for the electrochemical reaction can be written asV205

+Mg2+

+2xe-«MgxV205

.Electrochemicaltestshave shown that the insertion reactionsare

fairly

reversible. The amountofMg2+

inserted inV205

depends

on the nature oftheelectrolyte,

on the ratio between the amounts ofH20

andMg2+

in the solution aswell as on the absolute amountofH20

in theelectrolyte

[3].

Thehighest

coulombiccapacities ',

about200Ah/kg,

werereached onV205

(and V6013)

in acetonitrile solutioncontaining

1 MMg(C104)2

+1 M

H20

[3, 15].

TheamountofMg2

+insertedin

V205

decreases with thedecreasing

amount ofH20

in the solution andapproaches

about 20Ah/

kg

infairly dry electrolytes [3].

In order to facilitate the

Mg2+

insertion in theinterlayer

space of theoxide,

weattempted

to increase the distance between theV205

layers

by

introducing

metal ions in theV205 lattice,

forming,

thus,

vanadium bronzes.Indeed,

several vanadium bronzes such asNaV308

andMg(V308)2

showpromising

coulombiccapacities

ofup to 110Ah/kg

inrigorously dry electrolytes [4].

Obviously,

variations in thecrystal

structureof the insertion materials influence theirability

to accommodateMg2+

or other metal ions. Thepresent

workattempts

to determine the structures of theMg2

+-inserted

V205

aswellasofthe vanadium bronzes(which

arebothpoorly

crystalline).

Efforts have been made to correlate the results of the

crystallographic

structuralanalysis

of the vanadium bronzes with their electrochemicalbehaviour,

with the aim ofgaining

information necessary for the futuredesign

andoptimisation

of thesynthesis

of bronzes withhigher

coulombiccapacity.

1 Coulombiccapacityisdefined

aschargestored in1kgof theoxide andcorresponds with theamountof

Mg2+

insertedinthe oxide.Table 1. SchemeofpreparationofMg-insertedvanadium oxides*. v2o5 powder (I)" Synthesisof bronzes[4] (H20)y (III)" Driedat: 50°C 100°C NaV308. (H20)y (IX)"

Mg(V308)2|

(H20)y (IV) 200°C Nav3ug. ,(H20)y (X)" Nav3u8. (H20)y (XI)" Electrochemical cycling^aMgxV308

(H20)y (XVI)"^aMgxV308

(H20)y+TC| (XVII)" MgxV205 ÍV)" at100°C Mg(V308)2, (H20)y (XII)· Chemical Mg2+-insertion STOPioxidised^aMgxV308.

(H20)y+TC| (XVIII)" Mg1+X. (v3o8)2. (H20)y (XIX)" Mg¿+-insertion Chemically I Electrochemically STOPreduced! cycles 20.5w:yc!es MgxV205 +TC (XIII)"· MgxV205 +TC (XIV)"(*)The chemical formulas of thesamplesmay indicate eitherpreliminary compositionorthe compositionof the mainphaseof thesample (*")Samplestudiedby X-raypowderdiffraction

2.

Experimental

2.1. Materials

AsreceivedV205powder(I, Aldrich,99.6+ %)andV205 single

crystals2

(11)wereused asstartingmaterials fortheexperiments (Table 1).Thebronzes,NaV308andMg(V3Os)2were prepared asin [4]: anaqueous solution ofNaOH, or an aqueous suspension of

MgO, was stirred witha stoichiometricamount ofV205 (I)at ~50°C overnight. The

orange-yellow colourofV205 turnedgradually tored-brown under slowprecipitation of thehydratedbronze,

NaV308(H20),,

(III)orMg(V308)2(H20)),

(IV). The latterwas filtered, washed with H20, and vacuum-dried at room temperature for several days. Afteramildgrinding,thehydrated

bronzewasfurtherdried underdynamic

vacuumat50, 100, or200°C overnight (IX-XII, Table1). Note,the formula

(H20),,

denotesanunknown,variableamountof bound water,

including

y = 0. 2 The V205single crystals,

agift

of Dr. K. Kato of the National Institute for Research in Inorganic Materials, Tsukuba,Japan, wereprepared byY. Uchida andE. Bannai fromreagentgradeV205 of 99.99% purity usingthefloating-zone

techniqueinanimagefurnace

[16].

Detailed results ofinvestigationsofMg2

+-insertedsingle crystals

Valéry Nesper

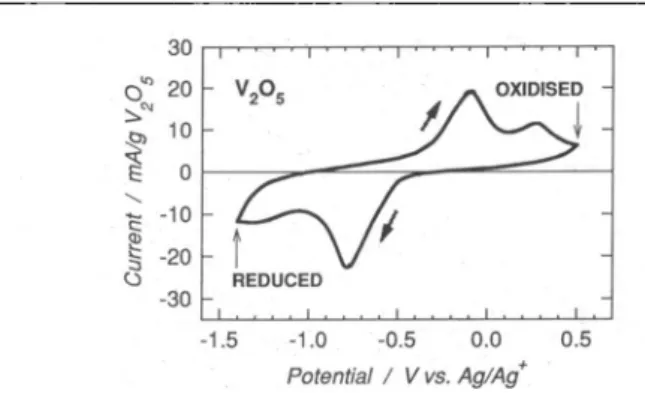

-1.5 -1.0 -0.5 0.0 0.5

Potential/ Vvs.

Ag/Ag*

Fig. 1. Cyclic voltammogram (first cycleat0.02 mV/s) in the 1 M Mg(C104)2 + 1 M

H20/AN electrolyteofaV205electrodecontaining50wt.% teflonised carbon(VI).

2.2.

Magnesium

insertionThecompoundsV205(I, II),NaV308(IX-XI)andMg(V308)2 (XII)werescreened for

their ability to insert (excess)

Mg2+

via chemical and electrochemical tests. Chemical insertion experiments involved placingeither about 0.5g ofa powdery material or aV205single crystal (II)incontactwithexcess1 Mdibutylmagnesiumsolutioninheptane

(Aldrich)underanAr

atmosphere,

andallowing

themto reactunder occasionalstirring

atroomtemperaturefortwomonths. The materialswerethen rinsed withheptaneseveral

times, dried,and examined for structuralchangesviaX-raydiffraction.

The electrochemical insertion of

Mg2+

in V205, NaV308 and Mg(V308)2 wasinvestigated using cyclic voltammetry at very slow potential sweeprates. To give the workingelectrodes sufficient electronicconductivityand mechanicalstability,eachofthe electroactive materialswasdry-mixedwith anequalpartof TC(TeflonisedCarbon: 25

wt.% PTFE + 75 wt.%acetylene black),and the mixture was

spread

by pressingon a currentcollector. To avoid oxygen and moisturecontamination,allsucceeding manipu-lations and measurementsdescribed belowwereperformed

eitherin an Ar-filled gloveboxinwhichtheH20and02levelswerenotpermittedtoexceed 5 ppm,orinhermetically

sealedcells assembledintheglove box.

Electrochemicalexperimentswereperformedintwokinds ofelectrolytes: (i)atroom

temperature in acetonitrile (AN) solutions containing 1 M Mg(C104)2 and various

amounts(0.02M

—

2.5M) ofH20,and (ii) at80°C in room temperature molten salts.

The salt melt contained 3 wt.% MgCl2, 56 wt.% A1C13 and 41 wt.% l-ethyl-3-methylimidazoliumchloride(EMIC).Theexperimentaldetails have beendescribed else-where [3, 4], Conventionalglasscells with a

free-hanging working

electrode, aswell ascells withworkingandcounterelectrodespressed togetherwithaspringwereemployed.

(With the lattercells, better electrochemical

performance

athighersweep rates, due tobetter electrical contact of the electroactive particles to the currentcollector, was ob-served.) The

working

electrodes hadgeometrical

areas of 1.3 —1.5cm2and contained10—20 mg of electroactive material. For the sake ofcomparison, the currents were

normalised bythemassof the electroactive material.A

magnesium

counterelectrode andan

Ag/Ag+

reference electrode were used in AN based solutions. In the salt melt,metallic aluminium servedasthe counterelectrode

against

which thepotentialswerealsomeasured.

Electrochemicallytreated

samples

for X-raypowder

diffractionmeasurementswerepreparedasfollows: The

working

electrodewasvoltammetrically cycled, starting

withareduction sweepfrom theopencircuitpotential. Then,itwasstabilised in the oxidised orreduced stateatthe

appropriate

potential(Fig.

1)overnight, removed from thecell,washed indrydeoxygenatedacetonitrileovernight,and dried inthegloveboxatmosphere

for severaldays.The electrodemassscrapedfrom thecurrentcollectorwasloadedin a

glasscapillarywhichwassealedafterwards.

Electrochemical magnesium insertion experimentswere performed also with V205 single crystals. Thecrystals were contacted by pressing them against a glassy carbon

currentcollector,

using

thespring-loadedelectrochemicalcelldescribed above. Theelec-trolytewas 1 MMg(C104)2 + 0.9MH20inAN. Inatypical experiment,thepotential

was sweepedat0.5µ /s fromits opencircuit valueto —1.4 V(vs. Ag/Ag+

). Then,the single crystal wasreduced at

—

1.4V for 5weeks. During thisprocedure, the orange-yellow colour of the V205 turned dark. The reduced crystal was washed with dry

deoxygenated

AN,dried in thegloveboxatmosphere,andanalysedafterwards.2.3. Structural

investigations

X-ray powderdiffractionpatternsofsamplesI,III, V,VIandIX—XIX,sealed underan

inert atmosphere in glass capillaries, were recorded using a STOE automatic powder diffractometer(CuKaradiation,Gemonochromator,small linearpositionsensitive detec-tor, data collection inDebyemode, 150stepswithin the20 interval of5

—

80°,1000sec

perstep). Thepatternsofthe sampleswere indexed with the TREOR and LATCON programs.

Asingle crystalfour-circle Nicoletdiffractometeras wellas alight microscopewere

usedtostudytheelectrochemicallytreatedV205sampleVIII.

Transmission electronmicroscopy (TEM)studies of thesamplesXIIIand XIVwere

performed on a Philips SM 30 ST transmission electron microscope equipped with a

detector forenergydispersive X-rayspectrometry (EDX) anda STEM attachment,as

wellaswithaPhilips500scanning microscopewithanEDXattachment.

Wavelength dispersiveelectron

probe microanalysis

( )[17]wasapplied

forthedetermination of theMgcontentinV, XII,XVI andXIXusingaCameca SX50equipped

with fivespectrometers(accelerating voltage20kV,beamcurrent20µ ).

Solidstate NMRspectraof the

sample

IIIwere recorded witha BruckerAMX400spectrometer equipped with a Wide-Bore-Magnet (B0 = 9.4 Tesla) and a high-speed

double-bearing MAS-probe.

3.

Results anddiscussion

3.1.

Hydrated

sodium vanadiumbronzesIII, IX,

X and XITo avoid a

possible

reaction of metallicmagnesium

with water,fairly

dry electrolytes

arepreferred

in aMg battery.

Because ourpreliminary

electrochemicalexperiments

have shown that the coulombiccapacity

ofpure

V205

significantly

decreases with thedecreasing

amount ofwaterinthe

electrolyte

[3],

vanadium bronzes of theLiV308

type

weresynthesised

and tested for

Mg2+

insertion. Incontrast to theV205

case, the bronzesallowanelectrochemical insertion of

Mg2+

fromarigorously dry

environ-ment. As

reported

in[4],

coulombiccapacities

ofup to 110Ah/kg

werereached for the best

samples

ofNaV308.

It follows from the

comparison

ofcoulombiccapacities

ofthe bronzesValéry Nesper

40 r

Fig.2.Cyclic voltammograms(thirdcyclesat0.05mV/s)in theMgCl2/AlCl3/EMICsalt melt of

NaV308(H20)v

dried at 50° C (IX) and 200° C (XI). The electrode contained 50 wt.% teflonised carbon.I_

(a)I

20.0 40.0 60.0 2 ,degr.

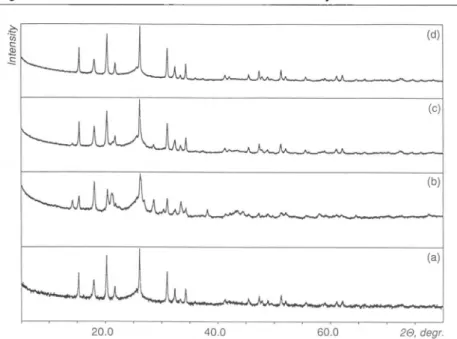

Fig.

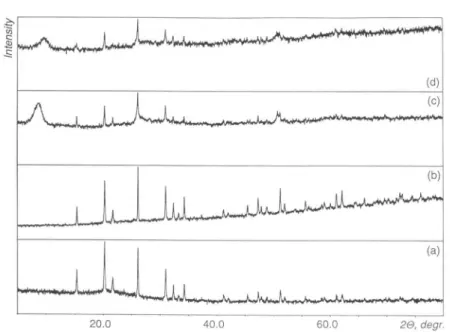

3.X-ray powderdiffraction patternsof(a)thebronzeNaV308(H20),

(III),and of theproductsof itsdrying

at(b)50° C(IX), (c) 100° C(X)and(d)200° C(XI).

electrochemically

much less active than the bronzes dried at <100°C.(There

is nosignificant

variance between the coulombiccapacities

of the50and 100°C

samples.)

This effect isillustrated inFig.

2.X-ray

diffractionpatterns

of the(poorly

crystalline)

bronzeNaVjOgtHzO),,

(III)

and theproducts

IX,

Xand XI ofdrying

of IIIat50,

100 and 200° C are similar. Thepatterns

have four common basicpeaks

(found

at 2 =11.31°,

25.84°,

28.31° and 50.73° forTable 2.Positions(20,degree) and intensities(/)ofthepeaksontheX-raydiffraction

patternsof

NaV308(H20),,

(III)and theproductsofdryingofIIIat50°C (IX),100°C(X),and200° C (XI). Ill IX X XI 20 / 20 / 20 / 20 / hkl* 7.30 13 8.13 40 8.05 25 8.03 35 100 8.90 52 8.24 20 8.23 35 11.42 44 11.31 100 11.61 100 11.78 100 11.72 40 001 12.55 88 14.64 10 200 22.88 36 23.32 16 25.84 79 25.87 85 25.82 51 25.73 82 110 27.30 13 28.31 76 28.34 67 28.30 58 28.28 87 28.52 74 111 28.88 53 30.12 20 30.15 32 -211 34.86 14 -103 38.90 19 38.68 27 -410 39.85 28 -303 40.04 25 40.29 27 40.60 26 50.73 50 50.70 98 50.66 47 50.50 100 204 60.12 30 66.34 27 -323 66.47 10 305 *

Reflections indexed with the unit cell of barnesite(a = 12.17

Â,

b = 3.602Â,

c7.78

Â,

ß = 95°2', V= 342.0Â3[18]).Table

2).

The shift tolarger

2 values in the seriesIII -> IX -> X -* XIand the

splitting (samples

X andXI)

of the firstpeak

(at

2 = 11.31° inIII),

and theapproximate

conservation of thepositions

of the three other basicpeaks

areworthy

of attention. Thesingle crystal

datapublished

forNaV308(H20)15

[18]

(existing

in nature as the mineralbarnesite)

were used for theindexing

of thepatterns

of III and IX —XI. Minorchanges

of thetwo unit cellparameters

bandc,and alarge

successive decrease of theparameter

aaccompanied

withasuccessive decreaseofthe unit cellvolume with theincreasing drying

temperature

(transition

III -» IX -» X ->XI)

wereobserved.

(Note

thatalatticeconstantvariationwithinonephase

was observed alsoforthe-phase

ofLixV205

bronzes[19].)

One may

suggest

alayered

character of thecrystal

structure of theNóvák,Valéry Nesper

lai

20.0 40.0 60.0 2 ,degr.

Fig.4.X-ray powderdiffractionpatternsof(a)thebronze

NaV308(H20)y

driedat100° C (X), and the products of(b) chemical (XVI) and (c, d) electrochemical (XVII, c and XVIII,d)Mg2+

insertion inX.andadecrease of the

interlayer separation

withwaterremoval. Thesplitting

ofthefirst basicpeak

ofX andXI mayindicateacoexistence oftwophases

with different watercontentinthesamples

Xand XI(Xa

andXb,

XIa andXlb).

Thus,

thedrying

processprobably proceeds

in distinctsteps,as, e.g.,reported

for the removal ofexcess water from thesolidgel

V205

·y

H20

[20].

A similar

abrupt change

of the unit cellparameters,

occurring during

awater removal in the course of

heating

as observed for III and IX—XI,

wasreported

earlier for the transition ofhydrated

sodium metavanadate:NaV03(H20)2

->(transition

phase)

-»/?-NaV03

[21].

The closeness of theunit cell sizes of the studied

hydrated

sodium vanadium bronzes and thecited metavanadates is

remarkable,

but a51V

solid state NMRstudy

ofthe

sample

INclearly

indicated an octahedralcoordination,

and not thetetrahedral coordination of vanadium atomscharacteristic for metavana-dates

(óiso

= -533±

10 ppm, <5 = 657 ± 10 ppm,^

=2

= -290±

10 ppm,

3

= —947 ± 10 ppm; fortheinterpretation

ofthe solid stateNMR dataon vanadium

compounds

see[22]).

Combining

the electrochemical and structuralresults,

it seems to be reasonabletosuggest

that thehydrated

bronze,

NaV308(H20)i.5,

iselec-trochemically

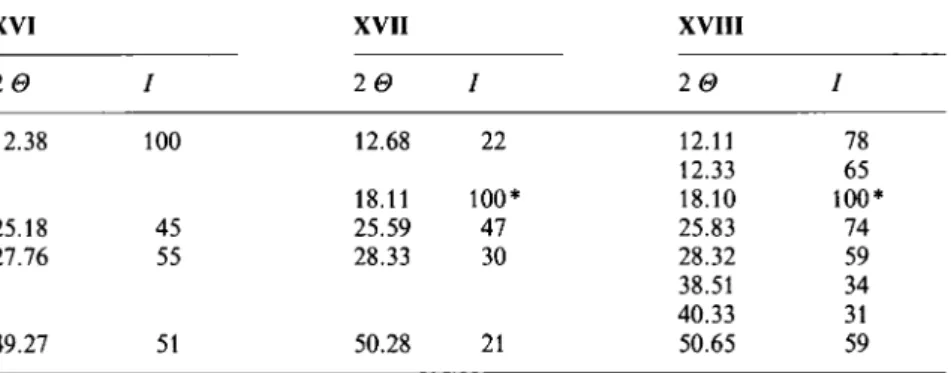

the most active constituent of the obtained Na-bronzes.Table 3. Positions(2<9, degree)and intensities (/)of thepeakson theX-raydiffraction

patterns ofthe products of chemical (XVI)and electrochemical (XVII, XVIII)

Mg2

+insertion in thehydratedsodium vanadium bronze(X).

XVI XVII XVIII

2 I 2 I 20 I 12.38 100 12.68 22 12.11 78 12.33 65 18.11 100* 18.10 100* 25.18 45 25.59 47 25.83 74 27.76 55 28.33 30 28.32 59 38.51 34 40.33 31 49.27 51 50.28 21 50.65 59 * Peak

100of triclinicPTFE[23] (fromteflonisedcarbon).

100°C,

and a new structure is formed which is able to accommodatesignificantly

lessMg2

+than the bronze

NaV^^ri-jO)^.

Infraredspectro-scopic

investigations [4]

have shown thatwaterisexpulsed,

anddehydrated

NaV308

is formedduring

thedrying

above 100° C.3.2. Productsof chemical

(XVI)

and electrochemical(XVII,

XVIII)

insertion ofMg2

* inthepartially dehydrated

sodiumvanadiumbronzeXThe

patterns

of thepoorly

crystalline products

XVI—XVIII ofMg2

+insertion in X

(Fig.

4,

Table3)

can also be describedusing

the four basicpeaks,

asthepatterns

ofIIIand thedrying products

of III discussedabove,

andcanbe indexed with the unit cell of barnesite.A

layered crystal

structurecan be

proposed

for thesamples

XVI —XVIII. The size of the unit cell(Xa:

344A3,

Xb: 293Â3)

decreasesduring

both the chemical(XVI:

242Â3)

and the electrochemicalMg2+

insertion(XVII:

227A3

and XVIII: 262Â3).

Theelectrochemically

reducedproduct

XVII has the smallest value of the unit cell volume. Note that recent electrochemicalexperiments [4]

have shown thatasignificant

amount ofMg2+

ions inserted inNaV308(H20)j,

during

the first voltammetriccycle

isirreversibly

bonded in thecrystal

lattice of the bronze.

Therefore,

theelectrochemically cycled,

oxidisedsample

XVIII containedtrapped

Mg2

+ ions.The contractionof the unitcell volumeof

NaV308(H20)y

during

Mg2

+insertion isnot

surprising;

asimilar effectwasalready

observed for cation-intercalatedV205(H20)i.6 xerogels [24].

Theélectrostrictionphenomenon

can

explain

this behaviour: theintensity

oftheelectrical fieldsurrounding

Valéry Nesper (d) (c) \******

LJxJ

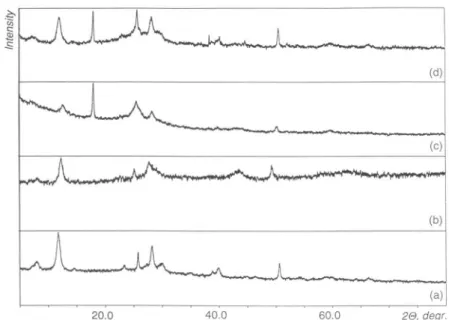

(b) (a) 20.0 40.0 60.0 2 ,degr.Fig.5.X-raypowderdiffractionpatternsof(a) V205(I), (b) Mg^^Os (V),(c)the bronze

Mg(V308)2(H20)^

driedat100°C(XII),and(d)theproduct Mg!+*( 308)2( 20),

(XIX)of chemical

Mg2+

insertionin XII.The

Mg

and Nacontents,foundby

for differentmicroparticles

in theproduct

XVI of chemicalMg2+

insertion inX,

varied in narrowintervalsof 11.7-12.2 at.% for

Mg,

and of 5.4-5.8 at.% for Na.3.3. ProductsV and XIX ofchemical

Mg2

+ insertioninV2Os (I)

andin the

Mg

bronzeIV,

XIIThe

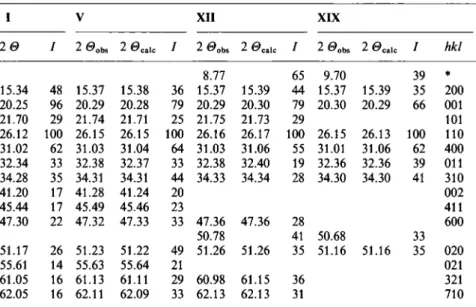

X-ray

diffractograms

of thesamples

I, V,

XIIand XIXarecompared

inFig.

5;

thepositions

of the diffractionpeaks

aregiven

in Table 4. Thepatterns of the

crystalline sample

I,

and of theproduct

V of the chemicalMg2+

insertion in I are very similar andrepresent

V205.

TheV205

unit cellparameters

calculated forIandV,

aswellasfor thosepeaks

ofXIIandXIX,

whichcan be indexed with theV205

unitcell,

arecompared

in Table 5 with the latticeparameters

ofelectrochemically prepared Mg0 2V205 [10],

and of

MgV205

synthesised

at900°C[25].

In contrast toMg0 2V2O5,

the distribution ofpeak

intensities in V is very similarto those observed inI,

andcould indicateanessentially

smalleramountof insertedMg2+

in Vascompared

toMg0.2V2O5. Indeed,

theinvestigation

showed acon-tent of 1.0 —1.2 at.% of

Mg

insample

V.(This

is in agreement with the conclusionsuggested

in[3]

thatwatermoleculesareessential for theMg2

+ insertion reaction ofV205.

Note that adry

environment is used for theTable 4.Positions(20,degree)andintensities(/)ofthepeaksontheX-raydiffraction

patterns ofthe products V and XIX ofchemical

Mg2+

insertion in V205 (I)and Mgbronze(XII).

I V XII XIX

20 I 20obs 20calc / 2<9obs 2 6»calc / 20obs 2 0calc / hkl

8.77 65 9.70 39 * 15.34 48 15.37 15.38 36 15.37 15.39 44 15.37 15.39 35 200 20.25 96 20.29 20.28 79 20.29 20.30 79 20.30 20.29 66 001 21.70 29 21.74 21.71 25 21.75 21.73 29 101 26.12 100 26.15 26.15 100 26.16 26.17 100 26.15 26.13 100 110 31.02 62 31.03 31.04 64 31.03 31.06 55 31.01 31.06 62 400 32.34 33 32.38 32.37 33 32.38 32.40 19 32.36 32.36 39 011 34.28 35 34.31 34.31 44 34.33 34.34 28 34.30 34.30 41 310 41.20 17 41.28 41.24 20 002 45.44 17 45.49 45.46 23 411 47.30 22 47.32 47.33 33 47.36 47.36 28 600 50.78 41 50.68 33 51.17 26 51.23 51.22 49 51.26 51.26 35 51.16 51.16 35 020 55.61 14 55.63 55.64 21 021 61.05 16 61.13 61.11 29 60.98 61.15 36 321 62.05 16 62.11 62.09 33 62.13 62.13 31 710 * This reflection is

contrarytotheothers,verybroadand, thus,

assigned

toanother phase.Table 5.Unit cellparametersofV205 (I),V205-relatedcomponentsofV,XIIandXIX,

and vanadiumpentoxidebronzesMg0 2V2O5 [10]andMgV205 [25],

I V XII XIX Mg0.2V2O5 MgV205

a(k)

11.5204(9) 11.513(2) 11.508(1) 11.508(8) 11.42 11.019b(k)

3.5674(5) 3.5640(6) 3.5617(3) 3.5679(6) 3.552 3.696c(Â)

4.3780(4) 4.3745(8) 4.370(2) 4.372(2) 4.468 9.965K(Â3)

179.93 179.50 179.12 179.50 181.2 405.8In

sample

XII,

thestudy

showed thepresenceofmicroparticles

with

distinctly

differentMg2+

content, viz.yellow microcrystals

with 0.14at.% of

Mg,

and brownmicrocrystals

with 1.3—

1.5 at.% of

Mg.

Themicroparticles

oftheproduct

XIX of thesubsequent

chemical insertion ofMg

in XII contain 3.8—

4.0 at.% of

Mg.

Note that severalphases

related toV205,

and acoexistence of differentphases having

the sameLicontent(multiphase

domains)

werereported

forLixV205

bronzes[19].

X-ray

powder

diffractionpatterns

of thepoorly crystalline samples

XII and XIXessentially

differ from thepatterns

ofI and V. Somepeaks

ontheNovak,Valéry Nesper

Fig.6.CrystalstructureofV205 [26].

in

comparison

withIandV,

but therearealsosome"new"peaks: (i) Strong

and diffuse

peaks

at 2 = 8.77°(XII)

and 9.70°(XIX)

whichcannot beindexed with the unit cell of IorV

(the

first reflection100,

which isactually

absent in the measuredpattern

ofI,

has 2 =7.67°);

and(ii)

newsharp

peaks

at 2 = 50.78°(XII)

and 50.68°(XIX)

which areonly slightly

shifted from the

V205

020peak

at 2 = 51.23° in thepattern

of V.Moreover,

there isa hintofasmall contraction of theaseparation

of theV205

crystalline

component

in the series I -* V -» XII -» XIX. Aslight

shortening

of the aseparation

and aslight

increase of the cseparation

(corresponding

to theinterlayer separation

in the structure ofV205

[26],

Fig. 6)

is characteristic for atopotactic

insertion inV205,

see, e.g., thestructural

study

ofelectrochemically

formedMg0.2V2O5

bronze[10].

Besides the

phase

with theV205

structure, we believe that in the newphase(s)

of thesamples

XII andXIX,

agood

ordering

existsonly

in onedirection,

b'. Thelength

of this axis isslightly

increased incomparison

with the bseparation

in I and V. The value of b' is 3.59Â

inXII,

and 3.60A

in XIX(calculated

underanassumption

that the newsharp peak

inpatterns

of XII and XIX is a 020peak).

The newphase(s)

of XII and XIX aredisordered in two other directions

(i.e.

in the a'c'planes).

Note that an earlierX-ray powder

diffractionstudy

ofelectroformedLixV205

bronzesshoweda conservation of the b

separation

of theV205

structurewith an increased Li contentparallel

to morepronounced

changes

ofthe a and cseparations

[27].

3.4. Products XIII —XV of electrochemical

cycling

oftheV2Os

electrode VIA

cyclic

voltammogram

of theV205/TC

electrode VI in anacetonitrile-based

electrolyte

is shown inFig.

1. TheX-ray

diffractionpatterns

ofthe

electrochemically

cycled

electrodes XIII —XV arecompared

with thepattern

ofa newelectrode VI inFig.

7and in Table 6. Thepatterns

of the20.0 40.0 60.0 2 ,degr.

Fig.7.X-ray powderdiffractionpatternsof(a)theelectrodemassV2Os/TC (VI)andof theproducts of electrochemical

Mg2+

insertion: (b)XIII(reduced electrode,after2l/2

cycles), (c)XIV (reducedelectrode, after20l/2

cycles), and (d) XV (oxidised electrode,after20cycles).

represent

asuperposition

of thepattern

ofV205

(or

components

with the unit cell closetoV205,

Table7),

and the mixture ofcrystalline

PTFE and carbon black. The electrochemical reduction of theelectrode VI leads tothe appearance of some "new"

peaks

in thepatterns

of XIII and XIV(besides

ofthepeaks

oftheV205

and TCcomponents).

It can be

speculated

that the appearance of theV205

features in the reduced electrode means that a fraction of theV205

is not accessible for theelectrochemical reduction. Thereasonmight

beapoorelectricalcontact ofV205

particles

tothecurrentcollector.Thishypothesis

is consistent with the fact that in thespring-loaded

cell,

where theworking

electrode ismechanically pressed

against

thecurrentcollector,

significantly

higher

cou-lombiccapacities (up

to230Ah/kg V205)

werereached incomparison

withthe

free-hanging

electrodes(about

170Ah/kg V205).

But

essentially

differentdistributionof thepeak

intensitiesof theV205

component

insample

XIII,

incontrast to thedistributionobserved for theV205-containing

new electrodeVI,

might

indicate the chemicalcompo-sition

MgxV205

of thiscomponent.

The presence ofMg2+

in theV205

microcrystals

found in the reducedelectrode XIIIwas confirmedby

EDXanalysis.

There is nopronounced change

of the unitcellparameters

of theValéry Nesper

Table 6. Positions(2 0,degree)and intensities( )ofthepeaks ontheX-raydiffraction

patterns ofthe productsXIII —XV ofelectrochemicalcycling of the V205-containing electrodemassVI.

VI XIII* XIV* XV*

2 0 / 20obs 2 0calc / 2 0obs 20calc / 20obs 20calc / hkl

14.25 22 14.23 5 15.33 53 15.42 15.37 38 15.45 15.40 52 15.46 15.41 54 200 18.02 79** 18.17 79** 18.16 43** 18.17 31** 20.26 91 20.39 20.36 63 20.35 20.34 75 20.38 20.35 82 001 21.10 56 21.35 41 21.36 8 21.70 28 21.81 21.79 23 21.79 21.77 20 21.81 21.78 25 101 22.03 13 22.49 12 25.79 16 25.87 25.61 34 25.68 25.61 21 25.94 25.62 16 201 26.12 100 26.22 26.20 100 26.21 26.18 100 26.24 26.23 100 110 27.01 34 28.40 20 28.65 34 28.67 11 30.36 13 31.02 65 31.06 31.02 48 31.12 31.04 60 31.12 31.05 62 400 32.39 29 32.44 32.47 18 32.43 32.42 26 32.48 32.48 26 011 33.48 33.41 37 33.44 33.37 16 111 34.27 31 34.39 34.34 22 34.38 34.35 33 34.40 34.40 32 310 38.18 23 41.33 11 41.44 41.41 11 41.33 41.35 12 41.36 41.37 12 002 43.54 17 43.56 8 43.76 12 44.44 17 44.43 5 45.42 13 45.46 45.52 10 45.50 45.54 13 45.57 45.59 13 411 47.40 20 47.29 12 47.42 22 47.44 20 600 47.93 11 47.95 47.97 11 47.91 47.94 10 302 48.98 10 49.00 48.99 15 012 51.27 22 51.35 51.34 18 51.28 51.27 22 51.31 51.39 22 002 52.09 13 52.14 52.00 19 52.10 52.09 13 601 58.05 18 59.10 11 412 61.11 12 61.19 61.18 11 61.21 61.27 11 321 62.17 14 62.19 62.20 13 62.20 62.26 13 710

* See the discussion ofnotindexed reflectionsinthetext. ** Peak ofPTFE(fromteflonisedcarbon).

indicates that

V205

can beregarded

as a three-dimensional frameworkhost,

rather thanatwo-dimensional one(as already suggested

in studies ofTable 7. Unit cellparametersofV205-relatedcomponentsof the electrodemassVI and

theproductsXIII —XVof its electrochemicalcycling.

VI XIII XIV XV

a(Â)

11.533(6) 11.520(7) 11.495(3) 11.489(3)è

(A)

3.562(1) 3.556(2) 3.561(1) 3.553(1)c(Â)

4.376(4) 4.357(2) 4.363(2) 4.3609(9)K(Â3)

179.93 178.50 178.62 178.02The unitcell

parameters

ofchemically

(V)

andelectrochemically

(XIII)

formedMgxV205

arevery close(cf.

Tables 5 and7).

Thus,

theproducts

ofMg2+

insertion inV205

might

be similar in bothcases.The new

peaks appearing

in theX-ray

diffractogram

of theV205/TC

electrode reduced at —1.4 V(vs.

Ag/Ag+)

after2l¡2

voltammetriccycles

(XIII)

can beseparated

into two groups:(i)

fivepeaks

presentalso in thesample

XIV reducedafter20i/2

voltammetriccycles,

and(ii) peaks

present

only

in XIII(Table 6).

Thesetwogroupsofpeaks

havetobelong

todifferentphases (e.g.

XHIa andXHIb),

because,

e.g., thestrongest

newpeak

in thepattern

of XIII(at

2 =21.10°)

is absent in thepattern

ofXIV.Thus,

thereduced electrode XIII may consist of five

phases:

V205

(or MgxV205),

carbonblack, PTFE,

XHIa(which

exists also inXIV),

and XHIb.The amount of the

phase

XHIb in the electrodeobviously

decreasesduring

cycling

as evidencedby

the absence ofcorresponding

peaks

in thediffractogram

of the electrode XIV reduced after2OV2

cycles.

Thisbehav-iour is consistent with the known fact that

MgxV205

exists in twophases

—

a stable orthorhombic

phase

(0

< <0.11)

andametastablephase

[6].

Note the XHIa and XHIbphases

are absent in theoxidised,

cycled

electrodeXV,

sothey

areproducts

of reversibleV205

reduction. Theindexing

of the XHIbphase

isambiguous.

One of the solutions is an orthorhombic unit cell[a

=17.69(1)

A,

b =13.003(4)

A,

c =3.360(2)

Â,

V = 773

A3]

with oneperiod equal

to that observed inMgV205

and theunit cell volume four time

larger

as ofMgV205.

Also the unit cell of thephase

XHIacannotbeelucidated,

because theindexing

of thecorresponding

linesgives

several solutions ofcomparable

reliability.

Thus,

the electro-chemical reduction of VIseemstolead toboth(i)

Mg2+

insertion inV205

with the conservation of theV205

structure, and(ii)

formation ofnewMg,V-containig phase(s)

(XHIa

or XHIa +XHIb).

The TEM

study

of XIII confirmed the presence ofmicrocrystals

withthe unit cell closeto

V205

inelectrochemically

reducedsamples.

Therewereobtained,

besides the commonV205 diffraction,

two kinds ofdiffractionpatterns.

Theinterplanar

distances from the firstone aredx

= 9.7Â

andd2

= 25.0Â.

Thepatterns

ofthe second kind indicate asuperstructure

Fig.8. Diffractionpatternofamicrocrystalof the reduced electrodeXIII.

beam

direction;

recording

of diffractionpatterns

suitable for the determi-nation of theinterplanar

distance for the "third direction"wasthereforenotpossible.

Wedidnotsucceed inperforming

areliableanalysis confirming

thepresenceof

Mg

within thegrains exhibiting

thesuperstructure.

The electrode XIV consists of four

phases:

one with the unit cell ofV205,

carbonblack, PTFE,

and a newphase structurally

relatedtoV205.

The

change

of thestructureof theproducts

of electrochemicalcycling

with the number ofcycles

(note

the observed differencebetween the electrodesXIII and

XIV)

was discussed also in[19]

forelectrochemically

insertedLixV205.

3.5. Electrochemical

Mg2+

insertionintheV2Os

single crystal

IIThe

V205

single crystals (II)

lost thesingle crystallinity

after theelectro-chemical

Mg2

+insertion.An

optical micrograph

ofthecrystal

VIIIshowedbroad lines and shadows of the dark

MgxV205

within theorange-yellow

V205

crystal.

Obviously,

the insertion process is very nonuniform. TheEDX

analysis

did not indicate the presence ofMg.

Thus,

the amount ofMg2

+ inserted in thesingle

crystals

wasrather low. Thechemical insertionof

Mg2+

in theV205

single crystal

resulted in noapparent

colourchange.

4.

Conclusions

The chemical and the electrochemical

Mg2+

insertion inV205

seems toV205

inPTFE-bonded electrodes ismorecomplex

and rather nonuniform.Atleasttwonew

phases (both possibly

Mg^V205

phases)

areformedduring

the reversible reduction ofV205

inwetacetonitrilecontaining Mg(C104)2.

The presence ofone ofthe newphases

in the electrode decreasesduring

electrochemicalcycling.

Upon

reoxidation,

theoriginal

V205

structureof the

MgxV205 phases

appears to be restored. In thehydrated

sodium vanadiumbronzes,

NaV308(H20)y,

twolayered phases

withdifferentwater contentcoexist. Thephase

NaV308(H20)i.5

iselectrochemically

themostactive one,which allows

Mg2+

insertion fromrigorously

dry electrolytes.

Dehydration occurring

above 100°C causes a decrease of theinterlayer

separations

aswell as a decrease in the coulombiccapacity

of thebronze,

sothepreparation

anddrying

of the bronzes below 100°C is recommended.Acknowledgements

We thank Dr. O.

Haas, PSI,

formanystimulating

discussions. Wearealso indebted to Dr. K. Kato of the National Institute ofInorganic

Materials,

Tsukuba,

Japan,

for the donation of theV205

single

crystals,

R.Wessicken,

,

for STEM measurements, H.Meyer

zuAltenschildesche, ,

for NMR measurements, F.Ried, ,

forstudy,

and W.Scheifele,

PSI,

for technical assistance. This work wassupported by

the Swiss "Bundesamt fürEnergiewirtschaft"

(Grant

No.EF-PROCC(91)018).

References

1. T. D.Gregory,R.J. Hoffman andR.C.Winterton,J.Electrochem.Soc. 137(1990) 775.

2. R. J. Hoffman,R. C.Winterton andT. D.Gregory,USPat.4,894,302(1990).

3. P. NovakandJ.Desilvestro,J. Electrochem. Soc. 140(1993)140. 4. P.Novak,W.Scheifele and O. Haas,Molten SaltForum 1

-2(1993/94)389. 5. J.Galyand M.Pouchard,Bull.Soc. Chim. France(1967)261.

6. J. Galy, M. Pouchard, A. Casalot and P. Hagenmuller, Bull. Soc. Fr. Mineral. Cristallogr. 90(1967)544.

7. R. Schöllhorn and H.Meyer, Mat. Res. Bull. 9(1974)1237. 8. R. Schöllhorn and W.Schmucker, .Naturforsch.30b(1975)975. 9. A. Lerf andR.Schöllhorn,Inorg.Chem. 16(1977)2950.

10. J. P. Pereira-Ramos,R. Messina and J. Perichon,J. Electroanal. Chem. 218(1987) 241.

11. P.G.Bruce,F.Krok,J.Nowinski,V. C. Gibson and K.Tavakkoli,J. Mater. Chem. 1(1991)705.

12. P.

Lightfoot,

F. Krok,J. L. Nowinski and P. G. Bruce, J. Mater. Chem.2 (1992) 139.13. P. G. Bruce, F. Krok, P.

Lightfoot,

J. L. Nowinski andV. C. Gibson, Solid State Ionics53-56(1992)351.14. R. E.Dueber,J. M.Fleetwood andP.G.Dickens,Solid State Ionics50(1992)329. 15. F.Joho,P.Novák,O. Haas and R.Nesper,Chimia 47(1993)288.

Nesper

16. K.Rato, personalcommunication,June 1992.

17. R.Gutmann,J.

Hulliger

andE.Reusser,J.Cryst.Growth 126(1993)578. 18. A. D.Weeks, D. R.Ross and R. F.Marvin,Am. Mineral.48(1963) 1187.19. J. M.Cocciantelli,J. P.Doumerc,M.Pouchard.M.Brousselyand J.Labat,J. Power Sources 34(1991) 103.

20. J. A. Jacobson: "Intercalation ReactionsofLayered Compounds", in Solid Stale

Chemistry. Compounds (A. K.Cheetham andP. Day, Eds.),p. 217.Clarendon Press,

Oxford,(1992).

21. K.Kato and E.Takayama,ActaCrystallogr. B40(1984) 102.

22. O. P. Lapina.V. M.Mastikhin,A. A.Shubin,V. N.Krasilnikov and K.I.Zamaraev. Prog.Nucl. Magn. Reson.Spectrosc.24(1992)457.

23. H.G.Killian,Kolloid-Z. 185(1962)13.

24. N.Baffier,L.Znaidi and J.-C.Badot,J.Chem. Soc.

Faraday

Trans. 86(1990)2623. 25. J. C. Bouloux,I. Milosevic andJ.Galy,J.Solid State Chem. 16(1976)393. 26. H. G. Bachmann, F. R.Ahmedand W. H. Barnes,Z.Kristallogr. 115(1961) 110. 27. S. Hub,A.Tranchantand R.Messina, Electrochim.Acta 33(1988)997.28. D. W. Murphy,P. A. Christian,F. J. DiSalvoand J.V.Waszczak, Inorg.Chem.18

![Table 1. Scheme of preparation of Mg-inserted vanadium oxides*. v2o5 powder (I)" Synthesis of bronzes [4] (H20)y (III)" Dried at: 50°C 100°C NaV308](https://thumb-eu.123doks.com/thumbv2/123doknet/14925916.663941/3.627.71.548.109.529/table-scheme-preparation-inserted-vanadium-oxides-synthesis-bronzes.webp)

![Fig. 6. Crystal structure of V205 [26].](https://thumb-eu.123doks.com/thumbv2/123doknet/14925916.663941/12.627.92.574.78.293/fig-crystal-structure-of-v.webp)