Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Paper (National Research Council of Canada. Division of Building Research); no.

DBR-P-884, 1979-06

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=dbbb5a07-25a9-4ec4-bb6f-e678482509bf https://publications-cnrc.canada.ca/fra/voir/objet/?id=dbbb5a07-25a9-4ec4-bb6f-e678482509bf

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001688

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Factors affecting temperature of fire-exposed concrete slabs

Lie, T. T.; Williams-Leir, G.

S e r

I I .

w

FACTORS AFFECTING TEMPERATURE OF

FIRE-EXPOSED CONCRETE SLABS

by

T-T.

Lie andG.

Williams-LeirReprinted

ftom

Fire and MaterialsVol.

3,No.

2, June 1979 p*74

-

79DBR

Paper No.884

Division

of

Building Research'

TH1

~ 2 1

B

+

National Research Conseil national

Council Canada

de recherches Canada

no.

884

cop. 2 btL:,d:fU%

-

Les auteurs examinent l'influence des divers facteurs qui determinent la temp6rature des dalles de b6ton expos6es au feu. Les auteurs ont effectu6 des 6tudes th6oriques et exp&rimentales, 2 partir descquelles ils obtiennent des tableaux de propri6tGs thermiques qui representent bien les propri6t6s des be'tons siliceux et qui se ~retellt aux cafcds de rgsistance au feu.

Factors Affecting Temperature of Fire-exposed

Concrete Slabs

r(l

.

*T. T. Lie and G. Williams-Leir

Fire Research Section, Division of Building Research, National Research Council of Canada, Ottawa, Canada KIA OR6

The influence of the various factors that determine temperatures in fire-exposed concrete slabs is examined, in particular that of material properties. Both experimental and theoretical studies have been carried out. From these a set of thermal properties has been derived that is representative of the properties of siliceous concrete and suitable for use in fire resistance calculations.

The fire performance of building elements can be determined by testing and, in many cases, by calculation, but the latter requires knowledge of the temperatures during fire exposure. Methods already exist for cal- culating the temperature history of various building elements such as walls, columns and beams. If the thermal properties of the materials themselves are known, accurate prediction of the temperatures of these elements during fire exposure will be possible.

In practice, the thermal properties of building materials at the temperatures experienced in fire are often not known precisely, and this is true of concrete. Its thermal properties depend strongly on the properties of the aggregate, which vary over a wide range and are difficult to determine accurately. It is possible, however, to select, for specific types of concrete, material properties that will probably produce conservative results in fire resistance calculations.

In the present study concrete slabs made with siliceous aggregate were examined. By taking account of the

I

factors that determine slab temperatures and by com- paring calculated with measured temperatures, it was possible to establish the material properties that I

reasonably represent this type of concrete.

FACTORS AFFECTING SLAB TEMPERATURES

t 1 During a fire, heat is transferred by convection and

radiation from the fire to objects exposed to the heating. I Part of the heat will be absorbed by the material of the I exposed object, part will be reflected. In slabs exposed to fire on one side only, the absorbed heat will be con- ducted to the inside, causing a temperature rise that depends on time and position within the slab. To deter- mine this rise, knowledge of the thermal conductivity and thermal capacity of the material is necessary. In addition, knowledge is required of the heat transfer from the fire to the slab. The various factors that determine slab temperatures will be considered in more detail.

Thermal properties

It is common to make a distinction between siliceous and calcareous aggregates. Analysis, however, of results of a large number of tests on concrete blocks made with aggregates from regular production runs of five major Canadian producers has shown no conclusive differences in the fire resistances of siliceous and cal- careous c0ncretes.l Results were similar for a series of tests on columns performed in Germany.2 On the other hand, tests carried out in the USA on slabs3 and columns4 showed that the fire resistances of speci- mens made with calcareous aggregate were appreciably greater than those made with siliceous aggregate.

An important factor in determining the thermal properties of concrete is the molecular structure of the aggregate. For example, crystalline materials have higher conductivity than amorphous materials. It is probable that the amount of material in the aggregate that undergoes endothermic reaction upon heating (dehydration, transformation and decomposition) also has great influence on the thermal properties of the aggregate. In siliceous aggregates, for example, the presence of quartz, which transforms from a-quartz to 8-quartz at about 550°C, will cause an increase in specific heat. In calcareous aggregates the presence of magnesite and dolomite, which dissociate at tem- peratures of approximately 350 and 750 "C, respectively, will affect the thermal properties of the aggregate. During dissociation heat is absorbed, so that the presence of magnesite and dolomite should be beneficial for the fire resistance of concrete elements. Its effect on the thermal properties of concrete, however, is not yet known precisely.

Studies show that concrete with quartz aggregate may be expected to have the highest thermal diffusivity of all normal weight concretes, and concrete with anorthosite aggregate the lowest diffusivity.5 In these studies calculated values of the thermal properties of both these concretes are given as a function of tempera- ture. Comparison with results of past tests indicates that the theoretical values for quartz concrete generally produce conservative results if used in fire resistance

CCC-0308-0501/79/0003-0074 $03.00

FACTORS AFFECTING TEMPERATURE OF FIRE-EXPOSED CONCRETE SLABS

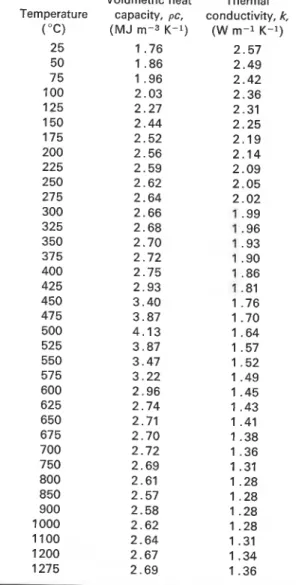

Table 1. Thermal properties calculated for normal weight concrete made with quartz aggregate as a function of temperatures

Volumetric heat Thermal Temperature capacity, pc, conductivity, k,

("c) (MJ m-3 K-l ) (W m - l K-l) 25 1.76 2.57 50 1.86 2.49 7 5 1.96 2.42 1 - 100 2.03 2.36 125 2.27 2.31 150 2.44 2.25 I . 175 2.52 2.19 200 2.56 2.14 225 2.59 2.09 250 2.62 2.05 275 2.64 2.02 300 2.66 1.99 325 2.68 1.96 350 2.70 1.93 375 2.72 1.90 400 2.75 1 .86 425 2.93 1 .81 450 3.40 1.76 475 3.87 1.70 500 4.13 1.64 525 3.87 1.57 550 3.47 1.52 575 3.22 1.49 600 2.96 1.45 625 2.74 1.43 650 2.71 1 .41 67 5 2.70 1.38 700 2.72 1.36 750 2.69 1.31 800 2.61 1.28 850 2.57 1.28 900 2.58 1.28 1000 2.62 1.28 1100 2.64 1.31 1200 2.67 1.34 1275 2.69 1.36

Table 2. Thermal properties calculated for normal weight concrete made with anorthosite aggregate as a function of temperature5

Volumetric heat Thermal Temperature capacity, pc, conductivity, k,

("c)

(MJ m-3 K-1) ( W m-1 K-1) 25 1 .81 1.24 50 1.91 1.25 75 2.01 1.26 100 2.09 1.27 125 2.32 1.28 150 2.51 1.29 175 2.57 1.29 200 2.60 1.29 225 2.62 1.29 250 2.63 1.29 275 2.64 1.30 300 2.65 1.31 325 2.66 1.32 350 2.66 1.32 375 2.67 1.32 400 2.69 1.32 425 2.84 1.31 450 3.30 1.30 475 3.75 1.28 500 3.97 1.25 525 3.60 1.22 550 2.99 1.20 575 2.70 1 .I9 600 2.65 1 .I8 625 2.63 1 .I7 650 2.66 1 .I7 675 2.74 1 .I6 700 2.80 1 .I5 750 2.78 1 .I3 800 2.72 1 .I3 850 2.69 1 .I4 900 2.70 1 .I6 1000 2.76 1 .I9 1100 2.80 1.20 1200 2.86 7.23 1275 2.89 1.25calculations. There is insufficient information, however,

, on how conservative the calculated results are. It is

not known, for example, whether the properties cal- culated for quartz concrete actually represent those

. of the least favourable concrete encountered in practice. For the purpose of obtaining more information on the validity of the theoretical material properties, the two sets of properties representing those of the two extremes have been selected for further examination. They are tabulated in Tables I and 2 as functions of temperature.

I Heat transfer

, In a fire, heat is received principally from luminous

*

flames, which have a high emissivity. If the thicknessof the flames is sufficient (normally the case in fully developed fires), heat radiation to exposed objects is substantial.

In test furnaces, flames are often less luminous and their thickness is such that heat transfer to the test specimen is influenced by the radiation from the furnace walls, which are cooler than the gases. As might be expected, therefore, the heat transfer in furnaces is

generally lower than the heat transfer from large real fires.

Another factor that affects heat transfer to the exposed object is the absorptivity of the material exposed to

the fire. In the present study a value of 0.9, derived

from data given in Ref. 7, will be used for the absorptivity of concrete.

Several methods exist for increasing the heat transfer of furnaces.8 One is to make the radiation transfer from the furnace walls as high as possible. In the present study this is achieved by utilizing an electricalIy heated,

heat resistant steel plate as the main radiating wall."

Ry keeping the plate at

a temperature close to theselected fire temperature curve, the problem of wall temperatures lower than the gas or fire temperatures can be eliminated.

CALCULATION METHOD

To calculate the temperature history of the slab, a finite difference method is used10 in which a cross-section of the slab is divided into a number of elementary layers

T. T. LIE AND G. WILLIAMS-LEIR

Boundary

- - - -

-PM slab-amb~ent a ~ r-- - -

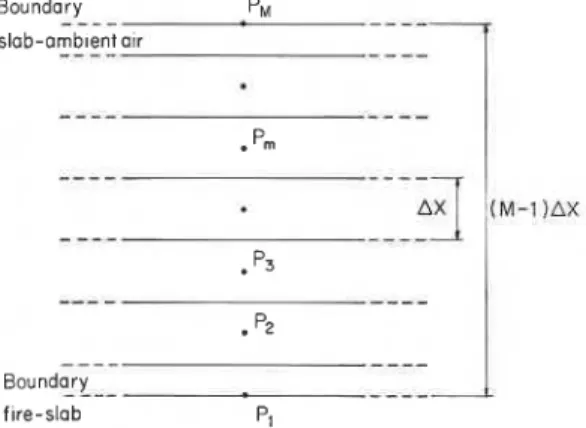

Figure 1. Arrangement of elementary layers in slab.

(Fig. 1). The thickness of each layer is Ax, except for the boundary layers which are half as thick. The thickness of the slab is ( M - l ) A x , where M is the number of layers into which the slab is divided. Each layer is represented by a point

P,,

and temperature in each elementary layer is assumed to be uniform and equal to that of the representative point. At the bottom the slab is exposed to the fire, and at the top it can cool in ambient air by radiation and convection.or

each elementary layer a heat transfer equation is written for time t = j A t , where j = 0 , 1 , 2 ,. . .

, and At is an appropriate time increment. With the aid of these equatibns the temperature of each layer can be succes- sively evaluated for any time t = ( j + 1)At if the tem- perature at time t = j A t is known. The procedure for deriving heat transfer equations for fire-exposed building elements has already been described in detailll and will not be discussed in this study; only the equations used for the calculation of the slab temperatures will be given.Equations for boundary between fire and slab

In the derivation of the equations for the boundary fire and slab it is assumed that the slab is exposed from below to a fire whose temperature increases according to the temperature-time curve specified in ASTM E119.12 This curve can be described approxi- mately by the following expressions : 1 3

1

T f = T o + - [I044 tanh (0.000 234 13t)

1.8

-498.2 tanh (0.000 270 4 4 t )

+

1286 tanh (0.002 475t)I ( 1 )The temperature at time t = ( j + 1)At of the boundary elementary layer of the slab, represented by the point P I , can be given by

Equation for interior of slab

For an elementary layer represented by a point Pm located inside the slab, the temperature at time t = ( j + 1)At is given by

Equation for boundary between slab and ambient air

-

eAt the boundary of the slab and air, heat is transferred .

from the slab to the air by convection and radiation.

For that transferred by convection, the conventional . I

expression given in Ref. 14 has been used in the deriva- tion of the heat transfer equations. It follows that the temperature of the slab at the unexposed side at time t = ( j + 1)At is given by

Stability criterion

To ensure that the error existing in the solution at any instant will not be amplified in subsequent cal- culations, a stability criterion must be satisfied; for a given value of Ax, this limits the maximum value of At. For fire-exposed slabs made of concrete the criterion is

where h=the upper limiting value of the coefficient of heat transfer at the fire-exposed surface at the time under consideration, given by: h = 4co(Tf

+

273)3 andpc and k are, respectively, the values of the temperature-

dependent volumetric specific heat and thermal con- ductivity of the concrete; in the temperature range under consideration they minimize the term between brackets in Eqn (6).

Calculation procedure

With the aid of ~ ~(1)-(5) the temperatures at any n s ~ point of the slab can be calculated in successive steps for any time t = j A t . Initially, at time t=O, the slab is at room temperature, here assumed to be 2 0 ° C . The first step is to calculate the temperatures in the various layers of the slab for time t = A t . These are used as initial values in the calculation of temperatures at time t = 2 A t . By repeating this process, the temperature

history of the slab can be calculated. 'f

EXPERIMENTAL

w Test furnace

The tests were performed in a furnace built mainly from insulating fire brick.9 Heat was supplied to the test specimen by a stainless steel panel heated electrically by silicon carbide elements. The temperature of the plate was controlled in such a way that the average steel temperature closely followed the standard curve specified in ASTM El 19.12

FACTORS AFFECTING TEMPERATUR E OF FIRE-EXPOSED CONCRETE SLABS Test specimens

The test slabs were made of concrete with coarse and fine aggregates, both containing more than 99

%

quartz, which is expected to produce the least favourable thermal fire resistance .of all aggregates currently used in industry. The concrete mix consisted of cement, sand and stone in ratios 1 : 2.36 : 3.54 by volume. The water-cement ratio of the mix was 0.52. (A s a m ~ l e of the cement was analysed and the main components are given in Table 3.)To eliminate the influence of moisture on the fire resistance of the slabs, the test specimens were dried in an atmosphere of about 100°C for several weeks after they had been cured. They were approximately 80 by 90 cm, with thicknesses of, respectively, 6, 10 and 15 cm. During the tests, temperatures were measured with thermocouples inserted in the centre of each slab, one at the exposed surface, one at mid-depth, and one at the unexposed surface.

DISCUSSION OF CALCULATED AND EXPERIMENTAL RESULTS

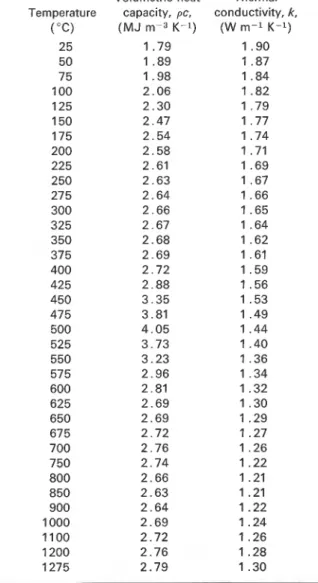

For comparing calculated with measured temperatures, calculations have been made of the slab temperatures for two sets of material properties. One set (Table 1) represents the material properties of the siliceous con- crete with the highest thermal diffusivity, mentioned above. The other is assumed to represent that of a siliceous concrete with an average thermal diffusivity, and is obtained by averaging the thermal properties of the two earlier selected concretes with extreme material properties (Table 4).

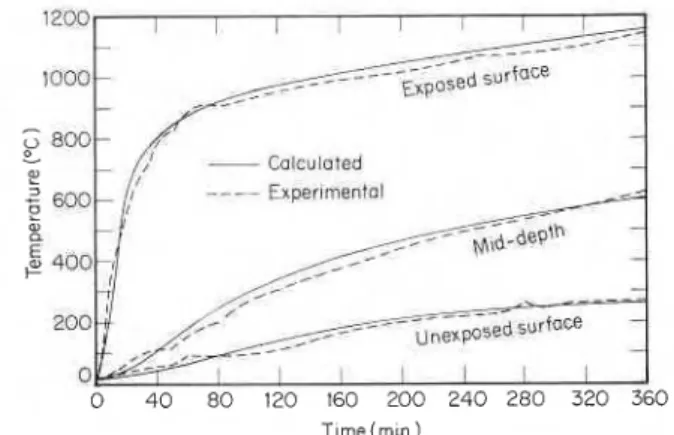

In Figs 2-4 measured temperatures are compared with calculated ones, using the average values of the thermal properties, for slab thicknesses of 6, 10 and 15 cm. It may be seen that measured and calculated temperatures are in good agreement. The influence of thermal properties on slab temperatures is illustrated in Fig. 5, where calculated temperatures are plotted for the 10 cm slab for the two selected sets of thermal properties. The curves show that the effect of thermal properties on slab temperatures is small in the range of thermal properties under consideration. This indicates that variations of thermal properties caused by variations in the molecular structure of siliceous aggregate cause only small variations in slab temperatures.

Because of the slight influence on concrete tempera- tures of the thermal properties of concrete made with siliceous aggregate, it is possible to select for siliceous concrete a standard set of representative thermal pro-

Table 3. Composition of cement used in tests

Weight

Composition percentage Composition

SiOz 20.92 NazO A1203 4.53 KzO Fez03 2.04 TiOz CaO 63.79 PzOs MgO 2.46 Mnz03 SO3 3.39 SrO Weight percentage 0.37 0.87 0.16 0.18 0.05 0.14

Table 4. Average thermal properties of normal weight concrete made with siliceous aggregate as a function of temperature

Volumetric heat Thermal

Temperature capacity, pc, conductivity, k,

("'3 ( M J m-3 K - l ) (W m - l K-l) 25 1.79 1.90 50 1 .89 1.87 75 1.98 1.84 100 2.06 1.82 125 2.30 1.79 150 2.47 1.77 175 2.54 1.74 200 2.58 1 .71 225 2.61 1 .69 250 2.63 1 .67 27 5 2.64 1.66 300 2.66 1.65 325 2.67 1 .64 350 2.68 1 .62 375 2.69 1 .6l 400 2.72 1.59 425 2.88 1.56 450 3.35 1.53 475 3.81 1.49 500 4.05 1.44 525 3.73 1.40 550 3.23 1.36 575 2.96 1.34 600 2.81 1.32 625 2.69 1.30 650 2.69 1 .29 675 2.72 1.27 700 2.76 1.26 750 2.74 1.22 800 2.66 1.21 850 2.63 1.21 900 2.64 1.22 1000 2.69 1.24 1100 2.72 1.26 1200 2.76 1.28 1275 2.79 1 .30

perties. Comparison of calculated and experimental results shows that the sets of properties given in Table 4, which are average thermal properties for siliceous concretes, is consistent with the behaviour under test of quartz concrete. The present study suggests, therefore, that they are representative of the thermal properties of dry siliceous concrete made with quartz aggregate. It is probable that, in practice, the aggregate will be less pure than the quartz aggregate used for comparison in the present study, and that it will contain other com- ponents. Because quartz is the least favourable aggregate from the point of view of thermal fire performance,5 it is likely that the selected standard set of thermal properties will for siliceous concrete generally produce conservative results when used in fire resistance cal- culations.

Another factor that favours the thermal fire per- formance of concrete is that it normally contains moisture. It is expected that for concretes containing adsorbed moisture, calculated results will not yield good agreement with those of tests. Methods exist, however, to take into account the influence of moisture on thermal fire resistance.6, l 2

T. T. LIE A N D G. WILLIAMS-LEIR

I

"'O i 1 - 1

-

CalculatedFigure 2. Slab temperatures as a function of time at various

depths (slab thickness: 6 cm).

Figure 3. Slab temperatures as a function of time at various

depths (slab thickness: 10 cm).

Figure 4. Slab temperatures as a function of time at various

depths (slab thickness: 15 cm).

It should be noted that mechanical effects such as shrinkage or expansion and spalling can also have a significant influence on the fire performance of concrete. The effects of these have not been considered in this paper.

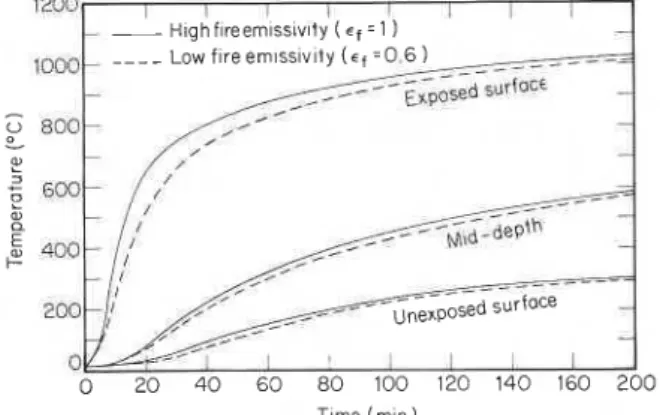

Whereas the molecular structure of the aggregate affects mainly the thermal conductivity of concrete, moisture and the occurrence of endothermic reactions affect the heat capacity of the material. As shown in Fig. 5, variation of thermal diffusivity, which for pure siliceous concrete is due mainly to variation of con- ductivity, has little influence on slab temperatures. The large variations observed in tests on impure siliceous

-

Averoge thermal diff~srvlty-

pa00

-

mFigure 5. Slab temperatures as a function of time at various

depths (slab thickness: 10 cm).

concretes can thus be attributed only to variations in thermal capacity, due presumably to moisture or to endothermic reactions in the impurities. Although these factors are usually beneficial for the thermal fire performance of concrete, they are difficult to control in practice.

A factor known to be significant in determining slab

temperatures that can easily be controlled is slab thick- ness. How the thickness of the slab affects slab tempera- ture is shown in Figs 6 and 7. Slab temperatures at mid-depth, calculated using the standard set of thermal properties, are plotted in Fig. 6 as a function of time for the three slab thicknesses investigated. The unexposed surface temperatures for the same slabs are shown in Fig. 7.

Sloh thir.kness

6 c m4

-Figure 6. Slab temperatures at mid-depth as a function of time

for various slab thicknesses.

F! - -

$

600- w -2

- p 400- Slob thickness - 200- - 0 0 20 40 60 8 0 100 120 140 160 180Figure 7. Slab temperatures at unexposed surface as a function

of time for various slab thicknesses.

7

FACTORS AFFECTING TEMPERATURE O F FIRE-EXPOSED CONCRETE SLABS

CONCLUSIONS

Development in recent years of methods that permit accurate calculation of the fire performance of concrete building elements has created a need for more precise knowledge of the properties of the various types of concretes that exist. For siliceous concrete it is possible

t to derive a set of representative thermal properties that

can be used as standard thermal properties for this

1 .

type of concrete in fire resistance calculations.

.Y The results of theoretical and experimental studies on

G

o 20 40 60 80 loo 120 140 160 200 dry siliceous concrete slabs indicate that of the various -? T ~ m e ( r n ~ n ) factors determining slab temperatures the thickness Figure 8. Slab temperatures as a function of time at various of the slab is the most important. The influences bothdepths (slab thickness: 1 0 cm). of heat transfer from fire to slab and of variations in

the thermal properties of concrete made with pre-

The influence of heat transfer from the fire to the dominantly siliceous aggregate are relatively small in the

slab was also investigated (Fig. 8). Calculated slab practical region.

temperatures at various depths are given as a function

of time for two cases, viz. for a slab exposed to fire Acknowledgement

with high emissivity (cf = 1), and for one exposed to The authors are grateful to P. E. Grattan-Bellew for valuable

fire with low emissivity (Ef=0.6). The results indicate advice during the selection and preparation of the concrete mix;

that the influence on slab temperature of the heat and wish to thank J. E. Berndt and D. W. Morwick for performing

the tests. This paper is a contribution from the Division o f Building

transfer from fire is provided it is Research, National Research Council o f Canada, and is published

exceptionally low. with the approval of the Director of the Division.

REFERENCES

1. L. W. Allen, Fire Endurance of Selected Non-loadbearing 9. J. A. C. Blanchard and T. Z. Harmathy, Small-scale Fire

Concrete Masonry Walls, National Research Council of Test Facilities of the National Research Council of Canada,

Canada, Division of Building Research, NRC 11275 National Research Council of Canada, Division of Building

(1 970). Research, NRC 3207 (1964).

2. W. Becker and J. Stanke, Brandversuche an Stahlbeton- 10. G. M. Dusinberre, in Heat Transfer Calculations by Finite

fertigstutzen; Deutscher Ausschuss fiir Stahlbeton, Heft 21 5, Differences, p. 293. International Textbook Company,

Berlin (1 970). Scranton, Pennsylvania (1 961 ).

3. M. S. Abrams and A. H. Gustaferro, J. PCA Res. Dev. Lab. 11. T. T. Lie, J. Heat Transfer 99 (1 ), 11 3 (1 977).

10 (2), 9 (1968). 12. Standard Methods of Fire Tests of Building Construction

4. W. A. Hull and S. H. Ingberg, Fire Resistance of Concrete and Materials. American Society for Testing and Materials,

Columns, US Department of Commerce, National Bureau Designation E l 19-76, Part 18, pp. 61 0-628. American

of Standards, Technologic Paper No. 272 (1 926). Society for Testing and Materials, Philadelphia (1977).

5. T. Z. Harmathy, Thermal Properties of Concrete at Elevated 13. G. Williams-Leir, Fire Technol. 9 (2), 132 (1973).

Temperatures, ASTM J. Mater., 5 (1 ), 47 (1 970). 14. H. M. Spiers, In Technical Data on Fuel, 6th Edn, p. 133.

6. T. Z. Harmathy, The Effect of Moisture on Fire Endurance World Press Conference, London (1 961 ).

of Building Elements, ASTM Special Technical Publication No. 385, pp. 74-95. American Society for Testing and

Materials, Philadelphia (1 965). Received 23 January 1979

7. C. H. Gilmore et al., in Chemical Engineer's Handbook, McGraw-Hill, New York (1 963).

8. T. T. Lie, in Fire and Buildings, pp. 42-44. Applied Science

Publishers Ltd, London (1972). 0 Heyden 8 Son Ltd, 1979

APPENDIX: NOMENCLATURE

List of symbols A increment

c specific heat (J kg-1 K-1) E emissivity

r , h coefficient of heat transfer at fire-exposed surface P density (kg m-3)

(W m-2 K-1

1

a Stefan-Boltzmann constant: 5.67 x W m-2,j 0, I, 2,

. . .

K-T . k thermal conductivity (W m-1 K-1)

Z

M number of elementary layers

P point Subscripts

t time (s) f of the fire

T temperature ("C) m, M at a point in the mth, Mth elementary layer

x coordinate (m) 0 initial

Greek letters

y coefficient expressing convective heat transfer from Superscript

horizontal slab surface to air: 2.49 W m-2 K-1.25 j a t t = j A t

This publication is being d i s t r i b u t e d by the Division of Building R e s e a r c h of the National R e s e a r c h Council of Canada. I t should not b e reproduced i n whole o r i n p a r t without p e r m i s s i o n of the original publisher. The Di- vision would b e glad to b e of a s s i s t a n c e i n obtaining s u c h permission.

Publications of the Division m a y b e obtained by m a i l - ing the a p p r o p r i a t e r e m i t t a n c e (a Bank, E x p r e s s , o r P o s t Office Money O r d e r , o r a cheque, m a d e payable t o the R e c e i v e r G e n e r a l of Canada, c r e d i t NRC) t o the National R e s e a r c h Council of Canada, Ottawa. KIA OR6 . Stamps a r e not acceptable.

A l i s t of a l l publications of the Division is available and m a y b e obtained f r o m the Publications Section, Division of Building Research, National R e s e a r c h Council of Canada, Ottawa. KlA OR6.