Publisher’s version / Version de l'éditeur:

Cement and Concrete Research, 16, January 1, pp. 31-39, 1986-01-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.1016/0008-8846(86)90065-7

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

The Effect of sand/cement ratio and silica fume on the microstructure

of mortars

Feldman, R. F.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=62c2dc17-b3de-4299-92e5-92a7cec7b361

https://publications-cnrc.canada.ca/fra/voir/objet/?id=62c2dc17-b3de-4299-92e5-92a7cec7b361

Reprinted from

Cement and Concrete Research

Vol. 16. No. 1. 1986

p. 31 -39

(IRC

Paper No. 1358)

Price $2.75

NRCC

25543

-Ser

Trn

N21d

1545/

National Research

Conseil national

).

1358

r(*

c.

2

ouncil Canada

de recherches Canada

BLDG

Institute for

lnstitut de

.- --

Research in

recherche en

Construction

construction

The Effect of Sand/Cement

Ratio and Silica Fume on the

Microstructure of Mortars

by R.F. Feldman

ANALYZED

Canad2

CEMENT and CONCRETE RESEARCH. Vol. 16, pp. 31-39, 1986. Printed in the USA. 0008-8846186 $3.00+00. Copyright (c) 1986 Pergamon Press, Ltd.

THE EFFECT OF SANDICEMENT RATIO AND SILICA FUME

ON THE MICROSTRUCTURE OF MORTARS

R.F. Feldman

Division of Building Research National Research Council of Canada

Ottawa, Ontario, K1A OR6

(Communicated by J.P. Skalny) (Received July 16, 1985)

ABSTRACT

Cement mortars containing 0 and 10% silica fume were prepared at a waterlcement + silica fume ratio of 0.60 and sandlcement ratios of 0,

0.5, 1.0, 1.5, 1.8, 2.0, 2.25 and 3.0. Pore-size distributions were studied by mercury intrusion and reintrusion. More pores of

(97+0.175) x

lo3

nm size form at the sand interface for mortars with silica fume than without it. There is only a slight difference in the fine pore distribution with and without silica fume.Introduction

Studies of portland cement paste and equivalent mortars show that the sand-matrix interface has a definite effect on the pore-size distribution

1 3 . Further work with portland cement

-

silica fume blends hasdemonstrated that the effect at the interface is magnified in this system (1). Addition of silica fume in pastes affects the hydration rate (4). The

freeze-thaw resistance is not affected, although it is greatly improved in mortars with sandlcement ratio of 2.25 (3). Pore volume with diameters in the

(97+0.875) x

lo3

nm range is greatly increased by the addition of silica fumeto mortar with sandlcement ratio of 2.25. These pores may occur at the

sand-matrix interface due to the interaction of silica fume and Ca(OH)2, which initially forms at the interface; a portion of these pores may not be as readily accessible to fluids (1,3).

Well-cured blends of several waste materials and portland cement have lower permeabilities than pastes or concretes without the addition, and haye demonstrated superior resistance to various forms of chemical attack (5-8).

Silica fume, in addition to causing very low permeabilities in blends, is a very reactive pozzolan (4,8). The sequence of reactions leading to a unique pore-size distribution in mortars can provide a material capable of resisting many forms of chemical and physical attack and of protecting other susceptible materials such as reinforcing steel.

Vol. 1 6 , No. 1 R.F. Feldman

m o r t a r s w i t h sandlcement r a t i o s v a r y i n g from 0 t o 3.0, w i t h and w i t h o u t t h e replacement of 10% p o r t l a n d cement by s i l i c a fume.

Experimental M a t e r i a l s

Type I p o r t l a n d cement w i t h C3A c o n t e n t of 11.82% and s i l i c a fume c o n t a i n i n g 95.2% S i 0 2 , 1.56% carbon, 0.27% K20 and 0.10% Na20 ( s u r f a c e a r e a 21 000 m2/kg) were used. Ottawa s i l i c a sand p a s s i n g ASTM C 109 was u s e d f o r m o r t a r w i t h s a n d l b i n d e r r a t i o s of 0, 0.5, 1.0, 1.5, 1.8, 2.0, 2.25 and 3.0. Binder i n t h e m o r t a r c o n t a i n e d 0 o r 10% s i l i c a fume. Mixes were p r e p a r e d a t w / ( c + s f ) of 0.60 (w = w a t e r , c = cement, s f = s i l i c a fume). No water-reducing o r a i r - e n t r a i n i n g admixtures were used.

Mixing

Cement, s i l i c a fume and w a t e r were mixed f o r 30 seconds i n t h e bowl of a Hobart Model N-50 mixer (ASTM C 305) a t a slow speed. A l l t h e sand was added and mixing c o n t i n u e d a t slow speed f o r 30 seconds. The mixer was stopped and t h e n mixing was continued a t medium speed f o r 30 seconds, a f t e r which t h e mix was allowed t o s t a n d f o r 13 minutes. Mixing was t h e n completed

by a f u r t h e r one minute a t medium speed. P r o p e r t i e s determined

Pore-size d i s t r i b u t i o n was determined i n a l l mixes a f t e r 28 days of c u r i n g time (Hg porosimetry t o a p r e s s u r e of 414 MPa). Specimens were d r i e d by vacuum and f i n a l h e a t i n g f o r a b o u t 24 h a t 100°C. Mercury was removed by h e a t i n g specimens a t 1 0 5 ' ~ i n vacuum f o r s e v e r a l weeks u n t i l weight r e t u r n e d t o o r i g i n a l v a l u e . R e i n t r u s i o n was performed on mixes c o n t a i n i n g s i l i c a fume a t sandlcement r a t i o s of 0, 1.5, 1.8, 2.0, 2.25 and 3.0.

R e s u l t s

Pore-size d i s t r i b u t i o n of m o r t a r s w i t h o u t s i l i c a fume

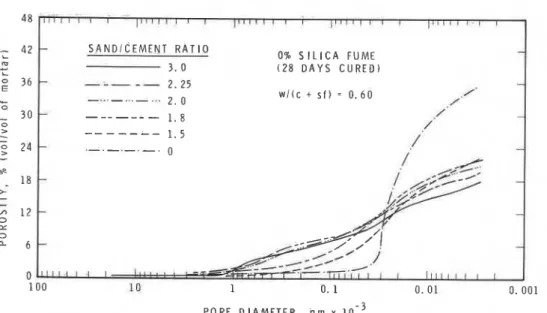

I R e s u l t s f o r t h e pore-size d i s t r i b u t i o n of m o r t a r s w i t h sandlcement r a t i o s of 0, 1.5, 1.8, 2.0, 2.25 and 3.0, c u r e d f o r 28 d a y s , w i t h o u t s i l i c a fume a d d i t i o n , p r e p a r e d a t a waterlcement r a t i o of 0.6, a r e shown i n F i g u r e 1. R e s u l t s of p o r o s i t y a r e based on t o t a l volume of m o r t a r sample. T o t a l p o r e volumes down t o 30 nm pore d i a m e t e r f o r a l l t h e mortar mixes a t e l a r g e r t h a n f o r p a s t e (sandlcement r a t i o of 0.0). The m o r t a r w i t h sandlcemerit r a t i o of 3.0 h a s t h e maximum t o t a l p o r o s i t y down t o 500 nm pore d i a m e t e r , but t h e p a s t e h a s , by f a r , t h e maximum t o t a l p o r o s i t y when a l l p o r e s a r e i n c l u d e d (down t o

2.9 nm).

Pore volumes c a l c u l a t e d i n t h i s way a r e n o t e n t i r e l y meaningful,

however, because, a s sand c o n t e n t i n c r e a s e s , an i n c r e a s i n g p r o p o r t i o n of t h e volume of t h e sample i s non-porous sand and a d e c r e a s i n g p r o p o r t i o n i s cement p a s t e , which c o n t a i n s t h e pores. I n o r d e r t o n o r m a l i z e t h e s e r e s u l t s , p o r e volume was c a l c u l a t e d a s a p e r c e n t of t h e p a s t e volume of t h e mortar. The sand volume was s u b t r a c t e d from t h e t o t a l volume of t h e o r i g i n a l m i x t u r e ; t h i s was done by c a l c u l a t i n g volumes of components, u s i n g d e n s i t i e s f o r t h e sand, cement and w a t e r . R e s u l t s a r e p r e s e n t e d i n F i g u r e

2.

The t o t a l p o r o s i t y a t 2.9 nm now i n c r e a s e s approximately w i t h sandlcement r a t i o ; t h e h i g h e s t and lowest p o r o s i t y i s 40.0 and 35.6% f o r t h e 3.0 and 0.0 sandlcement r a t i o , r e s p e c t i v e l y . However, t h e d i s t r i b u t i o n of p o r e s i s v a s t l y d i f f e r e n t ; f o r t h e 0.0 sandlcement r a t i o , t h e pore volume down t o 40 nm i s only about 2.5%, w h i l e t h i s v a l u e i n c r e a s e s t o 12, 19.5, 18.9, 20.5 and 21.2% f o r t h e sandlcement r a t i o s of 1.5, 1.8, 2.0, 2.25 and 3.0, r e s p e c t i v e l y .Vol. 1 6 , No. 1 33

MICROSTRUCTURE, MORTARS, SILICA FUME, SAND RATIO

-

4 2 S A N D I C E M E N T R A T I O m 0% S I L I C A FUME-

L ( 2 8 D A Y S C U R E D );

36-

. ..

-

..

.-

. . . w l ( c + s f ) = 0. 60-

0-

30-

0 > -...- - -

-2

2 4.-.-

-

6e. 18 > I--

12 0 E 0 a 6 0 100 1 0 1 0. 1 0.01 0.001 FIG. 1 P o r e - s i z e d i s t r i b u t i o n of m o r t a r s p l o t t e d a s volume p e r c e n t of m o r t a r . Sandlcement r a t i o s = 0.0 t o 3.0.0% S I L I C A FUME

SAND, CEMENT RATIO

(28 DAYS CURED)

FIG. 2 P o r e - s i z e d i s t r i b u t i o n of m o r t a r s p l o t t e d a s volume p e r c e n t of p a s t e p o r t i o n . Sandlcement r a t i o s = 0.0 t o 3.0. The p o r e volume i s d i v i d e d i n t o f o u r r a n g e s of p o r e d i a m e t e r s : (97+0.875, 0.875+0.175, 0.175+0.0175, 0.0175+0.0029)

-

103 nm. These a r e p r e s e n t e d i n T a b l e I , c a l c u l a t e d b o t h on t h e b a s i s of t o t a l m o r t a r volume andVol. 1 6 , No. 1 R.F. Feldman

1

r a n g e s , t h e two c o a r s e r p o r e r a n g e s i n c r e a s e i n volume w i t h sandlcement r a t i o ,and t h e two f i n e r r a n g e s d e c r e a s e . The volume of e a c h of t h e c o a r s e r a n g e s

and t h e sum of volumes of t h e s e r a n g e s i s p l o t t e d a g a i n s t sandlcement r a t i o i n

I F i g u r e 3.

TABLE I

Pore-size D i s t r i b u t i o n of Mortars. Sandlcement R a t i o = 0.0 t o 3.0.

0% S i l i c a Fume. w/(c+sf) = 0.60. 28 Days Cured.

- -

Sandlcement r a t i o 3.0

Pore d i a m e t e r P a s t e P a s t e P a s t e

(nm x 10-3) Normal p o r t i o n Normal p o r t i o n Normal p o r t i o n

97+0.875 1.79 4.04 1.22 2.37 1.14 2.10 0.875+0.175 3.89 8.79 2.3 4.47 3.40 6.25 0.175+0.0175 7.15 16.15 10.85 21.08 9.45 17.37 0.0175+0.0029 4.60 11.00 5.81 11.29 5.26 9.67 TOTAL 17.43 39.98 20.18 39.21 19.25 35.39 P a s t e P a s t e

Normal p o r t i o n Normal p o r t i o n Normal

97j0.875 1.64 2.88 0.18. 0.29 0.57 0.875+0.175 4.37 7.67 1.71 2.79 0.55 0.175+0.0175 9.65 16.83 11.66 19.0 19.84 0.0175+0.0029 5.38 9.44 8.2 13.36 14.88 - - TOTAL 21.04 36.92 21.75 35.43 35.84 Pore-size d i s t r i b u t i o n of m o r t a r s w i t h s i l i c a fume on f i r s t i n t r u s i o n The pore-diameter d i s t r i b u t i o n of m o r t a r s c o n t a i n i n g 10% s i l i c a fume ( c u r e d f o r 28 d a y s ) , w i t h sandlcement r a t i o s of 0.0, 0.5, 1.0, 1.5, 1.8, 2.0,

2.25 and 3.0, i s p r e s e n t e d i n F i g u r e 4. Volume c a l c u l a t i o n s a r e based on

p a s t e p o r t i o n . Whereas f e a t u r e s imposed on t h e c u r v e s due t o t h e i n f l u e n c e of

s i l i c a fume a r e e v i d e n t ( I ) , t h e r e i s c o n s i d e r a b l e d i f f e r e n c e between t h e m o r t a r s , a l t h o u g h t h e t o t a l p o r e volume o n l y v a r i e s between a p p r o x i m a t e l y 39.0

and 44.0% by volume. The i n f l u e n c e of s i l i c a fume may be observed i n

Table 11, where t h e p o r e volumes f o r t h e f o u r p o r e r a n g e s a r e c a l c u l a t e d , on t h e b a s i s of b o t h t h e t o t a l m o r t a r volume and t h e volume of t h e p a s t e p o r t i o n . G e n e r a l l y , t h e volume of p o r e d i a m e t e r r a n g e s (97+0.875 and

0.875+0.175) x 103 nm ( t h e c o a r s e r r a n g e s ) and (0.0175+0.0029) x 103 nm ( t h e

f i n e s t r a n g e ) i n c r e a s e s and t h a t of t h e (0.175+0.0175) x

lo3

nm r a n g ed e c r e a s e s a s s i l i c a fume i s added.

The volume of t h e p o r e s i n t h e two c o a r s e r r a n g e s and t h e sum of t h e s e

Vol. 16, No. 1

MICROSTRUCTURE, MORTARS, SILICA FUME, SAND RATIO

(A) 0% S I L I C A FUME (28 DAYS CURED)

wl(c

+sf)

=0.60

1 2

1 6

)-

1B)

10% S I L I C A FUME (28 DAYS CURED)

4

wl(c

+sf)

=0.60

P

0

1

I

I

I

01

2

3

S A N D I C E M E N T R A T I O

FIG. 3Plot of pore volumes ( % of paste portion) of various pore size ranges of mortars vs sandlcement ratios (0.0 to 3.0).

(974.875) x

lo3

nm range, the volume increases generally with sandlcement ratio, with a steep increase after a sandlcement ratio of 2.0. These values are also greater in each case than the volumes for the specimens without silica fume addition. The volumes for the range (0.875+0.175) x 103 nm varyin a somewhat random manner with sandlcement ratio within 4 to 7% pore volume. These values up to 1.5 sandlcement ratio are in excess of those for specimens without silica fume, but values for 1.8 and 3.0 sand/cement-ratio are lower.

The sum of the two ranges (97+0.875) and (0.875+0.175) x

lo3

nm are also shown in Figure 3B. Only a small change in volume of pores occurs from 0 to 1.8 sandlcement ratio but beyond 1.8 the increase is quite abrupt; values increase from an average of about 8% for sandlcement ratio up to 1.8, to over 15% for the specimen with a ratio of 3.0.Pore-size distribution of mortars with silica fume on reintrusion The pore diameter distributions on reintrusion for the mortars

Vol. 1 6 , No. 1 R.F. Feldman

TABLE I1

Pore-size D i s t r i b u t i o n of Mortars. Sandlcement Ratio = 0.0 t o 3.0. 10% S i l i c a Fume. w / ( c + s f ) = 0.60. 28 Days Cured.

--

-

Sandlcement r a t i o 3.0 2.25 2.0 1.8

Pore diameter P a s t e P a s t e P a s t e P a s t e

(nm x Normal p o r t i o n Normal p o r t i o n Normal p o r t i o n Normal p o r t i o n

97+0.875 4.6 10.30 2.78 5.36 1.69 3.09 1.98 3.45

0.0175+0.0029 8.41 18.83 7.99 15.42 9.2 16.80 9.47 16.51

TOTAL 19.62 43.93 23.28 44.92 22.68 41.42 22.49 39.21

1.5 1.0 0.5 0.0

P a s t e Paste P a s t e

Normal p o r t i o n Normal p o r t i o n Normal p o r t i o n Normal

-

-

9790.875 2.49 4.03 2.24 3.17 2.44 2:94 1.52

0.0175+0.0029 9.93 16.08 13.34 18.85 15.83 19.09 20.64

TOTAL 23.95 38.79 27.59 38.99 32.39 39.08 39.18

and 3.0 a r e p r e s e n t e d i n T a b l e 111. I n e a c h c a s e t h e r e i s a l a r g e i n c r e a s e i n t h e volume of p o r e s i n t h e c o a r s e r a n g e [ ( 9 7 + 0 . 8 7 5 ) x

lo3

nm] compared t of i r s t i n t r u s i o n ( T a b l e I I ) , t h e i n c r e a s e b e i n g g r e a t e r w i t h l a r g e r s a n d l c e m e n t r a t i o s . The volume c o n t a i n e d i n t h e two s m a l l e s t p o r e r a n g e s i s g e n e r a l l y lower f o r t h e r e i n t r u s i o n d i s t r i b u t i o n t h a n f o r t h e f i r s t d i s t r i b u t i o n .

A comparison of p o r e d i s t r i b u t i o n s between t h e r e i n t r u d e d specimen c o n t a i n i n g s i l i c a fume ( T a b l e 1 1 1 ) and t h e e q u i v a l e n t specimen w i t h o u t s i l i c a fume ( f i r s t i n t r u s i o n , T a b l e I ) r e v e a l s t h a t , w i t h t h e e x c e p t i o n o f t h e r a n g e (9790.875) x l o 3 nm, t h e y a r e s i m i l a r . The specimens p r e p a r e d a t a

sandlcement r a t i o of 2.0 a r e t y p i c a l of t h e specimens measured. I n t h e (0.0175+0.0029) x 1 0 3 nm r a n g e t h e volume f o r t h e r e i n t r u d e d specimen w i t h

s i l i c a fume i s 12.13% compared t o 9.67% f o r t h e specimen w i t h o u t s i l i c a fume; i n t h e r a n g e (0.175+0.0175) x l o 3 nm, t h e c o r r e s p o n d i n g v a l u e s a r e 14.02% t o 17.37%; i n t h e r a n g e (0.87590.175) x 103 nm, 6.30 t o 6.25%; and i n t h e r a n g e (97+0.875) x l o 3 nm, 10.74 t o 2.10%. The t o t a l p o r o s i t i e s a r e 43.19 t o 35.39%. D i s c u s s i o n The marked d i f f e r e n c e i n t h e p o r e d i s t r i b u t i o n of m o r t a r s a s a f u n c t i o n of s a n d l c e m e n t r a t i o a p p e a r s t o be a n i n t e r f a c i a l e f f e c t . As t h e s a n d l c e m e n t r a t i o i n c r e a s e s , t h e amount of i n t e r f a c e p e r volume of specimen s h o u l d

Vol. 1 6 , No. 1 3 7

MICROSTRUCTURE, MORTARS, SILICA FUME, SAND RATIO

S A N D I C E M E N T R A T I O 1 0 % SILICA F U M E - ( 2 8 D A Y S C U R E D ) w l ( c + s f ) = 0 . 6 0 - 2. 25 - . . .

-

. . . 2 . 0 - 1 . 8- - -

1 . 5-

- - -

- -- -

1 . 0. . .

0 . 5-

-

0-

- A - I I J I I 1 1 1 1 11 1 I I 1 1 1 1 1 B E I I .00 10 1 0 . 1 0 . 0 1 0 . 0 0 1 FIG. 4 P o r e - s i z e d i s t r i b u t i o n of m o r t a r s p l o t t e d a s volume p e r c e n t of p a s t e p o r t i o n . Sandlcement r a t i o s = 0.0 t o 3.0.However, o t h e r f a c t o r s may c o n t r i b u t e t o t h i s phenomenon. It h a s been shown t h a t d u r i n g h y d r a t i o n a p r e f e r e n t i a l d e p o s i t i o n of Ca(OHI2 o c c u r s i n t h e i n t e r f a c i a l zone ( l e s s t h a n 50 microns) around a g g r e g a t e s i n c o n c r e t e and around f i b r e s o r s a n d i n m o r t a r s (9-11). The l a y e r of Ca(OHl2 may be covered w i t h a l a y e r of e l o n g a t e d C-S-H g e l p a r t i c l e s . These l a y e r s have been

r e f e r r e d t o a s a d u p l e x f i l m ( 9 ) and t h e zone n e a r e s t t h e f i l m i s o n l y s p a r s e l y occupied a t e a r l y s t a g e s of h y d r a t i o n . L a r g e r Ca(OH)2 c r y s t a l s may develop i n t h i s zone a f t e r a few d a y s of h y d r a t i o n . This m o d i f i e d form of d e p o s i t i o n of p r o d u c t s i s l i k e l y t o c a u s e changes t o t h e p o r e

d i s t r i b u t i o n .

E f f e c t s of i n c l u s i o n s on h y d r a t i o n r a t e s and d e g r e e of h y d r a t i o n have been r e p o r t e d ( 4 , 1 2 ) ; i n c l u s i o n s may a l s o h a v e a n e f f e c t o n p o r e d i s t r i b u t i o n . Ca(OH)2 r e d u c t i o n i n t h e m a t r i x due t o i t s d e p o s i t i o n a t i n t e r f a c e s can reduce p e r m e a b i l i t y of t h e body and a c c e s s t o cement g r a i n s by H20; t h i s may r e s u l t i n l i m i t e d h y d r a t i o n r e l a t i v e t o mixes w i t h o u t sand and c a n a c c o u n t f o r i n c r e a s e d p o r o s i t y (4).

The a d d i t i o n of s i l i c a fume w i l l f u r t h e r i n f l u e n c e t h e p r o c e s s of p r o d u c t c r y s t a l l i z a t i o n around i n t e r f a c e s ( 1 , 4 ) ; t h e s i l i c a r e a c t s w i t h t h e Ca(OH)2 s t a r t i n g a t e a r l y t i m e s of h y d r a t i o n , c r e a t i n g b o t h a b e t t e r bond w i t h t h e a g g r e g a t e - m a t r i x i n t e r f a c e and l a r g e r p o r e s i n t h e v i c i n i t y of t h e m a t r i x . Some of t h e Ca(OH)2 c r y s t a l l i z e d around sand g r a i n s may r e d i s s o l v e t o r e a c t w i t h t h e r e l a t i v e l y i n s o l u b l e s i l i c a i n l o c a t i o n s away from t h e i n t e r f a c e .

The removal of Ca(OH)2 from t h e m a t r i x and i n t e r f a c e d e c r e a s e s t h e p e r m e a b i l i t y of t h e specimen ( 2 , 5 , 6 ) and t h e d e g r e e of h y d r a t i o n of t h e cement, r e s u l t i n g i n a h i g h e r p o r o s i t y (4,12). The low p e r m e a b i l i t y can be a c h i e v e d d e s p i t e a h i g h e r p o r o s i t y by l e a v i n g a h i g h d e g r e e of d i s c o n t i n u i t y

Vol. 1 6 , N o . 1 R.F. Feldman

TABLE 111

Pore-size D i s t r i b u t i o n of Mortars on R e i n t r u s i o n . Sandlcement R a t i o = 0.0 t o 3.0.

10% S i l i c a Fume. w / ( c + s f ) = 0.60. 28 Days Cured.

Sandlcement r a t i o 3.0 2.25 2.0

- -

Pore d i a m e t e r P a s t e P a s t e P a s t e

(nm x Normal p o r t i o n Normal p o r t i o n Normal p o r t i o n

TOTAL 18.02 40.35 23.35 39.56 23.65 43.19

1.8 1.5 0.0

P a s t e P a s t e

Normal p o r t i o n Normal p o r t i o n Normal

97j0.875 4.86 8.47 74.87 7.89 2.80

TOTAL 23.45 40.88 24.36 39.46 39.01

i n t h e p o r e s , o r by h a v i n g many i n k - b o t t l e p o r e s ( p o r e s w i t h l a r g e b o d i e s but narrow n e c k s ) .

Pore d i s t r i b u t i o n measurements by mercury i n t r u s i o n can r e v e a l t h e d i s c o n t i n u o u s n a t u r e of t h e p o r e s t r u c t u r e . Without s i l i c a fume, t h e p o r e

s t r u c t u r e changes w i t h sandlcement r a t i o , i . e . t h e c o a r s e p o r e component [(97+0.875) x l o 3 nm] i n c r e a s e s . Second mercury i n t r u s i o n shows l i t t l e d i f f e r e n c e i n t h e p o r e d i s t r i b u t i o n s (3). When s i l i c a fume i s added, f i r s t mercury i n t r u s i o n r e v e a l s a n i n c r e a s e i n b o t h t h e f i n e p o r e s

[(0.0175+0.0029) x 103 nm] and c o a r s e p o r e s ; t h e l a t t e r i n c r e a s e f u r t h e r w i t h sandlcement r a t i o , i n d i c a t i n g t h e i n t e r f a c i a l n a t u r e of t h e phenomenon.

Second mercury i n t r u s i o n , however, g i v e s r e s u l t s which a r e v e r y d i f f e r e n t from t h o s e of f i r s t i n t r u s i o n ; t h e s e r e s u l t s more c l o s e l y match t h e d i s t r i b u t i o n s of t h e specimens w i t h o u t s i l i c a fume, e x c e p t t h a t t h e amount of c o a r s e p o r e s

i s g r e a t e r , and i n c r e a s e s w i t h sandlcement r a t i o . T h i s o b s e r v a t i o n i n d i c a t e s t h a t t h e mercury i n t r u s i o n p a r t l y b r e a k s t h e pore s t r u c t u r e , e n t e r i n g f a i r l y l a r g e p o r e s a t h i g h p r e s s u r e s . A f a l s e i n d i c a t i o n of t h e p r e s e n c e of s m a l l p o r e s may t h u s be i n f e r r e d . The amount of r e l a t i v e l y i n a c c e s s i b l e c o a r s e p o r e s i n c r e a s e s w i t h sandlcement r a t i o and w i t h a r e d u c t i o n i n Ca(OH)2 c o n t e n t .

Vol. 1 6 , No. 1 39 MICROSTRUCTURE, MORTARS, SILICA FUME, SAND RATIO

P r e v i o u s work ( 3 , 6 , 1 3 ) h a s r e l a t e d t h e d i f f e r e n c e i n f i r s t and second mercury i n t r u s t i o n t o Ca(OH)2 c o n t e n t and p o r e d i s c o n t i n u i t y . T h i s work c o n f i r m s t h a t t h e phenomenon i s a l s o r e l a t e d t o t h e sand i n t e r f a c e .

Conclusions

1. Pores i n t h e (97+0.175) x 103 nm r a n g e a r e formed a t t h e i n t e r f a c e of

wand a g g r e g a t e i n m o r t a r s . These p o r e s i n c r e a s e w i t h sandlcement r a t i o i n

mixes both w i t h and w i t h o u t s i l i c a fume.

2. S i l i c a fume a d d i t i o n t o m o r t a r s r e s u l t s i n a n i n c r e a s e i n p o r e s of t h e (97+0.875) x 103 nm r a n g e a t t h e sand-aggregate i n t e r f a c e . A p o r t i o n of t h e s e p o r e s i s r e l a t i v e l y i n a c c e s s i b l e .

3. The pore d i s t r i b u t i o n of m o r t a r s c o n t a i n i n g s i l i c a fume d i f f e r s from

e q u i v a l e n t m o r t a r s w i t h o u t s i l i c a fume mainly by h a v i n g a l a r g e r c o a r s e p o r e component. D i f f e r e n c e s i n p e r m e a b i l i t y a r e due to a d i s c o n t i n u o u s p o r e s t r u c t u r e . 4. The l a r g e i n c r e a s e i n f i n e p o r e s t r u c t u r e o b s e r v e d on f i r s t i n t r u s i o n w i t h a d d i t i o n of s i l i c a fume

i s

r e a l l y d u e t o l a r g e b u t r e l a t i v e l y d i s c o n t i n u o u s p o r e s . Acknowledgements The a u t h o r w i s h e s t o t h a n k G.W. Chan f o r h i e v a l u a b l e h e l p i n performing t h e experiments. T h i s p a p e r i s a c o n t r i b u t i o n of t h e D i v i s i o n o f B u i l d i n g Research, N a t i o n a l Research C o u n c i l of Canada.R e f e r e n c e s

1. Huang Cheng-yi and R.F. Feldman, " I n f l u e n c e of S i l i c a Fume on t h e

M i c r o s t r u c t u r a l Development i n Cement Mortars". Cem. Conc. Res.,

15,

285(1985).

K.P. Peldman and Huang Cheng-yi, " M i c r o s t r u c t u r a l P r o p e r t i e s of Blended Cement Mortars and T h e i r R e l a t i o n t o h r a b i l i t y of Concrete S t r u c t u r e s Under Normal Outdoor Exposure", Hanover, 26-29 March 1984 ( i n p r e s s ) . Huang Cheng-yi and R.F. Feldman, "Dependence of F r o s t R e s i s t a n c e o n t h e Pore S t r u c t u r e of Mortar C o n t a i n i n g S i l i c a Fume". ( I n p r e s s . h e r . Conc. I n s t . J.)

Huang Cheng-yi and R.F. Feldman, "Hydration R e a c t i o n s i n P o r t l a n d Cement

-

S i l i c a Fume Blends". ( I n p r e s s . Cem. Conc. Res.)Bakker, R.F.M., P r o c e e d i n g s , F i f t h I n t e r n a t i o n a l Conference on

Alkali-Aggregate R e a c t i o n i n Concrete, Cape Town, South A f r i c a , 1981, N a t i o n a l B u i l d i n g Research I n s t i t u t e , C o u n c i l f o r S c i e n t i f i c and I n d u s t r i a l Research (1981).

R.F. Feldman, Proc. 1 s t I n t e r n . Conf. on t h e Use of Fly-Ash, S i l i c a Fume, S l a g and Other M i n e r a l By-Products i n Concrete, ACI SP 79, Vol. I, 415 (1983).

M. Regourd and B. Mortureux, Proc. 4 t h I n t e r n . Conf. on Cement Microscopy, Las Vegae, USA, 249 (1982).

P.K. Mehta and O.E. Gjorv, Cem. Conc. Res.

12,

587 (1982).B.D. Barnes, S. Diamond and W.L. I b l c h , J. Amer. Ceram. Soc.

62,

(1-21, 21 (1979).10. A. Catles-Giberques, J. Grandet and J.P. O l l i v e r , Proc. I n t e r n . Conf. on Bond i n Concrete. P a i s l e y C o l l e g e of Technology, S c o t l a n d , London (Apple S c i . ) 24 (1982).

11. R. Berger, D.S. Cahn and J.O. McGregor, J. Amer. Ceram. SOC.

2,

( I ) , 57 (1970).12. R.Sh. M i k h a i l and A.M. Youssef, Cem. Conc. Res.

6,

( 6 ) , 869 (1974). 13. R.F. Feldman, J. Amer. Ceram. Soc.67,

30 (198.6).T h i s p a p e r i s b e i n g d i s t r i b u t e d i n r e p r i n t form by t h e I n s t i t u t e f o r R e s e a r c h i n C o n s t r u c t i o n . A l i s t of b u i l d i n g p r a c t i c e and r e s e a r c h p u b l i c a t i o n s a v a i l a b l e from t h e I n s t i t u t e may be o b t a i n e d by w r i t i n g t o t h e P u b l i c a t i o n s S e c t i o n , I n s t i t u t e f o r R e s e a r c h i n C o n s t r u c t i o n , N a t i o n a l Research C o u n c i 1 o f C a n a d a , O t t a w a , O n t a r i o , K1A OR6. Ce document e s t d i s t r i b u e s o u s forme d e t i r e - + p a r t p a r 1 ' I n s t i t u t de r e c h e r c h e e n c o n s t r u c t i o n . On p e u t o b t e n i r une l i s t e d e s p u b l i c a t i o n s d e 1 ' I n s t i t u t p o r t a n t s u r les t e c h n i q u e s ou l e s r e c h e r c h e s e n m a t i e r e d e b s t i m e n t e n 6 c r i v a n t 3 l a S e c t i o n d e s p u b l i c a t i o n s , I n s t i t u t de r e c h e r c h e e n c o n s t r u c t i o n , C o n s e i l n a t i o n a l d e r e c h e r c h e s du Canada, Ottawa ( ~ n t a r i o ) , KIA OR6.