Publisher’s version / Version de l'éditeur:

Journal of the American Ceramic Society, 51, 6, pp. 337-340, 1968-09-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Interrelation of hardness, modulus of elasticity, and porosity in various

gypsum systems

Soroka, I.; Sereda, P. J.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=e8378a15-5747-4342-adf6-93146807dd1c

https://publications-cnrc.canada.ca/fra/voir/objet/?id=e8378a15-5747-4342-adf6-93146807dd1c

A

& A i.'p87tz,

Ileprinted f r o m t h e Journal of T l ~ e American Ceramic Society, Vol. 61, Xo. (i. June, 1908. & %, i s

Copyright 1968 b y t h e Americau Ceramic Society '" -4.

Interrelation of Hardness, Modulus of Elasticity,

and Porosity in Various Gypsum Systems

I.

S O R O K A * a n dP. J .

S E R E D ADivision of Duilding Rcscarch, National Research Council of Canada, Ottawa, Canada

T h e interrelation of hardness, modulus of elasticity, a n d porosity w a s investigated i n four gypsum systems. Results suggest t h a t intergrowth a n d interlocking of crystals sig- nificantly affect mechanical behavior, a t l e a s t h a r d n e s s a n d

modulus of elasticity, E. I n addition, both properties a r e

related to porosity,

p.

T h i s relation can b e described em-pirically by t h e exponential expression E = Eo exp ( - f:$).

I.

I n t r o d u c t i o nT

aE relation between porosity and n~echanical properties ofporous solids, including gypsum, has been reported in

numerous paper~.~-~"etailecI discussion of the available

information is outside the scope of the present paper and can

be found elsewhere 2 0 a 2 1 Generally, for otherlvise identical

conditions, mechanical properties such as strength and modulus of elasticity were related to porosity, with the rela- tion usually taking the form of an exponential expression

For example, S = Soe-b~, where S is the strength of the speci-

men with porosity

p,

So is the corresponding strength for zeroporosity, and b is an empirical constant related to the type of

material and to its pore geometry 2 * 7 A similar expression,

E = Eoe-lll, represents the relation bctween porosity and

modulus of elasticity fairly well "I1 Nevertheless, the use of

such expressions is sometimes criticized b e c a ~ ~ s e they are de-

vised on a purely elnpiricaI basis and do not satisfy the bound-

ary condition of E = 0 (or S = 0) for

p

= 1.Theoretical investigations of the problem have resulted in other cxpressions describing the porositjr-modulus of elasticity

r e l a t i 0 n . ? ~ < ~ 3 In general, all the iormulas suggested give

reasonably good agreement with experimental data; from this point of view a critical evaluation of the various expres- sions is hardly feasible. Finally, although some attempts have been made to allow cluantitatively ior pore geolnetry and particle size in the mechanical properties-pore iraction

re la ti or^,"^,^"^^ the problem has not yet been solved satisfac-

torily

Tests reported in the present paper wcre confined to the eflect ol crystal intergrowth and interlocking on some ine-

chanical properties of a porous solid This specific aspect was

suggested by recent work in which the mecl~anical properties

of portland cement pastes and compacts of bottle-hydrated ce-

ment were compared under exposure to different humidities 2"

Studying a system t h a t is distinctly crystalline, and in which intergrowth of crystals during hydration is a possibility, was

considered useful. Gypsum is such a systeln, and was selected

for comparison with the cement system.

11.

E x p e r i m e n t a l P r o c e d u r e ( I ) Preparationof

Specimens-411 specimens were flat disks 1 23 in. in diameter and having a nominal thickness of 0 050 in. They were prepared

and tested a t 50% rh and 22'C Only one type of plaster

was used, pottery plaster (hemihydrate produced by an "aridized" process in which gypsum is heated with traces of calcium chloride). Specimens of five systems were pre- pared, with as wide a porosity range as is technically possible for the system in question.

Syslenz I , I n S i t u IIy(lra(e(1 Pollery Plasler: The plaster was

mixed in vacuum with 1)oilcd clistillcd water to give cylinders

1 25 in in diameter and approxin~ately 3 in. long. I t was

inixed in Perspex tubes rotated continuously during the

hardening period This eliminated sedimentation and bleed-

ing phenomena and resulted in highly uniform specimens. After hardening, cylinders were sliced to give specimens

0 030 in thick Specimens of five porosities ranging from

50 to 70% were prepared; the corresponding water-plaster

ratio (by weight) was 0.64 to 1.36.

Porosity was calculated from the relation of plaster t o mix-

ing water."t Porosity was also detennined from the weight

and geometrical dimensions of the specimens, assuming com-

plete hydration This aszlmption was verified by deter-

mining the amount of coml~ined water using the t h e m o -

balance procedure Agreement between the two methods

was reasonably good, the maximum difference in the c a l c ~ ~ l a t e d values being only about 2%.

Syslenz 11, I11 S i t z ~ IIydrc~led Pollery Plusler Compuclerl at a Later Stage: After being machined and sliced, some of the in

situ hydrated specimens (system I ) were compacted in a closely fitting mold (0.003-in nominal clearance). I n each case thickness of the sliced specimens was adjusted t o yield the nominal thicknessoi 0 050 in. after compaction. Porosity,

controlled by the pressure applied, ranged from 5 t o 49y0.

13ecause the initial porosity was known, porosity after compac- tion was determined simply by the change in the dimensions of the specimen involved.

System I I I , Co~rzpacts of li~zlzydraled Pottery Plaster: Com-

pacts of hemihydrate were made by the technique described e l s e ~ h e r e , ~ ; the only change being t h a t a Teflon coating was applied t o the compacting surface of the two pistons. This treatment reduced friction and considerably reduced the

number of imperfect specimens produced In fact, the

Teflon treatment was critical for system 11; otherwise i t would hardly have been possible t o produce perfect specimens. Specimens of live porosities ranging from 18 to 42y0 were

prepared Again, porosity was controlled by the applied

pressure and determined from the weight and geometrical dimensions

System 111, comprising a different material (i.e , hemihy- drate as opposed to gypsum in the remaining systems), is not directly related to the present investigation and was prepared mainly to facilitate production of system IV. Consecjuently,

a l t h o ~ ~ g h relevant test d a t a are presented in some detail,

its properties and performance are discussed hereafter in a limited way only.

System I V , Hydrated Conzpacls of Poltery Plaster: Some of

the hemihydrate compacts (system 111) were allowed to hy-

Received September 8, 1967; revised copy received December

15, 1967.

The writers are, respectively, visiting scientist and head, Inor- ganic Materials Section, Division of Building Research, National Research Council of Canada.

*

I. Soroka is a research fellow, Building Research Station,Technion, Israel Institute of Technology, Haifa, Israel.

t

The densities of thc hcmihydrate and dihydrate were taken a s2.76 and 2.31 g/cm3. These values were used throughout the

zmic Society-Sorokc~ c~nti Seredn Vol. 31, No. G

P O R O S I T Y . P E R C E N T

Fig. 1. Hardness vs. porosity.

drate, being exposcd to watcr vapor lor 2-4 hr and then dipped into water for approxinlately 1 min. Four such cycles of ex-

posure to vapor and immersion i n water were made Com-

plete hydration, however, was not reached and the degrce of

hydration (calc~~lated froin the amount of combined water as

determined from the thermobalance test) varied from SO t o

S9y0, depending 011 the porosity of the unhydrated conlpact

This procedure rcsultcd in cornpacts of eight porosities rang- ing from 11 to 2G%.

System V , Compacts of Bottle-IIydrated Pollery Plnsler:

T h e bottle-hydrated plaster was prepared by mixing a 1 : 10

mixture of plaster and water for -4 hr in a tightly closed bottle

mounted on a rotating disk After being dried a? 30% rh, the

hydrated plaster was used to prcpare compacts of seven po-

rosities ranging from -1 Lo 29%

( 2 ) Testsfor Mechanical Properties

When specinlens reached ecluilibrium a t 50y0 rh and a ° C ,

two tests were conductccl: (1) Viclters hardness was dcter- mined with a Lcitz Miniload hardness testcr, with the load

adjusted in each case to give indentation to a depth ol 35 t o

5OP I-Iardness was taken as the average ol 10 tests illade

along an arbitrary diameter a t 0 1-in. intervals (2) Young's

modulus of elasticity was dctcrlnined with a n apparatus de-

scribed elsewhere 2 i

0 10 20 30 4 0 50 60 70

P O R O S I T Y , P E R C E N T

T o calibrate this apparatus, the modulus of elasticity in

compression of gypsun1 cylindcrs 1 25 by 2 in. was compared

with the results for clcflcction of disks cut from the cylinders. The average of livc inclepenclent tests was considered a s

Young's ~nodulus for ally given set of co~iditions

111.

Results and Discussion111 Figs 1 a11d 2 , respectively, hardness and modulus of

clasticity are plotted versus porosity, together with the corre-

sponding regression lincs These lines were calculated to fit

test d a t a using the least-squares method ancl assuming a semi-

logarith~nic relation between the factors involvecl Such a n

assumption resulted in fairly good agreement with the experi- nlental d a t a and holds for each of the systems prepared.

Perhaps the most important feature presented in Figs. 1

and 2 is the fact that, although the semilogarithmic relation

Ilolds for all systems prepared, in each this relation is repre- sented by a different regression line. This in turn implies that, although hardness and rnodulus of elasticity are related t o

porosity, these properties are governed also by additional

.

factors Under the conditions of this study, when all the sys-

terns are of the same material, i t may be argued t h a t a n y difference in their properties can only be attributed to some in- herent difference in their structure, such as the particle size and shape, the effective area of contact, or the degree of crystal intcrgrowth ancl interlocking

For the same porosity, specimens of systems I and IV gave the highest values for hardness and modulus of elasticity

(Figs 1 and 2) I n both systems the structurc is formed by

growth of the gypsum crystals from a supersaturated solution, allowing crystals to grow together a t points of contact and t o

interlock on hardening Under these conditions there can 11e

recrystallization a t acute angles of contact, bringing about a n

increased area of contact -411 these effects contribute to the

strength of these systems

Systems I and IV sl~oulcl form the two ends of a colninon

systeln and be rcpresentecl by a single regression line for each of the hardness and modulus of elasticity versus porosity rela-

tions T h e deviation noted in Figs 1 and 2 suggests that the

semilogaritl~mic relation does 11ot hold over such a wide range

of porosity (11 to 70%)

System I 1 specimens exhibited intermediate hardness and

moclulus of elasticity I t appears t h a t during the lormation of

this system h y colnpaction the primary structure of system I is progressively destroyccl ancl rcplaccd by a new structure corrc- sponcling t o t h a t of s y s t e ~ n

l'

This is verilied by thc factI I I I I II l l I I / I l l I

I

100 200 4 0 0 700 1 0 0 0 2000 4 0 0 0 7000 10000 20000C O M P A C T I N G P R E S S U R E . K G P E R C M ~

Fig. 5. Surface micrographs o f the gypsum systems.

June

1968

Hl~rdness, ~ l h d ~ ~ l ~ ~ s

of E l a s t i c ~ t y ,

and Porosity

in G y p s z ~ m

Systems

339

100 80 6 0 40 I 1 1 1 1 1 1 1 1 I 1 1 1 1 1 1 1 A - - / / 7 - 1

./!

- -I/?

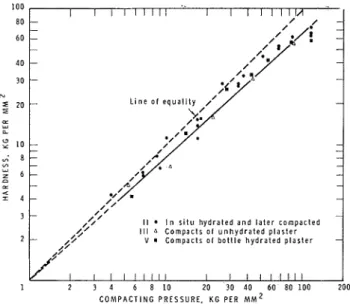

- - -Figure 3 shows the semilogarithmic relation between porosity and compacting pressure for specimens of systems 11,

111, and V Such a relation was found in previous work2'a2j

for a variety of materials

From the semilogarithlnic relation between hardness and

* g 20 z = ,., I 0 rn 8 - rn

30 -

/

- porosity on the one hand, and porosity and compacting pres-L ~ n e 0 1 e q u a l i t y

-

->!

.///'

.

- - - - - / /.

" -sure on the other, it follows that a relation should exist be-

tween hardness and compacting pressure (Fig 4) The data

indicate that all the systems involving compaction are repre- sented by a single regression line and that this line passes

through the axis origin This implies that the hardness of a

6 - z m - 4 */

.

/?

- 3 G// - I I I n s l t u h y d r a t e d a n d l a t e r c o m p a c t e d/+

1 1 1 A C o m p a c t s O I u n h y d r a l e d p l a s t e r 2 //// V.

C o m p a c t s 0 1 b o t t l e h y d r a t e d p l a s t e r - / / // I 1 1 I I I I I I I I I I I I I I Ispecimen depends on the pressure to which it was compacted I t can be explained on the grounds that in a porous material the indentation produced in the hardness test is primarily a localized compaction as opposed to the plast~c deformation occurring in a nonporous material

The deviation of the regression line from the line of equality

in Fig 4 is probably due to the friction between the specimen

and the wall of the mold; its value increases with the pres-

I 2 3 4 6 8 10 20 30 40 60 80 l o o 200 sure as would be expected I t appears, therefore, that the

C O M P A C T I N G P R E S S U R E , K G P E R M M ~

compacting pressure can be used to indicate the hardness of

Fig. 4 . Hardness vs. compacting pressure. specimens made by compaction if the correction for friction

could be estimated.

In the foregoing discussion the large differences in hardness and elastic behavior for the same porosities but different

that the regression lines of systans I1 and V intersect a t ap- methods of preparation were attributed to variations in their

proximately zero porosity structure and identified with crystal intergrowth and inter-

The values for hardness and modulus of elastic~ty a t zero locking. These features in the structure could be verified by

porosity should be the same for systems I1 and V because they electron microscopy T O this end the fracture surfaces of

represent the polycrystalline material that \vould be obtained specimens from the different systems were examined with an

by compaction a t very high pressure For systems I and IV, EMS5 electron microscope (Philips Electronic Equipment

however, these values at zero porosity have no practical Ltd , Toronto, Canada) and a scanning electron microscope

significance because such a material could not he produced by The electron micrographs in Fig 5 (,I through F) show a

ferences in the physical appearance and character of the struc- tures are apparent I-Iowevcr, the main features t h a t could be definitely identified were the intergrowth of crystals for systeln I (Fig. .5(B)) and the interlocking of crystals for sys- tem IV (Fig. 5(E)). These features confirm what has been concluded as the reasons for the much higher hardness and modulus of systems I and IV.

The structure of system I 1 (Fig S(C)) shows evidence for the destruction of the primary structure during co~npaction. The individual crystals arc fragmented and much shorter than they appear i n system I (Fig. 5(A)) but less disordered and fractured than systeln

V

(Fig. 5 ( F ) ) .IV.

ConclusionsWithin the limited scope of the present s t t ~ d y , several con- clusions were reached for a porous polycrystalline solid such as gypsum:

(1) I-Iardness and n~odulus of elasticity are related to

porosity. This relation can be described empirically in the form of an exponential expression already observed 1,y others for strengthq7 and n~odulus of e l a s t i ~ i t y . ~ - l ~ For present conditions the relevant expressions and parameters established for the various systems are given in Table I .

( 2 ) Intergrowth and interlocking of crystals significantly

affect mechanical properties, a t least hardness and modult~s of elasticity. Depending on porosity, hardness values were as much as four times higher (approximately) and modulus of elasticity u p t o ten times higher than corresponding values in otherwise identical systems in which crystal intergrowth is not very likely t o occur.

(3) I-Iardness is related to compacting pressure, suggesting the possible use of the latter parameter as a measure of hard- ness and perhaps some additional properties for porous sys- tems formed by con~paction

Acknowledgment

The authors gratefully acknowledge the assista~~ce of A. IZeznn- owich ancl the Pulp and Paper Research Institute for the scannii~g electron ~rlicrographs, E. G. Quinn for the electron micrographs, and T . F. Doherty in obtaining the esperi~nental results. References

I T . C. Powers, "Sonevaporable Water Cot~tctlt of Hardened Portland Cement Paste-Its Significance for Concrete Rescarch and Its Method of Determination," A S T B I Bztll., No. 158, 68-76

(Mgy 1949).

-

Eugene Ryshkewitch, "Compression Strcngth of Porous Sintercd Alumina and Zirco~~ia." J. 11?,1. Ceravz. Soc., 36 [2] 6 5 6 8 (1953).&I. D. Burdick and H. S. Parker, "Effect of Particle Size on Bulk Density and Strength Properties of Uraniuni Dioxide Speci- mens," ibid., 39 151 181-87 (1956).

R. L. Coble and W. D. Kingery, "Effect of Porosity 011 Physi- cal Properties of Sintered Aluinina," ibid., [ l l ] 377-85.

j K. K. Schiller; pp. 35-49 ill Mechanical Properties of Kon- Metallic Brittle Materials. Edited by W. H. Walton. Butter- worth & Co. (Publishers) Ltd., London, 1958.

D. J. Millard, "Relationship Between Strength and Poros~ty for Coal Compacts," Brzt. J. Appl. Phys., 10 [GI 287-90 (1959).

'

F. P. Knudsen, "Dependence of Mechanical Strength of Brittle Polycrystalline Specimens on Porosity and Grain Size," J. AWL. Cera~lz. Soc., 42 [ S ] 376-87 (1959).Table I. Summary of Test Data Parameters of Regression Lines

H a r d n e s s , H , vs. hlod. of elasticity. E , vs.

porosity, p porosity. p

II = IIo c x p ( - n p ) E = En c x p ( - b g )

SOTB:

P

= pore volume fraction.K. K Sclllller, "Skeleton Strciigtli aiid Critical Porosity L

i l l Set Sulpl~ate Plasters," Brll. J.

.IppI.

Pllys , 11 [ S ] 3 3 8 1 2 (1060)R. M. Spriggs, "Expressiori for Effect of Porosity oil Elastic ~ f o d u l u s of Polycrystalline Refractory Materials, Particularly Xlu~riiriu~n Oxicle," J. 1,1ln1,. Cera111. Soc., 44 [12] 628-29 (1961).

lo F. P. ICnudseii, "Effect of Porosity on Young's Moclulus of .-\luinina," ibid., 45 [ 2 ] 94-95 (196%).

"

R. M. Spriggs ancl L. A. Brissctte, "Expressions for Shear Modulus and Poisson's Ratio of Porous Refractory Oxides,"ibid., [ 4 ] 198-99.

L. J. Trostel, Jr., "Strength ancl Structure of Refractories as a Fuiiction of Pore Content." ibid.. 1111 563-64.

I", Spinner, F. P. Knudsen, ab;l ~ : ~ t o n c , "Elastic Coiistaiit-

Porosity Relations for Polycrystalline Thoria," J. Res. ~Vall. Blcr. Sld., 67C [ I ] 39-46 (1963).

"

S. Spinner, L. S t o ~ ~ e , a ~ i d F. P. Knuclsel~, "Temperature De-pendence of the Elastic Constants of Thoria Specimens of Vary- ing Porosity," ibid., [ 2 ] 93-100.

I" D. P . H. Hasselinan, "Relation Between Effects of I'orosity

on Strength and 011 Young's Modulus of Elasticity of Polycrystal- line Materials," J. ;I?IL. Ceran~. Soc., 46 [11] 564-65 (1963).

I G D. P. H. ~Iasselina~i, "On Porosity Dependence of Elastic

Moduli of Polycrystalline Refractory Materials," ibid., 45 [ 9 ]

452-53 (1962).

I7 D. P. H . Hasselman and R. M. Fulrath, "Effect of,,Small

Fraction of Spherical Porosity on Elastic Moduli of Glass, ibid.,

47 [ I ] 52-53 (1964).

la S. D. Brown, R . B. B i d d u l ~ h , and P. D. Wilcox, "A Strength-

Porosity Relation Invol\~ing Different Porc Geometry and Oricntation," ibid., (71 320-22.

I%. A. Helmut11 and D. H. Turk, "Elastic Moduli of Hardened

Portland Cement and Tricalciu~n Silicate Pastes: Effect of Porosity," Highzvay Res. Board, Special Report NO. 90, 1 3 5 4 4

(1966).

? O W . D. Kingery and R. L. Coblc; pp. 103-13 in Meclia~iical Behavior of Crystalline Solids, iI1all. JJllr. Sld. ( U . S . ) il/lotrograph., hTo. 59, 113 pp. (1963).

"

R. J. Stokes, "Correlation of Mechanical Properties withMicrostructurcs," iVoll. B ~ i r . Sld. ( U . S . ) BIisc. Publ. KO. 257, 41-72 (1964).

"

J . K. Mackenzie, "Elastic Constants of a Solid Containing Spherical Holes," Proc. Plzys. Soc. (London), 63B [ I ] 2-11 (1950).? 3 Z. Hashin, "Elastic Moduli of Heterogeneous Materials,"

J . ilppl. Meclz., 29 [ I ] 143-50 (1962).

"

P. J. Sereda, R. F. Feldman, atid E. G. Swenson, "Effect of Sorbed Watcr on Some Mechanical Pro~erties of Hvdrated Port- land Cement Pastes and Co~npacts," fl&hway Res. ~ o a r d , Special Report KO. 90, 58-73 (1966). e?j P. J. Serecla and R. F. Feldinan, "Compacts of Powdered lMaterial as Porous Bodies for Use in Sorption Studies," J. Appl.