READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Thermal properties of high strength concrete at elevated temperatures

Kodur, V. K. R.; Sultan, M. A.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=ff638e52-5ca6-42c2-b935-f590358cbf0d https://publications-cnrc.canada.ca/fra/voir/objet/?id=ff638e52-5ca6-42c2-b935-f590358cbf0d

Thermal properties of high

strength concrete at elevated

temperatures

Kodur, V.K.R.; Sultan, M.A.

NRCC-42052

A version of this document is published in / Une version de ce document se trouve dans:

CANMET/ACI/JCI Fourth International Conference on Recent Advances in Concrete Technology

Tokushima, Japan, June 7, 1998, pp. 467-480

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d’auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d’identifier la source de l’information et, dans certains cas, d’interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

J

-J

J

J

Ferro chrome SlagI

fireproof blocks at the

SP 179-29

Thermal Properties of High Strength

Concrete at Elevated Temperatures

by

V.K.R. Kodur and Mohamed Sultan

Synopsis: In recent years, high strength concrete (HSC) has become an attractive alternative to traditional normal strength concrete (NSC) . With the increased use of HSC, concern has developed regarding the behaviour of such concrete in fire. Studies are in progress at National Research Council of Canada for developing design guidelines for the use of HSC under fire conditions.

The behaviour of HSC columns is illustrated by comparing the fire resistance performance of HSC columns with that of NSC columns. Results from experimental studies that were carried out to determine the thermal properties of HSC, with and without steel fibre-reinforcement, at elevated temperatures are also presented. The effect of temperature on thermal conductivi ty, thermal expansion, specific heat and mass loss of HSC is discussed . Test data indicate that the type of aggregate has significant influence on the thermal properties of HSC, while the presence of steel fi bre-reinfo rcement has very little influence on the thermal properties of HSC.

Keywords: colurims (supports); fibers; fire resistance; high-strength concrete;

reinforced concrete; thermal properties; steels

468 Kodur and Sultan

Dr. Venkatesh Kwnar R. Kodur is a Research Officer at the Institute for Research in Construction, National Research Council of Canada. He has published over 60 papers in the structural and fire resistance areas . He is a Collaborative Investigator of Concrete Canada and a member of ACI 216 and the ASCE Committee on Structural Fire Protection.

Dr. Mohamed M. Sultan is the Manager of the Fire Resistant Construction Subprogram, Institute for Research in Construction, National Research Council of Canada. He has published over 80 papers in the fire resistance area. He was the recipient of the NFP A 1997 Harry C. Bigglestone Award for Excellence in Communication of Fire Protection Concepts.

INTRODUCTION

In recent years, the construction industry has shown significant interest in the use of high strength concrete (HSC). This is due to the improvements in structural performance, such as high strength and durability, that it can provide compared to traditional normal strength concrete (NSC). In Canada, HSC is being used in many applications such as bridges, off-shore structures and infrastructure projects. In recent years, its use has been extended to high rise buildings. The major use ofHSC in buildings is in columns.

In buildings, HSC structural members are designed to satisfy the requirements of serviceability and safety limit states. One of the major safety requirements in building design is the provision of appropriate fire safety measures for structural members. The basis for this requirement can be attributed to the fact that, when other measures for containing the fire fail, structural integrity is the last line of defence.

The results of fire tests (1, 2, 3) have shown that there are well-defined differences between the properties of HSC and NSC at high temperatures. Further, concern has developed regarding the occurrence of explosive spalling when HSC is subjected to rapid heating, as in the case of a fire (1, 3).

Studies are in progress at the National Research Council of Canada (NRC) to develop fire resistance design guidelines for the use of HSC for possible incorporation in codes and standards. The main objective of this research, being undertaken in partnership with industry, is to study the behaviour of HSC at elevated temperatures and to develop calculation methods for predicting the fire resistance for columns. For the development of such calculation methods, the properties of HSC at elevated temperatures are required.

In this paper, data from experimental studies on thermal properties at

1:

leer at the Institute for :=anada. He has published

He is a Collaborative 6 and the ASCE

ire Resistant Construction ional Research Council of stance area. He was the i for Excellence in

1wn significant interest in : to the improvements in bility, that it can provide In Canada, HSC is being uctures and infrastructure high rise buildings. The

jesigned to satisfy the One of the major safety appropriate fire safety :irement can be attributed the fire fail, structural

at there are well-defined _:: at high temperatures. ce of explosive spalling a fire (1, 3).

:ouncil of Canada (NRC) se of HSC for possible ve of this research, being 1e behaviour of HSC at ds for predicting the fire calculation methods, the

m thermal properties at

Recent Advances in Concrete Technology 469

elevated temperatures are presented for various types ofHSC.

RESEARCH SIGNIFICANCE

In order to understand and eventually predict the performance of HSC structural members, the material properties that determine the behaviour of the member at elevated temperatures must be known. The behaviour of a structural member exposed to fire is dependent, in part, on the thermal, mechanical and deformation properties of the material of which the member is composed.

To be able to predict the fire resistance of a structure, the temperatures in the structure must be determined. For such calculations, knowledge of the thermal properties, at elevated temperatures, of the materials that comprise the structure is required. Whereas these properties have been established for various normal strength concretes (4, 5), this is not the case with high strength concretes. In this study, the relevant thermal properties of various high strength concretes at elevated temperatures were measured. These properties included thermal conductivity, specific heat, thermal expansion and mass loss of the various high strength concretes at elevated temperatures.

The data presented in this study can be used as input to computer programs (6, 7) to determine the behaviour ofHSC structural members at high temperatures. Thus, the availability of thermal properties of HSC at elevated temperatures facilitates the use of calculation methods which are far less costly and time consuming than testing.

THERMAL PROPERTIES OF HIGH STRENGTH CONCRETE

To study the fire performance of high strength concrete structural members, tests have been carried out by exposing the full-scale HSC columns to fire. These tests were carried out in accordance with ASTM specifications (8) and the details are given in Refs. 9 and 10. From the test data, it was found that for HSC, the spalling of concrete under fire conditions is a major concern. The spalling is due to the low water-cement ratio in HSC (1 0) and has been observed in HSC structural members under laboratory and real fire conditions (3, 11). Spalling, which results in the loss of concrete during a fire, exposes deeper layers of concrete to fire temperatures, thereby increasing the rate of transmission of heat to the inner layers of the structure, including the reinforcement.

In order to predict fire performance and spalling behaviour of HSC, the thermal properties are required. Also, data from various studies (1, 10, 12) show that the presence of fibre-reinforcement and the use of carbonate aggregate can be used to minimize spalling in HSC. There is very little information on the thermal

470 Kodur and Sultan

and mechanical properties of HSC. Hence, in this study, the thermal properties of both plain HSC and steel fibre-reinforced HSC of two aggregate types were investigated.

The thermal properties that influence the temperature rise and distribution in a concrete structural section are thermal conductivity, specific heat, thermal expansion and mass loss. These properties depend on the type of aggregate and composition of the concrete mix. In this section, the thennal properties of HSC with the two most commonly used aggregates (siliceous and carbonate aggregate), as well as HSC with and without fibres, are presented.

Test Specimens

Four types of concrete specimens, namely, NRC1, NRC2, NRC3 and NRC4 were fabricated from 4 batches of concrete for studying the thermal properties. For all four batches, general purpose portland cement was used. The NRC4 specimen was made of HSC reinforced with steel fibres while the other 3 batches were made with HSC without steel fibres. The concrete mix in Batch 1 was made with siliceous stone aggregate while the mix in Batches 2, 3 and 4 was made with carbonate stone aggregate. The fine aggregate for all four batches consisted of silica-based sand. The mass (volume) percentage of steel-fibres in Batch 4 concrete mix was 1.77 (0.597). The mix proportions for the concrete were:

• cement

+

silica fume: 500 kg/m3 • coarse aggregate: 1100 kg/m3 • fine aggregate: 700 kg/m3 • water: 140 kglm3• steel fibres (Batch 4): 45 kglm3

The steel-fibres were added to the fresh concrete and mixed for about 5 minutes to ensure uniform dispersion. Vibrators were used to consolidate the concrete.

For each concrete mix, 152 mm x 304 mm cylinders and bricks of size 200 mm x 100 mm x 80 mm were fabricated. Compression tests were conducted using the cylinder samples at 28 days after the pouring of the concrete. The 28-day cylinder compressive strength for Batch 1 and Batch 2 was approximately 90 MPa while the corresponding strength for Batches 3 and 4 was approximately 80 MPa. The bricks were used to determine the thermal properties of the concrete at elevated temperatures.

· '

ly, the thennal properties of two aggregate types were

;rature rise and distribution vity, specific heat, thennal

1 the type of aggregate and

thennal properties of HSC s and carbonate aggregate),

NRC2, NRC3 and NRC4 ng the thennal properties. 1t was used. The NRC4 s while the other 3 batches ; mix in Batch 1 was made ; 2, 3 and 4 was made with four batches consisted of Jf steel-fibres in Batch 4 r the concrete were:

rete and mixed for about re used to consolidate the

linders and bricks of size >sion tests were conducted ng of the concrete. The latch 2 was approximately · and 4 was approximately I properties of the concrete

Recent Advances in Concrete Technology 471

The measured thennal properties were the thennal conductivity, specific heat, thennal expansion and the mass loss of the concretes at elevated temperatures. All measurements were made with commercially-available instruments. The experiments and the test specimens used are described in detail in earlier studies (5, 13), and are, therefore, only briefly described in this paper.

The test specimens for the detennination of the thennal conductivity and the thennal expansion were prepared by cutting the concrete bricks to appropriate size. Specimens for the detennination of the specific heat and mass loss were obtained by grinding a portion of the bricks. The relative humidity of the specimens at the time of testing was approximately 50%.

The thennal conductivity of the concretes was measured using a non-steady state hot wire method. The measurements were made in the temperature range between 20°C and 800°C.

The specific heat was measured using a Differential Scanning Calorimeter (DSC) for temperatures up to 600°C. Above 600°C, a high temperature Differential Thennal Analyzer (DT A) was used. The specific heat was measured up to 1 000°C.

The thennal expansion of the concretes was measured with a dilatometric apparatus, capable of producing curves that show the expansion of the concrete with temperature in the range from 20°C to 1 000°C.

The mass loss with temperature was measured by means of a Thennogravimetric Analyzer (TGA) in the temperature range from 20°C to 1000°C.

Results and Discussion

In this section, the thennal properties are compared for NRC1 with NRC2 specimens to show the influence of aggregate type (siliceous and carbonate) and for NRC3 with NRC4 specimens to show the influence of fibre-reinforcement on the various properties.

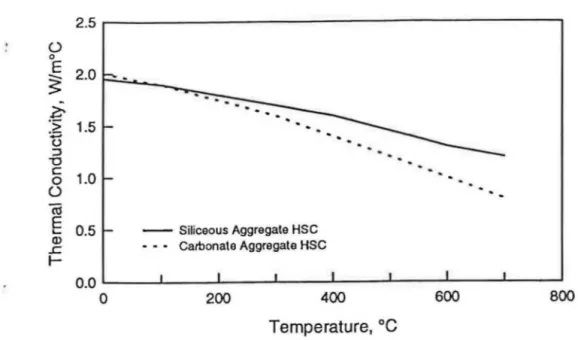

Thennal Conductivity -- The thennal conductivity of HSC, with siliceous and carbonate aggregates, is shown in Fig. 1a as a function of temperature. The thennal conductivity for both siliceous and carbonate aggregate concrete types decreases with increase in temperature. The thennal conductivity of siliceous aggregate concrete is higher than that of the carbonate concrete in the temperature range of 100°C to 800°C. This is due to the higher crystallinity of the siliceous aggregates as compared to that of the carbonate aggregate. The higher the crystallinity, the higher the thennal conductivity and its rate of decrease with

472 Kodur and Sultan

temperature ( 4). The effect of aggregate type on the thermal conductivity of HSC is similar to that ofNSC (14).

The thermal conductivity of plain and steel fibre-reinforced HSC is shown in fig. 1 b as a function of temperature. The thenn.al conductivity of steel fibre-reinforced HSC is slightly lower than that of plain HSC above 1 00°C. This can be attributed to the presence of steel fibre-reinforcement in concrete which helps in limiting the crack growth and propagation, and thus decreases the rate of heat transfer in the specimen.

Specific Heat -- The specific heat of HSC for the two types of aggregate is shown in Fig. 2a, as a function of temperature. For both types of concrete, the specific beat shows a peak at temperatures near 1 00°C and 425°C. The first increase is caused by evaporation of free water and the second by removal of crystal water from the cement paste (15). In these temperature regions, most of the heat supplied to the concrete is used for the removal of water and only a smaJI amoWlt is available for raising the temperature of the material. As a consequence, the specific heat increases substantially in these temperature regions. The increase in specific heat for the siliceous aggregate concrete, at about 500°C, can be attributed to the presence of quartz, which transforms in this temperature region.

The specific heat of HSC, similar to that of NSC, is also affected by other physicochemical processes that occur in the cement paste and the aggregates at temperatures above 600°C. The specific beat of carbonate aggregate concrete above this temperature is generally higher than that of siliceous aggregate concrete. Above 600°C, an enormous amount of heat is needed to raise the temperature of the carbonate aggregate concrete. This heat is approximately ten times the heat needed to produce the same temperature rise in siliceous aggregate concrete. The increase in specific heat is likely caused by the dissociation of the dolomite in the carbonate concrete and is beneficial in preventing spalling of the concrete (14).

The specific heat of plain HSC and steel fibre-reinforced HSC is shown in

Fig. 2b as a function of temperature. Both concrete types are of carbonate aggregate concrete. The test data are plotted up to 700°C. "Problems were encoWltered in measuring heat capacity with the DT A apparatus above 700°C.

The presence of steel fibres generally increases the specific heat of the fibre-reinforce.d concrete throughout the range considered. This can be attributed to the fact that the presence of steel fibres in HSC controls cracking and the progression of cracks at lower temperatures. This in turn translates into high heat capacity. However, the influence of the steel on the specific heat of the concrete is very small in the temperature range examined.

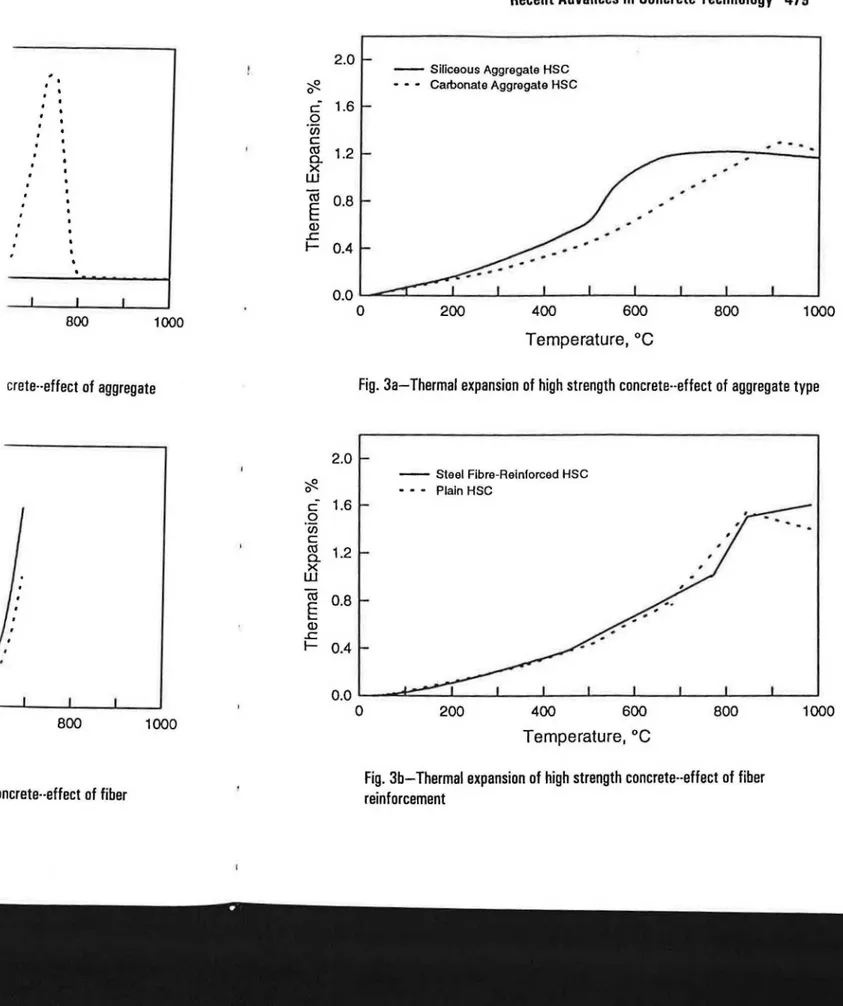

Thermal Expansion -- In Fig. 3, the variation of thermal expansion with concrete temperature for siliceous and carbonate aggregate HSC is compared. The type of aggregate has a significant influence on the thermal expansion. For

mal conductivity of HSC

reinforced HSC is shown >nductivity of steel fibre-bove 1 00°C. This can be

concrete which helps in xreases the rate of heat

two types of aggregate is th types of concrete, the ' and 425°C. The first セ@ second by removal of

erature regions, most of

• f water and only a small

セイゥ。ャN@ As a consequence, re regions. The increase tt about 500°C, can be tis temperature region.

is also affected by other e and the aggregates at nate aggregate concrete of siliceous aggregate is needed to raise the

セ。エ@ is approximately ten ;e in siliceous aggregate

,1 the dissociation of the

eventing spalling of the

torced HSC is shown in types are of carbonate 00°C. Problems were tratus above 700°C.

he specific heat of the This can be attributed 1trols cracking and the translates into high heat ific heat of the concrete

.hermal expansion with ate HSC is compared. hermal expansion. For

Recent Advances in Concrete Technology 473

the siliceous aggregate HSC, the thermal expansion increases with temperature up to about 700°C and then remains constant. The increase in thermal expansion near 550°C can be attributed to the transformation of quartz in the siliceous aggregate. This could contribute to spalling (14). For the carbonate aggregate HSC, the thermal expansion increases steeply with temperature above 500°C. This can be partly attributed to the disassociation of dolomite which is present in the carbonate aggregate.

The effect of steel fibre-reinforcement on thermal expansion of HSC is shown in Fig. 3b for carbonate aggregate HSC. Fibre-reinforced concrete has similar thermal expansion as that of plain concrete up to a temperature of about 800°C. Above 800°C, the thermal expansion of the plain HSC declines somewhat, due to further dehydration and shrinkage of the concrete (15), whereas the expansion of fibre-reinforced concrete increases steeply with temperature. This steep increase with temperature can be attributed to the presence of the steel fibres, which continue to expand at elevated temperatures. The yielding temperature for steel fibres is higher than for ordinary reinforcement.

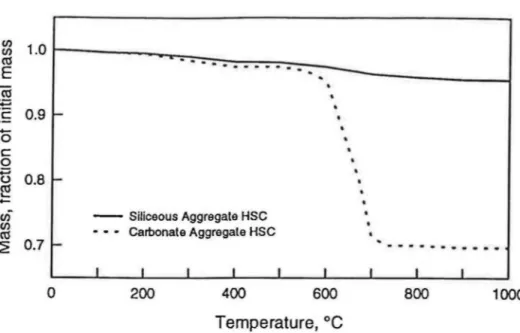

Mass Loss -- The test data from the TGA are presented in Fig. 4a in the form of thermogravimetric curves for the siliceous and carbonate aggregate HSC examined in this study. Previous studies (5, 14) have indicated that the type of aggregate has a strong influence on the mass loss and, therefore, on the density of the concrete at elevated temperatures. The mass loss for both concrete types is very small until about 600°C, where it is about 3% of the original mass. Between 600°C and 700°C, the mass of carbonate aggregate concrete drops considerably with the temperature. Above 750°C, the mass loss again decreases slowly with temperature. The substantial mass loss and decrease in density for carbonate aggregate concrete is caused by the dissociation of the dolomite in the concrete. This chemical reaction is expected to be beneficial in preventing spalling of concrete. In the case of siliceous aggregate concrete, the mass loss remains insignificant even above 600°C.

In Fig. 4b, the mass loss for the steel fibre-reinforced concrete is compared with that of plain HSC. The mass loss for both types of concrete is similar until about 800°C. Above 800°C, the mass loss in fibre-reinforced HSC is slightly higher than that of plain HSC. This can be attributed to the higher density of steel fibres. Overall, the mass loss of the concrete is not significantly affected by the presence of steel fibre-reinforcement in the temperature range of

ooc

to 1 000°C. SummaryBased on the above experimental data, the following points can be summarised:

474 Kodur and Sultan

• The thermal conductivity of siliceous aggregate HSC is generally higher than that of carbonate aggregate HSC. The effect of steel fibre-reinforcement on the thermal conductivity of HSC is very small.

• The type of aggregate has significant influence on the specific heat of HSC at elevated temperatures. Generally, the carbonate aggregate concrete has higher specific heat in the 600°C to 850°C range. The influence of steel-fibre reinforcement on the specific heat of the concrete is very small in the temperature range investigated.

• The thennal expansion of siliceous aggregate HSC is higher than that of carbonate aggregate concrete in the 20°C to 800°C temperature range. The thermal expansion of HSC is not significantly affected by the presence of steel-fibre reinforcement at temperatures up to approximately 800°C.

• The type of aggregate has significant influence on the mass loss of HSC, with carbonate aggregate having much higher mass loss, up to 30%, at temperatures of above 600°C. The mass loss of HSC is not significantly affected by the presence of steel-fibre reinforcement.

CURRENT RESEARCH

In the past, the fire resistance of structural members could be determined only by testing. In recent years, however, the use of numerical methods for the calculation of the fire resistance of various structural members is gaining acceptance (6, 7). These calculation methods are far less costly and time consuming. However, for the use of these calculation methods, the material properties at elevated temperatures are required.

At present, studies are in progress at NRC to develop mechanical properties of HSC at elevated temperatures. The data on thermal and mechanical properties are being used to develop thermal and mechanical relationships, as a function of temperature, for HSC. These relationships can be used as input to numerical models which can be used to detennine the behaviour ofHSC structural members at high temperatures (6). The development of computer programs for the calculation of the fire resistance of HSC columns is in progress at NRC. Simultaneously, fire tests are being conducted on full size HSC columns. These tests are to verify the models.

The computer programs will be used to carry out detailed parametric studies to investigate the influence of the various parameters, such as concrete strength and load intensity on the fire resistance of HSC columns. Data from the parametric studies will be used to develop design guidelines for predicting the fire resistance of HSC columns and to overcome the problem of spalling in HSC columns.

)C is generally higher than .eel fibre-reinforcement on

he specific heat of HSC at セイ・ァ。エ・@ concrete has higher 1e influence of steel-fibre ·ete is very small in the

;c

is higher than that of : temperature range. The fected by the presence of 'ximately 800°C.1e mass loss of HSC, with 1p to 30%, at temperatures ;nificantly affected by the

1bers could be determined ,umerical methods for the 1ral members is gaining t'ar less costly and time m methods, the material

to develop mechanical n thermal and mechanical 1anical relationships, as a . can be used as input to l1aviour ofHSC structural ,f computer programs for ; is in progress at NRC. ize HSC columns. These

out detailed parametric 1meters, such as concrete ' columns. Data from the ines for predicting the fire )lem of spalling in HSC

Recent Advances in Concrete Technology 475

CONCLUDING REMARKS

Based on the studies completed so far, it was found that:

l. The behaviour of HSC columns at high temperatures is significantly different from that ofNSC columns. The fire resistance of HSC columns is lower than that ofNSC columns.

2. The type of aggregate has significant influence on the thermal properties of !fSC at elevated. temperatures. The presence of carbonate aggregate in HSC mcreases fire reststance.

3. tセ・@ thermal properties, at elevated temperatures, exhibited by steel fibre-remforced HSC, are similar to those of plain HSC.

4. The studies, currently in progress at NRC, will generate data on the fire resistance of HSC columns and will identifY the conditions under which these columns can be safely used.

ACKNOWLEDGEMENT

The research presented in this paper is the result of partnerships between the National Research Council of Canada and the Portland Cement Association Canadian Portland Cement Association, Concrete Canada and the National

cィゥ。セ@

Tung University, Taiwan.REFERENCES

l. Diederichs, U., Jumppanen, U.M. and Schneider, U. "High Temperature Properties and Spalling Behaviour of High Strength Concrete"; Proceedings of Fourth Weimar Workshop on High Performance Concrete, HAB Weimar, Germany, 1995, pp. 219-235.

2. Kodur, V.K.R. "Behaviour of High Performance Concrete-Filled Steel Columns Exposed to Fire"; 25th CSCE Annual Conference Sherbrooke,

QC, 1997. '

3. Phan, L.T. "Fire Performance of High-Strength Concrete: A Report of the State-of-the-Art"; National Institute of Standards and Technology

Gaithersburg, MD, 1996. '

4. Lie, T.T., Editor. "Structural Fire Protection: Manual of Practice"; ASCE Manual and Reports on Engineering Practice, No. 78, American Society of Civil Engineers, New York, NY, 1993.

476 Kodur and Sultan

5. Lie, T.T. and Kodur, V.K.R. "Thermal and Mechanical Properties of Steel Fibre-Reinforced Concrete at Elevated Temperatures"; Canadian Journal of Civil Engineering, Vol. 23, No.4, 1996.

6. Kodur, V.K.R . and Lie, T.T. "A Computer Program to Calculate the Fire Resistance of Rectangular Reinforced Concrete Columns"; Third Canadian Conference on Computing in Civil and Building Engineering, Ottawa, Canada, 1996, pp. 11-20.

7. Sullivan, P.J.E., Terro, M.J. and Morris, W.A. "Critical Review of Fire-Dedicated Thermal and Structural Computer Programs"; Journal of Applied Fire Science, Vol. 3, No.2, 1993, pp. 113-135.

8. American Society for Testing and Materials. "Standard Methods of Fire Endurance Tests of Building Construction and Materials"; ASTM E119-88, Philadelphia, PA, U.S.A., 1990.

9. Kodur, V.K.R., "Studies on the Fire Resistance of HPC at the National Research Council of Canada; Proceedings, NIST Workshop on Fire Performance of High Strength concrete, Gaithersburg, MD, U.S.A., 1997.

10. Kodur, V.K.R. "Fibre-Reinforced Concrete for Enhancing the Structural Fire Resistance of Columns"; Proceedings, ACI Spring Convention, Seattle, WA, U.S.A, 1997 (in press).

11. Matsumoto, Y., et al. "A Study on Spalling Resistance of LMF Fibre-Reinforced High Strength Concrete"; Institute of Technology, Tokyo, Japan, 1994.

12. Kodur, V.K.R. and Lie, T.T. "Fire Resistance of Fibre-Reinforced Concrete"; Fibre Reinforced Concrete: Present and the Future, Canadian Society of Civil Engineers, 1997 (in press), pp. 1-46.

13. Lie, T.T. and Kodur, V.K.R. "Thermal Properties of Fibre-Reinforced Concrete at Elevated Temperatures"; Internal Report No. 683, Institute for Research in Construction, National Research Council of Canada, Ottawa, Canada, 1995.

14. Harmathy, T.Z. "Thermal Properties of Concrete at Elevated Temperatures"; ASTM Journal ofMaterials, Vol. 5, No. I, 1970, pp. 47-74.

15. Lie, T.T. "Fire and Buildings"; Applied Science Publishers Ltd., London, 1972.

16. Purkiss, J.A. "Steel Fibre-Reinforced Concrete at Elevated Temperatures"; International Journal of Cement Composites and Light Weight Concrete, Vol. 6, No. 3, 1984, pp. 179-184.

anical Properties of Steel res"; Canadian Journal of

am to Calculate the Fire olumns"; Third Canadian 1g Engineering, Ottawa,

Critical Review of Fire-ams"; Journal of Applied

andard Methods of Fire erials"; ASTM Ell9-88,

Jf HPC at the National -lT Workshop on Fire ·g, MD, U.S.A., 1997. nhancing the Structural ing Convention, Seattle,

;istance of LMF Fibre-セィョッャッァケL@ Tokyo, Japan,

セ@ of Fibre-Reinforced d the Future, Canadian

セウ@ of Fibre-Reinforced rt No. 683, Institute for 1cil of Canada, Ottawa,

:Jevated Temperatures"; 47-74. ublishers Ltd., London, levated Temperatures"; jght Weight Concrete, 0 0

E

セ@

;?;-セ@

() ::J -oc

0 0 (ijE

..._ Q) ..c I-0 0E

セ@

;?;-·:;;:

·.;::::; () ::J -o c 0 0 (ljE

._ Q) ..cI-2.5

2.0

1.5

1.0

0.5

0.0

2.5

2.0

1.5

1.0

0.5

0.0

Recent Advances in Concrete Technology 477

0

- - Siliceous Aggregate HSC • • • Carbonate Aggregate HSC200

400

Temperature, oc

600

800

Fig. 1 a-Thermal conductivity of high strength concrete .. effect of aggregate type

.

-

-

-

-

-

-

- -

-

--

.

- - - - -

.

-

-

-0

- - Steel Fibre-Reinforced HSC • • • Plain HSC200

400

Temperature, oc

600

Fig. 1 b-Thermal conductivity of high strength concrete .. effect of fiber

reinforcement

() 0 セ@

-

:;z

... セ@ro

Q) I478 Kodur and Sultan

QPセMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMセ@ - - Siliceous Aggregate HSC 8t- • • • Carbonate Aggregate HSC 6t-(.) 4t-:o::

·o

Q)a.

(/)2

0r-

•

I•

,-

-

..

.

...

_----."' セi@ I I I.

• • ·I" , I I I I0

200

400

600

800

1000

Temperature, oc

Fig. 2a-Specific heat capacity of high strength concrete··effect of aggregate

type

QPセMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMセ@ () 0 セ@-

セ@...

ro

Q) I 8 6(.)

4

:0::::·o

Q)a.

(/)

2

- - Steel Fibre -Reinforced HSC • • • Plain HSC

-

.

-

.

-

. .

-

-

. .

-

-

.

, olMMMセMMセMMMlMMMjMMセセ MMlMMMセMMMlMMセMMセ@ 0200

400

600

800

Temperature, oc

Fig. 2b-Specific heat capacity of high strangth concrete--effect of fiber

reinforcement

2.0 セ@ 0 c 1.6 0

·u;

cro

1.2a.

Xw

"@ 0.8E

<1> ..c 1- 0.4 0.0BOO

1000crete .. effect of aggregate

2.0 セ@ 0 c 1.6 .Q en c

ro

1.2a.

Xw

(ij 0.8E

<1> ..c 1- 0.4 0.0 800 1000oncrete .. effect of fiber

Recent Advances in Concrete Technology 479

- - Siliceous Aggregate HSC • • • Carbonate Aggregate HSC

--

.

0 200 400 600 800 1000

Temperature, oc

Fig. 3a-Thermal expansion of high strength concrete--effect of aggregate type

0 - - Steel Fibre-Reinforced HSC • • • Plain HSC 200 400 600

Temperature, oc

800Fig. 3b-Thermal expansion of high strength concrete--effect of fiber

reinforcement

480 Kodur and Sultan