Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Housing Note (National Research Council of Canada. Division of Building

Research); Volume 7

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=f66591dd-df03-4d99-9514-706a763a7c42

https://publications-cnrc.canada.ca/fra/voir/objet/?id=f66591dd-df03-4d99-9514-706a763a7c42

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Nail Popping: Moisture is the Trouble-Maker

Platts, R. E.

Se

r

~ ~ 7 1 1 0

~ 2 1 h 8

no.

7

c. 2BLDG

National Research Council

Canada

Division of Building Research

H O U S I N G N O T E N O . 7

NAIL POPPING:

MOISTURE IS THE TROUBLE-MAKER

Reprinted from Canadian Builder,

Vol.

XII,

No.

9,

September

1962,

p.

67-68

WET

DRY

FIGURE 1

-Wood

shrinkage nail popping (exaggerated)

Mail popping: Moisture

is the trouble-maker

By R. E. Platis'

Research Officer, Housing Section, Di- vision of Building Research, N.R.C.,

Ottawa.

House builders and buyers in Canada are faced with few problems more per- sistent and bothersome than nail popping. Protruding nail heads are behind the "pops" that mar the smooth finishes of drywall, the "buttons" in floor tile, and the looseness that allows much floor squeaking.

The usual cause is that wood shrinks and nails do not. If it remains imprac- tical for mass building operations to use fully seasoned lumber, then nails if used will pop, but the use of proper types and mcthods of nailing can reduce the prob- lem.

Adhesives now seem to be a promising way of eliminating these troubles in ap- plying finish materials, providing the wood is at least within the 19% moisture content limit set by Canadian Housing Standards.

Figure 1 shows in exaggerated detail how wood shrinkage causes nails to pop. The pop does not quite equal the shrink- age because the nail point pushes slightly further into the wood, but it is propor- tional to the shrinkage and to the length of nail in the wood. The drier the wood the smaller the pop, and the shorter the fastener the smaller the pop.

Wood may go into many houses at a moisture content of 25% or more, and in the winter may be dried to 6% to 9% moisture content in or near the heated interior. Under these conditions Eastern Spruce or Douglas Fir will shrink from

0.02 to 0.05 inch (1/32 to 1/16 inch) for every inch of depth.

(Most construction softwoods are little better. Even the Red Cedars or Eastern White Pines give only approximately 30% less shrinkage-an expensive partial so- lution.)

The initial pop under these conditions may be 0.02 to 0.04 inch for nails with

1 inch penetration, as with common dry- wall nails. This is enough to deface the drywall surface.

The Canadian Housing Standards re- quire that the wood be seasoned to 19% moisture content or less, which should reduce the nail pop somewhat, but can- not eliminate the difficulty. If, however, the wood can be seasoned before dry- walling to about 14% moisture content then the first winter's drying may shrink it only 0.01 inch or so in one inch, and the resulting nail pop, if any, should not be visible.

It is doubtful however if mass build- ing operations can afford pre-seasoned lumber, or the time to season it in place, since even one full winter of un- heated seasoning may only bring the wood to about 18% moisture content. Scheduling the operation to allow the closed-in house to be heated at least one week before drywall or finish flooring 1s applied can help dry the wood and re- duce nail popping considerably. This of course is easier said than done.

Shorter nails show proportionately less nail pop and should be used for all finishing where allowed. Holding power as well as pop must be considered. Com- mon nails lose much of their holding power as the wood first dries or cycles in moisture content from summer to

winter, and so shorter than normal com- mon nails should not be used.

Properly deformed nails with sharp annular rings have much higher sus- tained holding power and thus shorter nails can be used and nail pop will be reduced. Considerable testing also shows that proper annular rings reduce initial nail pop even more than the shortened nail length would suggest.

Further, common nails and particu- larly coated nails can show increasing, cumulative pop as the wood cycles in moisture content from winter to summer (drywall pop often shows up during the second or third winter rather than in the first), but annular ring nails can better resist this cycling movement.

Walls

Good drywall practice involves drying the framing as much as is possible, using the shorter (1%-inch) annular ring nails, and assuring that the board is held firmly against the studs while nailing. The well known "double nailing" sys- tem and other techniques of application are effective in pulling the board into place, and these should be well studied by all applicators. (Manufacturers, dry- wall applicators and trade schools offer information on these techniques.)

Better practice, very likely, is to use the automatic-set power screw applica- tions, as some large drywall concerns now plan to do.

Best practice might be to use ad- hesives. Since these are non-structural applications, the use of some adhesives on site should be possible if the wood is at least dried t o 19% moisture content as required by the Housing Standards. High-tack adhesives, such as rubber as- phalts, may now allow drywalling to the studs of interior walls without nails (although nails into the top and bottom plate are advisable, and readily hidden). On exterior walls and some ceilings, the vapour barrier prevents direct glu- ing, but the laminated approach may be used: %-inch board is nailed to the studs, and %-inch board is glued to it, usually using some nailing which is later driven through or pulled out (double-headed nails) when the adhesive has set.

This approach is common but some- what wasteful; thus some drywallers use only 2-inch strips of gypsum board nailed along the framing over the vapour barrier, and glue the final drywall to these strips.

Mounting drywall with screws to steel clips screwed to the studs is sometimes done for extra sound resistance, and will of course eliminate popping. Floors

In floors (subfloor, underlay and hard- wood flooring) most of the above holds true but mechanical working can per-

haps be as important as wood shrinkage.

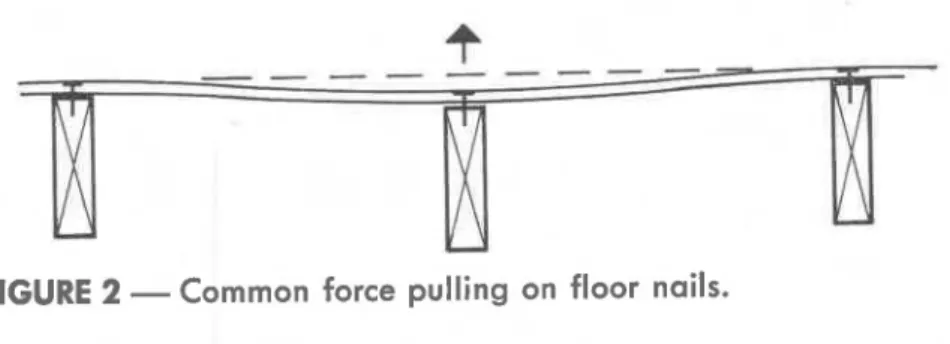

Figure 2 shows a common type of work-

?

PC------

-ing force with uneven joists that can back out nails, especially while cycling moisture content causes the wood to shrink back and forth along the nail shank. "Cupping" of board subfloors can similarly pull the nails. Footsteps then push the subfloor back, causing squeak-

ing o r "tramping," and the projecting

FIGURE 2

-

Common force pulling on floor nails.

nail can then damage tile if n o separatkunderlay is used.

Annular ring nails should always be used under resilient tile, and annular ring or at least spiral groove nails should be used in subfloor work for sustained holding power.

Coated nails should not be used as they appear to pop more and they can lose much of their holding power in softwoods. Squared, slightly barbed, or parallel grooved "special" nails are usu- ally little or no better than common

nails. Tapered nails which are sometimes used can be much poorer than common nails in holding power.

In summary, good practice for floors involves:

-selecting the joists so that similar crowns will be placed side by side;

--drying the lumber as much as is possible;

-using annular ring or at least spiral

groove nails;

-resetting all nails the last thing be- fore finishing.

The best practice, and perhaps the only way to eliminate completely squeaky floors, "buttoning" and similar faults may be to use adhesives. Beads of casein o r perhaps high-tack adhesives will prob- ably work very well (with few nails to hold until set), at reasonable cost and time.