Determination

of

the Proper Operating Range for the

CAFCA

ilB

Fuel

Cycle

Model

by

Jamie Warburton Submitted to the

Department of Nuclear Science and Engineering in Partial Fulfillment of the Requirements for the

Degree of

Bachelor of Science in Nuclear Science and Engineering at the

Massachusetts Institute of Technology June 2007

@ 2007 Jamie L. Warburton All rights reserved

The author hereby grants to MIT permission to reproduce and to

distribute publicly paper and electronic copies of this thesis document in whole or in part in any medium now knlown or hereafter created.

19 _

Signature of Author:

ep

nt of Nuclear Science and Engineering

May 17, 2007 .--1-. Certified by: Accepted by: MASSACHUSE&. " f fl j1 i OF TEicNo.OG Y

OCT

1 2 2007

LIBRARIES

Mujid Kazimi essof Nuclear Engineering Thesis Supervisor1

,. ...---

_-o ID uavi d G. ory

Professor of M ear Science and Engineering Chairman, NSE Committee for Undergraduate Students

ARGHIVWES

-1.----, _ __L__.lr.

Determination of the Proper Operating Range for the

CAFCA IIB Fuel Cycle Model

by

Jamie Warburton

Submitted to the Department of Nuclear Science and Engineering on May 18, 2007 In Partial Fulfillment of the Requirements for the Degree of

Bachelor of Science in Nuclear Science and Engineering

Abstract

The fuel cycle simulation tool, CAFCA II was previously modified to produce the most recent version, CAFCA IIB. The code tracks the mass distribution of transuranics in the fuel cycle in one model and also projects costs for various fuel cycle schemes. The mass distribution model also shows the schedule for deployment of recycling plants. All of these models are dependent on user inputs, some of which specify advanced technology type and capacity, plant lifetime and recycling facility capacity.

The behavior of CAFCA IIB resulting from the most recent modifications are investigated through extensive modeling of various nuclear fuel cycles. By re-modeling nuclear fuel cycle schemes in CAFCA IIB that were modeled in CAFCA II, the two results can be compared and conclusions can be drawn as to an discrepancies between the two. Specifically, the results representing TRU mass balance accumulation in the system, spent fuel separation plant construction and fertile free fuel spent fuel reprocessing plant construction are compared. Thus, these new runs will substantiate the accuracy of past work and expand the number of reactor options that have been evaluated by CAFCA IIB. Additionally, the new data help pinpoint the operating range for CAFCA IIB in which the code is accurate.

Overall, none of the results from the same conditions in CAFCA II and CAFCA IIB matched up perfectly. Therefore, in an effort to further evaluate the effectiveness of CAFCA IIB, the plant

lifetime input is tested in order to determine system sensitivities to that factor. This is done by modeling of nuclear fuel cycles while varying that single input, and comparing the results to the base or control case. Results suggest that different combinations of the various parameters are

ideal for each different strategy of reactor type.

Thesis Supervisor: Mujid Kazimi Title: Professor of Nuclear Engineering

Acknowledgements

The author is grateful for comments received during this work from Pavel Hejzlar and Dr. Ed Pilat of MIT.

Table of Contents

A bstract ... 2

A cknow ledgem ents...3

L ist of Figures... ... 5

L ist of T ables ... ... 7

N om enclature ... ... 8

Chapter I. Introduction... ... 9

I.A. The Nuclear Fuel Cycle... ... 9

I.B. The CAFCA Nuclear Fuel Cycle Model ... 10

I.C . M ethods ... ... 12

Chapter II. CAFCA II Results and Conclusions ... ... ... 15

Chapter III. Overview of Modification from CAFCA II to IIB ... 16

Chapter IV. Comparison of CAFCA II and CAFCA IIB Results ... 18

Chapter V. Determination of Sensible Operating Range...20

V.A. Summary from Comparison of CAFCA II and CAFCA IIB Results...20

V.B. Inspection of CAFCA IIB Results with Recycling PL of 30 Years ... 20

V.C. Inspection of CAFCA IIB Results with Recycling PL of 50 Years ... 22

Chapter V I. Conclusion... ... 24

R eferences ... 26

Appendix A: TRU mass balance - Low case with 40 yr. PL (II & IIB) ... 28

Appendix B: Spent fuel recycling plants - Low case with 40 yr. PL (II & IIB)... 34

Appendix C: TRU mass balance - High case with 40 year PL (II & IIB)...40

Appendix D: Spent fuel recycling plants - High case with 40 yr. PL (II & IIB)...46

Appendix E: TRU Mass Balance - Low case in CAFCA IIB with 30 year Plant Lifetime...52

Appendix F: SF Recycling Plants - Low case in CAFCA IIB with 30 year Plant Lifetime... 55

Appendix G: TRU Mass Balance - High case in CAFCA IIB with 30 year Plant Lifetime... 58

Appendix H: SF Recycling Plants - High case in CAFCA IIB with 30 year Plant Lifetime...61

Appendix I: TRU Mass Balance - Low case in CAFCA IIB with 50 year Plant Lifetime ... 64

Appendix J: SF Recycling Plants -Low case in CAFCA IIB with 50 year Plant Lifetime ... 67

Appendix K: TRU Mass Balance - High case in CAFCA IIB with 50 year Plant Lifetime... 70

List of Figures

Figure 1: TRU for LWR/CONFU strategy in CAFCA II - Low case, 40 yr. PL ... 28

Figure 2: TRU for LWR/CONFU strategy in CAFCA IIB - Low case, 40 yr. PL... 29

Figure 3: TRU for LWR/ABR strategy in CAFCA II - Low case, 40 yr. PL ... 30

Figure 4: TRU for LWR/ABR strategy in CAFCA IIB - Low case, 40 yr. PL... 31

Figure 5: TRU for LWR/GFR strategy in CAFCA II - Low case, 40 yr. PL... 32

Figure 6: TRU for LWR/GFR strategy in CAFCA IIB - Low case, 40 yr. PL ... 33

Figure 7: SFRP for LWR/CONFU strategy in CAFCA II - Low case, 40 yr. PL... 34

Figure 8: SFRP for LWR/CONFU strategy in CAFCA IIB - Low case, 40 yr. PL ... 35

Figure 9: SFRP for LWR/ABR strategy in CAFCA II - Low case, 40 yr. PL ... 36

Figure 10: SFRP for LWR/ABR Strategy in CAFCA IIB - Low case, 40 yr. PL ... 37

Figure 11: SFRP for LWR/GFR strategy in CAFCA II - Low case, 40 yr. PL... 38

Figure 12: SFRP for LWR/GFR Strategy in CAFCA IIB - Low case, 40 yr. PL ... 39

Figure 13: TRU for LWR/CONFU strategy in CAFCA II - High case, 40 yr. PL... 40

Figure 14: TRU for LWR/CONFU strategy in CAFCA IIB - High case, 40 yr. PL ... 41

Figure 15: TRU for LWRIABR strategy in CAFCA II - High case, 40 yr. PL... 42

Figure 16: TRU for LWR/ABR strategy in CAFCA IIB - High case, 40 yr. PL ... 43

Figure 17: TRU for LWR/GFR strategy in CAFCA II - High case, 40 yr. PL ... 44

Figure 18: TRU for LWR/GFR strategy in CAFCA IIB - High case, 40 yr. PL... 45

Figure 19: SFRP for LWR/CONFU strategy in CAFCA II - High case, 40 yr. PL ... 46

Figure 20: SFRP for LWR/CONFU strategy in CAFCA IIB - High case, 40 yr. PL... 47

Figure 21: SFRP for LWR/ABR strategy in CAFCA II - High case, 40 yr. PL...48

Figure 22: SFRP for LWR/ABR Strategy in CAFCA IIB - High case, 40 yr. PL ... 49

Figure 23: SFRP for LWR/GFR strategy in CAFCA II - High case, 40 yr. PL... 50

Figure 24: SFRP for LWR/GFR Strategy in CAFCA IIB - High case, 40 yr. PL... 51

Figure 25: TRU for LWR/CONFU strategy in CAFCA IIB - Low case, 30 yr. PL... 52

Figure 26: TRU for LWR/ABR strategy in CAFCA IIB - Low case, 30 yr. PL...53

Figure 27: TRU for LWR/GFR strategy in CAFCA IIB - Low case, 30 yr. PL ... 54

Figure 28: SFRP for LWR/CONFU strategy - Low case, 30 yr. PL ... 55

Figure 29: SFRP for LWR/ABR strategy in CAFCA IIB -Low case, 30 yr. PL ... 56

Figure 30: SFRP for LWR/GFR strategy in CAFCA IIB -Low case, 30 yr. PL... 57

Figure 31: TRU for LWR/CONFU strategy in CAFCA IIB - High case, 30 yr. PL ... 58

Figure 32: TRU for LWR/ABR strategy - High case, 30 yr. PL ... 59

Figure 33: TRU for LWR/GFR strategy in CAFCA IIB - High case, 30 yr. PL... 60

Figure 34: SFRP for LWR/CONFU strategy in CAFCA IIB - High case, 30 yr. PL... 61

Figure 35: SFRP for LWR/ABR strategy in CAFCA IIB - High case, 30 yr. PL ... 62

Figure 36: SFRP for LWR/GFR strategy in CAFCA IIB - High case, 30 yr. PL ... 63

Figure 38: TRU for LWR/ABR strategy in CAFCA IIB - Low case, 50 yr. PL... 65

Figure 39: TRU for LWR/GFR strategy in CAFCA IIB - Low case, 50 yr. PL ... 66

Figure 40: SFRP for LWR/CONFU strategy in CAFCA IIB - Low case, 50 yr. PL... 67

Figure 41: SFRP for LWR/ABR strategy in CAFCA IIB - Low case, 50 yr. PL... 68

Figure 42: SFRP for LWR/GFR strategy in CAFCA IIB - Low case, 50 yr. PL ... 69

Figure 43: TRU for LWR/CONFU strategy in CAFCA IIB - High case, 50 yr. PL ... 70

Figure 44: TRU for LWR/ABR strategy in CAFCA IIB - High case, 50 yr. PL ... 71

Figure 45: TRU for LWR/GFR strategy in CAFCA IIB - High case, 50 yr. PL... 72

Figure 46: SFRP for LWR/CONFU strategy in CAFCA IIB - High case, 50 yr. PL ... 73

Figure 47: SFRP for LWR/ABR strategy in CAFCA IIB - High case, 50 yr. PL ... 74

List of Tables

Table 1: Recycling plant lifetime variations ... ... 12

Table 2: Recycling facility capacity options ... ... 12

Table 3: Advanced technologies settings of industrial capacities ... 13

Table 4: LWR core specifications ... 13

Table 5: ABR core specifications ... 13

Nomenclature

II & IIB CAFCA II & CAFCA IIB ABR Actinide Burner Reactor

CAFCA Code for Advanced Fuel Cycle Assessment CONFU Combined Non-Fertile and U02

FFF Fertile Free Fuel

GFR Gas-cooled Fast Reactor

GNEP Global Nuclear Energy Partnership HM Heavy Metals (Uranium & Transuranics) LWR Light Water Reactor

PL Plant Lifetime

MA Minor Actinides

MT Metric Ton (1,000 kg) MTHM Metric Ton of Heavy Metal

SF Spent Fuel

SFRP Spent Fuel Recycling Plants TRU Transuranics

Chapter I. Introduction

LA. The Nuclear Fuel Cycle

The current nuclear fuel cycle in the United States is a once-through cycle, meaning that fuel is used once and then sent to be stored without any reprocessing or recycling. The implications of this type of fuel cycle are that it causes the build up of transuranic elements that maintain high radiotoxicity for thousands of years. This accumulation makes it difficult to guarantee that the resulting dose remains below a specified limit for a long period of time. Also, the decay heat associated with the buildup of actinides creates a need for multiple repositories. These conditions generate the motivation to recycle and burn the TRU which helps manage nuclear waste, and also to conserve uranium resources. The current Global Nuclear Energy Partnership aims to recycle fuel while still safeguarding against proliferation, and reduce the world's dependence on fossil fuels by means of increasing nuclear energy generation.

There are many options for nuclear fuel recycling and reprocessing, however the current problem is how to determine which reprocessing option is optimal given the present nuclear fuel cycle, resources and energy demands. One method to determine which approach to recycling is appropriate is by using a fuel cycle simulation program, such as CAFCA IIB, to evaluate the impact of various options and compare the output results [1]. So far, studies have been done for one set of fuel cycle parameters, however variations need to be considered in order to develop a more comprehensive approach. Along with the many input parameters that CAFCA IIB requires, it is also important to be aware of the current and projected world energy needs, the current and projected operating reactors, and the current and projected burnups to be used for nuclear fuel. With all of these issues in mind, the consequences of nuclear fuel technologies can be assessed using the CAFCA IIB code, thus providing useful insight into the impact of various nuclear system choices on the future of nuclear energy.

I.B. The CAFCA Nuclear Fuel Cycle Model

CAFCA IIB is a program that simulates nuclear fuel cycle systems and tracks nuclear fuel in the various components of a fuel cycle. There is an economic element to the program, which estimates the cost of various fuel cycle strategies and technology choices. In response to the increasing global need for nuclear energy, the simulations in CAFCA IIB are engineered to model the deployment of advanced nuclear technologies, namely advanced reactors and reprocessing options.

CAFCA IIB is written in Matlab, and it simulates the fuel cycle by tracking the mass flow of U and TRU, determining the infrastructure requirements for reactors and recycling facilities, and also tracking the cost of those operations. The front-end of the fuel cycle does not put any constraints on the introduction or development of advanced technologies in CAFCA IIB, so there is no model for the front-end fuel plants. Also, masses undergoing the cooling process are blended together depending on the number of years since discharge and the type of fuel. The code tracks the lifetime of reactors, and therefore also incorporates the decommissioning of reactors into the model generated.

CAFCA IIB is a model for the transition from a once-through to an advanced closed nuclear fuel cycle. The program tracks U and TRU and simulates the deployment of advanced

technologies in the context of increasing nuclear energy demand. Advanced technologies include advanced reactors that are capable of burning TRU and recycling plants that are capable of converting SF into fresh fuel. The code provides an output specifying TRU inventory, recycling facility and advanced reactor demand, as well as fuel cycle cost. The outputs in this report have been organized as to present similar cases together other as to facilitate comparison. The power demand model utilized in CAFCA IIB is exponential and assumes an annual growth rate of 2.4%. The first constraint that governs the model is that SF inventory must be reduced as fast as possible, and this factor contributes to the deployment of advanced technologies. Next, advanced technologies must operate at or above a specified minimum capacity factor throughout the lifetime of the technology. So, adding recycling plants is only allowed if those plants can be operated at the minimum capacity for the lifetime of forty years. Advanced reactors can only be built if the model projects that enough fuel will be present for the duration of the sixty-year

The inputs in CAFCA IIB include the simulation start, middle and end year, with the option of changing some parameters at the middle year. Other inputs include power demands for up to three different geographic regions, year of introduction of recycling technologies, and choice of recycling schemes for both the fast and thermal cases. The industrial capacity to build recycling facilities could be changed at the middle point (year). CAFCA IIB can also take into account the status of reactors currently operational, and incorporate their lifetimes into its calculations. The composition of fuel pins per batch is another input section in the code, along with the composition of batches and the reactor parameters such as number of batches in a core, reactor lifetime, power, cycle length and capacity. The recycling parameters considered include capacity for spent fuel separation, lifetime of recycling plant, loss coefficient of plant and recycling facilities for advanced fuel pins. The priority for spent fuel recycling can also be selected, along with enrichment percentages and losses associated with fabrication.

The cost model in CAFCA IIB calculates the average total production cost of electricity as determined by the capital, operation and maintenance and fuel cycle costs. The model assumes the operation and maintenance costs are fixed, while capital costs depend on the construction time, reactor lifetime and overnight cost of construction. The fuel cycle costs are determined by the cost for each step in the fuel cycle and the cost adjustment necessary to account for carrying charges and time elapsed. The model also predicts recycling prices as a function of a plants' nominal capacity, the result reflecting the effects of economies of scale in recycling plant production.

The final parameters that can be modified in CAFCA IIB are those pertaining to the economic outlook of the time period. These variables include tax rate, electricity fees, uranium mining and both public and private debt. One caveat to this system that must be considered when inputting these parameters is that the time step used is 1.5 years, as opposed to a 1-year time step that may be assumed if not explicitly stated.

All of the input parameters described can be used to either use the fuel cycle simulation module or the economic simulation module as relating to the fuel cycle. Essentially, for the fuel cycle simulation, CAFCA IIB allows the user to input parameters in order to achieve output results that are used to assess the impact of the corresponding choices in the overall fuel cycle strategy.

L C. Methods

CAFCA IIB will be used to examine the effect of various future technology choices on the accumulation of actinides in the fuel cycle. Only the fuel cycle model will be used for this analysis, not the cost model. Initially, CAFCA IIB will be used with a new iteration scheme to look at the effect of adding recycling in the fuel cycle on the actinide build up. Then, those results will be compared with the results obtained with the old iteration scheme in CAFCA IIB. Runs in the old iteration scheme in CAFCA II have already been completed by A. Aquien [1]. That report dealt entirely in CAFCA II and never in CAFCA IIB (it had not been created yet). In addition to re-running the same cases that were completed in the old scheme, new cases will be generated based on interesting parameters such as recycling plant lifetime seen in Table 1 below.

Table 1: Recycling plant lifetime variations Recycling Plant Lifetime

30 yr

40 yr

50 yr

The status of reactors currently in operation will not be taken into account in this study, nor will any modifications be made for the composition of fuel pins or composition of batches. The reactor parameters will also be kept constant throughout all runs. The recycling parameters for capacity of spent fuel separation and plant lifetime will be altered to include the variations in Table 1 above and Table 2 below.

Table 2: Recycling facility capacity options Recycling Facility Capacity (MTHM/yr)

Small Separation Capacity 1000

FFF Reprocessing 50

Medium Separation Capacity 2000

FFF Reprocessing 100

Large Separation Capacity 7000

FFF Reprocessing 200

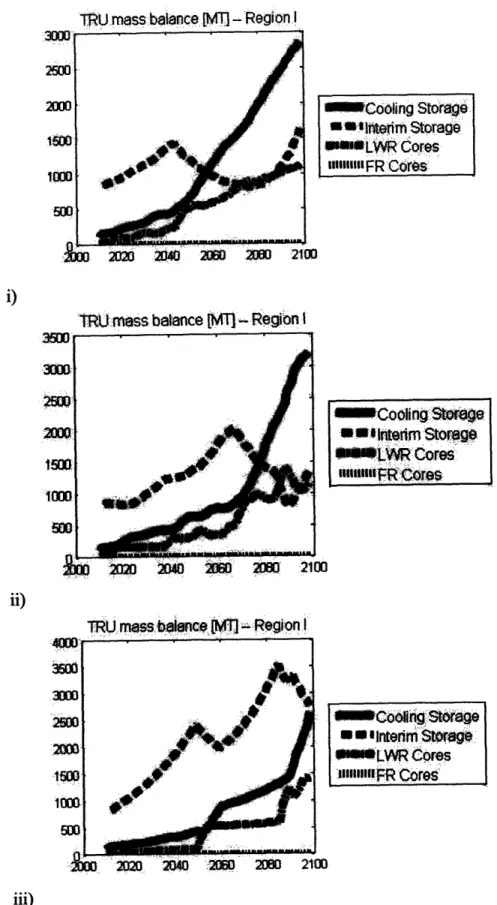

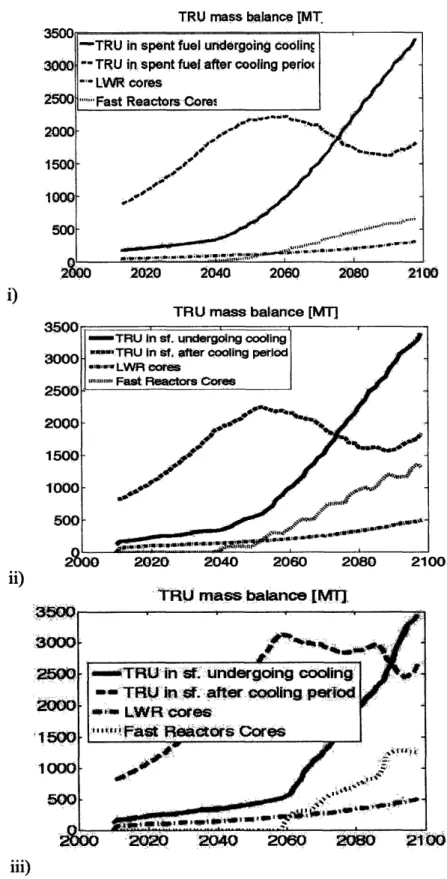

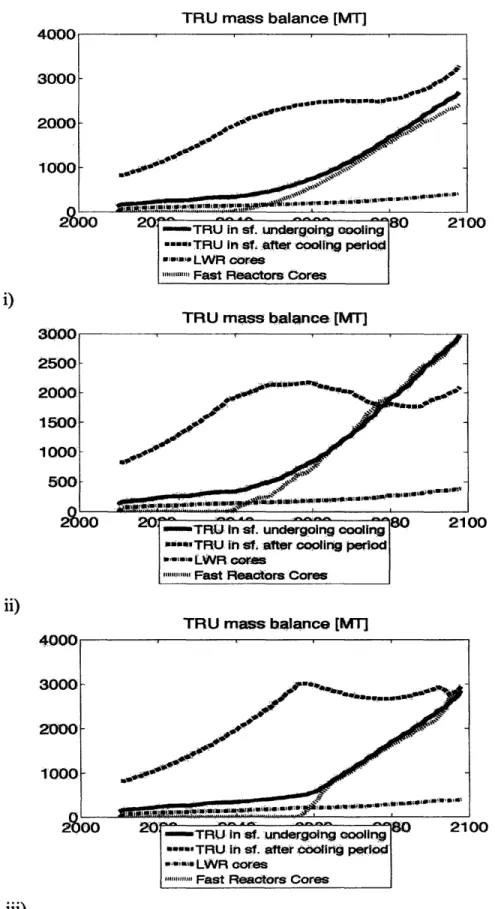

The outputs from the three recycling facility capacity options are presented on the same page in the appendices - the small case is first (labeled i), the medium case is next (labeled ii) and the

large case is last (labeled iii). Additionally, the recycling technologies have the industrial building of separation capacities seen in Table 3 below.

Table 3: Advanced technologies settings of industrial capacities Advanced Technologies (MTHM /yr)

Low Separation Capacity 125

FFF Reprocessing 10

High Separation Capacity 500

FFF Reprocessing 50

The priority for SF recycling, enrichment percentages and losses associated with fabrication will be left at their default values. The three strategies that CAFCA IIB uses, LWR/CONFU, LWR/ABR and LWR/GFR, have the corresponding core specifications seen in Tables 4, 5 and 6 below. The specifications for this section were taken from the Aquien report

[1], however for further reference more detailed CONFU, ABR and GFR resources are provided

in Schwageraus et al. [3], Romano et al. [4] and from the CEA Cadarache et al. [5], respectively.

Table 4: LWR core specifications LWR Core Specifications

Power 3,000 MWth

Power Density 104.5 kWth/I

Net Electric Output 1,000 MWe

Fuel UO2

Enrichment 4.2% U2 35

Burnup 50 MWd/kg

Number of Batches 3

Refueling Interval 1.5 years

Table 5: ABR core specifications ABR Core Specifications

Power 700 MWth

Power Density 76.5 kWth/I

Net Electric Output 315 MWe

Fuel Metallic Zr-TRU

Number of Batches 2

Table 6: GFR core specifications

GFR Core Specifications

Power 2,400 MWth

Power Density 100 kWth/l

Net Electric Output 1,128 MWe

Fuel U-TRU carbide

Number of Batches 3

Refueling Interval 2.5 years

All case studies in this report are based on the one-region setting in CAFCA IIB and do not allow

Chapter II. CAFCA II Results and Conclusions

Appendices A-D include the results for the TRU balance and SF reprocessing schemes produced from CAFCA II. The CAFCA IIB results are juxtaposed next to the corresponding

CAFCA II results for comparison, discussed in Chapter IV. Based on the CAFCA II results it

was determined that the capacity for building recycling facilities is more limiting than that for fast reactors with respect to TRU inventory reduction. Additionally, the reduction of TRU inventory in interim storage by 2100 by ABR and CONFU is comparable when the construction rate of advanced technologies is large enough. Finally, TRU recycling in CONFU/LWRs can avoid more TRUs in the system than either fertile-free ABR or GFR. However, if U resource utilization is a goal along with the TRU waste management, then GFRs with a conversion rate of

Chapter III. Overview of Modification from CAFCA II to IIB

CAFCA II and CAFCA IIB are exactly the same except for the modifications to the user

interface and changes in the feedback loop that makes sure the capacity factor of the recycling facilities is satisfied before building any additional facilities.

The most apparent modifications to CAFCA II are those pertaining to the user interface.

CAFCA IIB has a graphical user interface that is more user-friendly than that of CAFCA II.

Warnings regarding limitations of the model and input constraints were added in order to ensure that the user was aware of the acceptable inputs. In this same vein, the inputs for the model can be seen in CAFCA IIB at any point during code operation by selecting the "see current initial

conditions" option. This allows the user to check current parameters before, during and after the code-running process so no data is misrepresented due to user error. In an effort to increase the ease of usage of the code, CAFCA II was modified so that more than one screen can be open at a time [2]. A significant improvement in the code is that CAFCA IIB allows the user to save input data, load saved files and save simulation results. This is key for the comparison and analysis of large numbers of simulations.

The inputs to CAFCA IIB are grouped into screens by likeness and the output figures are grouped by region, allowing the user to input similar parameters at the same time and view cohesive results together. The user help file has been modified to be more clear, concise and easy to understand.

The default settings for CAFCA IIB are an LWR/ABR scheme with the ABR introduced in 2040, separation plant capacity ofl000 MT/yr, reprocessing plant capacity of 50 MT/yr, and minimum loading factor of 0.60. CAFCA IIB can be used as a stand-alone in the form of

CAFCA.EXE on any Windows computer or other machine that has the same operating system as the machine on which the application was compiled. However, the menu for figures does not work in this setting [2].

While no specifics regarding the changes in the fuel cycle model were given, the iteration loop that predicts whether recycling facilities can be built based on TRU accumulation was changed from CAFCA II to CAFCA IIB. The feedback to satisfy the capacity factor of the recycling facilities was also changed. Based on the results comparing the outputs from the two codes discussed in Chapter IV, modifications to this loop have to be made as the results disagree in several cases. It should be noted that the output figure titles changed from "TRU mass balance [MT]," "Spent fuel separation plants" and "FFFsf reprocessing plants" in CAFCA II to "TRU mass balance [MT] - Region 1," "Recycling plants -UO2sf - Region 1" and "Recycling plants - Adv SF- Region 1," respectively, in CAFCA IIB. Chapter V and VI discuss the various parameters of the disagreeing cases and try to pinpoint the appropriate operating range of the code based on this knowledge.

Chapter IV. Comparison of CAFCA II and CAFCA IIB Results

CAFCA II and CAFCA IIB were used to model cases where the plant was either

LWR/CONFU, LWR/ABR or LWR/GFR. In each of these cases, the recycling facility capacity was set to small, medium or large (specifications in Table 2), and the advanced technology industrial building capacity was chosen to be either low or high (specifications in Table 3). All possible combinations of these variables were chosen as inputs to CAFCA IIB, and finally all of those permutations were computed for recycling plant lifetimes of 30, 40 or 50 years.

TRU mass balance, spent fuel separation plants and FFF SF reprocessing plants are all output for a single run in CAFCA IIB. Appendices A-D show the results from CAFCA II and

CAFCA IIB side-by-side as to evaluate the differences between the two codes when the same

inputs are used. The first detail that must be noted is that there are scaling differences between the plots generated from CAFCA II and CAFCA IIB, so while some plots do not look equal, upon investigation of the axes they might be. Overall, none of the results from CAFCA II and

CAFCA IIB matched up perfectly. For the LWR/CONFU strategy, the high advanced

technology setting was most effective at generating similar results in CAFCA IIB as in CAFCA II. The TRU mass balances are the same and the SFRP plots are almost exactly alike with the exception of the large recycling facility case. The same is true of the LWR/ABR scheme, however the TRU mass balances resulting from this setting do not correspond. In the

LWR/GFR scheme, the low and high advanced technologies options were equally successful at replicating CAFCA II results, with none of the TRU mass balance plots matching up nor the large recycling facility capacity SFRP results.

One effect that was not studied was the extrapolation of model behavior as a function of TRU buildup. If the model dependence on TRU accumulation could be discerned from the plots of the TRU mass balance and recycling plant production, then the model could be more

effectively studied. Thus, with the model dependence on TRU buildup known, the results of

than pure plotted results. If the TRU buildup is different in CAFCA II than it is in CAFCA IIB for the same initial conditions, than clearly the SFRP construction is also going to differ between the two codes. But, if the TRU-plant relationship could be determined and compared for each strategy, perhaps the two codes would not seem to perform so differently. It is this TRU-SFRP construction relationship that is most important, as it will govern whatever initial conditions input into either code.

For the low advanced technologies case in the LWR/CONFU strategy, both CAFCA II and CAFCA IIB responded as expected in terms of building SFRP while TRU is present and accumulating (comparison of Figures 1, 2, 7 & 8). For the low advanced technologies case in the LWR/ABR strategy, the TRU mass balances hardly agree and as a result the SFRP results are very different. However, in CAFCA IIB it appears as though TRU is piling up and no plants are being built to deal with it until very late in the time period (Figures 3, 4, 9 & 10). In the

LWR/GFR strategy, the TRU mass balances between the two codes do not agree, however the SFRP constructions do agree for the small and medium recycling facility capacities.

Additionally, in the large recycling facility capacity case the SFRP plots are very similar, so perhaps some discrepancies could be attributed to changes in scale and axes (Figures 5, 6, 11 & 12).

In the high advanced technologies case in the LWR/CONFU strategy, the TRU mass balances between CAFCA II and CAFCA IIB do not agree, but the SFRP projections do agree for the small and medium recycling facility options (Figures 13, 14, 19 & 20). In the LWR/ABR case, the TRU projections are closer than they were for the LWR/CONFU strategy, however they still don not agree. This result is very interesting because the SFRP figures agree completely in all cases of recycling facility capacities (Figures 15, 16, 21 & 22). For the LWR/GFR strategy, the TRU projections have the same trend, but again do not agree completely. The SFRP figures agree in the small and medium recycling facility capacity models but not in that for the large recycling facility capacity (Figures 17, 18, 23 & 24).

Chapter V. Determination of Sensible Operating Range

for CAFCA IIB

V.A. Summary from Comparison of CAFCA H and CAFCA IHB Results

No results from CAFCA II could be replicated exactly in CAFCA IIB with the same initial settings. The differences between the two outputs are mainly due to code changes specifically on the feedback from checking on the expected capacity factor of the recycling facility and advanced reactor assembly. The high advanced technology option performed the best in the CAFCA II and CAFCA IIB comparison. This suggests that the loop affecting the

generation of spent fuel recycling facilities was changed in the modification of the codes and therefore while TRU accumulation may stay the same, the model behaves differently in response to it.

V.B. Inspection of CAFCA HB Results with Recycling PL of 30 Years

Appendices E-H contain the results from the simulations run in CAFCA IIB with a plant lifetime of 30 years, as opposed to the 40 year lifetime used in Appendices A-D. Interestingly enough, the optimal conditions for the 30 year PL that result in plots similar to those in CAFCA II and CAFCA IIB are the same conditions discussed that resulted in the best plots from CAFCA II and CAFCA IIB. This means that the high advanced technologies setting in the LWR/CONFU and LWR/ABR strategies and the low advanced technologies setting in the LWR/GFR strategy are optimal.

The figures for comparison of the TRU for the low CONFU strategy are figure 25 (30

these TRU plots are in agreement as far as mass balance trends (the overall mass balance should be different since the recycling plant lifetimes are different). The corresponding SRFP figures are figure 28, figure 8 and figure 7. A trend for the medium plant capacity seems to be present in each of these figures, however the other SRFP figures do not agree in trend or in value.

The figures for comparison of the TRU for the low ABR strategy are figure 26 (30 year, CAFCA IIB), figure 4 (40 year, CAFCA IIB) and figure 3 (40 year, CAFCA II). The trends present in figure 26 agree with those in figure 4 for all plant capacities, however neither agrees with figure 3. The corresponding SFRP figures are figure 29, figure 10 and figure 9. The trends in figure 10 agree with those in figure 29, however neither agrees with those in figure 9.

The figures for comparison of the TRU for the low GFR strategy are figure 27 (30 year, CAFCA IIB), figure 6 (40 year, CAFCA IIB) and figure 5 (40 year, CAFCA II). None of the trends present in any of these figures agree with each other. The corresponding SFRP figures are figure 30, figure 12 and figure 11. All of the trends in these figures agree with each other.

The figures for comparison of the TRU for the high CONFU strategy are figure 31 (30 year, CAFCA IIB), figure 14 (40 year, CAFCA IIB) and figure 13 (40 year, CAFCA II). The trends present in figure 13 agree with those in figure 14 and those in figure 31. The

corresponding SRFP figures are figure 34, figure 20 and figure 19. The trends present in figure 19 agree with those present in figure 34 except for those in the small capacity case and the trends in figure 19 agree with those in figure 20 except for in the large capacity case.

The figures for comparison of the TRU for the high ABR strategy are figure 32 (30 year, CAFCA IIB), figure 16 (40 year, CAFCA IIB) and figure 15 (40 year, CAFCA II). The trends present in figure 32 agree with those in figure 15, and seem to agree with but are shifted in figure

15. The corresponding SFRP figures are figure 35, figure 22 and figure 21. All of the trends present in these figures agree with each other.

The figures for comparison of the TRU for the high GFR strategy are figure 33 (30 year, CAFCA IIB), figure 18 (40 year, CAFCA IIB) and figure 17 (40 year, CAFCA II). The trends

for all of these figures agree, however in the small capacity case the maximum TRU mass balance is extremely different in figure 33 than it is for the other two figures. The corresponding

SFRP figures are figure 36, figure 24 and figure 23. All of the trends in these figures agree except for those in the large capacity case which do not correspond in any of the plots.

V. C Inspection of CAFCA IIB Results with Recycling PL of 50 Years

Appendices I-L contain the results from the simulation runs in CAFCA IIB with a plant lifetime of 50 years. The optimal conditions for the PL of 40 years are exactly the same as those for the 30 year PL. In these conditions, the TRU and SFRP agree completely with the 30 year PL and almost completely with the 40 year PL. However, even with these conditions, the TRU and SFRP for the LWR/ABR strategy are not accurate. The same is true for the LWR/GFR case where the TRU and SFRP do not correlate to each other well. With this information in mind, the best settings in the 50 year PL case that achieve the most accurate results are in the high

advanced technologies setting in the LWR/CONFU and LWR/ABR strategies and the low advanced technologies setting in the LWR/GFR strategy.

The figures for comparison of the TRU for the low CONFU strategy are figure 37 (50 year, CAFCA IIB), figure 2 (40 year, CAFCA IIB) and figure 1 (40 year, CAFCA II). The trends in figure 37 agree with those in figure 2 except for in the medium capacity case and agree with those in figure 1 except for the large capacity case. The corresponding SRFP figures are

figure 40, figure 8 and figure 7. The trends present in figure 40 agree with those in figure 7 and figure 8 except for in the large capacity case.

The figures for comparison of the TRU for the low ABR strategy are figure 38 (50 year,

CAFCA IIB), figure 4 (40 year, CAFCA IIB) and figure 3 (40 year, CAFCA II). The trends

present in figure 38 do not agree with those in figure 3, but do agree with those in figure 4. The corresponding SFRP figures are figure 41, figure 10 and figure 9. The trends in figure 41 only agree with those in figure 9 in the small capacity case, and agree with those in figure 10 except for in the medium capacity case.

The figures for comparison of the TRU for the low GFR strategy are figure 39 (50 year,

CAFCA IIB), figure 6 (40 year, CAFCA IIB) and figure 5 (40 year, CAFCA II). The trends

present in figure 39 agree with those in figure 5 only in the small capacity case, and agree with the trends in figure 6 in the medium capacity case. Figures 5 and 6 agree in the high capacity case. The corresponding SFRP figures are figure 42, figure 12 and figure 11. The trends present in figure 42 agree with those in figure 11 and figure 12.

The figures for comparison of the TRU for the high CONFU strategy are figure 43 (50 year, CAFCA IIB), figure 14 (40 year, CAFCA IIB) and figure 13 (40 year, CAFCA II). The

trends in figure 43 agree with those in figure 13 and figure 14. The corresponding SRFP figures are figure 46, figure 20 and figure 19. All of the trends present in figure 46 agree with those in figure 19 and figure 20.

The figures for comparison of the TRU for the high ABR strategy are figure 44 (50 year, CAFCA IIB), figure 16 (40 year, CAFCA IIB) and figure 15 (40 year, CAFCA II). None of the trends present in any of these figures agree. The corresponding SFRP figures are figure 47, figure 22 and figure 21. The trends present in figure 47 agree with those in figure 21 and figure 22 except for in the medium capacity case.

The figures for comparison of the TRU for the high GFR strategy are figure 45 (50 year, CAFCA IIB), figure 18 (40 year, CAFCA IIB) and figure 17 (40 year, CAFCA II). The large capacity cases in all of these figures agree in trends, however the other two capacity cases do not. The corresponding SFRP figures are figure 48, figure 24 and figure 23. Figure 48 does not agree with figure 24 or figure 23 in the small capacity case, however it does agree with both in the medium and large capacity cases.

Chapter VI. Conclusion

CAFCA II, a fuel cycle simulation tool, was written in Matlab and has since been

modified to the latest version CAFCA IIB. By tracking the mass distribution of TRU and U in the nuclear fuel cycle, the code projects the building of recycling facilities based on certain constraints that must always be followed. The main parameters for use in this study are

1. Fuel cycle option: CONFU (introduced in 2015), ABR or GFR fast recycling schemes (either introduced in 2040).

2. Recycling facility capacity: small (1,000 MTHM/yr separation plants and 50 MTHM/yr FFF reprocessing plants), medium (2,000 MTHM/yr separation plants

and 100 MTHM/yr FFF reprocessing plants) and large (7,000 MTHM/yr separation plants and 200 MTHM/yr FFF reprocessing plants).

3. Advanced technology building capacity: low case (construction capacity of separation plants is 150 MTHM/yr and construction capacity of FFF reprocessing plants is 15 MTHM/yr, and these numbers double at 2040) and high case

(construction capacity of separation plants is 500 MTHM/yr and construction capacity of FFF reprocessing plants is 50 MTHM/yr, and these numbers double at 2040).

4. Recycling plant lifetime: 30, 40 or 50 years.

By investigating all combinations of all of these parameters, the operating range of CAFCA IIB can be determined by seeking out the agreements between TRU mass balance and SFRP building. Additionally, by comparing the various plant lifetimes, the dependence on this particular variable can be determined and agreements across all PL can be assessed.

The low advanced technology setting with 50 year PL is appropriate for determining TRU mass balance in LWR/CONFU. The high advanced technology setting with 30, 40 and 50 year PL works for almost all TRU mass balance and SFRP calculations in LWR/CONFU. The high advanced technology in LWR/ABR is appropriate for the SFRP in the 40 yr PL, but not for

the TRU mass balance calculations. Additionally, the SFRP works in the 30 yr PL and is roughly suitable for use in the 50 year PL. The TRU in both of these cases are not in agreement. In the LWR/GFR strategy, both the low and the high advanced technologies are fitting for SFRP in 30 year PL and 50 year PL, however this does not fit for the TRU in either case. The low and high advanced technologies have equal results with the 40 year PL with none of the TRU results corresponding and only approximately 2/3 of the SFRP results corresponding. Thus, the

operating range for CAFCA IIB depends on the operating parameters in the simulation. There is no fine line at which the TRU mass balances in CAFCA IIB stop corresponding to the SFRP projections, instead this type of line exists in each setting in the code and under every strategy option.

References

[1]. A. Aquien, M.S. Kazimi and P. Hejzlar, Thesis: Fuel Cycle Options for Optimized

Recycling of Nuclear Fuel, MIT-NFC-TR-086, Cambridge: MIT Nuclear Fuel Cycle

Technology and Policy Program, June 2006.

[2]. Personal communication with Rodney Busquim, May 2007.

[3] E. Schwageraus, P. Hejzlar, and M.S. Kazimi, Optimization of the LWR Nuclear Fuel Cycle for

Minimum Waste Production, MIT-NFC-TR-060, CANES, MIT, October 2003

[4] T.Boscher, P. Hejzlar, M.S. Kazimi, N.E. Todreas, and A.Romano, Alternative Fuel Cycle

Strategies For Nuclear Power Generation In the 21st Century, MIT-NFC-TR-070-Rev. 1, CANES,

MIT, June 2005.

[5] CEA Cadarache, CEA Sacley, Argonne National lab, General Atomics, Brookhaven National Lab, MIT, Development of Generation IV Advanced gas-Cooled Reactors with Hardened/Fast

Appendix A: TRU mass balance - Low case with 40 yr. PL (II & IIB)

TRU mass balance [iT]

TRU mass balance [MT

TRU mass balance [MT]

O0

00

iii)

Figure 1: TRU for LWR/CONFU strategy in CAFCA II - Low case, 40 yr. PL

-TRU in speit fuel :ndergoing cooling

STRU in spent fuel after cooling perio(

-LWR cores

TRU

mass balance

EI

-Region

.

inO

Coling

Storage

*=lnterim Storage aUSWR Cores iniItlitIR COes

[inCooing Stor.age

*,.intei•m StorageOULW

R Cores

IWUHIPR Qores$ MPC.olig Storage*U•Intenm Storag..

SOMLWR COres III.lIIlIFR CoreS oO iii)Figure 2: TRU for LWR/CONFU strategy in CAFCA IIB - Low case, 40 yr. PL

II

TRU mass balance IMT

TRU mass balance [MT]

TRU mass balance .[M.

iii)

Figure 3: TRU for LWR/ABR strategy in CAFCA II - Low case, 40 yr. PL

-TRU in spent fuel undergoing cooling

-- TRU in spent fuel aftr cooling

perio-' LWR cores

"".... Fast Reactors Core.

- TRU in sf. undergoing cooling

"*,,'*TRU In St. after cooling period

Lf*-WR cores

0111111m, Fast Reactors Cores

OO

00

TRU mass balance [MT] -- Region I mCooling Storage S** 1 Interim Storage 1m3 LWR Cores IInilriFR Cores 2020 2040 2060 20 2100

TRU mass balance [MT]- Region I

1

N Cooling Storage **Ilnterim Storage 112LWR Cores IIIIIIII FR Cores 2020 2040 20 2080 2100TRU mass balance [(M -- Region I

01m Cooling Storage Sa tlnterim M Storage *1 LWR Cores III'II"I"FR Cores 2020 2040 2060 2080 2100

iii)

Figure 4: TRU for LWR/ABR strategy in CAFCA IIB - Low case, 40 yr. PL

3000 2500 2000 1500 1000 500 n 2x0 8000 70O0 5000 3000 2000 1000 2000

I ··

~

~

nrrvr:000

TRU mass balance [MT]

20G- -wTRU in -- 80O

st. undergoing cooling

*I* *TRU in s. after cooling period

***'*

LWR

cores

10" 1.1."1 Fast Reactors Cores

2100

TRU mass balance [MT]

00

TRU mass balance [MT]

00

iii)

Figure 5: TRU for LWR/GFR strategy in CAFCA II- Low case, 40 yr. PL

4000 3000 2000 1000 I., 200o I I ., , I. .*~ S enmea e im m m metl**'* E -L I -InrrLI

TRU mass balance [MT -- Region I

mMCooling Storage

'1Interim Storage

0m1ELWR Cores

MMIIIIIIFR Cores

TRU mass balance [MT- Region I

ammCooling Storage

*'*Interm Storage

4104

LWR

Cores

ll•FR 0CoesTRU mass balance [MT] - Region I

mOmOCooling Storage S*'lnterim Storage rImniLWR Cores IIIIIIIIIIFR Cores 00 iii)

Figure 6: TRU for LWR/GFR strategy in CAFCA IIB - Low case, 40 yr. PL

41

31 2 V1 tI 4MC 350 30 250 15C 10( 5( LAppendix B: Spent fuel recycling plants - Low case with 40 yr. PL (II & IIB)

Spent fuel separation plants

10

2

020

24

-Nuumber]

0-2000 2020 2040 2060 2080 2100 FFFsf reprocessing plants 4 2-2000 2020 2040 2060 2080 2100 1 1 0.5 0.50 -Capacity Factor - Capat FactorI

0 0

2000 2020 2040 2060 2080 2100 2000 2020 2040 2060 2080 2100

1 - Buit 1

0.52

I8

20

10

0.5201

2000 2020 2040 2060 2080 2100 2000 2020 2040 2060 2080 2100

Spent fuel separation plants

2-

21

20 2020 2040 2060 2080 2100 FFFsf reprocessing plants 2 -Number 202200 20 00 10 200 2020 2040 2080 2080 2100'- Capacity Factor - Capacity Factor]

2020

2040

2080

2080

2100

20R0

0

202

2080

2080

2100

0.5

0.5

2020 2040 2060 2080 2100 200 2020 2040 2080 2080 2100

Spent fuel separation plants

-Number 2020 2040 2060 2080 2100 -Capacity Factor Fa ,o 2020 2040 2060 2080 2100 FFFFf reprocessing plants 4

2-2 2020 2040 2080 2080 210)0 -capacity Factor 2oo00 2020 2040 2060 2080 2100f

Bt

ud'-Built

A

2%0 2020 2040 2060 2080 2100 200 2020 2040 2060 2080 2100 iii)Figure 7: SFRP for LWR/CONFU strategy in CAFCA II - Low case, 40 yr. PL

0O 1 0.5 2? 1

0.5

IC10 n1I ""= ·o.it

i 1- '0.5-Recycling plants - UO2sf-- Region I Recycli 4 2 -Number 2010 2020 2030 2040 20 260 2070 2080 2090 2100 10 2020 30 -; Capacity 05 - - 0.5-JCapacity Factor 0 20 230 2040 2050 2060 2070 2080 2090 2100 .10 2020 2030 2 1

05

[05

2010 2020 2030 2040 2050 2060 2070 2080 2090 2100 12020 2030 2Recycling plants - UO2sf - Region I

ng plants - Adv SF -- Region I

040 2050 20 2070 2080 2090 2100

Factor

340 2050 2060 2070 200 2090 2100

340 M 2070 200 2090 2100

Recye ing plants - Adv SF - Region I

2 2 INurnmber_ 10 2020 2030

:•

2040"

'

- • •,,-

2060 2060 2070 2080,•

2090•,

2100"'*r

---

0 20207

2030 2040 2050 2060 2070-

2080 2090-

21000.5

-

Capacity Factor Capaacity Factor 1 2 2040202G 2060 •2 0 2060 2070 2080 2090 2100 .0.5 210 2020 2030 2040 20 200 0 200 2090 2100 0 202 203 4 2050 206 2070 2080 2090 2100 .5Recycling plants- UO2sf -Region 1

I-

Nu'berlI

I

I 1

0.-10 2020 2030 2040 2050 2060 2070 2080 2090 2100

mod CaVI paty Factor

2010 2020 2030 2040 2050 2060 2070 2080 2090 2100

0 .5

1010 2 20 30 2040 2050 2060 2070 20B0 209 2 2100

Recycling plants - Adv SF -- Region I

1: nh .110 2020 2030 2040 2050 5 apacity Fa or 20 2070 2080 2090 2100 ',ub r .. D0 NJ,

Figure 8: SFRP for LWR/CONFU strategy in CAFCA IIB - Low case, 40 yr. PL iii)

I I I 1

1

Spent fuel separation plants

0

20-Number!

1 2000 2020 2040 2060 2080 2100 2000 2020 2040 2060 2080 2100 1 . 1 -Capaity Factor••0.5

0.5

-Capacity Factor 2000 2020 2040 2060 2080 2100 2000 2020 2040 2060 2080 21000.51

AMMMWA0MII

057[i

2000 2020 2040 2060 2080 2100Spent fuel separation plants

2Number 2020 2040 2060 2080 2100 2000 2020 2040 2060 2080 2100 FFFSf reprocessing plants 2020 2040 2080 2080 2100

&

2020

2040

20'60

20'80

2100

1 apac 0.5[,-Capacity

Facctor 200 2020 2040 2060 2080 2100 2 2020 M0 2040 200 2080 2100 0.5 0.5 2020 2040 2060 2080 2100 202 0 2000 2080 2100Spent fuel separation plants

2020

2040

2060

2080

2100

-Capacity Factor 0.5 2%0 2020 2040 2080 2080 2100 FFFsf reprocessing plants -Number A. Jnro 2& 2020 2040 2060 2080 2100 1 -Capacity Factor 2 2020 2040 2000 2080 2100 LBu!ltJ 0.50 20 22ft

2020

M40

2060

2M

.210

20 24

20••-11it0

2%0 2020 2040 2060 2080 2100 iii)Figure 9: SFRP for LWR/ABR strategy in CAFCA II - Low case, 40 yr. PL

Recycling plants - UO2sf -- Region I 0 2010 2020 2030 2040 2050 2060 2070 2080 2090 2100 1 05 10 2020 2030 2040 2050 2060 2070 2080 2090 2100 201 0 2030 2 2W 20 6 20;7 28 200 1

Recycling plants - Adv SF - Region I

I , , , , ' ,' ', ,

F

-_Number 10 2020 2030 2040 2050 2060 2070 2080 2100 0.5 20 2030 2 040 20 0 2 2070 20 2090 2100 2 0.5 2010 2020 2030 2040 2050 2060 2070 2080 2090 2100 )'> IRecycling plants - UO2sf -- Region I

mber o5 1 0.5 10 2020 20 2040 206 2060 2070 2080 2090 211 0.5 2010 :;5; rose 3;40 2050' 2060 20o.0 20M0 2090 21

Recycling plants -Adv SF - Region I

eNumber 2020 2030 2040 2050 2 270 2080 2090 210 Capacity Factor 0 5 1J0 2020 2030 2040 205o 2060 2070 2080 2090 2100 05¸

Recycling plants -UO2sf -- Reaion I Recycling plants - Adv SF

- Reion I

umber

1

2010 2020 2 2040 2060 2060 2070 2080 2090 2100 1 15 I Capaci'ty Factor 0 o2010 2020 2030 2040 20 2060 2070 2080 2090 2100oo SBuilt 0.5 2010 2020 2030 2040 200 2060 2070 200 209 2100 2010 2020 20 2040 20 S CapacityFactor 0.5 Numiber 3 2080 2070 2080 2090 0 10 2020 2030 2040 0Figure 10: SFRP for LWR/ABR Strategy in CAFCA IIB - Low case, 40 yr. PL 3

11

2100 I-iii) 00 30 00 00D0

T ' -N 1 I I I ;-1 r -I -1 I 1 i I-I N ISpent fuel separation plants -Number

5-2020 2040 2060 2080 2100 1 o. I-Capacity Factor 20 2020 2040 2060 2080 2100

Spent fuel separation plants

20

]--Number

2 2020. 2040 2060 2080 21100 -Capaz Factor-200 2020 2040 2060 2080 2100 ii)20 2D40 2060 28 210ii)

Spent fuel separation plants

2

2020

2040

2080

2080

2100

-Capact y Factor

0.5

2966-

2020

2040

2060

2000

2100

iii)

20 20. 200

nd

: .

7.1

yciingplants -UO2st- Region I

2 0 6 ber.

:200 20W0 2060 t70 2060 200 20

- CapacFactor

10 2 20i0 204020 O 2060. 0 200 oO 2 2100

2o200

M

A:2

"A

A

I

A' A

20 .. '0209 2A tRe, cling plants - UQ2sft- Region I

VnCepdi

]

2 2303b 20 200 86o 2 0e70 2080 2090 2100

Po m 20 400 205 0 2000 2080 I=.

fReycing9ant - UO2sf - Region I

10. 2020 201w 2D0 4 0 2050 2070 . . 2. 2 al 10

0'5s

1 202 m 2050 2060 200 20.0 :I2100:

S2020 W 20 60 20701 200 200 2100:

iii)

Figure 12: SFRP for LWR/GFR Strategy in CAFCA IIB - Low case, 40 yr. PL

Appendix C: TRU mass balance - High case with 40 year PL (H & IIB)

TRU mass balance [MT

TRU mass balance [MT:

TRU mass balance [MT

iii)

Figure 13: TRU for LWR/CONFU strategy in CAFCA II - High case, 40 yr. PL

-TRU in spent fuel undergoing coolint

*TRU In spent fuel after cooling periot --LWR cores

-TRU ij spent fuel undergoing cooling

- TRU in spent fuelafter cooling periot

" LWR coes:

Fast Reactors Core

TRU.rmass balane

:MT]

-Region

I

TRU mass balance o•M] - Regil

IMMa Cooling Storage *iiInterimStorage I LMtWR Cores nIIHiNIFR Cores MWCooling Storage i0Iinter1m Storage -LWR CorFes IIIIuIIIIIFR COrs

M

Cooling

Storage

*I mN•t ri .Storage llCaalr.cores HilIUIIIF CoresgFigure 14: TRU for LWR/CONFU strategy in CAFCA IIB - High case, 40 yr. PL

Mi

10

IU

----TRU mass balance [MT

TRU mass balancie (MT

TRiU mass balance [MT

iii)

Figure 15: TRU for LWR/ABR strategy in CAFCA II - High case, 40 yr. PL

-TRU in spent fuel undergoing coolinc

"- TRU in spent fuel after cooling perioc

- LWR cores

.--Fast Reactors Cores

-TRU in spent fuel undergoing cooling

-" TRU in spent fuel after cooling periot

LWR cores

... Fast Reactors Core.

TRU mass balance, MTI - Region I iMCooling Storage ' m Interim Storage

SIL

NWR Cores

Iun I,,,FRCores M oling Storage SMrntrim S, torage SLmR Cores *IIIIIIIIIR Cores MMM~Cootiri Storaige *moInterimrStorage MWWLWT Cores I FlIHRR ",CoresFigure 16: TRU for LWR/ABR strategy in CAFCA IIB - High case, 40 yr. PL

i-"d,

• In -·

TRU mass balance [MT]

TRU mass balance [MT]

DO

TRU mass balance [MT]

00

iii)

Figure 17: TRU for LWR/GFR strategy in CAFCA H- High case, 40 yr. PL

ýloo

i

TRU mass balance [MT] - Region I inCooling Storage S**i~nterim Storage ImUIaLWR Cores IIIIIIII"PFR Cores 2020 2040 2060 2080 2100

TRU mass balance [MT - Region I

riCooling Storage

*i Intenim Storage wimLWR Cores

BtiIlIIFR Cores

2020 2040 2060 2 2100

mass balance [MT] -- Region I

ý ýCooling Storage * Interim Storage m# LWR Cores I ~lulFR Cores CIO

iii)

Figure 18: TRU for LWR/GFR strategy in CAFCA HIB - High case, 40 yr. PL

4UU00 3500 3000 2500 2000 1500 1000 4000 3500 3000 2500 2000 1500 1000 600 lo v 2000 TRU '^^^

2000

~---Appendix D: Spent fuel recycling plants - High case with 40 yr. PL (II & IIB)

Spent fuel separation plants I-Number

10

0 - ---- -- . ... ... 2000 2020 2040 2060 2080 21001

0.5 -Capacity Factor 2000 2020 2040 2060 2080 2100 FFFsf reprocessing plantsL--N

u4umeýrj-2 2000 2020 2040 2060 2080 2100 1•

0.5

-Capacity Factor] 2000 2020 2040 2080 2080 21000

2000 2020 2040 2060 2080 2100 FFFsf reprocessing plants 0.5 2000 2o20 2040 2060 2080 2100 -C...0.5

0.5

2000

2020

2040

2060

2080

2100

Spent fuel separation plants

10. 2000 2020 2040 2080 2080 2100

.5

I-Capacity Factorl

0 2000 2020 2040 2060 2080 2100So0.5.5

2000 2020 2040 2060 2080 2100Spent fuel separation plants

2000 2020 2040 2060 2080 2100 capacity Factor

0.5

1

U0 2000 2020 2040 2060 2080 2100 0.50 2020 2040 2060 208 2000 2020 2040 2060 2080 2100 20 2 40 2080 2080 2100 2000 2020 2040 2060 208 2100 FFFsf reprocessing plants 220

2040 2-Nu060 2 2ber100 2000 2020 2040 2080 2080 2100 i -Capacity Factor 0.511

U 2000 2020 2040 2060 2080 2100 .I-BuI

Ik

2000 2020 2040 2060 2080 2100 iii)Figure 19: SFRP for LWR/CONFU strategy in CAFCA H - High case, 40 yr. PL

a-l ·

Recycling plants - UO2sf -Region I 5-,-umober 2010 20 2030 2040 2050 2060 2070 2080 2090 2100 i Capacity Factor 2010 2020 2030 2040 2050 2060 2070 2080 2090 2100 0 05 10 2020 230 2D40 200 2060 2070 2080 2090 2100

Recycling plants - UO2s - Region I

-Number

5 " DO 2020 2030 2040 2050 2060 2070 2080 2090 2100 0Capacity Factor 2010 2020 2030 2040 205o 2o6) 2070 2080 2090 2100 10 2 10 2020 20b3 2 2050 2060 207 200 2090 2100Recycling plants - U2s -- Region 1

4

4

Number

10 2020 2030 2040 2060 2060 2070 2080 2090 2100G.apacity Factor

0.5 0 2010 2020 2030 040 2050 2080 2070 2080 2090 2100 1 - -. 0.5 -Iin~8uiltI

A

Recycling plants - Adv SF - Region I

Recycling plants -Adv SF -Region I 2

Number

..

051

2020 20 2040 20o5 2060 2070 2080 2090 2100

Recycfing plants - Adv SF -Region I

02

0 2020 2030 C..c.. 2040 Factor..:2050 2060 2070 2000 20902100 . =- C apacity F actor I 05 4110 2020 2030 20403 2050 2060 2070 2080 Built 2090 2100A

Al

2010 2020 2030 2040 2050 2060 2070 20O0 2090 2100 2020 2030 2040 2 2060 2070 200 20 2100 iii)Figure 20: SFRP for LWR/CONFU strategy in CAFCA IIB - High case, 40 yr. PL

Spent fuel separation plants FFFsf reprocessing plants

20 ._ - ... ... - 10. .

...-10

2000 2020 2040 2060 2080 2100 2000 2020 2040 2060 2080 2100

1 1I

0.5-- Capacity Factor -05Capacity Factor

2000 2020 2040 2060 2080 2100 2000 2020 2040 2060 2080 2100

1iLt1J

1

M

2000 2020 2040 20680 2080 2100 2000 2020 2040 2060 2080 2100

i)

Spent fuel separation plants FFFsf reprocessing plants

Numumber er 2000 2020 2040 2060 2080 2100 2000 2020 2040 2060 2080 2100 0.5_ o. -Capaclty Factor! 0.5 . - ý--0--2000 2020 2040 2000 2080 2100 2000 2020 2040 2060 2080 2100

1

Ii

. M1III

0.5 0.5 0 0 2000 2020 2040 0 2080 2100 2020 2040 2060 2080 2100 ii)Spent fuel separation plants FFFsf reprocessing plants

4 -Number -Number

26oo 2020 2040 2060 2080 2100 i0o 2020 2040 2060 2080 2100

-Capacity Factoro Ca act

0.5 0.5

2000 2020 2040 2060 2080 2100

m

2020 2040 2080 2080 21000.5 0.5

?6 2020

2040

2060

2080

2100

2@

2020

2040

2060

2080

2100

iii)

Recycling plants -UO2sf -- Region I

Recycling plants - Adv SF -- Region I

20S-Number 1 0.5 010 20 20 2030 2040. Recycling pl 5-0 2020 2030 2040

10

2 - Number 2010 2020 2030 2040 2050 2060 2070 2080 2090 2100 Capacity FactorI

F"

F-; CapacityFactor 2050 2060 2070 2080 2090 2100S

0 2010 2020 2030 204 2050 206 2070 2080 2090 2100 22020 2030 2040 M5 2060 2070 20 2 2100ants - UO2sf - Region Recycling plants - Adv SF - Region I

2050 2060 2070 2080 209 21F00

CapacIty Factor 2050 2060 2070 2080 2090 2100

2010 2020 2030 2040 2050 2060 2070 2080 2090 2100.

Recycling plants - U2sf -- Region I

4~ 1 Number I 2010 020 M0 2 M' 2050 2060 2070 -20 2090 2 100 2-Number 10 2020 203 2040 200 2060 2070 2080 2090 2100 10 2020 2030 2040 2050 60 2070 2090 2100 0.5 2020 2030 2040 2050 2060 2070 2 2090 2100

Recycling plants -AdvSF - Region I

4

0

2 3 M 0 m 20r

0 I r f:13.acto di I -I Capacity Factor

10 2020 2030 2040 2050 2060 2070 2080 2090 21 10 2020 2030 20 2050 2060 2070 2080 2090 2100 2010 2020 2030 2040 2050 2060 2070 200

090

21002 0 2070 .. 2 1.02 202 4 20 -3 2040 2050 .-.nLn -) w iii)Figure 22: SFRP for LWR/ABR Strategy in CAFCA IIB - High case, 40 yr. PL

Spent fuel separation plants 20 --•Number! 10 2)00 2020 2040 2060 2080 2100 0.5ý -- Capacity Factor 2 00 2020 2040 2060 2080 2100 0.5 2~ 2020 2040 2060 2080 2100 i)

Spent fuel separation plants

2000 2020 2040 2060 2080 2100

0.5

L-ýCapacity

Factor2 2020 2040 2060 2080 2100

Spent fuel separation plants

2 2020 2040 2060 2080 2100 -Capacity Factor :0.5 2 2020 2040 2060 2080 2100 0.5 2&6 2020 2040 2060 2080 2100

iii)

Recycling plants -UO2sf -- Region I 10 - Number 2010 2020 2030 2040 2050 2060 2070 2080 2090 2100 0.5 Capacity Factor

0

2010 2020 2030 2040 2050 2060 2070 208 2090 2100Recycling plants -UO2sf- Region I

-Number

)10 2020 2030 2040 2050 2060 2070 2080 2090 2100 1 ....Capacity Fac

t

or

2010 2020 2030 2040 2050 2060 2070 2080 2090 2100 110 2020 2030 2040 2050 2060 2070 2080 2090 2100Recycling plants -UO2sf - Region l

0.5 : Number

0-

ý

CapaciýFactor

2010 2020 2030 2040 200 2060 2070 206 2090 2100 0.52020 2030 2040 200 2060 2070

2010 2020 Z2a 0 2060 2070m M 2100iii)

Appendix E: TRU Mass Balance - Low case in CAFCA IIB with 30 year Plant Lifetime

TRU mass balance [MT] -- Region I

m Cooling Storage il Interim Storage *" LWR Cores

Ft"IIIsIFR Cores

2020 2040 2060 2080 2100

TRU mass balance [MT] - Region I

*Cooling Storage **'Interim Storage

tiillVLWR Cores

"M"""FR Cores

2020 2040 2060 2080 2100

TRU mass balance [MT -- Region I

mlCooling Storage , m I Interim Storage uw*LWR Cores miit"" FR Cores 2020 2040 2060 2080 2100 iii)

Figure 25: TRU for LWR/CONFU strategy in CAFCA IIB - Low case, 30 yr. PL

3000 2500 2000 1500 1000 500 n i"0 100W M= u 5000 4000 3000 2000 1000 ^M• •ZE nL

TR.U mass balance (.T] -- Region'l M" Cooling. Stora'ge - I-lnterinm torage rl""WRC'C Cores IHlln:Fh. C.Ores Comtlig Storage =~neftn .Storage se•IWIR Cores mmunlhR.oes

Tflimass balance [T]a , Regiponl

M Coolng Storage

l*Interim" Strage

LWetR Cores

IlnntlER Cores

iii)

Figure 26: TRU for LWR/ABR strategy in CAFCA IIB - Low case, 30 yr. PL

45 40 .35 30 20 6 -- 1