Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Internal Report (National Research Council of Canada. Division of Building

Research), 1983-11-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=3ced9382-990f-4468-aa2c-717c091a34be https://publications-cnrc.canada.ca/fra/voir/objet/?id=3ced9382-990f-4468-aa2c-717c091a34be

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001321

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Fire tests on reinforced concrete columns: specimen no. 8

nen

Ser

IT H I

National Research

n.

485

Council Canada

Conseil national

derecherche Canada

FIRE TESTS ON REINFORCED CONCRETE COLUMNS, SPECIMEN NO. 8

byT.T. Lie and T.D. Lin

Private

copy for:DBR

Internal

Report 485NATIONAL RESEARCH COUNCIL OF CANADA DIVISION OF BUILDING RESEARCH

OBR INTERNAL REPORT NO. 485

FIRE TESTS ON REINFORCED CONCRETE COLUMNS, SPECIMEN NO. 8

by T.T. L i e and T.D. L i n

Checkedby: T.Z.H. Approved by: L .W. Gold Date: November 1983

Prapared for: Record Purposes

ABSTRACT

R e s u l t s of a f i r e t e s t on a r e i n f o r c e d c o n c r e t e column a r e given. The t e s t i s one of a s e r i e s of twelve t e s t s c a r r i e d o u t i n t h e f i r s t phase of a j o i n t s t u d y on t h e f i r e performance of c o n c r e t e columns by t h e N a t i o n a l Research Council Canada and t h e P o r t l a n d Cement A s s o c i a t i o n . The column was made w i t h s i l i c e o u s a g g r e g a t e .

I t s s e c t i o n s i z e was 305 x 305 mm (12 x 12 i n . ) . It was t e s t e d t o s t u d y t h e i n f l u e n c e of load on t h e f i r e r e s i s t a n c e of t h e column.

FIRE TESTS ON REINFORCED CONCRETE COLUMNS SPECIMEN NO. 8 by T. T. L i e and T. D. Lin* T e s t s were c a r r i e d o u t on a s e r i e s of r e i n f o r c e d c o n c r e t e columns a s p a r t of a s t u d y t o d e v e l o p methods f o r t h e d e t e r m i n a t i o n of t h e f i r e r e s i s t a n c e of such columns. The s t u d y was a c o o p e r a t i v e e f f o r t between t h e N a t i o n a l Research C o u n c i l Canada and t h e P o r t l a n d Cement

A s s o c i a t i o n . I n t h e f i r s t phase of t h e s t u d y 12 columns were t e s t e d . The columns were d e s i g n e d and manufactured by PCA i n Skokie, U.S.A., and t e s t e d i n t h e NRCC l a b o r a t o r i e s i n Canada. The specimens, method of t e s t i n g and t e s t r e s u l t s a r e d e s c r i b e d i n s u c c e s s i v e r e p o r t s .

T h i s r e p o r t d e a l s w i t h specimen No. 8 , which was t e s t e d t o s t u d y t h e i n f l u e n c e of l o a d on t h e f i r e r e s i s t a n c e of t h e column.

TEST SPECIMEN

The t e s t specimen c o n s i s t e d of a s q u a r e t i e d r e i n f o r c e d c o n c r e t e column. D e t a i l s of t h e specimen and i t s f a b r i c a t i o n a r e g i v e n below.

S e c t i o n s i z e : 305 x 305 mm (12 x 12 i n . ) Height: 3810 mm (12 f t 6 in.)

Materials

Cement: Type I , a g e n e r a l purpose cement f o r t h e c o n s t r u c t i o n o f r e i n f o r c e d c o n c r e t e s t r u c t u r e s .

Aggregate: S i l i c e o u s sand and g r a v e l from Eau C l a i r e , Wisconsin. The maximm s i z e of t h e a g g r e g a t e was 19 mm (314 i n . ) . The g r a d a t i o n curve is shown i n F i g u r e 1. P e t r o g r a p h i c i n f o r m a t i o n on t h e a g g r e g a t e , o b t a i n e d a c c o r d i n g t o ASTM ~295-7g1, i s g i v e n i n T a b l e 1. The p h y s i c a l p r o p e r t i e s of t h e a g g r e g a t e a r e g i v e n i n Table 2.

S t e e l r e i n f o r c e m e n t : Deformed 25M (No. 8 ) l o n g i t u d i n a l

r e i n f o r c i n g b a r s and 10M (No. 3) t i e s meeting t h e r e q u i r e m e n t s of ASTM D e s i g n a t i o n ~ 6 1 5 - 6 0 2 were used. The y i e l d s t r e n g t h of t h e 25M b a r s was 443.7 MPa (64.3 k s i ) and t h a t of t h e 10M b a r s 426.5 MPa (61.8 k s i ) .

C o n c r e t e mix: The c o n c r e t e mix was designed t o produce a 34.5 MPa (5000 p s i ) s t r e n g t h n o r a i r e n t r a i n e d c o n c r e t e . A w a t e r c e m e n t r a t i o

* S e n i o r r e s e a r c h e n g i n e e r , P o r t l a n d Cement A s s o c i a t i o n , Skokie, I l l i n o i s .

of 0.6 was used. The slump was 10

mm(3.92 in.).

Batch quantities are

given in Table 3 and measured properties of the concrete in Table 4.

Fabrication

Casting

The column was cast in a specially designed form. At the start of

the casting the front side of the form was left open for depositing

fresh concrete. The concrete was mixed in a 0.17 m 3 (6 ft3) tilting

drum mixer. Shovels and scoops were used to deposit concrete in the

form. A small internal vibrator was applied to consolidate the

concrete. As the casting progressed upwards, the window pieces were

successively closed and tightly bolted to the form to avoid possible

moisture leaks. Lifting hooks were embedded on opposite sides of the

test specimen at 800

mm(2 ft 7 112 in.) from the top of the column.

Acylindrical humidity well3 with a diameter of

4

mm (5132 in.) was

positioned at mid-height of the column for measuring the relative

humidity at mid-depth.

Reinforcing cage

The reinforcing cage was assembled by welding each end of four

longitudinal main reinforcing bars to a steel end plate. The bars were

cut to 3800

mrn(12 ft 5 112 in.) and machined at both ends, for a

length of 19 mm (314 in.) to a diameter of 19 mm (314 in.).

Figure

2

shows details of the finished bars. The dimensions of the end plates

were 533

x533

x25 mm (21

x21

x1 in.).

In each corner of the plate,

20.6 cm holes (13116 in.) were drilled to accommodate the longitudinal

bars. The centers of the holes were spaced 92.1 mm (3 518 in.) from

the centerlines of the plates. In this way a column was obtained with

a section of 305

x305 mm (12

x12 in.) and a cover of 47.6 mm

(1 718 in.) to the main reinforcing bars and 38.1

mm(1 112 in.) to the

stirrups. The main bars and stirrups were tied together to complete

the steel cage which, including the steel plates, was 3810 mm

(12 ft 6 in.) long.

Welding

The provisions of AWS Designation ~12.1-75 were followed when

welding plates and bars. These members were preheated with a propane

torch to 288OC (550°F), to prevent brittle failure during welding. The

side fillet weld was done around bars on the inner face of the bottom

plate. McKay E10018-D2 and DYTRON-579 welding rods were used. Both

types of welding rods have tensile strength of 834.9 MF'a (121 000 psi).

Mild-steel welding rods were used to fill up the

6

mm(114 in.) deep

holes on the outer faces of the plate. The rough surfaces of the

welded joints on the outer face of the plate were ground to a smooth

finish.

The top steel plate was welded after the casting of the columns.

Before positioning the top plate, a 6 mm

(114

in.) layer of mortar was

s p r e a d o v e r t h e t o p of t h e column t o e n s u r e good c o n t a c t between s t e e l and c o n c r e t e . The m o r t a r was made of one p a r t cement and t h r e e p a r t s s i l i c e o u s sand. Using t h e same procedure a s f o r t h e bottom p l a t e , t h e t o p p l a t e was welded on t h e o u t e r s i d e t o t h e b a r s and smoothed.

C u r i n g

The c o n c r e t e was cured under damp b u r l a p f o r s e v e n days a t 21 t o 24'C ( 7 0 t o 75OF). The form was t h e n s t r i p p e d , and t h e column

c o n d i t i o n e d i n a n atmosphere c o n t r o l l e d a t 21 t o 24'C (70 t o 75OF) and 30 t o 40% r e l a t i v e humidity. The column was removed f r o m t h e k i l n p e r i o d i c a l l y t o c o o l a t 23'C (73'F) s o t h a t t h e r e l a t i v e humidity i n t h e c o n c r e t e c o u l d b e measured.

Two hundred seventy-one days a f t e r t h e column was c a s t , t h e r e l a t i v e humidity i n t h e c e n t e r of t h e column r e a c h e d 85% and t h e column was wrapped i n p l a s t i c t o p r e v e n t change i n i t s m o i s t u r e c o n t e n t .

Butt-welded chromel-alumel thermocouples 0.912 mm t h i c k (0.0359 i n . ) were u s e d t o make thermocouple f r a m e s f o r measuring

c o n c r e t e t e m p e r a t u r e s a t d i f f e r e n t l o c a t i o n s i n v a r i o u s c r o s s s e c t i o n s of t h e columns. Each frame c o n s i s t e d of a number of thermocouples t i e d t o s t e e l r o d s t h a t were f i r m l y s e c u r e d t o t h e main r e i n f o r c i n g b a r s . The thermocouples w e r e a r r a n g e d t o measure t e m p e r a t u r e s a t t h r e e l e v e l s : a t one-quarter h e i g h t , a t mid-height and a t t h r e e - q u a r t e r h e i g h t of t h e column. A t mid-height t h e t e m p e r a t u r e s were measured a l o n g t h e whole l e n g t h of a c e n t e r l i n e and a d i a g o n a l of t h e s e c t i o n ; a t t h e o t h e r two l e v e l s t h e t e m p e r a t u r e s were measured o n l y a l o n g h a l f of t h e c e n t e r l i n e and h a l f of t h e d i a g o n a l of t h e s e c t i o n . The

l o c a t i o n s of t h e thermocouples i n t h e c o n c r e t e and t h e i r numbering a r e shown i n F i g u r e s 3 and 4.

I n a d d i t i o n , a number of thermocouples were mounted on t h e

r e i n f o r c i n g s t e e l b a r s and t i e s . The l o c a t i o n s o f t h e thermocouples on t h e s t e e l a r e shown i n F i g u r e 5 and i n more d e t a i l i n F i g u r e 6. A l l thermocouples were i n s t a l l e d i n s u c h a way t h a t t h e w i r e f o l l o w e d a n i s o t h e r m f o r a t l e a s t 12.7 mm (112 i n . ) from t h e j u n c t i o n .

Test Apparatus

The t e s t was c a r r i e d o u t by exposing t h e column t o h e a t i n a

f u r n a c e s p e c i a l l y b u i l t f o r t e s t i n g l o a d e d columns and w a l l s . The test f u r n a c e was d e s i g n e d t o produce t h e c o n d i t i o n s t o which a member might b e exposed d u r i n g a f i r e ; f o r example, f i r e t e m p e r a t u r e s , s t r u c t u r a l l o a d s , and h e a t t r a n s f e r . It c o n s i s t s of a s t e e l framework s u p p o r t e d by f o u r s t e e l columns w i t h t h e f u r n a c e chamber i n s i d e t h e framework (Fig. 7). The c h a r a c t e r i s t i c s and i n s t r u m e n t a t i o n of t h e f u r n a c e a r e d e s c r i b e d i n d e t a i l i n r e f e r e n c e 5. Only a b r i e f d e s c r i p t i o n of t h e f u r n a c e and t h e main components w i l l be g i v e n h e r e .

Loading Device

Three hydraulic jacks produce forces along the three principal

axes. The jack acting along the axis of the test column is located at

the bottom of the furnace chamber. The plate on top of this jack can

be used as a platform to which the column can be attached.

Furnace

Chamber

The furnace chamber has a floor area of 2642

x2642 mm

(8 ft 8 in.

x8 ft 8 in.) and is 3048 mm (10 ft) high. It is made of

insulating materials that will produce a high heat transfer to the

specimen. There are 32 propane gas burners in the furnace chamber,

arranged in eight columns, containing four burners each. The total

capacity of the burners is 4700 kW (16

xlo6

Btu/h).

Each burner can

be adjusted individually to obtain a high temperature uniformity in the

furnace chamber. The pressure in the furnace chamber is also

adjustable. It was set somewhat lower than atmospheric pressure.

Instrumentation

The furnace temperatures were measured with the aid of eight

chromel-alumel thermocouples. The junction of each thermocouple was

located 305

mm(1 ft) from the test specimen, at various heights. Two

thermocouples were placed opposite each other every 610 mm (2 ft) along

the height of the furnace chamber. The locations of their junctions

and their numbering are shown in Figure 8. Thermocouples Nos.

4

and 6

were located at a height of 610

mm(2 ft) from the floor, thermocouples

Nos.

2 and 8 at 1220 mm (4 ft), thermocouples Nos. 3 and 5 at 1830 mm

(6 ft) and thermocouples Nos. 1 and 7 at 2440

mm(8 ft).

The

temperatures measured by the thermocouples were averaged automatically,

and the average temperature was used as the criterion for controlling

the furnace temperature.

The loads were controlled and measured with pressure transducers.

The accuracy of controlling and measuring loads was about

5% at lower

load levels and better at higher loads.

The axial deformation of the test specimen was determined by

measuring the displacement of the jack that supports the column. The

displacement was measured using transducers with an accuracy of

0.002 mm.

Test Conditions and Procedure

The column was installed in the furnace by bolting its end plates

to a loading head at the top and a hydraulic jack at the bottom. For

this purpose eight 19

mm(314 in.) bolts spaced regularly around the

column

63.5 mm (2 112 in.) from the sides were used at each end.

On the day of the test, the moisture condition in the center of

measured p r i o r t o t h e s t a r t of t h e t e s t was 74%. The ambient t e m p e r a t u r e a t t h e s t a r t of t h e t e s t was 18'C (64'F).

The column was c a s t on 5 August, 1977 and t e s t e d on 12 September, 1980. It was s u b j e c t e d t o a l o a d of 1778

kN

(400 k i p s ) a p p l i e d a b o u t one hour b e f o r e t h e t e s t . A t t h e t e s t d a t e , t h e c y l i n d e r s t r e n g t h s of t h e c o n c r e t e measured on two c y l i n d e r s were 34.2 MPa (4952 p s i ) and 35.4 MPa (5138 p s i ) r e s p e c t i v e l y .During t h e t e s t t h e column was exposed t o h e a t i n g c o n t r o l l e d s o t h a t t h e a v e r a g e temperaure i n t h e f u r n a c e f o l l o w e d a s c l o s e l y a s p o s s i b l e t h e A S T M - E ~ ~ ~ ~ o r U L C - S ~ O ~ ~ s t a n d a r d temperature-time curve. T h i s c u r v e c a n b e approximately d e s c r i b e d by t h e f o l l o w i n g equation: Tf = 20

+

750 [l-exp(-3.79553Si)I+

1 7 0 . 4 1 f i ( 1 ) where Tf = t e m p e r a t u r e i n 'C, and T = t i m e i n h Tf 68+

1350 [1-exp(-3.79553Si)l+

3 0 6 . 7 4 f i ( 2 ) where Tf = t e m p e r a t u r e i n OF.During t h e t e s t , t e m p e r a t u r e s i n t h e f u r n a c e and i n t h e column were measured a t t h e l o c a t i o n s d e s c r i b e d e a r l i e r . The a x i a l

deformation of t h e column was a l s o measured. The column was c o n s i d e r e d t o have f a i l e d and t h e t e s t was t e r m i n a t e d when t h e h y d r a u l i c j a c k , which h a s a maximum speed of 76 mmfmin ( 3 in./min), c o u l d no l o n g e r m a i n t a i n t h e load.

TEST RESULTS

Measured Temperatures and Deformations

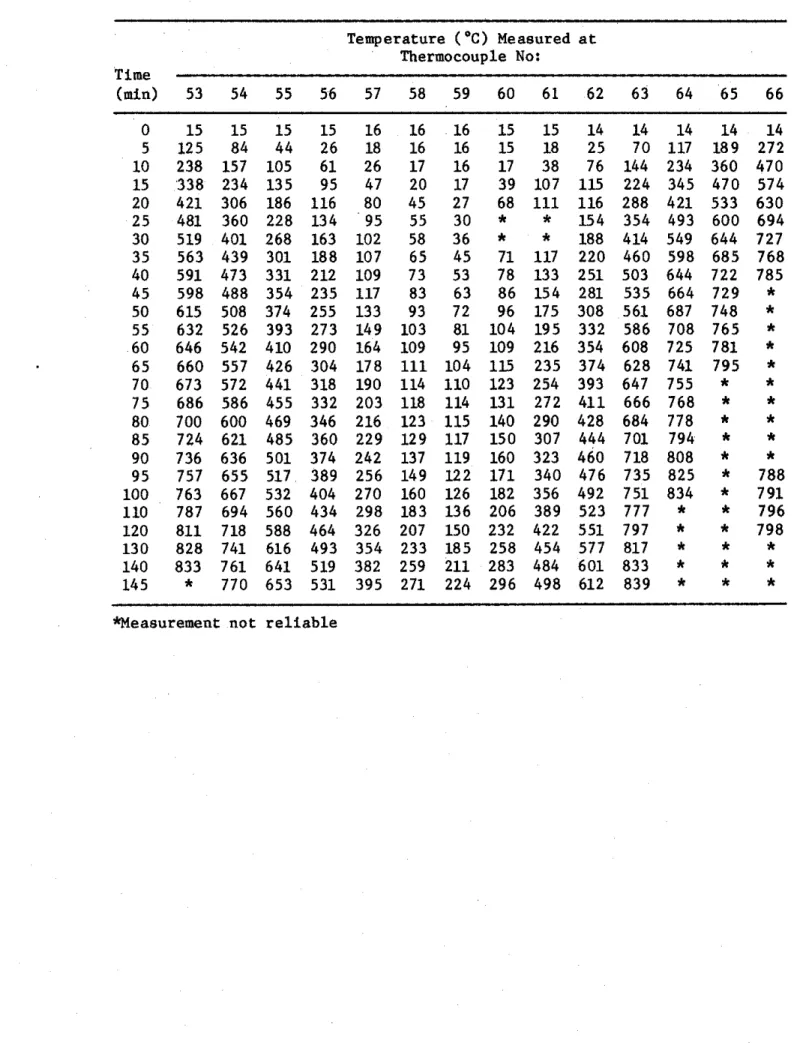

I n Table 5 t h e s t e e l t e m p e r a t u r e s a r e g i v e n f o r v a r i o u s t i m e s . The t e m p e r a t u r e s measured i n t h e c o n c r e t e s e c t i o n s a r e g i v e n i n T a b l e s

GA-D.

I n Table 7 t h e a v e r a g e f u r n a c e t e m p e r a t u r e and i n Table 8 t h e measured a x i a l d e f o r m a t i o n of t h e column a r e g i v e n f o r v a r i o u s t i m e s d u r i n g t h e t e s t .

The o b s e r v a t i o n s made d u r i n g t h e t e s t a f t e r v a r i o u s e x p o s u r e t i m e s a r e g i v e n on page 6.

T e s t Time

0:00 F i r e s t a r t e d .

0:27 Two s h o r t v e r t i c a l c r a c k s A and B appeared on t h e lower p o r t i o n of t h e e a s t f a c e of t h e column.

0:43 A h a i r l i n e crack C was seen on t h e upper a r e a of t h e s o u t h f a c e .

0:43 Two c r a c k s D and E became v i s i b l e on t h e upper e a s t f a c e . A

h a i r l i n e c r a c k

F

appeared on t h e n o r t h s u r f a c e .1:03 Cracks D and E extended t o j o i n t o g e t h e r . T h i s c r a c k DE was about 35 cm (14 i n . ) long.

1:05 Three more c r a c k s , I , G, and J were d e t e c t e d on t h e s o u t h face.

1:17 Column expansion due t o h e a t i n g reached i t s maximum v a l u e and s t a b i l i z e d .

1:21 Crack DE was now 45 cm (18 i n . ) long. A new c r a c k

H

appeared on t h eeast

f a c e .1:40 Crack DE widened t o 2 cm (3/4 i n . ) and extended t o a b o u t 60 cm (24 in.)

1:45 Crack K, about 90

cm

( 3 f t ) l o n g , was observed on t h e west f a c e .2:07 Crack DE was now about 1 cm (1/2 i n . ) wide.

2:26 A b i g e x p l o s i o n occurred. Column f a i l e d due t o c r u s h i n g of t h e c o n c r e t e . C o n c r e t e p i e c e s , 60-120 c m (2-4 f t . ) l o n g and 10-20 cm (4-8 i n . ) wide, f e l l from c r a c k s DE and K t o t h e f u r n a c e bottom.

F i g u r e 9 shows t h e g e n e r a l l o c a t i o n of t h e c r a c k s i n t h e c o n c r e t e a t 2 hours t e s t time.

F i g u r e 10 shows t h e t o p of t h e column a f t e r t h e t e s t .

DISCUSSION OF RESULTS

The method d e s c r i b e d i n r e f e r e n c e 9 was used t o c a l c u l a t e t h e t e m p e r a t u r e s of t h e main r e i n f o r c i n g s t e e l , and t h e t e m p e r a t u r e s a t v a r i o u s d e p t h s i n t h e c o n c r e t e s e c t i o n s . For t h e r e i n f o r c i n g s t e e l t h e t e m p e r a t u r e a t t h e c e n t e r h a s been chosen a s r e p r e s e n t a t i v e of t h e average t e m p e r a t u r e of t h e s t e e l .

F i g u r e 11 shows two average t e m p e r a t u r e s o b t a i n e d from measurements on two r e i n f o r c i n g b a r s d u r i n g t h e t e s t . These measurements were made w i t h thermocouples Nos. 3 and 9, l o c a t e d o p p o s i t e e a c h o t h e r w i t h r e s p e c t t o t h e c e n t e r of one b a r , and w i t h thermocouples Nos. 4 and 10, l o c a t e d o p p o s i t e each o t h e r on a n o t h e r b a r ( s e e Fig. 6 ) . The a v e r a g e of t h e t e m p e r a t u r e s measured a r e somewhat lower t h a n t h e c a l c u l a t e d t e m p e r a t u r e s and t h e average t e m p e r a t u r e measured w i t h thermocouples Nos. 3 and 9.

The t e m p e r a t u r e s measured on t h e s t e e l by t h e i n d i v i d u a l

thermocouples a r e shown i n F i g u r e 12. The d i f f e r e n c e i n t e m p e r a t u r e between two o p p o s i t e p o i n t s of t h e b a r

i s

r e l a t i v e l y small.The t e m p e r a t u r e s shown i n F i g u r e 13 were measured a l o n g a c e n t e r l i n e i n t h e c o n c r e t e s e c t i o n a t mid-height a t v a r i o u s d e p t h s . The curves show good agreement between measured and c a l c u l a t e d t e m p e r a t u r e s .

F i g u r e 14 shows t h e a x i a l deformation a s a f u n c t i o n of t i m e d u r i n g exposure t o a s t a n d a r d f i r e . The measured a x i a l d e f o r m a t i o n d u r i n g t h e test and t h o s e c a l c u l a t e d u s i n g t h e method d e s c r i b e d i n r e f e r e n c e 9 a r e shown. Up t o a b o u t 100 min, t h e r e i s good agreement between measured and c a l c u l a t e d a x i a l deformations. A f t e r t h i s , however, t h e measured r a t e of d e c r e a s e of d e f o r m a t i o n i s somewhat l e s s t h a n t h e c a l c u l a t e d deformation. The c a l c u l a t e d f a i l u r e t i m e was 1 2 1 minutes and t h e measured f a i l u r e t i m e was 146 minutes.

The comparison of measured and c a l c u l a t e d t e m p e r a t u r e s and

d e f o r m a t i o n s shows t h a t a l t h o u g h t h e p r e d i c t i o n s l i e on t h e s a f e s i d e , t h e d i f f e r e n c e s between them and t h e measured v a l u e s a r e n o t l a r g e .

1. Standard P r a c t i c e f o r P e t r o g r a p h i c Examination of Aggregates f o r Concrete (1979). ASTM C295-79, American S o c i e t y f o r T e s t i n g and M a t e r i a l s , P h i l a d e l p h i a , PA.

2. Standard S p e c i f i c a t i o n f o r Deformed and P l a i n B u l l e t - S t e e l Bars f o r Concrete Reinforcement (1 980). ASTM A615-80, American S o c i e t y f o r T e s t i n g and M a t e r i a l s , P h i l a d e l p h i a , PA.

3. Monfore, G.E. (1962). A Small Probe-Type Gauge f o r Measuring R e l a t i v e Humidity. J o u r n a l of t h e PCA Research and Development L a b o r a t o r i e s , Vol. 5, No. 2.

4. Reinforcing S t e e l Welding Code (1975). AWS-Dl2 .l-75, American Welding S o c i e t y , Manlius, NY.

5. Lie, T.T. (1980). New F a c i l i t y t o Determine F i r e R e s i s t a n c e o f Columns, Canadian J o u r n a l of C i v i l Engineering, Vol. 7, No. 3.

6 . Standard Methods of F i r e T e s t s of Building C o n s t r u c t i o n and

M a t e r i a l s (1979). ANSI/ASTM E119-79, American S o c i e t y f o r T e s t i n g and M a t e r i a l s , P h i l a d e l p h i a , PA.

7. Standard Methods of F i r e Endurance T e s t s of B u i l d i n g C o n s t r u c t i o n and M a t e r i a l s (1980). UL@SlOl-M1980. Underwriters' L a b o r a t o r i e s of Canada, Scarborough, Ontario.

8. L i e , T.T. and Harmathy, T.Z. (1972). A Numerical Procedure t o C a l c u l a t e t h e Temperature of P r o t e c t e d S t e e l Columns Exposed t o F i r e . F i r e Study No. 28, D i v i s i o n of B u i l d i n g Research, National Research Council of Canada, Ottawa, O n t a r i o , NRCC 12535.

9. L i e , T.T., Allen, D.E., Lin, T.D. and Abrams, M.S. F i r e R e s i s t a n c e of Reinforced Concrete Columns, D i v i s i o n of B u i l d i n g Research, National Research Council of Canada, Ottawa, t o be published.

TABLE 1 PETROGRAPHY OF SAND AND GRAVEL USED AS AGGREGATE

Composition of Sieve F r a c t i o n , Percent on Sieve of S i z e I n d i c a t e d Percent

Component Passing

19 mm 12.5 mm 9.5 m m 6 mm No. No. No. No. No. No. No. through

4 8 16 30 50 100 200 No. 200 - -- Granite 37.9 32.9 25.5 31.3 27 -0 27.6 12.3 7.4 1.9 4.4 0.6

-

Q u a r t z i t e 21.6 29.2 34.8 24.6 24.5 20.0 12.3 12.6 10.9 3.1 2.2--

Quartz 6.3 3.1 4.9 4.8 5.5 18.8 52.2 62.0 73.1 79.5 74.2 92.0 Sandstone-Quarts Conglomerate 1.9 0.8 3.1 5.1 5.5 8.3-

--

--

--

--

--

Rhyolite-Dacite 13.9 6.2 2.2 5.1 7.2 4.1 0.8 2.6 1.6 0.8 0.9--

Feldspar-

-

-

-

-

-

1.3 5.0 6.6 5.0 10.8 4.0 D i o r i t e 1.9 1.4 3.1 1.8 1.2--

-

--

--

-

--

-

Gneiss-Schist 2.5 5.1 10.5 9.3 7.5 4.1 6.4 1.8 0.9 1.1 0.6--

Basalt 1.9 4.5 4 .O 3.9 6.9 3.2 2.6 2.4 0.7-

0.3--

Mist. Igneous Rocks and Opaque Minerals-

0.3 0.9 0.6 0.6 1.5 2.1 1.2 2.0 5.3 7.0 2.0P a r t i c l e Shape 19 t o 6 rnm ( X ) No. 4 t o No. 16 (%) No. 30 t o No. 200

( % I

Subrounded t o rounded Subrounded t o subangular Angular

a " ~ r o n s t o n e , " made up of j a s p e r and hematite, i s included i n t h e c h e r t c l a s s i f i c a W n . b ~ n e l u d e s metagraywacke.

%he miscellaneous igneous rocks were s e v e r e l y a l t e r e d and p o s i t i v e i d e n t i f i c a t i o n was i q o s i b l e . The opaque minerals occurred i n t h e No. 50 and smaller s i e v e s i z e s and were l a r g e l y magnetite.

TABLE

2

PHYSICAL PROPERTIESOF

AGGREGATE S p e c i f i c g r a v i t y of s a n d S p e c i f i c g r a v i t y of g r a v e l Moisture c o n t e n t of s a n d , % Moisture c o n t e n t of g r a v e l , X S a t u r a t e d s u r f a c e d r y u n i t weight of g r a v e l , kg/m3 F i n e n e s s modulus of f i n e a g g r e g a t e F i n e n e s s modulus of c o a r s e a g g r e g a t eTABLE

3

BATCH QUANTITIESItem Q u a n t i t y (kg/m3) Cement

307.3

Coarse a g g r e g a t e1054.3

Sand871.5

Water153.7

TABLE

4

PROPERTIES OF THE CONCRETEP r o p e r t y Q u a n t i t y

A i r c o n t e n t , %

1.81

D e n s i t y , kg/m3

2393

Compressive s t r e n g t h a t

28

d a y s , MPaTABLE 5 MEASURED STEEL TEMPERATURES Temperature ( O C ) Measured a t Thermocouple No: Time ( m i d 1 2 3 4 5 6 7 8 9 10 50 197 243 230 5 5 221 267 255 60 244 289 280 6 5 266 309 302 70 287 328 324 75 307 345 344 80 327 362 364 8 5 346 378 382 90 364 394 400 9 5 382 409 418 100 400 424 436 110 435 454 469 120 467 483 500 130 497 513 530 140 524 545 562 14 5 536 563 582 *Measurement n o t r e l i a b l e

TABLE 6A CONCRETE TEMPERATURES MEASURED WITH THERMOCOUPLES I N

FRAME

ATemperature ( OC) Measured a t Thermocouple No: Time ( m i d 11 12 13 14 15 16 17 18 19 20 21 22 23 24 0 21 20 21 21 21 21 21 21 21 20 20 20 20 20 5 126 96 47 32 22

*

x*

23 33 67 118 178 269 1 0 231 173 104 67 30 21 2 1 21 33 84 141 222 341 466 1 5 330 256 130 99 50 24 21 28 84 127 207 332 461 585 20 415 332 178 123 73 33 24 42 105 143 280 418 547 665 25 481 392 221 146 104 50 29 47*

175 343 487 614 716 30 524 438 259 174 104 63 37 57 105 225 398 540 661 856 35 567 478 291 201 104 71 46 67 116 279 447 586 708*

40 602 512 324 229 107 78 55 76 133 322 492 633 745*

45 609 528 350 255 117 8 5 64 86 150 357 528 657 747*

50 628 547 373 277 131 92 72 97 168 387 555 681 670*

55 647 567 394 297 145 99 81 108 187 412 583 704 716*

60 664 585 413 316 160 108 92 117 207 434 608 723 736*

6 5 680 603 432 333 174 115 101 125 227 454 630 740 750*

70 695 620 449 349 186 122 109 132 247 472 650 756 762*

75 709 636 465 364 198 129 115 139 266 490 669 770 771*

80 721 650 480 378 209 135 121 145 284 506 685 782 777*

8 5 746 670 495 391 219 1 4 1 126 152 301 521 702 800 787*

90 758 684 509 404 229 147 130 159 318 536 718 816 789*

9 5 776 702 524 417 239 1 5 3 133 169 334 551 734 833 791*

100 783 712 538 430 250 159 136 180 350 567 750 845*

*

110 804 736 563 456 275 178 142 202 382 599 774 867*

~r 120 823 755 589 482 302 199 150 224 412 629 796 883*

x 130 841 775 615 509 332 222 165 247 442 656 818*

x x 140 856 793 638 534 361 247 193 271 470 677 834*

*

x 145*

802 650 545 375 260 207 284 484 686 840*

*

*

XMeasurement n o t r e l i a b l eTABLE 6B CONCRETE TEMPERATURES MEASURED WITH THERMOCOUPLES I N

FRAME

B - - Temperature ("C) Measured a t Thermocouple No: Time (min) 25 26 27 28 29 30 31 32 33 34 35 36 37 3 8 0 1 8 19 19 19 5 143 86 48 30 10 266 165 104 66 15 369 246 143 100 20 452 319 194 118 25 519 379 239 146 30 556 423 281 180 35 595 460 314 209 40 620 492 344 234 45 623 505 366 256 50 642 525 386 274 55 662 544 406 294 60 679 563 426 313 65 696 582 445 332 70 712 599 463 350 75 726 615 480 367 80 741 630 496 384 8 5 768 652 513 400 90 780 668 529 416 95 802 687 546 432 100 808 699 561 447 110 830 727 592 476 120 854 750 620 503 130*

773 648 529 140*

791 672 553 145*

798*

566 *Measurement n o t r e l i a b l eTABLE 6C CONCRETE TEMPERATURES MEASURED WITH THERMOCOUPLES I N FRAME C Temperature ( " C ) Measured a t Thermocouple No: Time (min) 39 4 0 4 1 4 2 4 3 4 4 45 46 47 4 8 4 9 5 0 5 1 5 2 measurement not r e l i a b l e

TABLE 6D CONCRETE TEMPERATURES MEASURED WITH THERMOCOUPLES I N

FRAME

DTemperature ( OC) Measured a t

Thermocouple No: Time (min) 53 54 55 56 57 58 59 60 61 62 63 64 65 66 0 1 5 15 1 5 15 16 16 16 1 5 15 14 14 14 14 14 5 125 84 44 26 18 16 16 15 18 25 70 117 189 272 1 0 238 157 105 61 26 17 16 17 38 76 144 234 360 470 15 338 234 135 9 5 47 20 17 39 107 115 224 345 470 574 20 421 306 186 116 80 45 27 68 111 116 288 421 533 630 25 481 360 228 134 95 55 30

*

*

154 354 493 600 694 30 519 401 268 163 102 58 36*

*

188 414 549 644 727 35 563 439 301 188 107 65 45 71 117 220 460 598 685 768 40 591 473 331 212 109 73 53 78 133 251 503 644 722 785 45 598 488 354 235 117 8 3 63 86 154 281 535 664 729*

50 615 508 374 255 133 93 72 96 175 308 561 687 748*

55 632 526 393 273 149 103 81 104 195 332 586 708 765*

60 646 542 410 290 164 109 95 109 216 354 608 725 781*

6 5 660 557 426 304 178 111 104 1 l 5 235 374 628 741 795*

70 673 572 441 318 190 114 110 123 254 393 647 755*

*

75 686 586 455 332 203 118 114 131 272 411 666 768*

r~ 80 700 600 469 346 216 123 115 140 290 428 684 778*

x 8 5 724 621 485 360 229 129 117 150 307 444 701 794*

*

90 736 636 501 374 242 137 119 160 323 460 718 808*

*

9 5 757 655 517 389 256 149 122 171 340 476 735 825*

788 100 763 667 532 404 270 160 126 182 356 492 751 834*

791 110 787 694 560 434 298 183 136 206 389 523 777*

*

796 120 811 718 588 464 326 207 150 232 422 551 797*

*

798 130 828 741 616 493 354 233 185 258 454 577 817*

*

x 140 833 761 641 519 382 259 211 283 484 601 833*

x x 145*

770 653 531 395 271 224 296 498 612 839*

*

*

*Measurement n o t r e l i a b l eTABLE 7 AVERAGE FURNACE TEMPERATURE

Time Temperature Time Temperature ( m i d ( "C) b i n ) (

"0

TABLE 8 MEASURED AXIAL DEFORMATION OF COLUMN

Time Deformation Time Deformation Time Deformation ( m i d

(4

(min) (mm) (min)(mm)

0 0 501.1

100 -0.2 5 0.2 5 5 1.1 10 5 -0.3 10 0.4 60 1.1 110 -0.7 15 0.9 6 5 1.1 1 15 -1.2 20 1.1 70 0.8 12 2 -1.7 25 1.1 7 5 0.8 125

-2.0 30 1.1 80 0.7 130 -2.7 3 5 1.1 8 5 0.613

5 -3.5 40 1.1 90 0.4 140-4.3

45 1.1 9 5 0.1 14 5 -5.5-

s i g n i n d i c a t e s c o n t r a c t i o n of column p a s t i n i t i a l s t a r t i n g p o s i t i o n100

50

30

16

8

4

9.5

19

37.5

m m

mrn

m m

S T A N D A R D S I Z E OF S Q U A R E M E S H S I E V E

F I G U R E 1

P L A T E

P L A T E

F I G U R E 2

S E C T I O N A - A

TIC

F R A M E C

O N F R O N T

S E C T I O N B - B

TIC

F R A M E

F I G U R E

3

L A Y O U T O F T H E R M O C O U P L E F R A M E S

T/C

FRAME

17 16 15 14 13 12 11 A 3130

29 28 27 26 25 B 45 44 43 42 41 4 0 3 9 C 59 58 57 56 55 5453

D F I G U R E 4 L O C A T I O NA N D

N U M B E R S O F T H E R M O C O U P L E S I N A S E C T I O N48 mm CLEAR COVER TO TIC 4, 5, 6, 10 &IN,RE;~:ING BAR

4 25 M BAR

THICK STEEL PLATE 7 I

F I G U R E 5

S E C T I O N A - A S E C T I O N 8 - 8 ( F R O N T ) ( F R O N T ) S E C T I O N C - C S E C T I O N D - D T / C 4

-

. _ r - - - r - - - 1TIC

l o-

-LP

I I I I I I L- - -

J ( F R O N T ) ( F R O N T ) A L L S E C T I O N S A R E V I E W E D F R O N T O R D O O R S I D E F R O M THE T O P ( E A S T ) F I G U R E 6 T H E R M O C O U P L E S O N R E I N F O R C I N G B A R S (305 m m x 305 m m C O L U M N )FIGURE 7 TEST FURNACE

D O O R ( E A S T S I D E ) S I D E V I E W

I

F I G U R E 8 L O C A T I O N A N D N U M B E R S OF T H E R M O C O U P L E S I N C O L U M N F U R N A C E C H A M B E RE A S T W E S T

N O R T H S O U T H

F I G U R E 9

FIGURE 10

I

----

-

C A L C U L A T E D M E A S U R F D , A V E R A G E T I C 3 . 9 .- -

.-

M E A S U R I D . A V E R A G E T I C 4 , LO-

-

.-

-

/ I T I M E , m i n F I G U R E 11 C A L C U L A T E D A N D M E A S U R E D A V E R A G E T E M P E R A T U R E S O F M A I N R E I N F O R C I N G B A R S T H E R M O C O U P L E N O .---

U l o o.---

----

10 T I M E , m i n F I G U R E 12 T E M P E R A T U R E S M E A S U R E D O N M A I N R E I N F O R C I N G B A R S1 0 0 0 r I C A L C U L A T E D