Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

CIB 2004 Conference Proceedings, pp. 1-6, 2004-05-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=6c0dee05-aa84-4a49-8ad6-11635e91845e https://publications-cnrc.canada.ca/fra/voir/objet/?id=6c0dee05-aa84-4a49-8ad6-11635e91845e

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

The Benefit of intended-use (performance-based) standards in support

of objective-based codes

The Benefit of intended-use (performance-based)

standards in support of objective-based codes

Di Lenardo, B.; Cécire, L.; Poirier, G.; Waters, R.

NRCC-47357

A version of this document is published in / Une version de ce document se trouve dans :

CIB 2004 Conference Proceedings, Toronto, Ontario, May 1-7, 2004, pp. 1-6

The Benefit of Intended-Use (Performance-Based) Standards in Support of Objective-Based Codes CIB 2004 Conference

T5S4 Performance Based Codes and Standards

Bruno Di Lenardo, Luc Cecire, Gilles Poirier, Ron Waters Abstract

In many countries a move towards performance-based codes has already begun with varying degrees of success. In Canada, the move is currently underway towards objective-based codes where the

objectives are articulated around the acceptable solutions. In dealing with innovation as an alternate solution there will remain a complexity for verifying compliance. To compliment objective-based codes, the standards community could undertake the development of performance-based standards for an explicit ‘intended use’ which could be universal and apply to innovation as an alternate solution.

This paper explores the benefits and complexity involved for developing performance-based standards for the intended use of a construction material or system. These standards would be universal and assist in product/system compliance verification for innovation meeting the code objectives. The paper presents a case study of Canadian insulation industry that is primed for the development of performance-based standards for their industry.

INTRODUCTION

In Canada, the building regulatory system is moving towards the use of an Objective-Based Code (OBC). A national public review process has been completed and the OBC should be published in 2005 and adopted into regulation by the Provinces shortly afterwards. After adoption many building officials may see very little impact on their current task of code compliance verification. The current building codes, with technical updates, continue to be the requirements which are considered ‘acceptable solutions’ meeting the objectives of the codes. In dealing with new and innovative products as an ‘alternate solution’ in the objective-based code, the objectives, the sub-objectives and functional statements will provide more guidance than currently exists in assessing the compliance of innovation.

Bergeron et al1 explains that alternate solutions within an objective-based code format will be assessed based on ‘first principles’ against the objectives and performance requirements outlined in the OBC. For the acceptable level of performance the current acceptable solutions can be used as a ‘benchmark’ for the same function or intended use. In Canada, the Canadian Construction Materials Centre (CCMC), the country’s national construction evaluation service, conducts the majority of evaluations of innovative products that building officials often rely upon for their compliance verification. The CCMC, since its inception in 1988, has been producing Technical Guides that outline performance-based protocols and criteria to be met by the innovation to meet the intent of the current National Building Code of Canada. The CCMC, in many cases, has essentially been developing testing protocols based on first principles and establishing acceptance criteria based on current code benchmarks, very much in line with the anticipated objective-based code process. However, much more explicit guidance will now be available with published objectives, sub-objectives and functional statements relating to the requirements contained in the OBC.

Author’s Note

Bruno Di Lenardo, P. Eng., is currently an Evaluation Officer with the Canadian Construction Materials Centre (CCMC), Institute for Research in Construction (IRC), National Research Council of Canada (NRC), Ottawa, Canada.

Luc Cecire, P. Eng., is currently an Evaluation Officer with the CCMC, IRC, NRC, Ottawa, Canada. Gilles Poirier, P. Eng., is currently an Evaluation Officer with the CCMC, IRC, NRC, Ottawa, Canada. Ron Waters, P. Eng., is currently an Evaluation Officer with the CCMC, IRC, NRC, Ottawa, Canada.

CCMC Technical Guides have been developed for products on a case-by-case basis based on individual product submissions. In developing these Technical Guides the CCMC has collaborated with experts from many technical fields and disciplines to develop an evaluation approach and criteria to assess product performance. Based on this experience and interaction with industry and the research community over the years, there exists adequate knowledge to develop universal performance-based protocols and criteria for entire classes of products and systems for specific intended uses. These performance-based approaches could be incorporated into standards to assist industry and to compliment the objective-based code.

Standards Development Intended-Use Performance Standards

Most product standards are currently prescriptive in nature and are dedicated to a specific ‘material’, which is represented by a specific manufacturing industry. An example is in top row shown in Figure 1 below representing the Canadian insulation industry and the Canadian respective insulation materials. There standards are entirely insulation ‘material’ specific. It is acknowledged, that although the current insulation standards may be prescriptive some specified material properties are indirectly linked to some historically ‘known’ underlying acceptable field performance. Unfortunately over the years the paper trail and knowledge-base has not been maintained on the underlying link to performance. This has resulted in many product standards being considered by many to be no more that product specifications.

In Canada there is a rapidly changing insulation industry, with new industry players in the marketplace, and ever changing member participation on standard committees. Because standards have an unclear link to performance, there is confusion within some standard committee members surrounding the prescribed physical properties, the accelerated aging protocols, the test conditions specified and the assigned criteria. There is added confusion when manufacturers attempt to expand the standard to qualify for other intended uses within the building envelope. For example, an insulation attempting to qualify for air leakage control, in addition to providing thermal resistance could result in the individual insulation material standards going off in different directions. Industry’s attempt to include more than one ‘intended-use’ within the same standard invariably leads to confusion within committee discussions with respect to properties and criteria important to one or both intended uses. This situation needs to be rationalized to become more productive and efficient if we are to deal with a compendium of technical issues and set in motion, and maintain, the link with the objectives of the OBC.

One suggestion is to allow for two distinct streams of standards development. One stream would apply to for the current crop of product standards that are material-specific and a second stream would apply to performance-based standards that would be ‘intended-use’ specific as shown in Figure 1 below. Many of the benefits of performance-based standards are similar to the benefits of the objective-based code format2, namely:

• greater flexibility in application

• improved clarity of requirements

• greater ease of use

• reduced need for change

• more responsive to innovation, and

FIGURE 1. Two Standards Development Streams Current Material Standards & Intended Use (New).

With the current stream of insulation material standards, the respective insulation industry would continue to set the grade for the material properties and quality of material they agree to release into the

marketplace. This scenario exists now and would be business-as-usual as the second performance-based stream is developed and these new intended-use standards put in place. The second stream would involve the creation of standards committees that would focus only on the performance for the intended-use giving consideration to the environmental effects of that intended performance for the specific application. The fundamental performance of insulation is to provide the anticipated thermal resistance for the anticipated service life of the building. The second stream committees would consider the service life the insulation would be subjected to in terms of the environmental conditions (i.e. temperature cycles, condensation & drying cycles, etc.) within the building envelope.

For instance, insulation materials intended for above-grade walls would be subjected to temperature and humidity cycles as well as condensation-and-drying cycles. For roof applications, the summer

temperatures would be higher so higher temperatures would be in the conditioning protocol before thermal resistance values are assessed. Insulations which are subject to high-temperature degradation would be appropriately de-rated or possibly disqualified for use in roof applications. For below-grade applications, with moisture present and soil pressure to resist, the performance protocol would address conditioning to simulate these effects before the thermal performance is assessed. The committee members would have to agree on the conditioning parameters, the length of conditioning time, etc. Much would be regional climate dependent and various grades or qualification classes could be established for the regulators to choose the level of performance being sought in their jurisdiction.

Once the second stream is established it will benefit both innovative insulations and current ‘acceptable solutions’ insulation materials that would like to qualify for another intended-use. New and innovative insulations such as Open-Cell Foams (OCFs), shown in Figure 1, do not have a current product standard but one is under development. The innovative OCF insulations could initially qualify as a suitable ‘wall insulation’ to obtain entry into the marketplace until the industry product standard is completed. Some insulations may qualify for above-grade-walls and roofs only, such as many fibrous insulations, and will be designated for walls and roofs only. Other insulations, such as foam plastics, may qualify for all intended uses for walls, roofs and below-grade. In addition, insulation systems that can also be used for air leakage control (i.e. designated air barrier system within the building envelope) within a certain system design, could attempt to qualify to a performance-based air barrier system standard. Similarly, an

insulation acting as a vapor barrier for vapour diffusion control, could qualify as the vapour barrier for the building envelope in meeting a performance-based vapour barrier standard.

Certain insulations, by meeting the respective performance standard, could qualify for use in providing all three functions of thermal resistance (i.e. condensation control), air leakage control and vapour diffusion

control. The proposed performance-based stream for intended-use in the building is an excellent way to qualify the minimum expected performance for any material/system. The requirements would be generic and universally applicable to all materials and would go along way in helping industry understand the expectations of product/system performance.

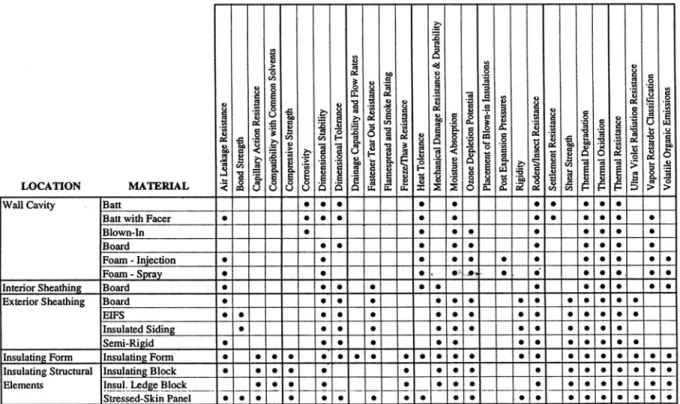

In Canada, some discussion has begun for the development of intended-use insulation standards. The Canadian insulation industry engaged a consultant3 to compile and rationalize the relevant properties of all insulations for various applications. Table 2 below illustrates the results of this study. This table is for insulations for above-grade wall insulations based on ‘location’ of the built element within the wall assembly as listed in the first column. The upper row lists the material characteristics or performance attributes that need to be addressed.

TABLE 2. Compendium of Above-grade Insulation Types and Properties.

For each type of insulation material & location some of the performance attributes were judged less important or not relevant and were discounted by the consultant. However, some fundamental performance characteristics are expected of most insulations, such as: thermal resistance, thermal oxidation, thermal degradation, rodent/insect resistance, moisture absorption and dimensional stability. This could be considered a good starting point for establishing a performance-based protocol and criteria that applies to all insulations while other material-specific attributes may be more suited to remain within the industry material insulation standard. The challenge for the scientific community and industry is to devise a universal test procedure capturing these six fundamental properties that are applicable to all insulation product types (i.e. boards, batts, loose-fill, spray insulation). While this universal protocol is achievable, a motivated driving force is lacking to set this development in motion.

Performance and Durability CSA Guideline on Durability in Buildings

If the development of universal intended-use standards are put in motion a crossroad will be reached where a decision is necessary on the expected level of durability or resistance to environmental

conditions within the building envelope. The Canadian Construction Materials Centre (CCMC), along with many other product assessment or product evaluation bodies across the globe, have had to develop both

performance-based protocols and criteria and also address the durability issue to meet the intended, although implicit, durability performance within building codes. So there is a plethora of performance-based protocols already in use dealing with the performance and durability of materials. One example discussed below is the CCMC Technical Guide for “Air Barrier Systems of Exterior Walls of Low-Rise Buildings”4 developed in 1995.

This Technical Guide has two sections: the air barrier system qualification protocol and the durability assessment. The first section for the air barrier system is completely performance-based and is applicable to any material/system that seeks to qualify as an air barrier system. This first section could become the first section of performance-based standard for the second stream of performance-based standards for intended use proposed above. The second section in assessing the durability of the air barrier system reverts to a durability of the component ‘material’ in a prescriptive manner rather than a universal performance-based approach to addressing durability of the air barrier system. There were many reasons for this including: 1) many accelerated aging standardized test methods are intended for small-scale specimens as opposed to full-scale specimens, 2) industry did not appear ready to accept a departure from the current approach of material tests specified within their respective industry standards and 3) potentially prohibitive qualification costs if the technical guide deviated from current accepted small-scale prescriptive approaches.

That was the situation in 1995, however, since then there have been many changes in the mindset of many industry players. Many see the value in performance-based full-scale testing and the

durability/degradation assessment of the full-scale specimen before-and-after aging. When the performance-based protocol and criteria are representative of the field situation, manufacturers realize the benefit of the product’s successful testing in providing an assurance that their product will perform in the field. Conversely, manufacturers also see the benefit if they discover that their products do not do well, demonstrating a product they may not want to introduce in the marketplace without further improvements. With the current knowledge in degradation mechanisms of materials and increasing availability of full-scale test equipment with environmental chambers the time is right for developing universal performance-based protocols and criteria for many building materials. To facilitate this task the committee can take advantage of the CSA S478-1995 standard, Guideline on Durability in Buildings. The CSA S478-1995 standard is a comprehensive document intended to guide designers and building owner/user on how they can address the durability/service life expectations of all building components. The document outlines the various degradation mechanisms that can adversely affect all aspects of a building and on an item-by-item basis the owner can verbalize his expectations and the designer can then begin the selection of appropriate materials and designs to meet the expectations. This CSA Guideline could be used for the durability portion for each intended use standard in performance based terms. Acceptance Criteria Setting

To facilitate the decision maker with selection of the grade of product that would most suit their respective needs, the performance-based standard committee could establish a multitude of classes, for example 3 to 5 classes, of durability levels for which the products may qualify. These classes would provide a relative scale for selecting an acceptable ‘minimum’ for a jurisdiction or a higher level as specified by a designer or an owner. The actual performance in the field would always be dependent on the regional climate and exposure of the product and the regulator could take this into account by also choosing a level of redundancy.

CONCLUSIONS

The intent of this paper is to signal that the time is ripe within the construction industry for a discussion and debate on the development of performance-based standards for the intended use in the building. The development of these standards would:

• clarify intended requirements and assist manufacturers in developing a better understanding performance expectations of their products and under what environmental conditions.;

• provide clarity for more focused construction product development and innovation;

• provide a universal protocol that would not need to change unless an adjustment to the protocol is warranted;

• the clarity provided by an intended-use standard would facilitate discussions between the manufacturing industry and user groups.

Although the examples given above for insulations and air barrier systems appear ready-to-go there remains some work to be done and decisions to be made. In Canada, this could take a few years to develop and more years to be incorporated into the OBC. For these benefits of intended-use standards to be put into practice, someone must lead the discussion and champion the cause on behalf of all the construction industry stakeholders which would support and benefit from this initiative.

References

1. Bergeron, Denis, Bowen, Bob, Tubbs, Beth, Rackliffe, Tony, “Acceptable Solutions”, CIB World Congress, April 2001, Wellington, NZ

2. Chauhan, Raman B., “The Canadian Approach to Fire Safety-Objective-Based Building Codes for 2001”, Proceedings, Pacific Rim Conference of Building Officials and 2nd International Conference of Performance-Based Codes and Fire Safety design Methods. May 3-9, 1998

3. Gerald R. Genge Building Consultants Inc., “Study of Thermal Insulation Standards for Residential Applications”, submitted to The Canadian Coordinating Committee for Thermal Insulation Standards and Quality, March 1995.

4. IRC Publication, “Air Barrier Systems for Walls of Low-Rise Buildings: Performance and Assessment”, March 1997.

Bibliography

1. Beller, Doug, “Risk, Reliability and Performance-Based Codes and Standards”, Clark University Workshop on Use of Risk Concept in Performance Based Building and Fire Regulation

Development, 1999.

2. CSA S478-1995, “Guideline on Durability in Buildings”.

3. Bukowski, Richard W., “The Role of Standards In a Performance-based Building Regulatory System”, Proceedings, Society of Fire Protection Engineers and American Institute of Architects. September 17-18, 2002, Baltimore, MD, 15-24 pp, 2002 AND Performance-Based Codes and Fire Safety Design Methods, 4th International Conference. Proceedings. March 20-22, 2002, Melbourne, Australia. 4. Bukowski, Richard W., Hirano, Yossy, Tackcliffe, Tony, “Standard Linkages to a Performance-Based

regulatory Framework”, NIST Building and Fire Laboratory, USA, Building Research Institute of Japan and The British Board of Agrement, UK.