Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

CONCREEP 7 Workshop on Creep, Shrinkage and Durability of Concrete and

Concrete Structures [Proceedings], pp. 579-584, 2005-09-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=da353c26-0fba-4c52-b6f9-7a92ebb5e5aa https://publications-cnrc.canada.ca/fra/voir/objet/?id=da353c26-0fba-4c52-b6f9-7a92ebb5e5aa

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Internally-cured high-performance concrete under restrained shrinkage

and creep

Internally-cured high-performance concrete under

restrained shrinkage and creep

Cusson, D.; Hoogeveen, T.

NRCC-48141

A version of this document is published in / Une version de ce document se trouve dans :

CONCREEP 7 Workshop on Creep, Shrinkage and Durability of Concrete

and Concrete Structures, Nantes, France, Sept. 12-14, 2005, pp. 579-584

Concreep7 Workshop on Creep, Shrinkage and Durability of Concrete and Concrete Structures, Nantes, France, 12-14 September 2005, pp. 579-584.

Internally-cured high-performance concrete

under restrained shrinkage and creep

Daniel Cusson – Ted Hoogeveen

National Research Council Canada, Institute for Research in Construction 1200 Montreal Road, Building M-20, Ottawa, Canada, K1A 0R6

Daniel.Cusson@nrc-cnrc.gc.ca; Ted.Hoogeveen@nrc-cnrc.gc.ca

ABSTRACT: This paper presents the results of structural laboratory testing of large prismatic high-performance concrete (HPC) specimens under restrained shrinkage and tensile creep. The structural behaviours of concrete specimens having different amounts of pre-soaked structural lightweight aggregate (SLWA) are compared. The results show that the use of SLWA in HPC can effectively prevent autogenous shrinkage when compared to the control

HPC, which exhibited a large shrinkage strain of –260 µε within 24 hours. The quantities of

SLWA used in HPC (up to 20% sand replacement) did not adversely affect the slump, air content, strength, or modulus of elasticity.

KEYWORDS: high-performance concrete; restrained shrinkage; tensile creep, internal curing

1. Introduction

High-performance concrete (HPC) made with low water-cement ratio often exhibits early cracking due to self-desiccation. A research program is underway at the National Research Council to develop low-shrinkage HPC for the design of cost-effective and durable concrete structures. This paper presents the test results of large prismatic HPC specimens under restrained autogenous shrinkage. Structural lightweight aggregate (SLWA), made of porous expanded shale, was used to provide effective internal curing and reduce self-dessication and cracking of HPC.

The testing system and methods developed for studying restrained shrinkage and creep of HPC present some new features over existing approaches (Kovler 1994; Bjontegaard et al. 1999). Large specimens with a size of 200x200x1000mm enabled the study of the behaviour of concrete elements that can include coarse aggregate and reinforcing bars. The system imposes restrained shrinkage with a preset degree of restraint, for which the restraining load is transferred to concrete by four continuous embedded reinforcing bars. This is considered to be representative of the field conditions for reinforced concrete structures with restrained shrinkage. A clear advantage of using a degree of restraint lower than unity is that restrained shrinkage testing can be conducted without failing high-shrinkage concrete specimens.

2 Concreep7

2. Experimental program

The control concrete (identified as CTRL) used ASTM Type 1 cement, had a cement-sand-aggregate ratio of 1:2:2 and a water-cement ratio of 0.34. Two variations of this mix design included 6% and 20% replacements of normal-weight sand by pre-soaked structural lightweight aggregate, identified as SLWA-L and SLWA-H, respectively. The use of SLWA was not found to affect the slump or air content. After placing the concrete, the forms were not removed during testing to avoid disturbing the sensors and to prevent thermal shock. For each type of concrete tested, all specimens and samples were prepared from the same batch of concrete and sealed with plastic sheets to prevent external drying shrinkage during testing.

Figure 1 presents the main test setup. The axial strain was measured with electrical strain gauges placed at the centre of the four 10-mm rebars. The test apparatus included a closed loop servo-hydraulic system to control the actuator, using the rebar-mounted strain gauges as the feedback signal for the control loop. The force, measured by a load cell, was transmitted to the concrete by the rebars with their ends welded to the stiff end plates connected to the rigid test frame.

An unrestrained companion specimen was also prepared with no reinforcement. Free shrinkage was measured with LVDTs placed at both ends of the specimen. Two relative humidity (RH) sensors were placed in the specimen for the determination of internal drying due to self-desiccation. Thermocouples (TC) were embedded in concrete and placed on steel bars at the locations shown in Figure 1.

50mm cover 10mm rebars SG and TC at midlength of each rebar Fixed end connected to stiff frame Pinned end connected to actuator Cross-section (200x200mm) Cross-section (200x200mm)

Elevation of restrained specimen (1000x200mm) Elevation of unrestrained specimen (1000x200mm)

TC

LVDT RH/T

RH/T

TC

Internally-cured HSC under restrained shrinkage 3

Additional tests were also conducted in parallel on small concrete samples, including thermal expansion coefficients, and compressive and tensile strengths at different times. The temperature history was measured for each concrete specimen and sample, and maturity was calculated for each size of specimen in order to consistently use the different sets of results in the calculations (Cusson et al. 2005).

3. Analysis of results

All specimens were tested under realistic temperature regimes. The temperature of concrete reached 45°C approximately 12 hours after casting and returned to 25°C two days after casting. The concrete temperature was used to define the time of initial setting – time at which strains and stresses were zeroed for the calculations. The theoretical background is presented elsewhere (Cusson et al. 2005).

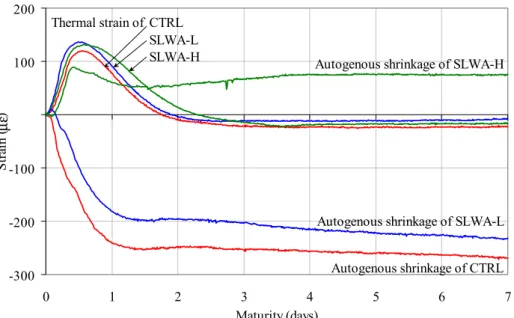

3.1. Free shrinkage testing

Figure 2 presents the autogenous shrinkage and thermal strains as functions of maturity. The three concrete specimens had similar thermal strains with peak values near 135 µε. The SLWA-L specimen had a small improvement in shrinkage over the control, while the SLWA-H specimen exhibited a drastic improvement with an initial expansion, which was maintained thereafter. The results show that most autogenous shrinkage caused by internal drying developed within 1 day of setting. This observation suggests that the prevention of autogenous shrinkage cracking in HPC structures should involve techniques that must be effective shortly after setting.

0

Figure 2. Concrete strains in unrestrained specimens -300 -200 -100 100 200 0 1 2 3 4 5 6 7 Maturity (days) St ra in ( µε ) Autogenous shrinkage of CTRL Thermal strain of CTRL SLWA-L

Autogenous shrinkage of SLWA-L Autogenous shrinkage of SLWA-H SLWA-H

4 Concreep7

3.2. Restrained shrinkage testing

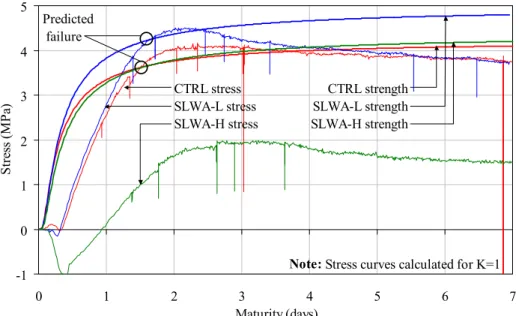

In order to avoid failing the CTRL and SLWA-L specimens during testing, a degree of restraint close to 0.9 was maintained. For the SLWA-H specimen, a degree of restraint close to 1.1 was imposed during testing (i.e. the system was actually pulling slightly on the specimen). Figure 3 illustrates the normalised concrete stress in the large specimens compared to the best fits of their corresponding splitting tensile strengths measured on 100x200 mm cylinders. Each stress curve shown in the figure is the actual stress measured in concrete divided by the degree of restraint used in the experiment. This normalised stress represents the stress that would be obtained in a restrained shrinkage test with a full degree of restraint (K=1).

The CTRL and SLWA-L specimens performed similarly with a predicted failure at about 1.5 days of maturity under full restraint (K=1). The SLWA-H specimen displayed an initial expansion resulting in compressive stresses during the first day, followed by low tensile stresses thereafter. With a maximum tensile stress/strength ratio obtained near 3 days of maturity, the use of SLWA in the amount of 20% sand replacement proved very effective in reducing the risk of cracking in HPC. Note that, although the SLWA-H specimen displayed positive values of shrinkage (expansion) during the 7 days of testing (Figure 2), tensile stresses were generated in the specimen after the first day. This is the combined effect of the major decrease in thermal stresses due to the cooling between 0.5 day and 2 days, and the very rapid increase in the modulus of elasticity at the same time.

Figure 3. Concrete stresses in restrained specimens -1 0 1 2 3 4 5 0 1 2 3 4 5 6 7 Maturity (days) S tre ss (M P a) Predicted failure CTRL stress SLWA-L stress SLWA-H stress CTRL strength SLWA-L strength SLWA-H strength

Internally-cured HSC under restrained shrinkage 5

4. Discussion

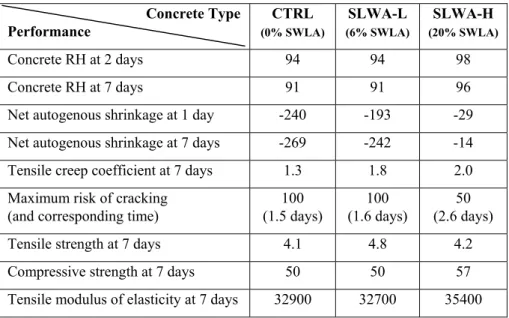

Table 1 summarises some of the key results and enable the comparison of the three concrete specimens. The SLWA-L specimens with 6% sand replacement offered a negligible reduction in concrete RH, a moderate increase in the creep coefficient, a small reduction in autogenous shrinkage, and no significant improvement in the risk of cracking over the control concrete specimens. The strengths and modulus of elasticity were not adversely affected by the addition of SLWA. It is clear that a 6% sand replacement for the HPC used in this study is not enough to provide substantial reductions in shrinkage and risk of cracking.

Table 1. Measured performance results for the different concrete specimens Concrete Type Performance CTRL (0% SWLA) SLWA-L (6% SWLA) SLWA-H (20% SWLA) Concrete RH at 2 days 94 94 98 Concrete RH at 7 days 91 91 96 Net autogenous shrinkage at 1 day -240 -193 -29 Net autogenous shrinkage at 7 days -269 -242 -14 Tensile creep coefficient at 7 days 1.3 1.8 2.0 Maximum risk of cracking

(and corresponding time)

100 (1.5 days) 100 (1.6 days) 50 (2.6 days) Tensile strength at 7 days 4.1 4.8 4.2 Compressive strength at 7 days 50 50 57 Tensile modulus of elasticity at 7 days 32900 32700 35400

The SLWA-H specimens with 20% sand replacement offered a net reduction in self-dessication (evidenced by higher concrete RH) resulting in a total prevention of autogenous shrinkage, as well as a moderate increase in the creep coefficient and a clear improvement in the risk of cracking over the control HPC. The strengths and modulus of elasticity were not affected by the addition of SLWA.

The amount of 20% sand replacement for this particular mix design was the maximum recommended value given by the SLWA producer. This recommendation agreed with published equations (Zhutovsky et al. 2004; Bentz et al. 2005) for the determination of the amount of pre-soaked lightweight aggregate needed to cancel the chemical shrinkage resulting in autogenous shrinkage. These equations will be verified further for this particular HPC after the testing of an additional series of concrete specimens containing an amount of SLWA near 12%.

6 Concreep7

5. Summary and conclusions

To investigate new approaches to preventing shrinkage cracking in HPC structures, testing procedures were developed to compare the structural behaviour of HPC specimens made with and without additions of SLWA – a formulation change designed to provide internal curing to HPC. The following conclusions are drawn: 1. Autogenous shrinkage of the control specimen, caused by significant internal

drying, increased rapidly to a strain of –260 µε within one day and remained constant thereafter. The prevention of autogenous shrinkage cracking in HPC structures should involve techniques that must be effective shortly after setting. 2. A 6% sand replacement with SLWA was found to reduce autogenous shrinkage

moderately and increase creep; not enough to reduce the risk of cracking when compared to the control. Failure was predicted at 1.5 days under full restraint. 3. A 20% sand replacement with SLWA enabled the complete elimination of

autogenous shrinkage and provided some expansion; enough to reduce the risk of cracking down to a maximum of 50%.

4. The quantities of SLWA used in this HPC (up to 20%) did not adversely affect the slump, air content, strength, or modulus of elasticity.

Acknowledgments

The authors would like to thank Mr. John Roberts of Northeast Solite Corporation for providing the pre-soaked structural lightweight aggregate, and Mr. Glendon Pye of NRC for his technical assistance.

6. References

Bjontegaard, O., Kanstad, T., Sellevold, E.J., Hammer, T.A. (1999): “Stress Inducing Deformations and Mechanical Properties of High-Performance Concrete at Very Early Ages,” 5th Int. Symposium On Utilization of High-Strength/High-Performance Concrete, Sandefjord, Norway, June, 1027-1040.

Bentz, D.P., Lura, P., Roberts, J.W. (2005): “Mixture Proportioning for Internal Curing,” Concrete International, February, 1-6.

Cusson, D., Hoogeveen, T.J., Mitchell, L.D. (2005): “Restrained Shrinkage Testing of High-Performance Concrete Modified With Structural Lightweight Aggregate," 7th International Symposium on Utilization of High-Strength/High Performance Concrete, Washington USA, June, 20 pp.

Kovler, K. (1994): “Testing System for Determining the Mechanical Behaviour of Early-Age Concrete Under Restrained & Free Shrinkage”, Materials & Structures, 27, 324-330. Zhutovsky, S., Kovler, K., Bentur, A. (2004): “Influence of Cement Paste Matrix Properties

on the Autogenous Curing of High-Performance Concrete,” Cement and Concrete Composites, 26, 499-507.