ia

4 44

Research Project SOA 78-416 Final Report, September 1979

MIT-NE-238

NUCLEAR ENGINEERIANa

READING ROOM1 M It

A COMPARATIVE ASSESSMENT OF THE LMFBR AND ADVANCED

CONVERTER FUEL CYCLES WITH QUANTIFICATION OF RELATIVE

DIVERSION RESISTANCE

Principal Investigator

Carolyn D. Heising

Prepared by

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

A COMPARATIVE ASSESSMENT OF THE LMFBR AND ADVANCED CONVERTER FUEL CYCLES WITH

QUANTIFICATION OF RELATIVE DIVERSION RESISTANCE

Research Project SOA 78-416

Final Report, September 1979 MIT-NE-238

Prepared by

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

Cambridge, Massachusetts 02139 Principal Investigator Carolyn D. Heising Research Assistants I. Saragossi P. Sharafi Prepared for

Electric Power Research Institute

3412 Hillview Avenue Palo Alto, California 94304

EPRI Project Manager

R.F. Williams Nuclear Power Division

compared with respect to their relative economic potential and diversion

resistance. These systems include the LWR once-through cycle with and without extended burnup, the LWR and LMFBR on uranium/plutonium recycle with and without CIVEX reprocessing methods and lastly, advanced

con-verters in symbiosis with breeders on a denatured thorium cycle. To

quantify relative diversion resistance, a method based on multi-attribute decision theory was applied. Economic potential was measured on the basis of a simple mills/kWh fuel cycle cost model. Preliminary results

indicate that the LWR-LMFBR (U/Pu) cycle can be made as diversion

re-sistant as the LWR once-through cycle if CIVEX-like methods are utilized.

The denatured thorium cycle shows no obvious diversion resistance

ad-vantage and exhibits some economic penalty when compared to the other alternatives. The economic calculations show that the choice between cycles is less likely to be affected by direct economic considerations

than by institutional factors such as fuel cycle implementability on an

industry-wide basis, acceptability to U.S. regulators and the final prospects for their adoption by U.S. utilities.

i

CONTENTS

Page

I. SUMMARY... 1

A. Alternative Nuclear Systems for the U.S . ... 1

B. Alternative Fuel Cycle Strategy Economics... 3

C. Economic Results... 5

D. Alternative Fuel Cycle Diversion Resistance... 6

E. Results/Conclusions... 10

II. INTRODUCTION... 13

A. Purpose of Study... 13

B. Study Analysis Approach... 13

C. Historical Perspective... 15

III. DESCRIPTION OF FUEL CYCLE STRATEGIES... 19

A. Basis for Choice of Reference Fuel Cycle Strategies 19 B. Description of Strategies... 21

1. Strategy A: LWR Once-Through with/without Extended Burnup... 21

2. Strategy B: Plutonium Recycle in LWRs and Breeders... 23

3. Strategy C: Denatured Thorium Cycles in Advanced Converters and Breeders... 27

C. Review of Previous Studies... 31

IV. ALTERNATIVE FUEL CYCLE ECONOMICS... 39

A. Busbar Electrical Generating Cost Model... 39

B. Key Assumptions/Cost Data... 41

C. Results and Sensitivity of Analysis... 43

V. ALTERNATIVE FUEL CYCLE DIVERSION RESISTANCE ... 49

A. Diversion Resistance Quantification Methods... 49

B. Application of Diversion Resistance Quantification Method to Fuel Cycle Strategies... 53

VI. CONCLUSIONS... A. Comparison of Economic Costs and Diversion

Resistance Between Strategies...

B. Regulatory, Institutional and Industrial

Acceptance Aspects... C. Study Recommendations... REFERENCES APPENDICES Appendix A: Appendix B: Appendix C:

Support Calculations for Electrical

Generating Costs Comparison... Support Calculations for Diversion

Resistance Comparison...

A Comparison of Available Diversion

Resistance Quantification Methods...

81 81 83 90 91 A-1 B-1 C-1

4

Iiii

ILLUSTRATIONS

Figure Page

1. Alternative Nuclear Power Strategies for U.S.

Deployment (1980-2050)... 2

2. Relative Economics of the Alternative Strategies... 6

3. Strategy A: Fuel Cycle for 1000 MWe LWR on Once-Through Uranium Cycle... 20

4. Strategy B: Fuel Cycle for 1000 MWe LWR on U/Pu Recycle... 22

5. Strategy C: Fuel Cycle for 1000 MWe Liquid Metal Fast Breeder Reactor... 22

6. Flow Chart of PUREX Process for Treatment of Low Enriched Uranium Fuel... 24

7. Modified PUREX Process with Pu-238 Spiking and Np Recycling.. 28

8. Flowsheet for On-Site Facility Based on the AIROX Process.... 30

9. Flow Diagram of the Tin-Nitride Reprocessing Scheme... 30

10. Flow Diagram of Strategy C with ACRs Only... 32

11. Flow Diagram of the Symbiotic System with Separate Processing of Blanket and Core Spent Fuel (T1 )... 32

12. THOREX Process T1: Separate Processing of Blanket and Core Fuel... 34

13. THOREX Process T2: Coprocessing of Core and Blanket Fuel... 34

14. Chemical Flowsheet for THOREX Process... 34

15. Results of Economic Analysis... 46

16. Determination of Development Time... 60

17. Isotope Composition of Reactor Grade Plutonium... 61 C.1 Possible Combinations of Selvaduray's Safeguard Parameter

V

TABLES

Table Page

1. Economic Assumptions Used in Calculating Total

Electricity Generating Costs of Each Strategy (1975 $)... 3

2. Assessment of Diversion Resistance Attributes for Selected Alternative Fuel Cycles... 8

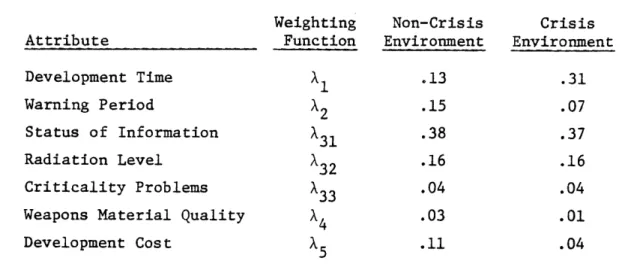

3. Pareto Weights on Diversion Resistance Attributes ... 10

4. Pareto Weights on Diversion Resistance Attributes... 52

5. Strategy A: LWR Once-Through Diversion Resistance ... .56

6. Time Table for Reprocessing Spent Fuel... 58

7. Strategy B: LWR w/Reprocessing Diversion Resistance ... 64

8. Strategy B: LWR w/Reprocessing: Clandestine PUREX Plant Diversion Resistance... 66

9. Strategy B: LMFBR w/Reprocessing Diversion Resistance ... 68

10. Strategy B: LMFBR w/Reprocessing: Clandestine PUREX Plant Diversion Resistance... 70

11. Strategy C: Denatured Thorium Cycle Diversion Resistance... 72

12. Comparison of Strategies... 74

13. Ranking of Alternatives (Non-Crisis Environment) ... .78

14. Ranking of Alternatives (Crisis Environment)... 79 B.1 Strategy A (Non-Crisis Environment): Support Caluclations

for Table 5... . B-2

B.2 Strategy A (Crisis Environment): Support Calculations for Table 5... B-2

B.3 Strategy B (B1): Support Calculations for Table

7...s...B-B.4 Strategy B (B ): Support Calculations for Table 8... B-10

* B-10

B.6 Strategy B (B2): Support Calculations for Table 1...B-12

B.6 Strategy B (B2) Support Calculations for Table 10 ... B-16

B.7 Strategy C: Support Calculations for Table 11... B-20

C.1 Overall Proliferation Risk Index (PRI) for Three LWR Fuel

Cycle Options (Silvennoinen's Method)... C-7

C.2 Numerical Assignments Associated with Qualitative Rating

C.3 Correspondance Between Method Attributes... ... C-8

C.4 Final Resul .3: Rankings Placed on Pathways to Weapons Usable

Material... C-10

C.5A-G Application of Diversion Resistance Methods to Sample

Problem... C-12

I

vii

NOMENCLATURE

C= unit price of ith fuel cycle step, 1975 $ C~u = cost of plutonium product, $/gm Puf, 1975 $

C = cost of urnaium, $/lb U 0 , 1975 $ E = energy produced by batcR, kWh

e ap = capital cost contribution to busbar cost, mills/kWh ef = levelized fuel cycle cost, mills/kWh

e. = initial core contribution to busbar cost, mills/kWh e = operating and maintenance cost, mills/kWh

e t = total busbar electricity cost, mills/kWh

fb = debt fraction

F. = discount factor applicable to ith fuel cycle step

fs 7= equity fraction

M s = transaction quantity involved in the ith step of the fuel

1 cycle

r = effective discount rate

rb = rate of return to bond holders r = rate of return to stock holders

t = irradiation time of steady state fuel batch, hr

t. = time at which payment of credit for step i will occur, hr V (x.) = value function of ith attribute

Vtx x 5) = total value function to proliferator of a diversion route

x = ith diversion resistance attribute, i=1-5

x = development time, yrs x 2 = warning period, fraction

x 31 = 2log0 of the radioactivity level, R/hr at lm from source

x 32 = sta us of information, dimensionless

x-33 = criticality problem rating, dimensionless

x 4= weapons material guality, dimensionless

x5 = monetary cost, 10 1975 %

X. = ith attribute weighting function, dimensionless

A. Alternative Nuclear Systems for the U.S.

Recent events have emphasized the need for further study into alternatives to the LWR-LMFBR plutonium based fuel cycle because of increased concern over nuclear proliferation risk. 1,2 Discussions on

this topic, however, have not been based on thorough analytical studies of the relative risk associated with the LWR-LMFBR and alternative nuclear systems. Risks associated with the once-through cycle, the alternative to closing the LWR fuel cycle, have not been quantified nor have the relative risks of denatured thorium alternatives been

compared quantitatively with those of the LMFBR. Proponents of the denatured thorium alternative have argued that such a system would al-leviate the near-term need for a breeder reactor while simultaneously decreasing proliferation risk.3,4 However, these arguments have not been put to the test of a careful, quantitative comparative analysis. It is the purpose of this study to analyze and compare available nuclear systems through the application of quantitative risk analysis and cost-benefit methods.

Three alternative nuclear systems available for implementation

by the U.S. government have been singled out for comparative analysis

in this work: (1) the standard light-water reactor (LWR) once-through

fuel cycle operating under either normal operating conditions or on extended burnup, (2) the LWR and liquid metal fast breeder reactor (LMFBR) on a U/Pu fuel cycle utilizing either PUREX or CIVEX reprocess-ing methods, and (3) the LWR combined with advanced converter reactors (ACRs) operating with or without fast breeder reactors (FBRs) on de-natured thorium cycles (Fig. 1). The CIVEX methods examined in this study which have recently been proposed5 include for LWR fuel: (1) denaturing of plutonium with a Pu-238 spike as outlined by Allied Gulf Nuclear Services (AGNS),6,7 (2) the Rockwell International AIROX

method,8 (3) coprocessing with actinide partitioning,9 and (4) the

2

Figure 1 Alternative Nuclear Power Strategies for U.S. Deployment (1980-2050)

Strategy Description

with extended burnup up to 60,000 MWO/MT+ LWR (once-thru) permanent storage of spent fuel A. LWR Once-Thru

without extended burnup

CIVEX CIVEX

8. LWR+LMFBR LWR(U/Pu) (ireprocessing LMFBR(U/Pu) (reprocessing

with U/Pu Recycle N alternotives) alternatives)

PUREX PUREX

LWR w/o Recycle LWR HWR (U/Th P cciei

+ ACR (denatured (once-thru) ACR FBR (U/Pu core, (reprocessing

C. ttMorium)+ FBR(U/Pu Th blanket) alternatives)

core, Th blanket) ITGRU/Th) PUREX/

Other Nuclear THOREX - system (e.g.,

fission-fusion hybrid)

fuel, the Electric Power Research Institute (EPRI) CIVEX scheme,10 which utilizes Zr and Ru spikes, has been compared with a standard PUREX-based LMFBR fuel reprocessing method.

In examining the once-through alternative, we consider the effect of extended burnup on economics, uranium resource utilization and fuel cycle management. The Carter Administration has tended to favor those

manage-ment schemes that can lengthen the uranium resource base for LWRs. Attention is concentrated on the potential for extending the burnup of LWR fuel examining the time frame for widescale introduction in addition to regulatory and/or institutional problems that might arise from commer-cial introduction. Preliminary work by Fard and Driscoll has shown that the extended burnup alternative could significantly prolong the uranium resource base while not introducing major economic penalties. However, the material integrity of LWR fuel under such conditions is only now being tested,12 and safety-licensing problems might likely eliminate any advantage of this alternative.1 3

With respect to the third alternative--the denatured thorium fuel cycle--the impact of introducing advanced converter reactors was speci-fically analyzed. In particular, the high temperature gas reactor (HTGR)

and CANDU heavy water reactor were examined following the "evolutionary" 6 strategies suggested by Dahlberg, et al. at General Atomic and Feiveson

a. Financing Data

= tax traction = 0.5

ts = tb = 0.5

rb = .03. rs = .08

b. Capital Cost Data LWR: 690 S/kWe HWR: 1.2 x LWR HTGR: 1.15 x LWR LMFBR: 1.3-1.7 x LWR

c. Capacity Factors Assumed H WR All Others Planned CF 0.85 0.75

Actual CF 0.75 0.65

d. Fuel Cycle Cost Data

Thorium: 33 S/kg Enrichment: 85 S/SWU Fabrication/Refabrication (S/kgHM): -LWR U5-U8 95 Pu-U 277-315 U5-U8-Th 114-187 U3-U8-Th 360-710 -HTGR U5-U8-Th 343-565 U3-U8-Th 733-1335 Th 180-290 -LMFBR Pu-U8 Core 550-850 U Blanket 95 Th Blanket 95 Reprocessing (S/kgHM): -LWR PUREX 200 AIROX 50-60 Coprocessing 200 Pu-238 Spike 210 THOREX 200

-HTGR (THOREX for U-Pu-Th) 440-990

-HWR (THOREX for U-Pu-Th) 215

-LMFBR

PUREX 300-450 EPRI CIVEX 330-495 THOREX

(for Blanket) 200 Spent Fuel Shioment (S/kgHM)

-LWR: 13. HTGR: 73.

HWR: 10. LMF8R: 69 Waste Shipping and Disposal Cost (S/kgHM)

-LWR (U/Pu Recycle): 65, LWR (once-thru): 185, HTGR: 85. HWR: 65. LMFBR: 140

B. Alternative Fuel Cycle Strategy Economics

The economics of the alternative fuel cycles were analyzed by calculating the total busbar electrical generating costs for each stra-tegy based on the following simplified model:

(1) et = e + eic + ef + e

cap ic fom

The fuel cycle cost was calculated based on the following formulation:

1000 (2) ef 0 Z M.CiF. f E i= i i i where (3) F .= (1+r)

(tf /2)-t

l-T T l-T and (4) r = (1-T)fb rb + f rThis model assumes that: (1) fuel expenses are treated as a depreciable investment, (2) the rate of return does not include an allowance for

inflation (constant dollars are assumed), (3) revenue and depreciation

charges for each batch occur at the middle of the irradiation interval, and (4) only equilibrium batches are considered. Reprocessing costs are estimated based on the cost of modifying a reference PUREX plant to the specifications required by the particular CIVEX process under

4

Reactor capital costs are estimated as the cost of a typical light water reactor multiplied by a factor defined as the ratio of the capital cost of the advanced reactor type divided by the capital cost of a

reference LWR. The resulting expressions for the total busbar electrical

generating cost as a function of nuclear strategy are:

Strategy A: LWR Once-Through

(5) e = 21.00 + 0.096 C (normal operation)

t u

(6) et = 20.78 + 0.087 C (extended burnup)

t u

Strategy B: LWR on U/Pu Recycle

(7) et = 20.92 + 0.074 Cu (PUREX reprocessing) (8) et = 22.02 +0.080 Cu (AIROX reprocessing)

(9) et = 21.3 + 0.077 Cu (Pu-238 Spike)

LMFBR on U/Pu Recycle

(10) et = 26.24 + 0.123 CPu (low value, PUREX)

= 33.42 + 0.123 CPu (high value, PUREX)

where CPu is the fissile plutonium value that renders utilities indifferent between consuming plutonium in LWRs versus LMFBRs: (11) C = 0.65 Cu - 37 for low FBR capital cost

= 0.65 Cu - 80 for high FBR capital cost

(12) et = 26.54 + 0.123 CPu (low value, EPRI CIVEX) = 33.88 + 0.123 CPu (high value, EPRI CIVEX)

Strategy C: ACR on Denatured Thorium

(13) e = 22.36 + 0.054 C (low value)

t. u

= 24.0 + 0.054 Cu (high value)

u

6

C. Er:onomic Results

On the basis of these relations, busbar electricity costs have been calculated for the three strategies as a function of U308 cost (Figure 2).

From these results, several preliminary observations can be made. At 40 $/lb U308, the LWR on either PUREX or coprocessed reprocessing appears the most aconomically attractive alternative. The economic penalty

asso-ciated with the AGNS Pu-238 spiking scheme is small and virtually

insignificant; for U308 costs above 60 $/lb, this alternative becomes more

economic than the LWR on extended burnup although the trade-off between the two is highly sensitive to assumptions on reprocessing costs and the ore savings attainable by reoptimizing the fuel for extended burnup. The cost penalty associated with the AIROX scheme, mostly due to

enrich-ment penalties, appears significant. The reoptimized once-through LWR

cycXl is preferable to the AIROX scheme until very high ore prices are reached (>180 $/lb U308).

The range of uncertainty associated with the self- sufficient breeder

economy is quite large. The median electricity cost we calculate of

30 mills/kWh (1975 $) is higher than the reoptimized once-through LWR until a uranium price of over 100 $/lb U308 is reached. The breakeven

point is reached at 55 and 145 $/lb respectively for the low and high values of the LMFBR electricity cost range. These results are not

significantly affected when the EPRI CIVEX reprocessing scheme is used instead of PUREX. In the early period of the deployment of advanced converters (Strategy C), high costs may be observed because of high costs of thorium reprocessing and refabrication due to their recent commercial introduction. However, experience in time would tend to decrease costs as economies of scale become realized and the industry matures. At 40 $/lb U308, the thorium alternative appears to cost only 5% more than

Strategies A or B--a small penalty. It is also important to note that Strategy C exhibits the lowest costs as uranium price increases because of lower U308 consumption rates. This effect would probably not be apparent in the early years of system deployment when the growth of the system would be greatest because of the large initial inventory of

6

Figure 2 Relative Ecomomics of the Alternative Strategies

35

30

25

80

120

Cu($/lb

U

30

8)

160

D. Alternative Fuel Cycle Diversion Resistance

Fuel cycle diversion resistance was quantified using an assessment methodology developed at M.I.T. by Dr. I. Papazoglu et al.14 The metho-dology is based on the principles of multiattribute decision analysis1 5 wherein a set of indices or attributes which characterize the

prolifera-tion resistance of nuclear systems is defined and evaluated for alterna-tive systems.

Diversion resistance is expressed in terms of a set of five attri-butes that must be considered in a potential diverter's decision to use a particular technology to derive weapons material. These attributes are:

(1) the development time, or the time it takes from start to finish to

develop a nuclear explosive using diverted nuclear material, (2) the warning period, defined as the percentage of the development task left to

)

Al LWR Non Reoptimized

A2 LWR Reoptimized

BI

LWR Purex

B2 LWR Coprocessing

B3LWR Airox

B4LWR Pu-238 Spiking

Cl HTGR (Denatured Thorium)

C2HWR (Denatured Thorium)

40

complete at the time of detection by outside agents, (3) the inherent difficulty of utilizing the technology as a source of nuclear fissile material defined further by a breakdown into three sub-attributes--the radioactivity level of the process, the status of scientific and tech-nical information know about the process by the potential proliferator and the level of criticality problem associated with the process, (4) the weapons material quality, defined as the type of nuclear material diverted (i.e., either weapons or reactor grade plutonium, or enriched uranium (U-233 or U-235), and lastly, (5) the development cost of the explosive construction attempt.

Each of these five attributes has been preliminarily assessed for the three fuel cycle strategies examined in this study. These results are given in Table 2. To derive a quantitiative indicator of the

relative diversion resistance of each strategy, a.value function for each attribute has been defined so that a dimensionless numerical indicator for each route can be calculated. The numerical indicators for each attribute are then multiplied by weighting factors (A ) and summed over the number of attributes to arrive at a single numerical indicator for each fuel cycle strategy.

Basically, the purpose of the value function is to provide a

numerical measure of the relative attractiveness of the various prolifera-tion pathways available to the would-be proliferator. Assuming preferen-tial independence between attributes (i.e., the proliferator's value placed on each attribute is independent of the value placed on any other attribute), the value function is:

5

(14) V(x -x 5 = . V

Because the third attribute (inherent difficulty) is divided into three sub-attributes, the above expression becomes:

(15) V(x -x5 1 V 1(x1) + 2 V2 (x2)

3

+ X 3j V3j (x3j + X4 V4 (x4 j=1

8

Table 2 Assessment of Diversion Resistance Attributes foir Selected Alternative Fuel Cydles

Status of Radiation Information* Level

Warning Period (Level of Science. (R/hr at im Weapons Development Overall Ranking Development (% of Task to Level of Tech- from Material Cost 5

Fuel Cycle Strategy Time (Yrs.) be Completed) nology) Source) Criticality Quality (10' S) I V

Strategy A: LWR Once-Thru

-Covert Reprocessing Facility 2-4 1 E (2,2) , 33 Medium Reactor 6-16 -.23

and Covert Diversion Grade Pu

- Covert Reprocessing Facility 2-4 1-3 E (2,2) 33 Mediim Reactor 6-16 -.24

and Overt Diversion Grade Pu

-Overt Indigenous Reprocessing 1.5-3 40-70 E (2,2) 33 Medium Reactor 6-16 -.36

Facility and Overt Diversion Grade Pu

*Status of Inloanation: This attribute is assessed as a separate ranking of bWh the level of science and level ot technology known about a particular technology. The levels are: I. known. 2 readily available and 3=unknown or classified. The letters refer to one of the nine possible orderings of these levels: A(1.1) = best known. 1(3.3) = least known.

Status of Radiation Information Level

Warning Period (Level of Science. (R/hr atlm Weapons Development Overall Ranking Development (% of Task to Level of Tech- from Material Cost 5

Fuel Cycle Strategy Time (Yrs.) be Completed) nology) Source) Criticality Quality (10* S) I X V

Strategy 8: LWR and/or LMFBR Material on U/Pu Recycle Diversion

Overt Covert Overt Covert (Independentof overt or covert operation) Overt Covert - 81: LWR (U/Pu) without LMFBR

-PUREX Commercial Plant .5 5 1 1 A (1,1) 10-4-10-6 Medium R.Gr.Pu 2 -.09 -.18

-Coprocessing Com. Plant 1 5 50 1-3 8 (1.2) .66 Low R.Gr.Pu 3.5-6 --1l -.19

-Pu-238 Spike Com. Plant 100 100 100 100 I (3.3) 104-10-6 Medium R.Gr.Pu 1000 -1.0 -1.0

-AIROX Commercial Plant 1.5 5 90 1-3 E (2.2) 6.6 Low R.Gr.Pu 5.5-8 -. 11 -.23

-Tin Nitride (Pyrometalgy.) 1.5 5 90 1-3 E (2.2) .66 Low R.Gr.Pu 5.5-8 -.Is -.23 - 82: LWR + LMFBR (U/Pu)

-PUREX Commercial Plant .5 5 1 1 A (1.1) 10-4-10-6 Medium R.Gr.Pu 2 -.09 -.18

-EPRI-CIVEX Com. Plant 1-1.5 5 40-70 1 A (1,1) 165 Medium R.Gr.Pu 4-12 - 29 -.22

Status of Radiation Information Level

Warning Period (Level of Science, (R/hr at Im Weapons Development Overall Ranking Development (% of Task to Level of Tech- from Material Cost 5

Fuel Cycle Strategy Time (Yrs.) be Completed) nology) Source) Criticality Quality (10' $) 1 .V

Strategy C: Denatured Thorium Material Advanced Coverters and Diversion

Fast Breeders (U/Pu/Th) Overt Covert Overt Covert (Independent of overt or covert operation) Overt Covert -Diversion from LWR Spent Fuel 1 5 1-3 1 8(1,2) 33 Medium R.Gr.Pu 4-12 -.15 -.21

Ponds with covirt PUREX Plant Built Indigenously with Com-mercial THOREX Plant in Country

-THOREX Commerbal Plant with .5 1 1 1 8 (1,2) 0 Medium High En- 2 -.08 -.10

Separate Processing of F8 - riched

Blanket and Core (T1) U-233

-THOREX Commercial Plant with 1.1 1.1 55-77 4-6 E (2,2) 0 Medium R.Gr.Pu 4-12 -.31 -.i6

-Coprocessing of Core and Blanket (T2)

-Build Clandestine THOREX Plant T1 T1 T1 T1

to Process ACR or FBR Fuel 1-1.5 1 8(1.2) 0 Medium High En- 3.5-12 .L -. 9

riched

U-233

where the value functions for each of the five attributes are: development time: (16) V (x) e 1, =1 .49 non-crisis, (16 1.83 crisis warning period: (17) V2 (x 2) = eYX 2 - 1, y = 6.93 radioactivity level: (18) x 31 0 1 2 3 4 5 6 V 31 (x31 0 -. 02 -.16 -5 -.84 -. 96 -1

status of information (x3 2 referring to levels denoted as 32

A, B, C...I): (19)

x32 Al D B E G C H F I

V 32 (X32 0 -01 -. 05 -. 16 -. 37 -. 67 -. 84 -. 95 -. 99

criticality problems (x3 3 either "High," "Medium," or "Low"):

(20) V 33("Low") = 0, V3 3 ("Med") = -. 5, V3 3("High") = -l

weapons material quality (x4 refers to type of material): (21) V 4(r.g.Pu) = -1, V 4(w.g-.Pu) = -. 5,

V 4(H.E.U-233) = -. 25 and V4(H.E.U-235) = 0

and finally, for monetary development cost:

S

-4

(22) V5( 5 = -ax 5; a = 2.6 x 10 , S = 1.27 non-crisis -5

a = 10 ,

S

= 1.9 crisisWeighting functions (A) derived from interviews with selected experts utilizing a standard Delphi technique were assessed for two hypothesized

10

Table 3 Pareto Weights on Diversion Resistance Attributes

Weighting Non-Crisis Crisis Attribute Function Environment Environment

Development Time A1 .13 .31

Warning Period A2 .15 .07

Status of Information x31 .38 .37

Radiation Level A3 2 .16 .16

Criticality Problems x33 .04 .04

Weapons Material Quality A4 .03 .01

Development Cost A5 .11 .04

Combining these weighting functions with the value functions described above, the final numerical indicators (E A V ) were calculated as shown

i i

in Table 2. Note that on a scale that varies form -1 to 0 the more negative the final indicator, the more diversion resistant the technology. Thus, a ranking of -.08 would indicate a very low diversion resistance while a ranking of -.8 a very high degree of diversion resistance.

E. Results/Conclusions

The assessment shows that the LWR-LMFBR (U/Pu) fuel cycle (Strategy B) can apparently be made as diversion resistant as either the

LWR on the once-through cycle or any combination of advanced converters operating on a denatured thorium cycle. The final quantitative rankings indicate that through use of CIVEX-like reprocessing methods such as Pu-238 spiking, the diversion resistance of the plutonium-based cycles can be increased to at least the resistance level of the once-through cycle. Moreover, it is evident that unless coprocessing or some other equivalent technology is used to increase the diversion resistance of the THOREX process, the denatured thorium alternative can be less diversion resistant than either the LWR once-through (Strategy A) or the LWR-LMFBR

(U/Pu) case (Strategy B).

From the preliminary results of this study, it is suggested that the LWR-LMFBR (U/Pu) cycle can be made at least as diversion resistant as

either the once-through cycle or any combination of advanced converters

on denatured thorium cycles if CIVEX-like processes are utilized. This may be achievable, on the basis of our economic results, without

substan-tially affecting the relative economic compe-titiveness of the mixed oxide fuel cycle. We also conclude that the AIROX method is probably not

attractive because of its increased costliness and inability to increase diversion resistance vis-a-vis other available CIVEX-like reprocessing methods. Our preliminary study of the institutional problems indicates that the choice between alternative nuclear systems is less likely to be influenced by direct economic considerations (i.e., the total cost of electricity to the American consumer) than by institutional factors such as fuel cycle implementability on an industry-wide basis, acceptability to U.S. regulators and the final prospects for fuel cycle adoption by

a

4

A. Purpose of Study

The purpose of this study is to quantify the risk-cost-benefits of the LWR-LMFBR fuel cycle in comparison with alternative advanced converter fuel cycles that have been suggested for future use. Emphasis is placed on U.S. nuclear planning alternatives but international implications of fuel cycle decisions are also examined. Risks that are quantified and/or compared include: (1) health, environmental and safety, (2) nuclear

theft and sabotage (subnational diversion) risks, (3) nuclear prolifera-tion (naprolifera-tional diversion) risks, and (4) instituprolifera-tional licensing - regula-tory risks. Primary effort has been directed toward the quantification of diversion resistance between fuel cycles in the context of alternative routes to weapons material attainment.

B. Study Analysis Approach

This study employs quantitative methods to estimate both the econo-mic costs and relative diversion resistance of three alternative nuclear power strategies projected for U.S. deployment over the next few decades

(1980 - 2050). Particular emphasis is placed on the LWR-LMFBR plutonium based fuel cycle, which had been the preferred strategy of choice until economic uncertainties and concern over proliferation brought the

strate-gy under re-consideration. In addition to diversion resistance,

dis-cussion is made of the potential differences in other technological risks

such as health-environmental-safety and subnational diversion. Also, a

contrast of institutional problems between fuel cycle alternatives is

made. However, the major emphasis in this study has been directed toward

the quantification of the relative diversion resistance between fuel cycle alternatives.

Work under the project has been divided into three tasks, which are covered in this report as follows:

TASK I (Primary)

Quantification of the risk related costs of alternative nuclear fuel cycles, particularly the proliferation-diversion resistance of the LWR-LMFBR plutonium based cycle versus alternative

advanced converters on denatured thorium (or uranium) fuel cycles (Section V, VI, Appendix B).

14

TASK II

Quantification of economic benefits of a breeder based nuclear economy in comparison with proposed alternative

advanced converter nuclear economics (Section IV, Appendix A). TASK III

Development of analytic framework for comparison of alternative advanced nuclear fuel cycles (potentially applicable to NASAP and/or INFCE studies) (Section VI).

In performing these tasks, appropriate methods have been developed and extended to quantify the relative electrical busbar costs and diver-sion resistance of the three nuclear fuel cycles under consideration. Also, a review of recent studies that pertain both to analysis of alternate fuel cycles and to diversion resistance quantification has been made (Section IID and Appendix B).

In approaching Task I, a multiattribute decision theory model developed at MIT was utilized because it was found to be the most com-prehensive method currently available (see Appendix C for a review of existing diversion resistance quantification methods). Institutional problems dealing with the implementability of each fuel cycle was dis-cussed in terms of lead times for development and commercial demon-stration in the United States. For Task II, electrical generating costs were determined to be the single most critical attribute

affect-ing U.S. electric utility choice betweencompeting nuclear systems.

Electricity cost, as generated by nuclear units, depends strongly on the cost and scarcity of uranium resources. However, capital costs for reactors not presently commercialized in the U.S. are also critical determinants of a strategy's relative economic

attractiveness. The approach we have taken to analyze Tasks I and II constitutes the analytic framework we suggest for comparison of alternative advanced nuclear fuel cycles (Task III); we believe that a similar approach should be taken within the NASAP and INFCE studies.

Historical background to the NASAP/INFCE studies is given in Section

IIC of this report.

To some, especially those engaged in the nuclear industry, the emergence of the nuclear proliferation issue has occurred at a most inopportune time. Already beleaguered by environmental, health and safety concerns coupled to the less tangible risks of theft and

sabotage, the concern over proliferation has seemed only an additional burden to the industry. With the events at Three Mile Island, the

public questions the efficacy of nuclear power to an even greater extent than before. But even before TNT, events had led nuclear spokesman Alvin Weinberg to observe that "nuclear energy is in trouble".17 This observation has been reinforced by events at TMI even while concerns over proliferation have only seemed to subside in the wake of public reaction to the accident. In the midst of this unfortunate historical period for nuclear power, it is important that those in positions to affect energy policy strive for a balanced view in deciding the future course of nuclear power. Concern over reactor safety must be balanced not only against other risks such as pro-liferation, but also against the economic impact of policy decisions. When discussing alternative fuel cycles from the viewpoint of

pro-liferation risk minimization, it is therefore imperative that both safety and economic differences be simultaneously considered so that conclusions can be drawn on a balanced basis.

The emergence of the proliferation issue occurred most recently after India's successful 1974 detonation of a nuclear explosive using material illegally diverted from a Canadian imported research reactor. As a result, the international safeguards system was laid open to re-view. American pressure for change increased further after 1976 when West Germany, Brazil, France, Pakistan and South Korea began to

con-clude commercial agreements for the international sale of reprocessing technology. However, proliferation has been a continual concern of the arms control - political science community since the advent of nuclear explosivesduring World War II.

In the U.S., the history of civilian nuclear power began in 1946 with the formation of the Atomic Energy Act (Acheson-Lilienthal)

16

commercial development. This early act underlies current Carter

Administration positions on the strict control of nuclear materials, 4 then of interest because of the arms race with the U.S.S.R. and now

of concern because of the rise of worldwide terrorism and the fear of nuclear proliferation.

In 1954, a major revision of the Atomic Energy Act occurred with 4 President Eisenhower's change in policy toward commercial nuclear

power expressed in his famous "Atoms for Peace" speech delivered at the United Nations. This policy helped stimulate the world's desire for nuclear research and commercial reactors which were sold at highly subsidized prices. Congress loosened controls over nuclear materials to promote the private nuclear sector and the International Atomic Energy Agency (IAEA) was organized to safeguard and assist the growing worldwide nuclear industry. During the 1960's, this policy was

generally continued.

Then, in the 1970's, a resurgence of interest took place in safeguards and proliferation in reactions to increase in terrorist acts around the world, the findings of several investigations that existing safeguards were inadequate, the Indian detonation of 1974 and public concern over the viability of nuclear power as an accept-able energy source. In response to these events, the government re-organized several agencies and passed stringent regulations on the export of sensitive technologies and the handling and transportation of nuclear materials, the most recent being the Nuclear Non-Proliferation Act of 1978 (NNPA). Also, on April 20, 1977, President Carter deferred indefinitely the commercialization of nuclear fuel reprocessing and the plutonium-based breeder reactor. He also called for and created the International Nuclear Fuel Cycle Evaluation INFCE) and the U.S, government's Nonproliferation Alternative Systems Assessment Program

(NASAP) which were to study alternative nuclear technologies and

institutional arrangements that might reduce the connection between civilian nuclear technology and the risk of proliferation. These studies were to be completed by 1980 in order to better achieve inter-national concensus on the future of nuclear power. The study that is covered in this report explores three possible strategies the US. could

resistance. This study therefore relates directly to the stated goals of the NASAP and INFCE projects.

A. Basis for Choice of Reference Fuel Cycle Strategies

Three advanced nuclear power strategies are examined in this study that could be implemented in the United States between 1980 through 2050:

Strategy Description

A LWR once-through with or without extended burnup B LWR with U/Pu recycle + LMFBR with U/Pu recycle C LWR once-through + advanced converter (HWR or HTGR)

on denatured thorium cycle + FBR with thorium blanket As another permutation of these strategies, we also examined the effect of civilian extraction (CIVEX) fuel processing techniques on the relative diversion resistance and economics of the overall strategy, particularly for Strategy B. The following reprocessing methods were examined:

LWR LIMFBR/Other FBR

1. PUREX 1. PUREX

2. Coprocessing + Actinide Partioning 2. EPRI-CIVEX: Zr+Ru Spikes

3. Pu-238 Spiking 4. AIROX

5. Pyrometallurgy (Tin Nitride)

These three strategies were chosen based on the findings of previous studies and based on current government policy regarding the future of advanced nuclear systems in the United States (Part C of this Section details the results of previous studies). The use of thorium in light water reactors was not examined here because of findings by other

investi-gators30,34,37 that such use was not economic relative to uranium cycles and that thorium is best used in advanced convertor reactors.

For the once-through alternative strategy A, the effect of extended burnup (up to 60,000 MWd/MTHM) on economics, uranium resource utilization and fuel management have been examined. The current administration tends to favor those management schemes that can lengthen the resource base for LWRs on the once-through cycle while maintaining competitive fuel cycle economics vis-a-vis coal fired plants. Attention has been directed in

Strategy A: Fuel Cycle for 1.000 MWe LWR on Once-Through Uranium Cycle URANIUM MINES/MILLS

[-A

ENRICHMENT PLANTF-A

FABRICATION PLANT FUEL ASSEMBLIES 27,271 kg U 3.3 w/o U235 INSIDE NWS IRRADIATED SSPENT FUEL FUEL STORAGE 150 D AYS COOLED SPENT FUEL F-1F]

OUTSIDE NWSLIGHT WATER REACTOR

1000 MWe

THERMAL EFF.: 0.325

EXPOSURE TIME :I1OO DAY

BURNUP:33,000 MWD / MT

CAPACITY FACTOR-: 0.80

CD

Figure 3

this strategy and any regulatory or institutional problems that might influence timing (see Section VIB).

For Strategy B, we emphasize that LWRs on U/Pu recycle can also be optimized for maximum resource efficiency and/or fuel cycle cost minimi-zation. This point has not been widely recognized among some policy-makers, but is certainly well know among experts in the fuel management

area.26 With respect to Strategy C, this study specifically analyzes the impact of Advanced Converter Reactor (ACR) introduction on the U.S.

economy and on diversion resistance. In particular, the study focuses on the denatured thorium schemes proposed by General Atomic (HTGR and GCFR

4 3

utilization) and Feiveson, Von Hippel and Williams as evolutionary strategies alternative to the plutonium based breeder. This strategy is chosen for comparison with the once-through alternative (Strategy A) and plutonium recycle alternative (Strategy B) because of the recent

federal government interest in this alternative (Strategy C) and because of the lack of any quantitative comparison to date of the relative eco-nomics and diversion resistance of this strategy.

B. Description of Strategies

1. Strategy A: LWR Once-Through with/without Extended Burnup

Strategy A assumes light water reactors on a uranium once-through

cycle with fuel either -exposed to an average of 33,000 MWD/MT or on

extended burnup up to 60,000 MWD/MT. A description of the fuel cycle for this strategy is given in Figure 3. For the purposes of the diversion resistance assessment (Section V of this report), it is assumed that only reactors are allowed within the boundaries of a non-weapons state (NWS) with fresh fuel supplied from outside the country and spent fuel stored inside the country for periods of ten years or more. The impact of a policy wherein long-cooled spent fuel is returned to the weapons states possibly to a multinational center located outside the NWS is also examined.

4

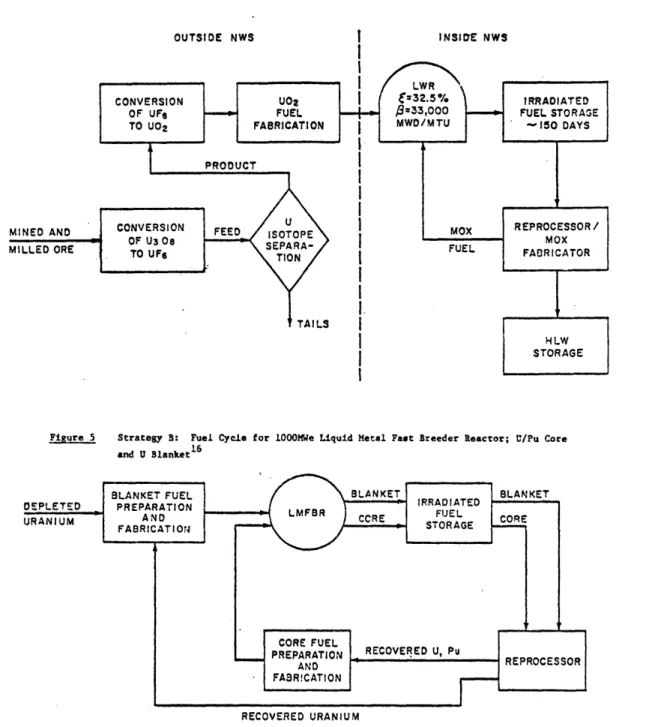

22Figure 4 Strategy B: Fuel Cycle for 1000 MWe LWR on U/Pu Recycle16

Figure 5 Strategy B: Fuel Cycle for 1000MWe Liquid and U Blanket1 6

Metal Fast Breeder Reactor; U/Pu Core

I

I

I

RECOVERED URANIUMI

I

I

2. Strategy B: Plutonium Recycle in LWRs and Breeders

Strategy B is composed both of light water reactors and liquid metal fast breeder reactors allowing reprocessing of spent fuel and U/Pu

recycle. This is the strategy originally expected to be implemented in the United States and which is being implemented in France and the Soviet Union. The following figure describes this strategy:

CIVEX IVEX

LWR (U/PU) Reprocessing LMFBR (U/Pu) Reprocessing

Alternatives Alternatives

PUREX PUREX

Included in this strategy are various reprocessing alternatives that might decrease diversion resistance below the level inherent to the tra-ditional PUREX process. Of course, it is not clear today which

repro-cessing technology will be adopted, if any, in future civilian U.S. operations.

For the purposes of assessing diversion resistance, it is assumed that Strategy B can be divided into two sub-systems. First, it is assumed that Non-Weapons States (NWS) are restricted to operating LWRs but are

allowed to operate commercial reprocessors to process fuel from their LWRs. In this system (B*), breeders are assumed to be operated outside

the NWS or not at all. For the second sub-system (B**), both LWRs and LHFBRs are allowed to be operated inside NWSs along with their correspon-ding fuel processing facilities. The fuel cycle flow diagram for an LWR or U/Pu recycle is given in Figure 4 and for the LMFBR in Figure 5.

For the case of LWR fuel reprocessing, the following processes have been considered: (1) PUREX, (2) coprocessing + actinide partitioning, (3) Pu-238 spiking (denatured plutonium), (4) AIROX, and (5) the tin nitride pyrometallurgical process. These processes were selected because of their

contrasting differences that presumably impact on the diversion resistance of LWR spent fuel reprocessing. For the LWFBR, two reprocessing methods are examined: (1) PUREX and (2) EPRI-CIVEX: Zr+Ru Spiking. These are the

only two processes which recently have been suggested for LMFBR spent fuel processing. Each are now described.

4

24

I

Flow Chart of PUREX Process for Treatment of Low Enriched Uranium Fuel

FEED SOLUTION FROM DISSOLVER

HNO

3 REDUCING WATER SCRUB SOLUTION

(FISSION PRODUCTS) Figure 6 WATER

I

0

4

4

I

I

The PUREX process is an aqueous solvent extraction technique that was developed in the late 1940's; it is the only commercially available repro-cessing technique today. A flow chart of the PUREX process is given in Figure 6. A solution of 30 vol.% tributylphosphate in a kerosene-type diluent is employed as the solvent with nitric acid as the salting agent.

A separation is accomplished because of the extraction of uranyl nitrate

and plutonium (IV) nitrate and the relative inextractability of fission products and plutonium (III) nitrate. By changing the oxidation state of plutonium, it can be separated from uranium. The heart of the PUREX process consists of two solvent extraction cycles for gross

decontamina-tion of each product: one cycle providing decontaminadecontamina-tion and partidecontamina-tioning of uranium and plutonium and the second providing further decontamination of separated products.

Coprocessing is a PUREX based solvent extraction concept involving recovery of all the actinides in the spent fuel as a product group. It

has been shown that this can be accomplished by a simple modification of

the PUREX process. The recovered actinide product group can be reconsti-tuted as a fuel for recycle in LWRs or liquid-metal fast breeder reactors (LMFBRs) either by addition of moderately enriched uranium for the LWR or by controlled partial partitioning of uranium in the L4FBR. Potential

for proliferation can be reduced for substantial diversion since plutonium is not separated from its actinide homologs nor is the recovered actinide fuel fully decontaminated from the fission products.

The Pu-238 spiking concept has been suggested by AGNS and deVolpi at ANL for conventional LWR fuel design, including the option to recycle plutonium in mixed-oxide (MOX) fuels. In this concept, the reactor is fueled in such a way that the plutonium produced during reactor operation contains an unusually high percentage of the isotope Pu-238 (about 5% as compared to 1%). Because of the high heat generation rate of Pu-238, elevated material temperatures would result when significant concentrations of Pu-238 are present. The high temperature encountered during the fabri-cation, assembly, and storage of a nuclear device would be expected to severely complicate weapons productions because the high explosive sur-rounding the fissile trigger would probably melt. Therefore, the spiking of Pu with the isotope Pu-238 to a concentration greater than 5% by weight

26

would make reactor generated plutonium considerably less attractive for weapons purposes. Unlike other spikes that are being considered to com-plicate the diversion of reactor plutonium (e.g., the introduction of a gamma emitting spike such as Co-60), the heat spike (i.e., Pu-238) cannot be removed by chemical techniques. Also, according to deVolpi, methods by which to separate the isotopes in a mixture such as would be encountered are not well known or available:

"Separation of the fissile fraction from the Pu-238, Pu-239, Pu-240, Pu-241, Pu-242 chain would be very difficult with

existing technology... .The relative irreversability of the plutonium chain offers a marked improvement over a relatively

reversible diluent such as U-238 in U-233 or even U-235 when

starting with a few percent enrichment."

A schematic of the modified PUREX process that the Pu-238 spiking scheme

requires is shown in Figure 7. Note that Np would be separated out and sent to the fuel fabricator as a precursor of Pu-238 formed during reactor operation as follows:

I Pu-238 (2 days)

Np-237 Np-2381

(7 days)

U-235 --- n-- U-236 U-237 n U-238, n

(n, 2n)

AIROX (Atomics International Reduction Oxidation) is a relatively new technique that refers to a reprocessing cycle using thermal chemical reactions to cause chemical compound changes. An important aspect from a diversion resistance perspective is that it employs both gaseous and solid materials--no liquids are used. AIROX was initially developed for LWR's in the early 1960's and has gone through several cycles of

demon-stration, including fuel fabrication and irradiation. The cyclic AIROX 4 process thermally converts UO2 to U3 08 with air termperature at 4000 C and

reduces the U308 to UO2 with hydrogen in nitrogen at 6000 C. Oxidation

produces an " 30% volume increase that stresses the compound sufficiently

to cause cladding rupture and a breakup of the UO2 structure that partially 4

pulverizes the fuel material. This pulverization permits release of

trapped volatile fission gases, commutes to oxide fuel and provides gaseous oxygen access to the unreacted fuel. Ultimately, a particle size distribution is generated that is suitable for pelletization and refabri-cation. A schematic of the process is given in Figure 8.

The tin-nitride process, chosen as an example of a pryometallurgical process, calls for dissolving the spent nuclear fuel in liquid tin followed

by selective nitriding of the uranium. The fission products would either

form nitrides or intermetallics that float, whereas the uranium nitrade precipitates would sink along with the plutonium and other actinide ni-trides. The uranium is recovered as a nitride which may be either reduced to its metallic state or be converted to oxide, carbide, or halide for enrichment, as the case may dictate. A schematic of the process is

given in Figure 9.

3. Strategy C: Denatured Thorium Cycles in Advanced Converters and Breeders

Strategy C is based upon the utilization of thorium fuel. It is composed of an LWR without recycle in the once-through cycle, an advanced convertor reactor (ACR) operating on a denatured thorium cycle, and

finally a fast breeder reactor (FBR) utilizing an U/Pu core and thorium blanket. Deployment of thorium cycles, development of commercial scale thorium reprocessing plants and thorium breeders have not been commer-cially established. The proliferation resistance of thorium reprocessing techniques has also not been demonstrated.

In this strategy, FBRs act as a fuel factory in addition to a power source by supplying the fuel requirements of ACRs. The symbiotic system is more efficient in its usage of uranium in the long run than are ACRs alone. FBRs are introduced because as uranium cost increase they become more competitive and cheaper to run than ACRs. FBRs might be introduced at the same time as ACRs or after ACRs have been deployed alone. Figure 10 shows the flow diagram of Strategy C when only ACRs are deployed. The flow diagram of the symbiotic system is shown in Figure 11.

0

28Figure 7 Modified PUREX Process with Pu-238 Spiking and Np Recycling6'7

I

I

ESS

50%

U-236

TO TAILS

U3 08MAKE-UP

15% Np

4

U30s

TO WASTE

I

There is a tradeoff between the rate at which the symbiotic system can grow and the ratio of dispersed ACRs to confined U-233 generating breeders. Indeed, increasing replacements of fertile U-238 by fertile

Th-232 in FBRs leads to: (1) an increase in the amount of U-233 available ACR

for ACRs and therefore an increase in the ratio, and (2) a decrease in the amount of Pu produced and therefore a decrease in the growth rate of FBRs which are the factories of U-233. Except for relatively small growth rates of demand for nuclear energy, and given that a relatively

ACR

large A ratio is desirable (otherwise the purpose of the symbiotic system which is to confine fresh Pu fuels to a few sites is defeated),

U-235 fueled ACRs or LWRs will be required with the symbiotic system. With regard to THOREX reprocessing methods for both ACR and LMFBR

-fuel, both conventional THOREX and non-conventional, conceptual CIVEX-like THOREX processes have been examined.*

We define two separate THOREX processes for use with the FBR blanket and core spent fuel:

T : Separate Processing of Blanket and Core Fuel -- In this concept, the core fuel consisting of denatured U-233 and plutonium

produced during fuel irradiation in the reactor would be coprocessed such that U/Pu would not be found in separated streams while the blanket fuel containing thorium and the

bred U-233 would pass through a THOREX processing stage to separate out a pure U-233 stream (Figure 12), and

T2: Coprocessipng of Core and Blanket Fuel -- This method would not produce a pure U-233 stream, thus increasing diversion resistance but impacting on ACR/FBR fuel fabrication economics. In this concept, thorium would be separated out in the first stage extractor. Coprocessing of the remaining fuel would separate the usable products (U-233, U-238, Pu) from the fission product wastes. The coprocessed mixture would then be sent to a

refabrication plant for both ACR and FBR fuels (Figure 13).

* The only attempt at co-processing uranium-thorium appears to be work being donducted at the High Temperature Iaterials Laboratory at San

Jose State University. The wark is a modification of the tin nitride process. It is in a very early stage and there is insufficient infor-mation available at this time to be able to make realistic economic

30

Figure 8 Flowsheet for On-Site Facility Based on the AIROX Process.

PRODUCTS CLADDING

U

4

I

GASEOUS FISSION PRODUCTS U-Pu-FISSION PRODUCTS (POWDER)4

Figure 9 Flow Diagram of the Tin-Nitride Reprocessing Scheme

[METALLIC-URANIUMF CLUEL EOREA.COR

SPENT OXIDE, CARBIOE

R NITRIDE FUELS a

ANO CLADOING SPENT FUEL (U+ FP) (SOLIDS) FP TRAP

INERT ATMOS__ PREMELT STAGE-A

STOICHIOPAETRic QvOLA ILE | 550*C 'CARBON TO IPT R"

REDUCE OXIDE U(WI + NON-VOLATILE FP .U

LT j G , . .- ITROGEN TiN SOLUTION14

1350*C LOOP TO REMOVE FP FRCM SOLVENT

METAL (DISTILLATION 8/OR HIGH PRESSURE NITRIDE PRECIPITATION)

UN

SOLID FP 8 CLADDING

-.- JN (TO REAC1OR IF DESIRED)

VACUUM (N2 OFF) Tim STAGE C

INTERMETALLIC OF URANIUM AND OTHER ACTINIOES DISTILL OFF TIN OR ACO Mg TO OXIOIZE SOLUT ICN

REDUCE URANIUM SOLUSILITY TO FORM OXIOE

U METAL . U (REACT TO FORM UFO

OR CARBIDE)

I

4

The THOREX process chemical flowsheet is given in Figure 14. Note that in the traditional process, U-233 is separated out in a pure stream. Unless this stream is denatured with U-238 and/or other isotopes of uranium, the existence of the pure U-233 stream could constitute as much a diversion risk as does the existence of the purified reactor-grade plutonium stream in the PUREX process. The THOREX process is a solvent extraction process which employs tri-n-butyl phosphate (TBP) as

the extractant, nitric acid catalyzed with fluoride ion as the thorium-dissolution agent with either aluminum nitrate or nitric acid as the salting agent. The U-233 product is isolated by ion exchange. Thorium is less extractable than uranium and is recovered in column 1B by

contac-ting the organic product from the previous column with dilute nitric acid. The thorium product is concentrated by evaporation.

C. Review of Previous Studies

A review of the literature was undertaken to determine previous

study results related to each of the three nuclear power strategies examined in this report.

1. Strategy A: LWR Once-Through (With/Without Extended Burnup) The work of Driscoll, Abbaspour and Fard at MIT was reviewed.

1 1

'1 7 In that work, the fuel cycle economics of improved uranium utilization in LWRs were estimated. Conclusions were that: (1) increasing core burn-up was economically advantageous so long as the number of staggered core batches was increased concurrently, (2) the thorium fuel cycle in LWRs was not found to be economically competitive, (3) steel clads could- be useful in very dry cores where its superior properties might be advantageous, and

(4) increasing the scarcity related escalation rate of ore price or the

absolute cost of ore does not alter the mnajor conclusions.

In the work of A. Roberts at EPRI 12,13 demonstration of fuel perfor-mance at high burnup was reviewed. He points out three major problems

for LWR fuel at high burnup: (1) internal pressure buildup due to release of fission products (relates to LOCA effects), (2) zircaloy waterside

corrosion , and (3) zircaloy susceptability to attack by fission products generated by fissioning oxide fuel requiring a support barrier be placed

6

326

Figure 10 Flow Diagram of Strategy C With ACRe Only

I

I

I

IRRADIATED

STOREDTHORIUM W.G. PLUTONIUM

Figure 11 Flow Diagram of the Symbiotic System with Separate

Processing of Blanket and Core Spent Fuel (T )*

4

between the UO2 and the zircaloy inner surface (either copper plated on

the inner diameter surface or zirconium co-extruded with the zircaloy). To modify current fuel designs to minimize these three effects, a long and expensive demonstration program is likely.

Other work reviewed included Golay, Saragossi and Sefcik's work at

MITl8,19 and work done by the DOE on estimating the charge for spent fuel

20

storage and disposal services. Discussion of the conclusions that can be drawn on the basis of this work is found in Section IV of this report. Also, current DOE policy on the extended burnup alternative was reviewed.21,22

2. Strategy B: LWR and/or LMFBR on U/Pu Recycle With/Without CIVEX Reprocessing Methods

For this strategy, a review of the literature concerning civilian extraction (CIVEX) processes was conducted.* The work by Pobereskin et

9

al. on coprocessing was used to establish cost estimates on this process, the work by Levenson and Zebroski for the LMFBR EPRI-CIVEX process,10 and the work by Asquith et al. to establish AIROX estimates. Information on

the denaturing of plutonium concept was derived from work done at AGNS7 and by de Volpi at Argonne National Laboratory.6

Other work that has been done in this area and was used as background

material included the paper representing DOE positions by Saul Stranch 25

on alternatives to plutonium separation, Eschbach on fuel

cycles with reduced proliferation characteristics 26 and the work by the Atomic Industrial Forum on technical deterrents to proliferation.5 Experi-mental work on proving the validity of CIVEX-like processes is being

carried out in Italy by Moccia et. al.28 Work on the relative economics of fuel cycle strategies is being done by Manne and Richels of Stanford and EPRI.2 9

4

340

Figure12 THOrEX Process T Separate Processing of Blanket and

Core Fuel

Figure 13 THOREX Process T2: Coprocessing of Core and Blanket Fuel

STORAGE OF

SPENT FUEL CORE AND

BLANKET

FIRST STAGE EXTRACTION

U-233, U-238, THORIUM

Pu, FP

COPROCESSING FIRSOUT

I PRODUCTS

U-233, U-238,

Pu I

Figure 1.4 Chemical Flowsheet for THOREX Pvocess

23