Publisher’s version / Version de l'éditeur:

Journal of Coatings Technology, 56, 719, pp. 57-60, 1984-12

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Investigation of factors influencing outdoor performance of two-part

polysulfide sealants

Karpati, K. K.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=76606ac4-19e2-4f0a-8062-1c78accf47d4 https://publications-cnrc.canada.ca/fra/voir/objet/?id=76606ac4-19e2-4f0a-8062-1c78accf47d4'I?

a

23d

126b

National Research

Conseil national

2

Iill6

#

Council Canada

de recherches Canada

INVESTIGATION OF FACTORS INFLUENCING OUTDOOR PERFORMANCE

OF TWO-PART POLYSULFIDE SEALANTS

by K.K. Karpati

ANALYZED

Reprinted from

Journal of Coatings Technology

Vol. 56, No. 719, December 1984

p. 57

-

60

.

_.

.- .--*--

--

\

-

DBR Paper No. 1264

Division of Building Research

Un produit d16tanch6itg 3 base de polysulfide

2

deux composants

a subi des contraintes cycliques de traction et de compression

pour dgterminer son comportement

lorsque soumis aux

intempgries.

Les rgsultats des essais et des observations ont

r6vgl6 que les mouvements cycliques sont les principaux

facteurs qui influencent la tenue du produit.

Investigation of Factors

Influencing outdoor Performance

Of Two-Part Polysulfide Sealants

Klara K. Karpati

National Research Council of Canada'

A two-part polysulfide sealant had been exposed on a strain-cycling exposure rack to investigate the factors that influence its weathering characteristics. The results, evaluated by tensile tests and by visual observations, revealed that cycling movement is the most important factor the sealant undergoes.

INTRODUCTION

The behavior of building sealants subjected to natural weathering has been studied to determine how different chemical types respond and to establish the conditions necessary for developing laboratory test methods that will reliably predict how the materials weather. In these studies sealants were exposed on a strain-cycling exposure rack' that simulates the movements of exterior building joints. They were then assessed visually and tested mechanically, since it has been established2 that tensile tests made at room temperature are appropriate for characterizing two-part polysulfide sealants. Previous papers have described the behavior of silicone sealant^'.^;

the present work reports the investigation of a two-part polysulfide sealant.

EXPERIMENTAL

in. (12.7 X 25.4 X 76.2 mm). Both bars were first rubbed clean with acetone and then cleaned with trichloro- ethylene vapors.

After two months of laboratory curing at 72O F (22OC) and 50% R H , the specimens were exposed for three years, starting in November 1974. They were installed at the yearly average temperatures of 32-37" F (0-3OC) to ensure full extension in winter and compression in summer. Forty-eight specimens were exposed in a vertical position on an outdoor strain-cycling rack facing south, where movements range from rt14 to f 30% yearly in 24 steps giving two repeat specimens at each movement. Another 36 specimens were exposed at movements of only +16% yearly; these were used for tensile tests because they did not show the permanent deformation that occurs with larger movements. Some specimens were constrained so that no movement could take place on exposure, while others were stored at a constant temperature of 72°F (22OC) and relative humidity of 50%; these were tensile tested along with the strain-cycled specimens.

Tensile tests were made at 72O F (22°C) on an lnstron machine at the beginning of exposure and after one-half, one, two and three years. Instead of testing several specimens at the same rate, four different extension rates were used. Although the direction in which the curves tend t o move can be established by either method, the reliability of the results is increased if a similar trend is found at different rates.

A light grey, two-part polysulfide sealant was applied

without primer on aluminum substrates. The sealant bead RESULTS AND D~SCUSS~ON was 0.50 X 0.50 X 2.00 in. (12.7 X 12.7 X 50.8 mm), and

the aluminum bars (grade 6061T6) were 0.50 X 1 .OO X 3.00 Visual Evaluation

The specimens exposed on the strain-cycling rack *I)IV, of Build~ng Research, Huild~ng Materials Sect~on. Ottawa, Ont K I A OR^ Canada. deteriorated progressively during the three years of

Reprinted from the December1984 issueof the JOURNAL OF COATINGS TECHNOLOGY Volume 56; Number 719; Pages 57-60.

Copyright 1984 by the Federation of Societies for Coatings Technology Philadelphia, Pennsylvania, U.S.A.

K K. KARPATI

(a) (b)

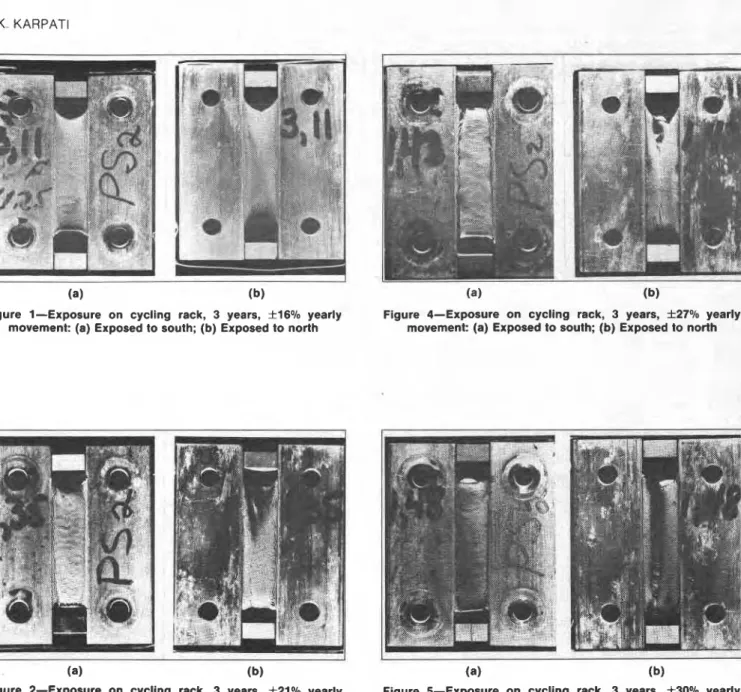

Figure 1-Exposure on cycling rack, 3 years, f 16% yearly Figure 4-Exposure on cycling rack, 3 years, f 2 7 % yearly

movement: (a) Exposed to south; (b) Exposed to north movement: (a) Exposed to south; (b) Exposed to north

(a) (b)

Figure 2-Exposure on cycling rack, 3 years, f21°/0 yearly Figure 5-Exposure on cycling rack, 3 years, f30% yearly

movement: (a) Exposed to south; (b) Exposed to north movement: (a) Exposed to south; (b) Exposed to north

(a) (b) (a) (b)

Figure 3-Exposure on cycling rack, 3 years, f24% yearly Figure 6-Compression occurring in the third summer at f 30%

TWO-PART POLYSULFIDE SEALANTS

0

I

A0 [,I, 200 300 1DU 5 L 1 b o o

P E R L E N T E X T E N S I O N

Figure 9-Curves resulting at 0.05 cmlmin extension rate (22OC)

(a) (b)

Figure 7-Exposure on cycling rack, 2'12 years, after 8 months of curing; f 3 0 % yearly movement: (a) Exposed to south;

(b) Exposed to north

movement has a n amplitude of about one-fifth that of the yearly movement and is therefore quite substantial. As the sealant is extended, it may be presumed that viscous flow takes place, sulfur bonds can break, and molecular chains slip easily on each other. These bonds can reform at other places in relaxed positions. As aconsequence, the sealant cannot take up its original shape at the end of the cycle and permanent deformation results. Once a de- crease of the cross-section has occurred as a result of permanent deformation, it progresses in successive cycles because the stress is concentrated at the narrow part of the sample. As a result, the material bulges on one side and forms a cavity on the other. Figure 6 shows the compressed state, while the previous figures show the specimens a t the original width.

The specimens exposed without movement showed no deformation but their surfaces were cracked, though less than in the cycled ones. No visual changes occurred in specimens stored in the co,nstant-temperature room during the three-year period.

A few specimens were also exposed following laboratory curing for eight months. After 2% years (including two winters) they showed n o cavity fosmation, but cracks deeper than those on the other specimens developed on both sides (Figure 7). When zero exposure exposure, but none showed complete failure. Deteriora-

tion consisted of crack formation on the south side and cavities on the north side, which was somewhat sheltered by the supporting aluminum slabs. Figures 1 to 5 give representative pictures of the deterioration that occurred progressively over three years. One can see that at k 1 6 % movement there is only a negligible amount of permanent deformation, although surface cracks appear. The cavities become more pronounced above +20% and show a sudden increase around

f

30%, with a marked thinning of the cross-section. The cracks on the surfaces receiving direct sunshine also increased with the amplitude of the yearly movement.Cavities form in successive cycles of the movement that occurs every day during the yearly cycle. The daily

I I I 'J 0

0 1 0 0 200 300 400 5 0 0 6 0 0 P E R C E N T E X T E N S I O N

Figure 8-Two-part polysulfide sealant exposed on strain-cycling rack (A), without movement (FX) and stored in the laboratory (CTR). Number of curves averaged shown in brackets (n) if more

than one. Extension rate 0.5 cmlmin (22OC)

P E R C E N T E X T E N S I O N

Figure 10-Curves resulting at 0.005 cmlmin extension rate (22" C)

K.K. KARPATI

P E R C E N T E X T E N S I O N

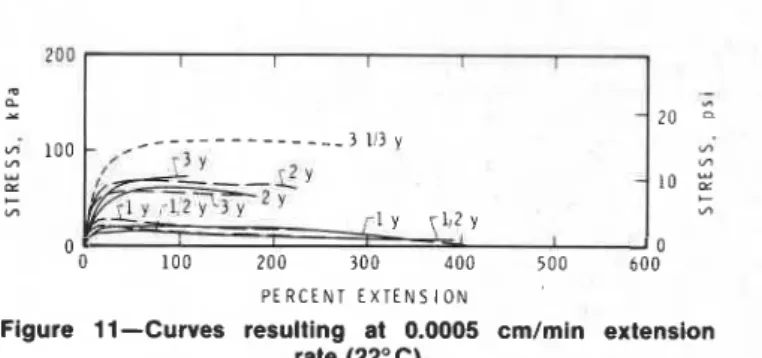

Figure 11-Curves resulting at 0.0005 cmlmin extension rate (22" C)

is compared with half a year's exposure, it may be seen from the tensile curves in Figure 8 that these specimens have already undergone a considerable amount of hardening. This is not, of course, the way the sealant normally cures, but the same degree of hardness could be achieved at the start by changing the formulation; such products may exist o n the market. In a harder type of product, therefore, the probable failure mechanism would be propagation of cracks through the cross-section near the interface. Tensile values could not be obtained from the specimens exposed after eight months' curing because of uncertainty about the loss of cross-section due to cracks.

Tensile Tests

The changes in the mechanical properties were in-

vestigated by tensile tests o n specimens exposed at

+

16%yearly movement, where deformation was negligible, and o n samples without movement, exposed and unexposed. The curves obtained are shown in Figures 8-1 1 for rates of 0.5,0.05,0.005 and 0.0005 c m / min, respectively. All four plots have the same scale to permit easy comparison. The continuous lines indicate exposure with strain-cycling, the dashed lines exposure without it, and the dotted lines represent specimens stored in the constant temperature room. The number of years of exposure are marked on the curves, with the number of tests in brackets.

The curves of Figure 8 for a rate of 0.5 c m / min indicate that the modulus goes up with time under all conditions and reaches the highest vatues when stored in the constant temperature room. The modulus increase is less if the sample is exposed, and even less if subjected to bothstrain cycling and exposure. The differences between curves obtained after different exposure times tend to disappear with decreasing extension rate, especially after two t o three years of exposure and at lower rates.

CONCLUSIONS

When weathered on the strain-cycling rack, a two-part polysulfide sealant formed cavities o n the side sheltered from direct sunshine. The same material when weathered without cycling or stored in the laboratory did not undergo permanent deformation. ,This proves the im-

portance of the effect of cyclic movement o n the performance of two-part polysulfide sealants, revealing it as the most important factor in test methods intended to evaluate their performance. During the three years of observation there was no perforation of the cavities, but progress in that direction indicates that this is the mechanism leading to failure in this type of material.

At values lower than f 2 0 % yearly cyclic movement the deformation was negligible, but it gradually increased above that value, and a cyclic strain of +30% brought about a marked decrease in most of the original cross- section. This indicates that the sealant should not be exposed t o more than over the +25% movement recommended by the manufacturers and that service life would increase with decreasing yearly movement.

The cracks that developed on the south side, though shallow, deepened with exposure time and amplitude of movement. In a harder, more crosslinked product, failure would probably proceed along these cracks and cavity formation might not occur. This is evident from the specimens stored in the constant-temperature room for eight months, then strain-cycled o n the exposure racks through two winters. This unnatural curing produced no sagging, but deeper cracks developed o n both sides of the specimens. With a sealant of a different formulation, this type of failure could occur with natural weathering.

Tensile tests confirmed the visual observations. They revealed that although the modulus increased (that is, the material hardened in time, with or without exposure), both exposure and cyclic movement caused softening of the sealant. Tensile tests could be carried out only o n

specimens subjected to no more than f 16% yearly

movement because permanent deformation or cracks developed at higher movements; but it is safe t o assume that lowering of the modulus due t o cycling would continue with increasing amplitude of movement. Thus, increased amplitude of joint movement could be used t o accelerate failure in a laboratory test.

ACKNOWLEDGMENT

The author wishes to thank R.C. Seeley for experi- mental assistance. This paper is a contribution from the Division of Building Research, National Research Council of Canada, and is submitted with the approval of the Director of the Division.

References

( I ) Karpati, K.K. and Sereda. P.J.. "Weathering Rack for Sealants." JOOKYAI O t COAl l l ( i S TI CHNOI O ( i Y . 49. NO. 626. 44 (1977). (2) Karpati. K.K.. "Mechanical Properties of Sealants." . l o r ~ ~ \ n i OF

PAI~-1. TI-CHYOI o c i ~ . 45. N o . 580. 49 (1973). (3) Karpati. K.K.. Atlheri\~.v Age. 23. No. 1 1, 41 ( 1980).

(4) Karpati. K.K.. "Quick We;~thcring Teat for the Screening o f Silicone Sealants." .lor'r<.inl o t C ~ A I 1 % ~ TI:CI~YOI o c ; ~ . 56.

No. 7 10. 29 ( 1984).

T h i s p a p e r , w h i l e b e i n g d i s t r i b u t e d i n r e p r i n t form by t h e D i v i s i o n of B u i l d i n g R e s e a r c h , remains t h e c o p y r i g h t of t h e o r i g i n a l p u b l i s h e r . I t s h o u l d n o t be r e p r o d u c e d i n whole o r i n p a r t w i t h o u t t h e p e r m i s s i o n of t h e p u b l i s h e r . A