Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Research Report (National Research Council of Canada. Institute for Research in

Construction), 2005-01-19

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=27ada9ca-b587-4753-9a2b-6ac5789b8e60 https://publications-cnrc.canada.ca/fra/voir/objet/?id=27ada9ca-b587-4753-9a2b-6ac5789b8e60 For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20377131

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Heat Release Methods

Heat Release Methods

Research Report 186

Date: 19 January 2005

Authors:

Abderrazzaq Bounagui

Noureddine Bénichou

Ahmed Kashef

Published byInstitute for Research in Construction National Research Council Canada Ottawa, Canada

ABSTRACT

Heat release rate is one of the main inputs to zone and Computational Fluid Dynamics (CFD) fire models. It defines the fire size and its growth. This report presents the various methods found in the literature that have been used to predict the heat release rate. These methods are also grouped in the heat release rate tool (HRRTool) that is being developed in the Fire Research Program at the Institute for Research in Construction. HRRTool allows the user to select the method of choice and generate the heat release data in the format required for input in CFD and zone fire models.

TABLE OF CONTENTS

ABSTRACT ... I

TABLE OF CONTENTS... II

LIST OF TABLES... III

NOMENCLATURE...IV

1

INTRODUCTION... 1

2

HEAT RELEASE METHODS... 1

2.1 Heat Release Rate Prediction from Statistical Data

... 1

2.1.1 Domestic upholstered furniture

... 1

2.1.2 Public upholstered furniture

... 1

2.2 Time-squared Heat Release Model

... 2

2.3 Semi-Universal Fire

... 4

2.4 Upholstered Furniture Fires

... 4

2.5 Pool Fires

... 5

2.6 Wood Pallets

... 6

CONCLUSIONS

... 7

REFERENCES

... 8

LIST OF TABLES

Table 1 Summary of NBS Calorimeter tests4

... 2

Table 2 Values of

α

for different growth rates... 4

Table 3 Values of different factors required for the expression10

... 4

Table 4 Data for large pool (D>0.2 m) Rate Estimate10

... 6

NOMENCLATURE

v

A

burning surface area (m2) fA

horizontal burning area of the fuel (m2);D

pool diameter (m)t

time (s) bt

burn time (s).

m

′′

mass loss rate unit area (kg/m2s).

∞

′′

m

mass loss rate per unit area for an infinite pool (kg/m2s) cH

∆

heat of complete combustion (MJ/kg).

Q

total heat release rate of the fire (W). 0

Q initial heat release rate

k extinction-absorption coefficient of the flame (m-1) Greek Symbols

α

constant for a particular fuel of a fuel package (kW/s2)χ

combustion efficiencyβ

mean beam length correction for the flameHeat Release Methods

ByA. Bounagui, N. Benichou and A. Kashef

1

INTRODUCTIONThe move to performance-based codes, the increase complexity of building design, the progress made in the understanding of fire phenomena and the advances made in computer technology have led to the increase use of computer fire models. Heat release rate is the most important parameter that is required as input to zone and field models since it controls the characteristic of the fire. Therefore, the Fire Research Program at the Institute for Research in Construction has developed a heat release rate tool1 that groups different heat release methods found in the literature. The tool allows the users to create heat release rate data from various methods and convert the data into the format suitable in commonly used zone and Computational Fluid dynamics (CFD) fire models. This report presents the heat releases methods that have been implemented in the tool.

2

HEAT RELEASE METHODS2.1 Heat Release Rate Prediction from Statistical Data

Based on the work of Hoglander and Sundstrom2, two methods have been derived from the Combustion Behaviour of Upholstered Furniture (CBUF) database to predict the heat release rate for domestic and public furniture. The expressions of the heat release rate as a function of time for both types of furniture are as follow:

2.1.1 Domestic upholstered furniture

The heat release rate for upholstered furniture is developed based on the analysis of the statistical data for this type of furniture and is given as:

( )

(

(

)

)

−

−

=

2 .3

4

.

0

exp

2500

50

t

t

Q

0 0 > = t t where:

t

: time (min); .Q

: heat release rate (kW).2.1.2 Public upholstered furniture

The heat release rate that was developed for public furniture, based also on the analysis of the statistical data, is given as:

( )

(

(

)

)

−

−

=

2 .4

2

.

0

exp

1500

50

t

t

Q

0 0 > = t t

1

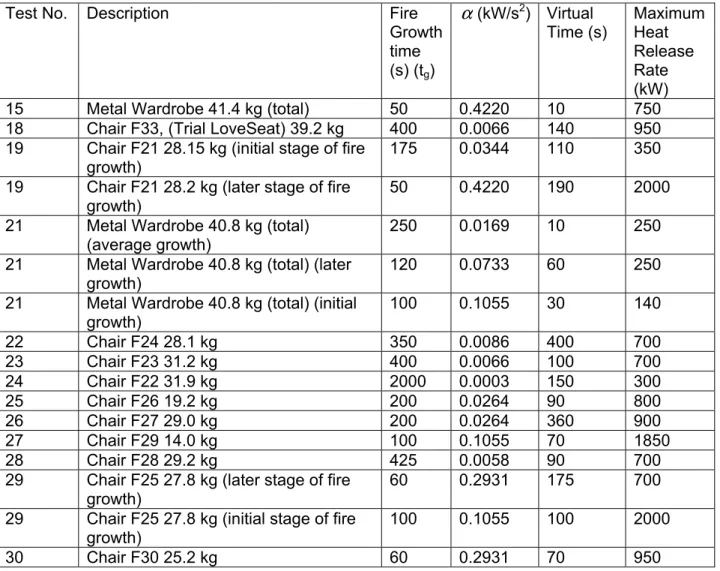

2.2 Time-squared Heat Release Model

The T-squared fire has been widely reported in the literature. It relates rate of growth of the energy release rate with the square of time through a factor

α

. The heat release rate is expressed as3:( )

2 .t

t

Q

=

α

where:t : time from established ignition (s);

α

: growth rate factor for a particular fuel of a fuel package (kW/s2);.

Q

: heat release rate (kW).Table 1 lists a large number of furniture calorimeter tests and provides the corresponding values of the fire growth time tg, the growth rate factor

α

, the virtual time tv and the maximum heatrelease rate for each test. The virtual time is generally taken to be the time from established ignition, when significant energy starts to be released. The fire growth time tg is the time to reach

the maximum heat release rate.

Table 1 Summary of NBS Calorimeter tests4

Test No. Description Fire

Growth time (s) (tg)

α

(kW/s2) Virtual Time (s) Maximum Heat Release Rate (kW) 15 Metal Wardrobe 41.4 kg (total) 50 0.4220 10 750 18 Chair F33, (Trial LoveSeat) 39.2 kg 400 0.0066 140 950 19 Chair F21 28.15 kg (initial stage of firegrowth)

175 0.0344 110 350

19 Chair F21 28.2 kg (later stage of fire growth)

50 0.4220 190 2000

21 Metal Wardrobe 40.8 kg (total) (average growth)

250 0.0169 10 250

21 Metal Wardrobe 40.8 kg (total) (later growth)

120 0.0733 60 250

21 Metal Wardrobe 40.8 kg (total) (initial growth) 100 0.1055 30 140 22 Chair F24 28.1 kg 350 0.0086 400 700 23 Chair F23 31.2 kg 400 0.0066 100 700 24 Chair F22 31.9 kg 2000 0.0003 150 300 25 Chair F26 19.2 kg 200 0.0264 90 800 26 Chair F27 29.0 kg 200 0.0264 360 900 27 Chair F29 14.0 kg 100 0.1055 70 1850 28 Chair F28 29.2 kg 425 0.0058 90 700

29 Chair F25 27.8 kg (later stage of fire growth)

60 0.2931 175 700

29 Chair F25 27.8 kg (initial stage of fire growth)

100 0.1055 100 2000

30 Chair F30 25.2 kg 60 0.2931 70 950

31 Chair F31 (Loveseat) 39.6 kg 60 0.2931 145 260 37 Chair F31 (Loveseat) 40.4 kg 80 0.1648 100 2750 38 Chair F32 (Sofa) 51.5 kg 100 0.1055 50 3000 39 1/2 in Plywood wardrobe with Fabrics

68.8 kg

35 0.8612 20 3250

40 1/2 in Plywood wardrobe with Fabrics 68.32 kg

35 0.8612 40 3500

41 1/8 in Plywood wardrobe with fire-ret. 36.0 kg

40 0.6594 40 6000

42 1/8 in Plywood wardrobe with fire-ret. ( Interior finish, initial)

70 0.2153 50 2000

42 1/8 in Plywood wardrobe with fire-ret. ( Interior finish. Later)

30 1.1722 100 5000

43 Repeat of 1/2 in Plywood Wardrobe with Fabrics 67.62 kg

30 1.1722 50 3000

44 1/8 in Plywood Wardrobe with F-R Latex Paint 37.26 kg

90 0.1302 30 2900

45 Chair F21 28.3 kg (large hood) 100 0.1055 120 2100

46 Chair F21 28.3 kg 45 0.5210 130 2600

47 Chair, Adj. Back Metal Frame, Foam Cushions 20.8 kg

170 0.0365 30 250

48 Easy Chair C07 11.5 kg 175 0.0344 90 950

49 Easy Chair F34 15.68 kg 200 0.0264 50 200

50 Chair, Metal Frame, Minimum Cushion 16.52 kg

200 0.0264 120 3000

51 Chair, Molded Fiberglass, no Cushion 5.28kg

120 0.0733 20 35

52 Modeled Plastic Patient Chair 11.26 kg 275 0.0140 2090 700 53 Chair, Metal Frame with Padded Seat

and Back 15.5 kg

350 0.0086 50 280

54 Loveseat Metal Frame with Foam Cushions 27.26 kg

500 0.0042 210 300

56 Chair, Wood Frame w/ Latex Foam Cushions 11.2 kg

500 0.0042 50 85

57 Loveseat, Wood Frame w/ Foam Cushions 54.6 kg

350 0.0086 500 1000

61 Wardrobe, ¾-in. Particleboard 120.33 kg

150 0.0469 0 1200

62 Bookcase, Plywood with Aluminum Frame 30.39 kg

65 0.2497 40 25

64 Easy Chair Molded Flexible Urethane Frame 15.98 kg

1000 0.0011 750 450

66 Easy Chair 23.02 kg 75 0.18776 3700 600

67 Mattress and Boxspring 62.36 kg (later fire growth)

350 0.0086 400 500

67 Matress and Boxspring 62.36 kg (initial fire growth)

1100 0.0009 90 400

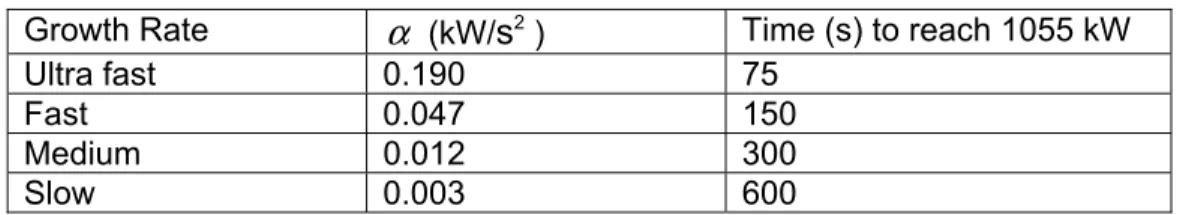

T- squared fires have been used extensively in the US for the design of detection systems5. Table 2 presents the various categories of

α

which are commonly used6.Table 2 Values of

α

for different growth rates6Growth Rate

α

(kW/s

2 ) Time (s) to reach 1055 kWUltra fast 0.190 75

Fast 0.047 150

Medium 0.012 300

Slow 0.003 600

2.3 Semi-Universal Fire

The semi-universal fire is designed to provide a broad range of heat release rates. This fire type has been included in ASET fire model7. The heat release rate is determined by the following expression:

( )

(

(

(

)

)

)

(

)

(

)

− − = 349 005 . 0 exp 300 6 . 145 01 . 0 exp 400 025 . 0 exp 10 . t t t t Q 147 t t t ≤ ≤ ≤ ≤ ≤ 349 349 6 . 6 . 147 0The expression provides the heat release for a fire spreading through an imaginary fuel package consisting of a polyurethane mattress with sheets, fuel similar to wood cribs and polyurethane on pallets, and commodities in paper cartons stacked on pallets8.

2.4 Upholstered Furniture Fires

Babrauskas9 developed a model to predict the peak heat release rate and the burning time based on generic materials characteristics of the furniture item. The peak heat release rate is expressed as:

[ ][ ][ ][ ][

FF PF CM SF FC Qmax 210.

=

]

(kW)Table 3 presents the different values and the meaning for the factors required for the expression.

Table 3 Values of different factors required for the expression10 Factors Description Values for specific materials

FF Fabric factor 1.00 for thermoplastic fabrics (e.g., polyolefin) 0.40 for cellulosic fabrics (e.g, cotton)

0.25 for PVC or polyurethane film-type coverings

PF Padding factor 1.00 for polyurethane foam, latex foam or mixed materials 0.40 for cotton batting or neoprene foam

CM Combustion mass

(kg)

User’s input

SF Style factor 1.5 for ornate convoluted shapes 1.25 for intermediate shapes

1.0 for plain, primarily rectilinear construction FC Frame combustibility

factor

1.66 for non-combustible frames 0.58 for melting plastic

0.30 for wood

0.18 for charring plastic

The burning time is determined as follow:

[ ][ ]

max . ,Q

h

CM

FM

t

b=

∆

cnet where bt

: burn time (s);FM : frame material factor;

1.8 for metal or plastic frames 1.3 for wood frames

net c

h

,∆

: effective heat of combustion of the fuel item (kJ/kg). 2.5 Pool FiresThe heat release for pool fires has been widely reported in the literature5, 8, 11, 12. Mass loss rates are given by the following expression:

(

)

[

k

D

]

m

m

′′

=

∞′′

1

−

exp

−

β

. . where: .m

′′

: mass loss rate unit area (kg/m2s);.

∞

′′

m

: mass loss rate per unit area for an infinite pool (kg/m2s);k : extinction-absorption coefficient of the flame (m-1);

β

: mean beam length correction for the flame;D : pool diameter (m).

Table 4 Data for large pool (D>0.2 m) Rate Estimate10 Material Density (kg/m3) . ∞

′′

m

(kg/m2s)∆

H

c(MJ/kg))k

β

(m -1) Liquide H2 70 0.017 120.0 6.1 LNG (mostly CH4 ) 415 0.078 50.0 1.1 LPG (mostly C3H8) 585 0.099 46.0 1.4 Butane (C4H10) 573 0.078 45.7 2.7 Benzene (C6H6) 874 0.085 40.1 2.7 Hexane (C6H14) 650 0.074 44.7 1.9 Heptane(C7H16) 675 0.101 44.6 1.1 Xylene (C8H10) 870 0.09 40.8 1.4 Acetone (C3H6O) 791 0.041 25.8 1.9 Dioxane (C4H8O2) 1035 0.018 26.2 5.4 Diethyl ether (C4H10O) 714 0.085 34.2 0.7 Benzine 740 0.048 44.7 3.6 Gasoline 740 0.055 43.7 2.1 Kerosine 820 0.039 43.2 3.5 JP-4 760 0.051 43.5 3.6 JP-5 810 0.054 43.0 1.6 Transformer oil, hydrocarbon 760 0.039 46.4 0.7Fuel oil, heavy 940-1000 0.035 39.7 1.7

Crude oil 830-880 0.0022-0.045 42.5-42.7 2.8 Polymethylmethacrylate

(C5H8O2)n

1184 0.020 24.9 3.3

The heat release rate is given by:

( )

t

A

fm

H

cQ

=

χ

∆

. " . (MW) where: fA

: horizontal burning area of the fuel (m2);χ

: combustion efficiency;c

H

∆

: complete heat of combustion (MJ/kg). 2.6 Wood PalletsWood pallets are made up of a rectangular element stacked on top of each other which is a common fuel source at industrial locations. The heat release rate for a standard pallet size of 1.22m by 1.22 m is given as10: ) 027 . 0 1 ( ) 14 . 2 1 ( 1450 . M h Q= + c − where:

:

ch

stack height (m):

M

moisture content6

in the derivation of the formula.

The expressions somewhat over predict the burning rates if applied to short stacks, with stack height

h

c≤

0

.

5

mCONCLUSIONS

The various methods that have been found in the literature to predict the heat release rate have been reported in this document. The HRRTool groups these methods and allows the designer to generate the heat release rate that can be used for their design. The tool also generates the heat release data in a format that can be easily integrated into zone or CFD fire models.

References

1. Bounagui, A., Benichou, N., Reid, I. And Hum, J., “Heat Release RateTool User Guide”,

National Research Council of Canada, Institute for Research in Construction, Research Report, (in press).

2. Holglander, K. and Sundstrom, B., “Design Fires for Pre-Flashover fires”, SP Report 1997:36, 1997.

3. International Organization for Standardization (ISO), “ Fire Safety Engineering – Part 2:

Design Fire Scenarios and Design Fires”, ISO Technical Report, (ISO/TR 13387-2:(E),

1999.

4. Schifility, R. P. et al., SFPE Handbook of fire Protection Engineering. Third Edition.

Boston, National Fire Protection Association, Quincy, MA, 2002.

5. Bjorn Karlsson and James G. Quintiere, “Enclosure Fire Dynamics”

6. NFPA, Guide for smoke and Heat Venting, NFPA 204M, National Fire Protection Association, Quincy, MA, 1985.

7. Cooper, L. Y., “ Estimating Safe Available Egress Time from Fires,” NBSIR 80-2172, National Bureau of Standards, Washington, Dc., 1980.

8. An Introduction to Mathematical Fire Modeling, Second Edition,” Technomic Publishing Co., Chapter 5, July 2000

9. Babrauskas, V. and W. D. Walton, “A simplified Characterization of Upholstered Furniture Heat Release Rates”, Fire Safety Journal, 11:181-192, 1986.

10. Babrauskas, V., “Burning Rates”, SFPE Handbook of fire Protection Engineering. First

Edition. Boston, National Fire Protection Association, Quincy, MA, 1988.

11. Babrauskas, V., “Estimating Large Pool Fire Burning Rates,” Fire Technology,

19:251-261, 1983.

12. SFPE Handbook of fire Protection Engineering. Second Edition. Boston, National Fire

Protection Association, Quincy, MA, 1995.