READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at Decision-support system for service life asset management: the BELCAM project

Lounis, Z.; Vanier, D. J.; Lacasse, M. A.; Kyle, B. R.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=28c4b3b7-4514-439e-b2b3-02c8943428f3 https://publications-cnrc.canada.ca/fra/voir/objet/?id=28c4b3b7-4514-439e-b2b3-02c8943428f3

DECISION-SUPPORT SYSTEM FOR SERVICE LIFE ASSET MANAGEMENT: THE BELCAM PROJECT

Decision-support system for service life

Z. LOUNIS, D.J. VANIER and M.A. LACASSE

Institute for Research in Construction, National Research Council, Ottawa, Canada B.R. KYLE

Public Works and Government Services Canada, Hull, Canada Abstract

This paper presents the framework of a stochastic decision-support system for life cycle asset maintenance management of building elements and systems. This system is based on a probabilistic modeling of the performance and risk of failure of building components. The maintenance optimization is formulated as a stage and multi-objective optimization problem where the simultaneous satisfaction of several conflicting objectives, including minimization of maintenance costs, maximization of performance, and minimization of risk of failure, is sought. Compromise programming is used to determine the optimal ranking of the deteriorated components in terms of their priority for repair and replacement, by achieving a satisfactory trade-off between the competing or conflicting objectives. A product model of the building system is used to provide the data framework for collecting and processing data.

Keywords: Data collection, risk-based maintenance management, multi-objective optimization, product model, stochastic performance model.

Résumé

Cet article présente les grandes lignes d’un système stochastique d’aide à la décision en ce qui concerne la gestion de la maintenance des composants du bâtiment pendant leur durée de vie utile. Il s’agit d’un système basé sur la modélisation probabiliste de la performance et du risque de dégradation des composants. L’optimisation de la maintenance y est présentée comme un problème complexe, dont les objectifs sont multiples, car il s’agit d’atteindre simultanément plusieurs objectifs contradictoires comme la réduction des coûts de maintenance, la maximisation de la performance et l’élimination des risques de dégradation. La méthode d’analyse de compromis sera employée pour déterminer la classification optimale des composants détériorés en fonction des priorités de réparation et de remplacement, en réalisant un compromis satisfaisant entre les objectifs contradictoires. Une modélisation des produits de construction est employée pour fournir les cadres de référence pour la collecte et le traitement des données.

Mots clés : collecte des données, gestion de la maintenance axée sur les risques, optimisation d’objectifs multiples, modélisation de produits, modélisation stochastique de la performance.

1 Introduction

A review of recent Canadian construction statistics shows that $8.5 billion is spent annually on repairs and maintenance of buildings (Vanier 1998). An effective decision-support system is needed by asset managers to assist them in identifying optimal maintenance strategies that minimize life-cycle costs and risk of failure for a network of building systems and components. The development of such a system is the main objective of the Building Envelope Life Cycle Asset Management (BELCAM) project (Vanier and Lacasse 1996; Lounis et al. 1998). The BELCAM project has identified two achievable goals that will assist asset managers in the course of their work:

1. To develop reliability-based methodologies to predict the performance and service life of building components;

2. To establish protocols to optimize the maintenance management of building systems.

The use of the BELCAM system will enable facilities managers and owners to overcome some of the challenges facing them regarding: (i) prioritization of facilities for repair, and (ii) optimized time and repair action. The implementation of such a system will result in extended service lives for building components and systems, lowered life-cycle costs, and potentially lower risks of failure.

Given the time-dependence and uncertainty associated with roofing performance, Lounis et al. (1998) proposed a probabilistic Markovian model for the assessment and prediction of performance and probability of failure. The consequences of failure are evaluated from available data on maintenance and failure costs that depend on the building type, or occupancy, and mode of failure (i.e., water leakage, loss of energy control, loss of serviceability, deck collapse).

The maintenance optimization problem is formulated as a sequential, stochastic and multi-objective optimization problem; where the satisfaction of several conflicting objectives is considered, including: (i) minimization of maintenance and repair costs; (ii) maximization of network performance; and (iii) minimization of risk of failure. The multi-objective optimization problem is solved by using compromise programming methods (Lounis and Cohn 1995) that seek to determine the optimal ranking of deteriorated roof sections, in terms of their priority for repair and replacement, by achieving a satisfactory trade-off between all competing objectives.

The probabilistic performance prediction model and the multi-objective optimization procedure have considerable data integration and communication demands that will be effectively met through the use of a product model. Product modeling refers to the digital representation of elements that completely defines a product for all applications over its expected life. The proposed product model requires three major components (Vanier 1998): (i) elemental aggregation model of typical roofing systems; (ii) classification model of in-field roof performance characteristics; and (iii)instantiation of the subject roof portfolio.

This paper describes the framework needed to collect and analyze data required to prioritize repair and replacement projects in a given roof portfolio. It also identifies

how the Markovian models, multi-objective optimization procedure and product models can be used to assist decision makers maximize the return on investment of their maintenance expenditures. The BELCAM project is concentrating on the life cycle maintenance management of low-slope roofs in the initial three years of the project. The methodologies developed during the course of the BELCAM research will be readily applicable to other building envelope systems.

The proposed decision-support system is shown schematically in Figure 1, and consists of the integration of the following three subsystems or enabling technologies: 1. Probabilistic models for performance prediction and risk assessment;

2. Multi-objective optimization procedure for decision making under conflicting objectives;

3. Product model of the roof system that provides the data framework for collecting 4. and processing data.

Fig. 1: Decision-support system for asset management: BELCAM methodology

2 Stochastic maintenance management system

The following section presents the framework for a stochastic maintenance management system that integrates a probabilistic performance prediction model and a risk assessment model with a multi-objective optimization algorithm.

2.1 Performance prediction using probabilistic Markovian models

The condition or performance of roofing components and systems deteriorate with time as a result of environmental degradation factors (temperature, solar radiation, water, wind), traffic loading, inadequate maintenance and poor workmanship. Given this fact, considerable uncertainty and variability are associated with the performance of roofing components, resulting from the uncertainty and variability in the environmental factors, quality of workmanship and maintenance level.

Therefore, a probabilistic Markovian model, and more specifically a discrete

In-field Performance

Data

Maintenance & Failure Cost Data

Risk & Cost Assessment Probabilistic Performance Prediction Multi-Objective Maintenance Optimization Product Modelling

Markov chain that captures both the time-dependence and randomness of the roofing performance is used to model both the deterioration and repair processes. The condition of roofing components is represented by discrete condition ratings obtained

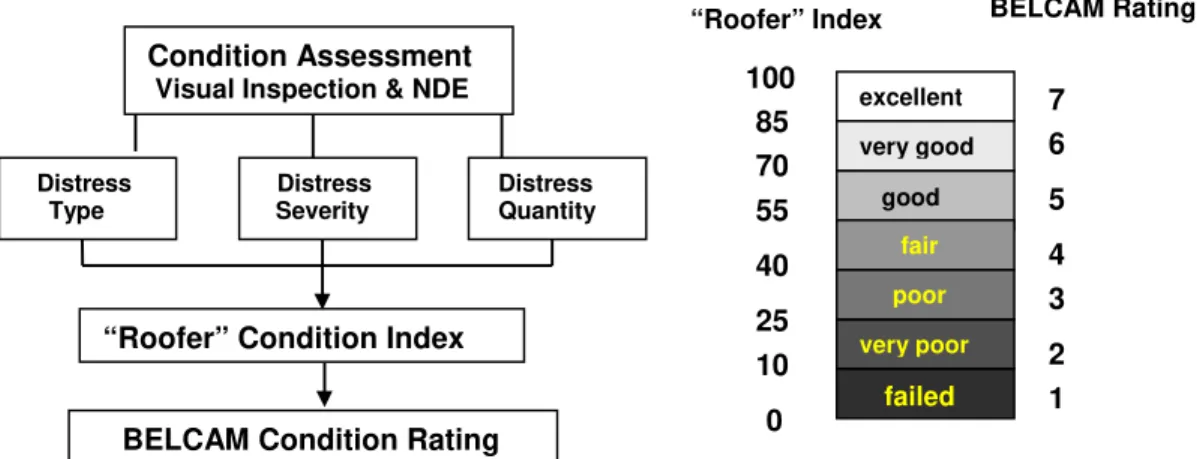

by mapping the assessed damage levels obtained using the “Roofer” condition assessment system (Bailey et al. 1990) to the 1 through 7 rating scale shown in Figure 2.

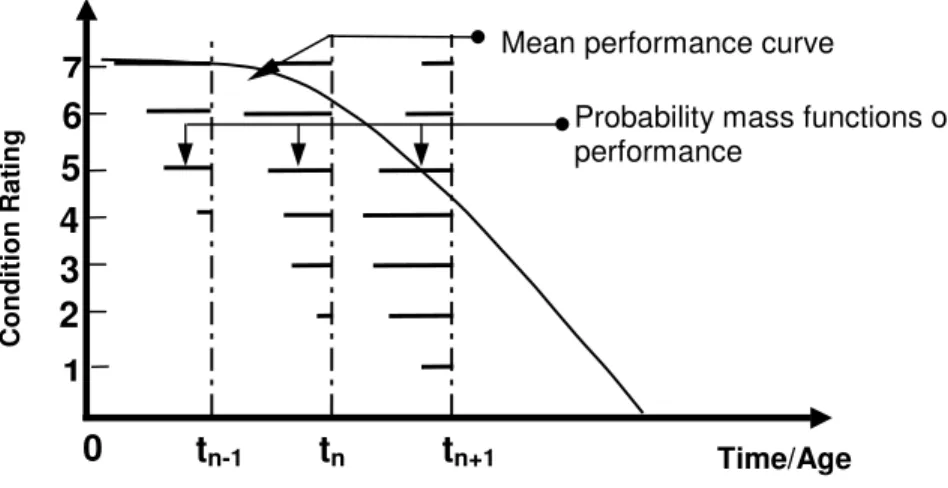

The underlying assumption of the first-order Markov chain model is the dependence of the rate of deterioration on the current stress and cumulative damage only, and not on the entire stress history. The transition probability, pij, represents the

likelihood that the roofing condition will change from state i at time tn to a lower state

j at time tn+1.

Fig. 2: Condition assessment of roofing components

The development of the Markovian model requires a relatively limited amount of historical performance data at two or more points in time. Once the one-step transition probability matrix is generated, the future performance of the roofing component can be predicted using the n-step transition matrix as follows:

P{S(tn)} = P{S(0)}Pn (1)

in which P{S(tn)} is the state probability matrix at time tn after n transitions; P{S(0)}

is the initial state probability matrix; and P is the transition probability matrix. The probabilistic prediction of the performance using Eq. (1) is illustrated in Fig. 3, which indicates the evolution with time of the probability mass function of roofing performance. BELCAM Rating v. excellent very good good fair failed very poor poor 7 6 5 4 3 2 1 100 85 70 55 40 25 10 0 “Roofer” Index Distress Type Distress Severity Distress Quantity

“Roofer” Condition Index

BELCAM Condition Rating Condition Assessment

Fig. 3: Probabilistic Markovian modeling of deterioration

Probability mass functions of performance tn+1 Condition Rat ing 7 1 2 3 4 5 6

Mean performance curve

The transition probability matrix is determined from the historical performance data, collected during inspections, and is dependent upon several explanatory variables, including: age, environmental conditions, material type, quality of work executed as well as the amount and quality of maintenance.

2.2 Risk assessment

A modern built-up roof system has in general five basic components: namely, a waterproofing membrane, thermal insulation, flashings, structural deck and possibly a vapor or air barrier. In general, there is some correlation between the performance of different components, that in turn has a direct impact on the performance of the entire roofing system, and its risk of failure. A roof is a multi-component system with multiple failure modes that can be modeled as a hybrid system comprised of a combination of series and parallel subsystems. The probability of failure of each roofing component is time-variant and changes with time as a result of degradation or repair. The probability of failure can be determined using a systems-reliability approach, taking into account the correlation between different components and failure modes. In addition, the corresponding risk of failure of the roofing system may be evaluated once the consequences of failure are assessed. Two main failure modes can be identified:

1. Envelope failure, defined by the loss of the envelope main functions, namely water tightness and energy control;

2. Structural failure, or deck failure, that includes collapse and loss of serviceability. The envelope failure at this time is the main concern of the BELCAM project. The cost of envelope failure depends on the value and vulnerability of the building contents under the roof, the costs of repair, energy costs and other incurred costs, such as costs of relocation and disruption.

2.3 Stochastic and multi-objective maintenance optimization system

At the network-level of roofing maintenance management, effective decision making requires the determination of the optimal prioritization of roofing projects for maintenance, repair and refurbishment (MR&R), including the time of repair and repair action. This optimization is a rather complex task, owing to: the large stock of deteriorated roofs; limited maintenance funds; uncertainty in the performance of roofing components; and, difference in the risk of failure associated with different buildings, roof sections and components. An effective maintenance management system should include all relevant objectives, such as: minimization of MR&R costs; maximization of network reliability; and minimization of risk of failure. Hence, it is clear that the actual maintenance management problem is multi-objective in nature and requires the determination of an optimal maintenance strategy to achieve the best trade-off between these conflicting objectives.

The multi-objective maintenance management problem can be mathematically stated as follows (Lounis and Cohn 1993; Lounis and Vanier 1998):

min f(x)= [ f1(x) f2(x) ………. fm(x) ]T x ∈ΩΩΩΩ==== (2a)

Ω

ΩΩ

Ω====={x ∈ N: Sx(t) ≤=5} (2b)

where f = vector of objective functions; ΩΩΩΩ= subset of the roofing network that at time t contains roofs with condition ratings (Sx) less than or equal to 5 and that

require maintenance, and N= entire roofing network. The solution of this maintenance management problem can be obtained using vector optimization techniques, and more specifically, the compromise programming approach (Lounis and Cohn 1993, 1995; Lounis and Vanier 1998). In compromise programming, the “best” or satisficing solution is defined as one that minimizes the distance from the set of Pareto optima or efficient solutions to the so-called “ideal solution”. This ideal solution is defined as the solution that yields the extreme (minimum or maximum) values for all objectives. The adopted priority index is based on the minimization of the normalized deviation from the “ideal roof for repair” that is associated with the “ideal vector objective f*” measured by the family of Lp metrics defined as follows

(Lounis and Cohn 1995):

p / 1 m 1 i p i i i i x p ) x ( f min ) x ( f max ) x ( f min ) x ( f min ) x ( L min ù ê ê ë é − − = = Ω ∈ (3)

These Lp (1≤ p≤∞) metrics indicate how close the satisficing solution is to the ideal

solution. Another alternative to the above approach is possible through weighting of different objectives, depending on the sensibility of the decision maker toward risk (risk averse or risk prone), economics and network reliability.

The proposed optimization approach represents the first step towards the development of a comprehensive roofing management system. The next step is the optimization of MR&R strategies within a finite or short term planning horizon, followed by an optimization within a longer planning horizon at both network- and project- levels of management. This task is achieved through the combination of the dynamic programming approach with the proposed multi-objective optimization procedure

3 Regional surveys and data collection

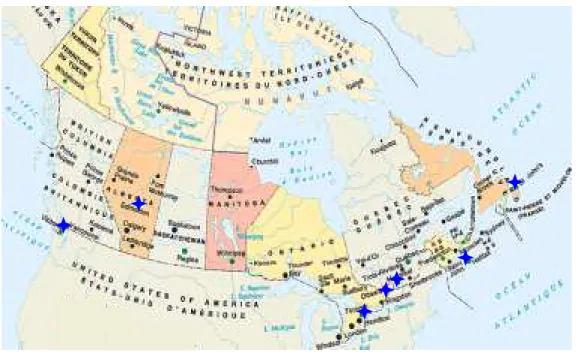

The development of the probabilistic Markovian model is based on historical performance data of roofing components and systems collected throughout Canada. The participating Canadian agencies in the BELCAM project are identified by the star symbol in Figure 4. These sites represent a wide range of buildings in geographically diverse and hence, climatically different regions of the country. Each agency gathers information on roofs under their mandate and forwards the data for inclusion in a central database.

sample roof sections that are representative of various climatic zones, construction techniques and maintenance practices and histories. Further data treatment will permit groupings relative to several explanatory variables. As additional performance data become available, the prediction model can be continuously improved using the Bayesian-updating method (Madsen et al. 1986).

Fig. 4: Data collection sites and environmental characterization

3.1 Standardized data collection tools

Following an evaluation of available roofing inspection and maintenance management software (Vanier et al. 1998), “MicroROOFER vers.1.3” (Bailey et al. 1990; USACERL 1995) was chosen as the data acquisition software for the project. The software review examined four commercially-available packages relative to their ease of use, required minimum hardware configurations, operating platforms and database structure, their technical and reporting features as well as their ability to interface and link with other applications. MicroROOFER was considered to be the most comprehensive software package of the products studied, with respect to service life prediction.

The ROOFER methodology uses various quantified visual inspection indicators to determine a component condition rating for the roof flashing and membrane, whereas the condition rating of the insulation is determined from core sampling and evaluation of the percentage of wet insulation. These condition ratings conveniently map to the discrete condition states adopted in the discrete Markov chain model described earlier, and shown in Figure 2.

A review of existing data collection technologies lead to the expansion of the standard data collection framework to include the Fujitsu 1200 Stylistic pen-based computers running Microsoft Windows 95 operating system. The utility of digital

images was clearly recognized and, although not explicitly a component of the standardized data collection package, each agency participating in the regional survey is encouraged to use these visual recording techniques as part of their "survey kit". 3.2 Roofing condition assessment information requirements

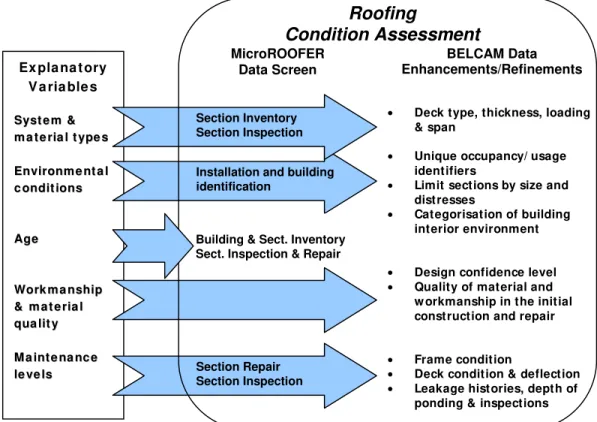

An examination of the existing data fields of MicroROOFER (USACERL 1995) and the BELCAM information requirements, relative to the identified explanatory variables, revealed numerous data gaps. In order to assure that adequate information was collected on all aspects of roofing performance (design and as-built conditions, material and workmanship quality, and condition of structural elements), additional requirements were mapped to appropriate storage locations within MicroROOFER. In all cases, the identified BELCAM protocol requirements can be recorded in existing “remarks” fields in MicroROOFER. The interaction between the explanatory variables, MicroROOFER data and BELCAM specific information is illustrated in Figure 5.

The Roofing Condition Assessment Survey (RCAS) methodology assists in obtaining consistent and easily interpreted information by detailing recommended methods of data collection and recording. A web-based On-line RCAS Manual provides a description of the MicroROOFER program requirements (USACERL 1995), as well as the data needed to fulfil requirements for the explanatory variable (Kyle 1998). An example of the recommended inspection procedures, rating scale and data input instructions for roof deck condition (as found in the on-line manual) is presented in Figure 6.

BELCAM Data Enhancements/Refinements • Deck type, thickness, loading

& span

• Unique occupancy/ usage identifiers

• Limit sections by size and distresses

• Categorisation of building interior environment

• Design confidence level • Quality of material and

w orkmanship in the initial construction and repair

• Frame condition

• Deck condition & deflection • Leakage histories, depth of

ponding & inspections Ex pla na t ory V a ria ble s S Syysstteemm&& m maatteerriiaallttyyppeess E Ennvviirroonnmmeennttaall c coonnddiittiioonnss A Aggee W Woorrkkmmaannsshhiipp & &mmaatteerriiaall q quuaalliittyy M Maaiinntteennaannccee l leevveellss Section Repair Section Inspection Installation and building identification

Section Inventory Section Inspection

MicroROOFER Data Screen

Building & Sect. Inventory Sect. Inspection & Repair

Roofing

Condition Assessment

Fig. 6: RCAS instructions and rating scale for roof deck

The RCAS provides all regional surveyors with easily-accessed information on roofing defects, their definitions, how and what to inspect, as well as a consistent methodology to record specific roofing distresses. Use of the on-line RCAS manuals, coupled with the pen-based systems and digital cameras, reduces learning time required to conduct inspections and minimizes the time between inspection and data entry. Over 500 roofs are being surveyed in the course of the project, with inspections recurring annually.

4 Integration of decision-making tools

As mentioned earlier, the main requirements of the BELCAM project are: (i) collection of in-field performance data (as described above); and (ii) development of performance and service life prediction models using these data. The improved performance prediction model will lead directly to the optimization of maintenance expenditures. The following steps are needed to accomplish these requirements: 1. Regional survey crews collect baseline building information, including drawings 2. Crews collect electronic information on current condition using MicroROOFER,

on-line RCAS Manuals and pen-based systems, including digital images of distresses;

actions and associated expenditures to assess life cycle costs and MR&R investment level;

4. New data are uploaded to a central server to update the probabilistic model and the MR&R and failure costs;

5. Operator queries the central database on issues regarding specific roofing components to establish the remaining service life; and

6. The performance and service life data calculated above, in conjunction with risk and MR&R costs data, are used by the asset managers to optimize their

maintenance expenditures using multi-objective and dynamic programming approaches.

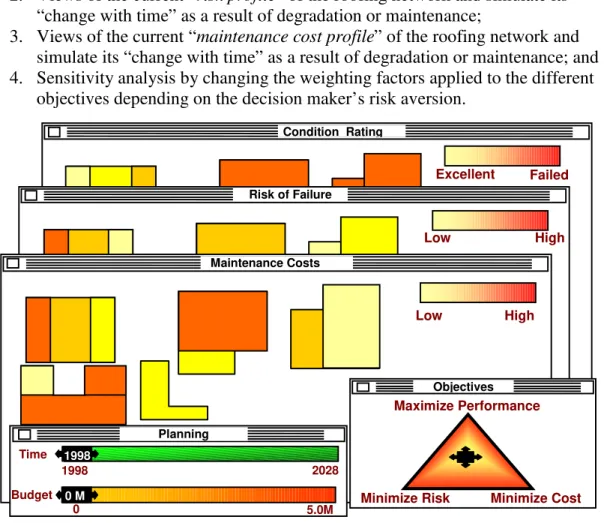

5 Envisioned user interface

The decision-making tool must have an intuitive interface such as the one proposed in Figure 7. This interface would permit the user with quick and efficient: 1. Views of the current “condition or performance profile” of the roofing network and simulate its “change with time” as a result of degradation or maintenance; 2. Views of the current “risk profile” of the roofing network and simulate its

“change with time” as a result of degradation or maintenance;

3. Views of the current “maintenance cost profile” of the roofing network and simulate its “change with time” as a result of degradation or maintenance; and 4. Sensitivity analysis by changing the weighting factors applied to the different

objectives depending on the decision maker’s risk aversion.

Fig. 7: Proposed user interface

Excellent

Hig

Risk of FailureFaile

LowExpensiv

Objectives Minimize Risk Maximize Performance Minimize Cost Planning Time Budget 0 5.0M 1998 2028 0 M 1998 Low High High Failed Maintenance Costs Condition Rating6 Conclusions

A stochastic and multi-objective decision-support system is proposed for the optimization of roofing maintenance management at both network and project levels. A discrete Markov chain model is used to predict the performance of the roofing system during its service life. The maintenance optimization aims at simultaneously satisfying several conflicting objectives, including the minimization of the MR&R costs and risk of failure and the maximization of the roofing network reliability or condition rating. Compromise programming is used to determine the optimal ranking of deteriorated roofs in terms of their priority for repair and replacement.

BELCAM’s first goal of developing techniques for service life prediction is addressed by the probabilistic Markovian modeling of performance of roofing components. The second goal of optimizing maintenance management is addressed by multi-objective optimization. These two goals could not be addressed without the use of product modeling, which provides the data integration requirements for this project. The research plan is presented in this paper; however, considerable work is still required to collect the requisite data, to integrate the required applications, and to test and validate the techniques proposed in this paper. The decision-making tools proposed in this paper will assist asset managers to predict the remaining service life of roofing systems and will allow them to optimize the expenditures of their maintenance dollars. Conceptually, the techniques developed in the BELCAM project are readily applicable to other building envelope systems.

7 References

Bailey, D.M, Brotherson, D.E., Tobiasson, W., and Knehans, A. (1990), “ROOFER: an engineered management system (EMS) for bituminous built-up roofs”, USACERL Technical Report M 90/04.

Kyle, B.R. (1998), “Roofing Condition Assessment Survey (RCAS) methodology within the BELCAM framework: HTML on-line manual”, National Research Council, Ottawa, Canada.

Lounis, Z., and Vanier, D.J. (1998), “Optimization of bridge maintenance management using Markovian models”, Proc. 5th International Conference on Short and Medium Span Bridges, Calgary, Vol. 2, pp. 1045-1053.

Lounis, Z., Vanier, D.J., and Lacasse, M.A. (1998), “A discrete stochastic model for performance prediction of roofing systems”, Proc. CIB World Congress, Gävle, Sweden, Vol. 1, pp. 305-313.

Lounis, Z., and Cohn, M.Z. (1993), “Multiobjective optimization of prestressed concrete structures”, ASCE J. of Struct. Engrg., Vol.119, No.3, pp. 794-808. Lounis, Z., and Cohn, M.Z. (1995), “An engineering approach to multicriteria

optimization of highway bridges”, J. of Microcomputers in Civ. Engrg., Vol.10, No.4, pp. 233-238.

Madsen, H. O., Krenk, S. and Lind, N.C. (1986), Methods of Structural Safety, Prentice Hall Inc., Englewood Cliffs, N.J.

USACERL (1995). MicroROOFER, Version 1.3. U.S. Army Corps of Engineers, Construction Engineering Research Laboratories.

Vanier, D.J. and Lacasse, M.A. (1996), “BELCAM project: service life, durability, and asset management research”, 7th Conf. on Durability of Building Materials and Components, Stockholm, Sweden, Vol. 2, pp. 848-856.

Vanier D.J. (1998), “Product modeling: helping life cycle analysis of roofing systems”, The life cycle of construction it innovations: Technology transfer from research to practice, Stockholm, Sweden, pp. 423-435.

Vanier, D.J., Doshi H., Kyle, B.R., and Marcellus, R.W. (1998) “Roofing maintenance software review: The art of roofing condition inspections.” Roofing Contractors Institute Interface, Vol. XVI, No. 3, pp. 10-18.