Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Paper (National Research Council of Canada. Division of Building Research); no.

DBR-P-1025, 1981-11

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=0ececf73-8188-4209-957c-5e00a87a7578 https://publications-cnrc.canada.ca/fra/voir/objet/?id=0ececf73-8188-4209-957c-5e00a87a7578

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001781

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Assessment of fire resistance requirements

TH1 N21d no. 1025

c. 2

---

CONSEIL NATIONAL DE RECHERCHES DU CANADA NATIONAL RESEARCH COUNCIL OF CANADAAssessment

o f

Fire

Resistance Requirements

by J. R. MEHAFFEY and T. Z. HARMATHY

Reprinted from FIRE TECHNOLOGY Vol. 17, No. 4, November 1981

p. 221-237

DBR Paper No. 1025 Division of Building

I

Le calcul de la charge thermique normaliste, quantificateur succinct du potentiel de propagation par destruction des feux compar- timentb, est grandement simplifit par l'utilisation de deux equa-- tions semi-empiriques. Ces dernihes permettent de comprendre directement la relation entre le potentiel destructeur d'un feu et les caracttristiques principales du four d'essais et de sa teneur en com- bustibles. Une fois connue la charge thermique produite par le four, il est possible de dtterminer les conditions de resistance au feu de ses parois au moyen d'un graphique donnant la relation entre la charge thermique normaliste et la durke de l'essai standard de tenue au feu pour le four d'essais particulier. Les limites d'application de la formule de Law servant it prtvoir les conditions de rtsistance au feu sont Ctudites it la lumiere de ces rbultats.

Vol. 17, No. 4, November 1981

Assessment

o f Fire

Resistance Requirements

J. R. MEHAFFEY and T. Z. HARMATHY

National Research Council of Canada Division of Building Research

The calculation of normalized heat load, a succinct quantifier of the potential of compartment fires to spread by destruction, is greatly simplified by the introduction of two semi-empirical equations. These afford direct insight into the relation between the destructive poten- tial of fire and the principal characteristics of the fire compartment and its contents of combustibles.

A

LTHOUGH the bases on which code writers bring down their decisionson fire resistance requirements have changed over the years, the in- fluence of Ingberg's fire load concept1 is still recognizable. That concept, developed some 40 years ago, claims that the destructive potential of com- partment fires is proportional to the specific fire load (mass of combustibles per unit floor area), and that the fire resistance requirement for compart- ment boundaries should also be allocated in proportion to the specific fire load.

Although still widely used, the concept was soundly disproved by the results of subsequent experimental research. The outlines of a rational way of assigning fire resistance requirements has recently emerged, following the identification of a parameter as a unique quantifier of the potential of enclosure fires for destructive ~ p r e a d . ~ With this new understanding, deci- sions regarding fire resistance requirements are a matter of matching the values of the parameter calculated for real-world conditions with those developed for test conditions.

The calculation of the parameter quantifying the destructive spread potential of fires under real-world conditions is quite straightforward; but since it involves an iterative technique, it may prove somewhat time con- suming for those who attempt to perform it without a programmable calculator. To eliminate the need for iteration, the feasibility of expressing that parameter by an approximate empirical equation has been examined. The results of the examination are reported in this paper.

Copyright O 1981 NATIONAL FIRE PROTECTION ASSOCIATION

D E S T R U C T I V E S P R E A D A N D C O N V E C T I V E S P R E A D O F F I R E S

The belief that the spread of fire in buildings can be prevented by the use of compartment boundaries of sufficient fire resisting quality originated in an oversimplified concept of the mechanism of spread of fires in buildings. That concept pictures all building compartments as perfectly isolated from each other, and the spread of fire as taking place by successive failures of the compartment boundaries. The idea of a completely isolated compart- ment is, however, just a crude abstraction. Fire cannot develop in a fully isolated compartment; it must have access to air. Consequently, a fire com- partment must be in communication with at least one other (inside or out- side) space, e.g. through an open door, a broken window, or some kind of in- tercompartmental opening or duct. Clearly, there is a t least one route along which a fire can spread by convection - by the advance of flames and hot gases. A fire in a compartment has, therefore, two kinds of spread potential

- destructive and convective.

This paper deals only with one of the two components of fire spread; it is intended to provide a method of assessing the potential of fires to spread destructively. The designer must remember that measures implemented to prevent the spread of fire by destruction will not, of themselves, render a building firesafe. Observations over the last several decades have clearly shown that the potential of fires for convective spread far outweighs their potential for destructive spread.

N O R M A L I Z E D H E A T L O A D

The parameter that has been identified as a succinct descriptor of enclosure fires for spread by destruction is referred to as (overall) "normalized heat load." H. I t is defined as

where q is the heat flux penetrating the boundaries of the enclosure on fire, 7

is the duration of fire exposure (usually taken as equal to the fully developed period of fire), t is time, and &is the thermal inertia of the boundaries of the enclosure (k is thermal conductivity, e is density, and c is specific heat). The thermal properties of a number of common construction materials are listed in Table 1.

Reflecting on Equation 1, the normalized heat load is the heat absorbed by a unit surface area of the enclosure during fire exposure divided by the thermal inertia of the enclosure boundaries. If, as is usual, the boundaries of the enclosure are formed by a number of different materials, the heat flux

TABLE 1. T pica1 Values of Thermal PropeTties of Common Construction Materials

(in hoistureless Condition) for Appropriate Temperature Intervals

Thermal Conductivity Density Specific Heat Thermal Inertia

Ma terial k e c d 6 c

I W m - K-'l (kg m-3) (J kg"K-') (J m-2s-"2K-')

Steel 42.0 Marble 2.0 Normal weight concrete 1.68 Fire clay brick 1.15 Brick 1.10 Lightweight concrete 0.46 Plasterboard 0.27 Vermiculite plaster 0.25 Wood 0.15 Insulating firebrick 0.25 Mineral wool (fiberfrax) 0.04

and the thermal inertia are to be looked upon as weighted averages of values applicable to the individual boundary surfaces.

where A , is the surface area of the i-th boundary, A, is the total surface area of the enclosure, q, is the heat flux penetrating the i-th boundary surface, and

Jk7,c,

is the thermal inertia of the i-th boundary.Clearly, it is also possible to define a normalized heat load for each in- dividual boundary of the enclosure. Analogous to Equation 1,

I t has been proved3 that, in general,

This Equation has been referred to as the theorem of uniformity of nor- malized heat load.

As H is a unique descriptor of the potential of fire for destructive spread, Equation 5 is an expression of the claim that the potential of a fire is the same towards all boundaries of the enclosure.* This being so, the re-

*

This claim is not as obvious as it appears to be. In fact, in some (rare) cases it may not be even approximately valid.quirements concerning the fire resistance of all boundaries must also be the same. Conversely, specifying the same fire resistance requirement for all boundaries of an enclosure is a practice that relies on the validity of the theorem of uniformity of normalized heat load.

S E M I - E M P I R I C A L E X P R E S S I O N F O R T H E N O R M A L I Z E D H E A T L O A D

According to statistical data, the fire load in modem buildings, despite the increasing use of plastics, consists predominantly of cellulosics. Since, in addition, fires of cellulosics excel in their destructive potential,* it ap- pears to be a safe practice to assume that the fire load consists fully of cellulosics.

By reflecting on the meaning of Ingberg's fire load concept,' one recognizes that it has been built on the implicit assumption that in a fire the bulk of the fuel energy is eventually absorbed by the compartment boun- daries. The normalized heat load pertaining to the assumption that all heat release by the fuel is absorbed within the compartment is

1 G A H

H , = -

*

-A,

where the subscript m has been affixed to H to indicate that it represents the conceivable absolute maximum, G is the total fire load (total fuel mass), and A H is the heat of combustion of the fuel.

Fortunately it has been found that the normalized heat load on the com-

partment boundaries is only 10 to 40 percent of H,. Some of the fuel energy

is released outside the compartment, but even of the portion released inside some energy will leave the compartment with the fire gases as sensible heat

and some will be lost by radiation through the ventilation opening. A

multitude of calculations performed by the detailed iterative technique mentioned earlier indicates that the normalized heat load, in other words the potential of fire for destructive spread,

increases less than in proportion to the fire load,

decreases as the ventilation of the compartment increases, and decreases as the thermal inertia of the boundaries increases.

The numerical results of these calculations formed the basis for an in- vestigation that resulted in the following semi-empirical equation:

Two variables, 6 and a , have not been defined. 6 (1 1) is a factor that ac-

counts for the fact that (in general) only part of the heat of combustion is released inside the compartment. I t is to be estimated from the following equation:

0.79-

whichever is less (8)

1

where hc is the height of the compartment.

is a variable that characterizes the ventilation of the compartment. I t is defined as

where

ea

is the density of environmental atmosphere, Av is the area of ven-tilation opening (window or door), h is the height of the ventilation opening,

and g is the acceleration due to gravity. The considerations that have led to

the development of Equation 7 are discussed in the Appendix.

As the specific fire load G/A, (where A, is the floor area of the compart-

ment) may vary rather markedly from compartment to compartment, the

selection of the value of G for the fire safety design must be based on an

analysis of statistical data. If the compartment boundaries are simple "dividing elements" without essential structural functions, the design

value for G/AF is usually taken as the 80th percentile in the cumulative plot

for the applicable occupancy. If, on the other hand, the compartment boun- daries are "key elements" that play an important part in the structural per- formance of the building as a whole, some extra degree of safety is justified.

The selection of G may be based on considerations propounded by Lies and

outlined later by H a r m a t h ~ . ~

The ventilation parameter, a , is a measure of the minimum ventilation of the compartment. This occurs under "classic" draft-free conditions. As

discussed by H a r m a t h ~ , ~ the presence of drafts causes the value of to in-

crease over that calculated from Equation 9 and thus (by virtue of Equation

7) to reduce the value of the normalized heat load, a value for obtained

from Equation 9 may be used in assessing the potential of fires for destruc- tive spread.

I t is of interest to examine the normalized heat load in relation to its limiting value, as expressed by Equation 6. Combining Equations 6 and 7

and using A H = 18.8 X

lo6

J kg-' in the former (because the fire load isTechnology

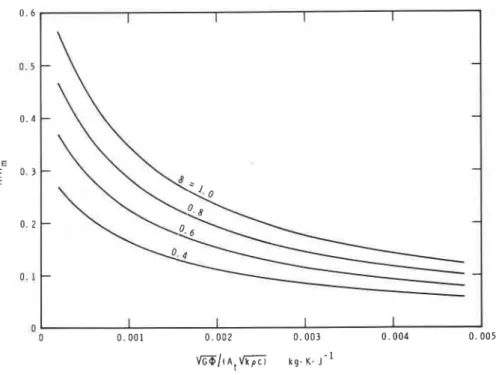

An interesting feature of this equation is that the group m/Atd&F

appears to be the dominant variable. H/H, is plotted against this variable,

with 6 as a parameter, in Figure 1. I t provides insight into the relative ineffi-

ciency of fires from the point of view of spread by destruction.

Figure 1. Nonnalized heat load imposed on compartment boundaries, as a fraction of

hypothetical maximum value.

A S S E S S M E N T O F F I R E R E S I S T A N C E R E Q U I R E M E N T S

As standard test fires are in a sense also enclosure fires, it is possible to characterize their potential for destruction by the value of the normalized heat load; this is, among other factors, a function of the duration of the test fire. Harmathy has recently investigated3 the effect of those "other factors" on the normalized value of heat load imposed on the test specimen and ascertained that the size of the test furnace and the absorption coefficient of

the furnace gas are the most important. He found that, for large, deep fur-

naces (e.g. full-scale floor furnaces) heated by a fuel that produces highly emissive combustion gases, the relation between the normalized heat load (imposed on either the test specimen or the furnace wall, in accordance with the theorem of uniformity of normalized heat load) and the duration of test

(also denoted by 7 ) can be approximated by a single curve

-

Curve 1 inFire Resistance

majority of existing test furnaces, the normalized heat load versus testing

time curve, if determined, would in all likelihood follow a flatter course, the

degree of flatness depending mainly on furnace size, emissivity of furnace gas, and the nature of the furnace lining materials. From measurements conducted on the absorption coefficient of the furnace gas, Harmathy

estimated that Curve 2 in Figure 2 is probably applicable to the floor test

furnace a t the National Research Council of Canada.

I t is rather disturbing that the fire resistance ratings developed for various building elements in fact may depend to quite an extent on the

laboratory conducting the tests. Uniformity in interpretation of fire test

results can only be achieved by the standardization of test facilities. As long as non-uniformity exists, the fire resistance requirements should, in a strict sense, be decided on the basis of test results from specific test laboratories. Once the normalized heat load versus time of testing curve is available for a specific furnace (e.g., from measurements described in Reference 3). it is a straightforward procedure to assign fire resistance requirements for compartment boundaries to ensure their satisfactory performance in real- world fires. I t involves the following steps:

Calculate the (overall) normalized heat load,

H,

for the compartmentin question, using Equations 7 and 8 (or perhaps the detailed iterative technique).

Enter this value of H along the ordinate axis of the normalized heat

load versus testing time plot for the designated furnace. (For the floor fur-

Figure. 2. Unified correlations between ij7lac and 7, for standard fire tests; Curve 1 -

for a highly efficient test furnace, and Curve

%

- for the floor test furnace in the author's labomtory (estimated).nace at DBRINRC, this plot is represented by Curve 2 in Figure 2.) Read the corresponding value of the testing time along the abscissa this time is the fire resistance requirement. Clearly, if specimens of the compartment boundary elements can survive a test fire of this duration, the compartment boundaries themselves are capable of resisting the destruc- tive spread of any fire that may occur in the compartment.

C O M P A R I S O N W I T H L A W ' S F O R M U L A Law and her colleagues in Great developed a simple empirical formula for fire resistance requirements, T,, in terms of the total fire load

and some geometric characteristics of the compartment:

ti

T, = 78

JA, (A, - A,)

Although this formula does not take into account the thermal inertia of the compartment boundaries, and the effect of ventilation is accounted for only in a simplified way (by the inclusion of the ventilation opening, A "), there have been claims of its successful application.

A series of calculations has been performed to examine the apparent suc- cess of Law's formula. In these, the fire resistance requirement, T,, was studied as a function of the ratio G/A, (fire load per unit surface of compart- ment boundary) for selected values of thermal inertia,

e,

and ratio, +/A,, the latter characterizing compartment ventilation. The dimensions of the compartment were selected to be representative of a room in a residential building: 8 by 3.8 m, 2.4 m in height.Earlier, in testing the accuracy of the results yielded by Equations 7 and 8 against those obtained by the iterative technique, careful consideration was given to selecting the practical range of variation for all three essential variables. That for the thermal inertia of the compartment boundaries was chosen as

The lowest value corresponds to wood, the highest to normal weight con- crete (see Table 1). The value 742 (listed in the caption for Figure 3) represents plaster, and 1080 can be looked upon as typical of residential or office space lined with contemporary materials.

For the other two variables, G/A, and +/A,, the following ranges were selected:

0 10 20 3 0 4 0 5 0 0 10 20 30 40 5 0 0 ' 10 20 30 4 0 50 F I R E L O A D R E F E R R E D T O C O M P A R T M E N T S U R F A C E A R E A . G I A t k g . r n - '

Figure 3. Fire resistance requirements, --according to Law's formula, - according to the semi-empirical method of this paper. (Jkec in J m-' s"" K-'; +/A, in kg m-a s-', 6 dimen- sionlessl.

These cover the majority of conditions to be met in practice. The corre sponding range of variation for 6 is, for practical values of the compartment height (from Equation 8),

The results of the study are presented in Figure 3, the dashed curves representing Law's formula. The full line curves were obtained by using Equations 7 and 8 to calculate the normalized heat load, H, entering H along the ordinate axis of Figure 2 and reading the value of the fire resistance requirement, T, (i.e. the required minimum time of exposure to

standard test) along the abscissa axis. Curve 1 of Figure 2, representing ideal, well-designed test furnaces, was used in the hope that updating the test standard ASTM E 119, would invoke steps to improve and equalize the efficiency of all existing test furnaces. Under existing conditions, the values of T, obtained by using Curve 1 are, in all probability, 10 to 30 percent too

low.

In this light, the following conclusions can be drawn from an examina- tion of Figure 3. Under low and average ventilation conditions, Law's for- mula yields results in fair agreement with those derived by the procedure described in this paper, especially if the thermal inertia of the compartment boundaries is slightly on the high side. Under high ventilation conditions, the agreement is poor; Law's formula predicts much higher fire resistance

requirements than the calculation method based on Equations 7 and 8 and Figure 2.

I t may be noted that the inability of Law's formula to account for certain characteristics of the fire compartment was earlier noted by Pettersson" who also offered rudimentary measures of correction.

C O N C L U S I O N S

The discovery that the potential of fires for destructive spread can be quantified by a single parameter, the overall normalized heat load, has af- forded a new perception of the problem of the assessment of fire resistance requirements. The evaluation of that parameter for real-world fires is, however, encumbered by computational difficulties. These can be overcome by the use of a semi-empirical calculation technique based on Equations 7 and 8; it also offers the advantage of direct insight into the nature of the relation between the normalized heat load and the most essential characteristics of the compartment and its contents of combustibles. A fur- ther outcome of the semi-empirical investigations is the discovery that the normalized heat load, as a fraction of its maximum conceivable value, can be expressed with the aid of two variables (see Equation 10 and Figure I), the principal variable including essentially all characteristics of the compart- ment and the fuel.

Once the normalized heat load for a compartment is known, the fire resistance requirement for the compartment boundaries can be determined by means of a graph depicting the normalized heat load for the fire test fur- nace as a function of the length of fire test. This method of assessment of fire resistance requirement is examined against that based on Law's for- mula and its versatility illustrated.

N O M E N C L A T U R E

A = area, boundary surface area, m2

c = specific heat; without subscript: specific heat in the expression of overall thermal inertia, J kg-'K-'

C = empirical factor, dimensionless

g = acceleration due to gravity, 9.81 m s-2

G

= total fire load, kgh = height; without subscript: height of ventilation opening, m H = normalized heat load, sl"K

A H = heat of combustion, J kg-'

i = 1 , 2 , 3 ,

. . .

k

= thermal conductivity; without subscript: thermal conductivity in the expression of overall thermal inertia, W m-'K-'1 = hypothetical flame height, m

-

q = overall heat flux, W m-l

Q

= rate of heat evolution within the compartment, WR

= rate of "burning," kg s-IU

= mass flow rate, kg s-'t = time, s

T

= average temperature, K6 = fraction of fuel energy released within the compartment, dimen- sionless

q = density; without subscript: density in the expression of overall ther-

mal inertia, kg m-3

7 = duration of (fully developed period of) fire; length of fire exposure;

fire resistance time, s = ventilation parameter, kg s-' Subscripts a = of atmospheric air C = of compartment F = of floor g = of compartment gas

i = of or for the i-th boundary or boundary surface m = maximum

r = required

t = total for the compartment

V

= of the ventilation openingR E F E R E N C E S

' Ingberg, S. H.. "Tests of Severity of Building Fires." NFPA Quarterly, Vol. 22, No. 1

(19281, pp. 43-61.

'

Harmtthy, T. Z., "The Possibility of Characterizing the Severity of Fires by a Single Parameter, Fire and Materials, Vol. 4 , No. 2 (1980), pp. 71-76.Harmathy, T. Z., "The Fire Resistance Test and I t s Relation to Real-World Fires." To be published.

Harrnathy, T. Z., "Fire Severity: Basis of Fire Safety Des' resented a t International Symposium on Fire Safety of Concrete Structures. ACI Ki98onvention, Puerto Rico. September 1980.

Lie, T. T., ''Safety Factors for Fire Loads," Can. J. Civil Engineering, Vol. 6, NO. 4 (19791,

pp. 617-628.

Thomas, P. H., "The Fire Resistance to Survive a Bum-Out," Joint Fire Research Orqanization, England. Fire Research Note 901 (1970).

Law, M., "A Relationship between Fire Grading and Building Design and Contents." Jo$t Fire Research Organization, England, Fire Research Note No. 877 (1971).

Law, M., "Prediction of Fire Resistance," Symposium No. 5, Joint Fire Research Organization, Her Majesty's Stationery Office, London, En land (19731,

Pettersson, 0.. ~6Structural ire P r ~ t e c t i o n , ~ ' Lund fnstitute of ~eEkOIOgy, Lund. Sweden, Bulletin 80 (1978).

A P P E N D I X

The iterative technique for calculating the process variables for a com- partment fire, and through them the overall normalized heat load, has already been described in several publications, most recently by Har-

math^.^

Only a brief outline of the technique wiU be presented here. The input information needed to determine the characteristics of com- partment fires of cellulosics has been listed in Table 4 of Reference 4. I t shows that almost half the input data consist of either constants or quasi- constants and thus can be ignored. Those that must be included relate either to the fuel, namely its quantity, or to the compartment, its geometric characteristics and thermal inertia.It has been pointed out4 that six equations are needed to describe the process of fully developed compartment fires. Of the six, three are energy balances - one over the fuel surface, the second over the ventilation open- ing, and the third over the compartment surface.

The energy balance over the fuel surface usually serves in developing an equation for the rate of "burning", R, or more exactly for the rate of con- sumption of fuel by pyrolysis. With cellulosic fuel, however, such an energy balance is not needed because R can be described by the following empirical equations

If the first equation is applicable, the fire is referred to as ventilation con- trolled, if the second, it is fuel surface controlled.

The second energy balance can be utilized in developing an expression for the heat flux absorbed by compartment boundaries. By disregarding the radiant heat loss from the compartment (consistently much lower than the convective heat loss), the following equation results:

where tj is the heat flux absorbed by the compartment boundaries, averaged over all boundaries and temporally over the period of full-fire development,

Q is the (average) rate of evolution of heat from the fuel within the compart- ment,

U.

is the rate of flow of air into the compartment, andTa

is the average temperature of the compartment gases (average "fire temper- ature"), averaged spatially over the compartment volume and temporally over the period of full-fire development. (The meaning of the constants and the various terms in Equation A2 are explained in Reference 4.)The third energy balance, that over the compartment boundaries, can be rearranged in an expression for

(A,,

F i e Resistance

(see Reference A1 for further details). 7, as earlier discussed, is the duration of (fully developed) fire. As the rate of consumption of fuel, R, is fairly con- stant during the period of full development, T can be expressed as

The remaining two equations are as follows:

and

Q = R(12.456

+

1.82) X lo6(See Reference 4 for further information concerning these equations.) 6 ac- counts for the fact that, in general, only part of the energy of the volatile decomposition products of the fuel is released inside the compartment.

In the earliest models of compartment fires, the possibility of combus- tion outside the compartment was disregarded for mathematical conve- nience. In subsequent models, the rate of entry of air through the ventila- tion opening was regarded as the sole factor that determines whether com- bustion takes place outside. Assuming perfect mixing between the air and the volatile pyrolysis products, these models led to the suggestion that com- bustion outside the ventilation opening is an unmistakable characteristic of ventilation controlled (poorly ventilated) fires. Experimental data reported by Butcher et al.A2.A3 did not support this suggestion.

After examining these and other data, Harmathy came to the conclu- sion1° that the presence or absence of outside combustion depends not so much on rate of entry of air into the compartment as on rate of entrainment of air already in the compartment into the flames. He argued that since the bulk of air is entrained by the rising fire plume, the height of the compart- ment, h , ought to be an important factor in the entrainment. He recom- mended the following empirical equations for the calculation of 6:

(he 1 1 ) ~ ' ~ (~7[a1)

6 =

{

whichever is less1 (ATPI)

where 1 is a hypothetical flame height to be calculated as

Six equations, A1 to A6, are now available for calculating the process variables: R, U., Q, ij,

F8,

and 7. The values of R, U,,Q,

and T are obtaineddirectly from Equations Al, A5, A6 and A4. q and

Tg

may then be calculated by an iterative solution of two simultaneous equations, A2 and A3. Once ij and 7 are known the normalized heat load is obtained from the following equation:which follows from Equation 1 by virtue of the fact that

In developing a semi-empirical approximation for the normalized heat load, it is essential to ensure that any error in the approximation is on the safe side. Consider first a very destructive fire, one for which (as known from earlier discussions) G is large and 9 and

&Z

are small. Such a fire is expected to be ventilation controlled; according to Equations A1 and A4 its duration isSince T is very large,

Tg

can be approximated as follows (see Equation A3):This equation is expected to yield an overestimate for ij and naturally also for H , and thus will result in an error on the safe side.

By substituting into Equation A2 the expressions

Q,

U a ,

andFg

from Equations A6, A5, and A12, respectively (using the approximation [1.05Fg-

293.21 = 1.05[z

-

293.2]), then eliminating from the resulting equation first 7 (with the aid of Equation A1 1) and then R (using Equation Al(a)), after rearrangement the following equation will resultAn expression for the normalized heat load, H, can now be obtained by multiplying the left side of Equation A13 by

TIJG

(according to Equa- tion A9) and its right side by the equivalent term Gl(0.02369 (see again Equation A l l ) . The result iswhere C is a dummy constant (here C = 1) introduced to allow for further empirical modification of the equation. Under ventilation controlled condi- tions, Equations A7 and A8(a) are applicable to the calculation of 6; this fact is reflected by Equation 8.

Although Equation A14 has been arrived at by considerations ap- plicable only to ventilation controlled fires, it seems to indicate for any kind of fire the nature of dependence of the normalized heat load on the three

-

principal variables, G/A,, +/A,, and Jkec. I t is natural to speculate, therefore, that (possibly after some further empirical adjustment) its ap- plicability may be extended to fuel-surface controlled fires as well.To examine the tenability of this speculation a multitude of calculations were performed, using both the detailed iterative technique and the semi- empirical method based on Equations 8 and A14. The calculations covered the same ranges for the three principal variables as those given earlier in connection with Law's formula. The results selected for illustration in Figures A1 and A2 also relate to a room 8 by 3.8 m and 2.4 m in height.

Only a small fraction of the calculation results, those deemed to substan- tiate the principal conclusions, have been plotted in Figures A1 and A2. The open circles in Figure A1 represent values obtained by the detailed iterative technique; the solid curves, values obtained by the use of the semi-empirical method represented by Equations 8 and A14 with C in Equation A14 set equal to 0.833.

I t is noteworthy that for the most common range of the thermal inertia, 436<

fi

c

1080, the semi-empirical method yields an accuracy better than 5 percent. Forfi

= 2192 (the case of normal weight concrete) its accuracy is poorer, especially a t larger values of the ventilation parameter, but the error is on the safe side.The most important, and to some extent surprising, result of the study is that although Equation A14 was developed for severe ventilation con- trolled conditions, with the C = 0.833 adjustment it appears to be ap- plicable to both ventilation controlled and fuel-surface controlled fires. The equation presented in the main text (Equation 7) is that adjusted form of Equation A14. The study also showed that the accuracy of the empirical method is somewhat better if 6 is calculated for any fire from Equation 8, which (as Equations A7 and A8 indicate) was originally recommended for ventilation controlled conditions only.

Although the total surface area of the compartment, A, may vary widely under practical conditions, compartment height, ha usually stays approximately constant, about 2.4 m. Consequently, the variables G/A, and

F I R E L O A D R E F E R R E D T O C O M P A R T M E N T S U R F A C E A R E A . G I A t k g ' m - 2

Figure Al. Comparison of calculation results obtained by the iterative technique (circles) and by the semi-empirical method of this aper (lines). Solid curves and dashed curves indi ate ventilation controlled and fuel-surKce controlled conditions, respectively. (& in J m-' s-'" K-I; +/A, in kg m-' s-'; 6 dimensionless).

@/A, do not scale in the same way as 6 when A, is doubled or halved. (The

design values for G/A, and @/A, are expected to remain roughly unaltered,

when A, is doubled, and 6 will probably decrease.) I t is, therefore, crucial to

examine the predictive ability of Equation 7 in combination with Equation

8 a t variable values of 6, while G/A,, @/A,, and J k c a r e held constant. The

results of such an examination are illustrated in Figure A2. The agreement

of results obtained by the iterative technique (open circles) and the em-

pirical method (full lines) appears to remain good as 6 is varied. I t is evident,

therefore, that the semi-empirical method is indeed capable of predicting with fair accuracy the normalized heat load, i.e. the potential to spread by destruction, of fires of cellulosics under either ventilation controlled or fuel- surface controlled conditions.

In reflecting on the semi-empirical method described in this paper, one may object to the fact that its validity has been established only against a supposedly more accurate method, theoretical in nature, not against ex- perimental data. The principal difficulty in supplying experimental confir- mation is that using the normalized heat load in characterizing the potential

of fires for destructive spread is a relatively new devel~pment,~ and until

recently3 no experimental technique has been available for its evaluation. There are two arguments, however, that the authors can offer in support

0

0 10 2 0 3 0 40 50 60

F I R E L O A D R E F E R R E D T O C O M P A R T M E N T S U R F A C E A R E A . G l A , k g . m - 2

Figure A2. Comparison o f calculation results obtained by iterative technique (circles) and semi-empirical method o f this paper (lines).

of the semi-empirical method. The first is that the detailed iterative tech- nique on which the method has been founded was proved earlier1° to yield satisfactory agreement with experimental data. The second is that, irrespec- tive of its foundation, the method affords conclusions consistent with those derived from a multitude of observations over the years.

R E F E R E N C E S

" Harmathy, T. Z., "A New Look a t Compartment Fires, Parts I and 11," Fire Technology, Vol. 8, No. 3 and 4 (1972). pp. 196-217, 326-351.

"' Butcher. E. G., Chitty. T. B., and Ashton, L. A., "The Temperatures Attained b Steel

in Building Fires," Joint Fire Research Organization. England. Fire ~ e s e a r c h ~ e c h n i c J ~ a p e r N n 15 1066

- 7 - . -",

A3B~tcher. E. G., Bedford. G. K.. and Fardell, P. J., "Further Experiments on Temperatures Reached by Steel in Buildings," Proceedings of Symposium held a t Fire Research Station, January 1967, Joint Fire Research Organnation, England, 1968, p. 1.

This pa r is a contribution from the Division of Buildin Research, National Research Council of fanada. and is published with the approval of thebirector of the Division.

ing Research of the National Research Council of Canada. I t should not be reproduced in whole or in part without permis- sion of the original publisher. The Division would be glad to

be of assistance in obtaining such permission.

Publications of the Division may be obtained by mailing the appropriate remittance (a Bank, Express, or Post Office Money Order, or a cheque, made payable to the Receiver General of Canada, credit NRC) to the National Research Council of Canada, Ottawa. KIA 0R6. Stamps are not acceptable.

A list of all publications of the Division is available and may

be obtained from the Publications Section, Division of Build- ing Research, National Research Council of Canada, Ottawa.