Publisher’s version / Version de l'éditeur:

Technical Translation (National Research Council of Canada), 1960

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20386614

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at Tests on Masonry Mortars

Hummel, A.; Wesche, K.; National Research Council of Canada. Division of Building Research

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=dbe5465e-4187-44d1-bfb1-29e292af6c25 https://publications-cnrc.canada.ca/fra/voir/objet/?id=dbe5465e-4187-44d1-bfb1-29e292af6c25

FROM

FORTSCHR. U. FORSCHUNGEN 1M BAUWESEN. SER. D. (24): 15 - 31, 1956

TESTS ON MASONRY MORTARS

NATIONAL RESEARCH COUNCIL OF CANADA NRC TT· 887 D. A. SINCLAIR OTTAWA 1960 TRANSLATED BY BY

A. HUMMEL AND K. WESCHE TECHNICAL TRANSLATION 887

J

THIS IS THE SIXTY - SECOND OF THE SERIES OF TRANSLATIONS

PREPARED FOR THE DIVISION OF BUILDING RESEARCH

NRC TT· 887

PREFACE

Unit masonry is a traditional bUilding material used extensively throughout Europe, North America and

elsewhere. Certain important properties of mortar

for unit masonry, however, are not yet completely understood, for example that of "workability". This translation has accordingly been prepared of an

article from the German technical literature which is considered to provide useful information on some of the important properties of mortar for unit masonry.

The translation was prepared by Mr. D.A. Sinclair of the Translations Section of the National Research Council to whom the Division of Building Research records its thanks.

Ottawa, April 1960

R.F. Legget, Director

NATIONAL RESEARCH COUNCIL OF CANADA

Technical Translations 887

Title: Tests on masonry mortars

(Versuche an Mauermorteln)

Authors: A. Hummel and K. Wesche

Reference: Fortschr. u. Forschungen im 3auwesen, ser. D, (24):

15-31, 1956

TESTS ON MASONRY セortars

1. Purpose of Tests

In DIN 1053 the masonry ュッイエセイウ are determined solely by their volumetric ratios. However, since these mortars may consist of

widely different bonding agents and mixtures of bonding agents, this gives no clear indication of their technical properties. Further-more, the mortar properties depend on other influences and environ-mental factors, the effects of which are still not entirely clear.

For these reasons the Institut fur Bauforschung of the Rhein.-Westf. Technische Hochschule Aachen undertook extensive investiga-tions in the years 1953 and 1954 with a view to answering the

following questions:

1.1 How do various cements respond during hardening to the addition of various building limes?

1.2 Do the most important testing methods known at the present

time adequately express the workability of the mortars?

1.3 Are the strengths of the various masonry mortars affected by

a prolonged curing at +5°C in comparison with curing at the standard temperature of +20oC?

1.4 How is the effect of two extreme grain sizes of sand expressed in the strength of the different mortars and what effect in this respect has the "looseningll of the sands due to an

intrinsic moisture content of three percent by weight at the volumetric proportions of mortar materials provided for in DIN 10531

1.5 How does the strength of the masonry mortars made from the

different bonding agents and mixtures of bonding agents develop up to the age of one year? Do the strengths become equalized at advanced ages, as hoped for, for example, in the case of

the lime mortars? How does the addition of various limes affect

the compressive strengths of cement mortars and how do the individual cements react to these additions?

- - - -...f

-4-1.6 Are the strengths of the masonry mortars correctly expressed in the former classification of DIN 10531

The tests described in the present paper were carried out as part of a research program authorized by the North-Rhine Westphalian Minister for Reconstruction in March 1952, in conjunction with a research program on IIMortars for free- stand ing ch imneys" • The

results of this latter study have already been reported in a preceding paper*.

2. Scope of the Tests

The tests are classified as follows:

2.1 Preliminary tests to determine the standard properties of the bonding agents employed

Types of bonding agent High calcium lime·· paste

High calcium hydrated lime

Hydraulic lime*·· (plaster and masonry lime) Semi-hydraulic lime****

Pressure hydrated lime (ultra-hydraulic lime) Portland cement Z 225

Portland cement Z 325

Blast furnace cement Z 225

Abbreviation employed TNT WH WK HK HHK PZ PZH HZ or HOZ In order to ensure a 28-day standard compressive strength for the blast furnace cement Z 225 under 300 kg/em the cement was ground

*

*****

****A. Hummel. TeRts on mortars for free-sta.nding chimneys. Fortschr. u. Forschungen im 3auwesen, sere D, (24): 5-14,

1956. (NRC TT-886)

rrranslator ' s note: German IITtlcisska1k" = lime containing more than 90% CaO (cf. Brockhaus der セャウウ・ョウ」ィ。ヲエ und der Technik, Leipzig, 1955).

Translator's note: Ger'1lan "Wasserkalk"

=

lime containing more than 10% silicic acid, alumina and iron; slakes on addition of water (ibid).Translator's note: "hydraulische Kalk"

=

lime containing more than 15% s111c1c acid, alumina and iron (ibid).

-5-separately in the manufacturing plant.

The mortar sands were composed of equal parts by weight of grain sizes 0/0.2, 0.2/1 and 1/3 mm.

2.2 Suoplementary preliminary tests on mixtures of binding agents The mixtures of bonding agents were also tested for constancy of volume and hardening.

2.3 Main tests on the masonry mortars

Included were:

21 series of mortars from dry, fairly coarse sand;

4 series of mortars from fairly coarse sand with a moisture content of 3% by weight;

21 series of mortars from dry comparatively fine sand.

The test soecimens were 4 • 4 • 16 prisms; they were tested at the ages of 28, 90 and 360 days for unit weight, flexural and

compressive strength.

The prisms of all mortar series were cured continuously at a temperature of +20oC or +5°C, as the case may be.

In all, 92 series of tests were conducted.

3. Description of Tests and Results

3.1 Results of ウセ。ョ、。イ、 tests of bonding agents

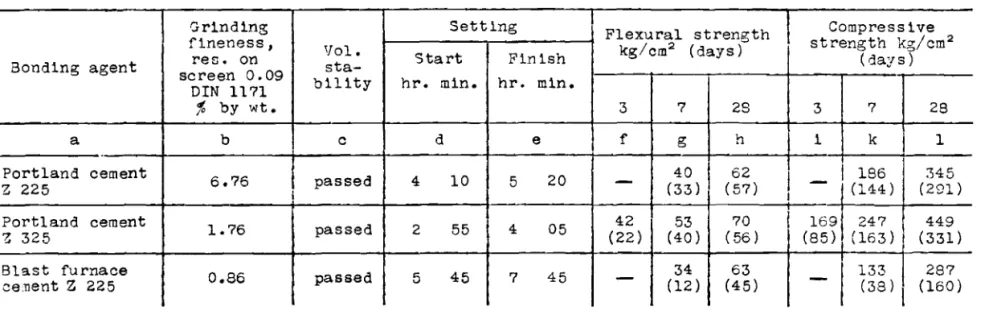

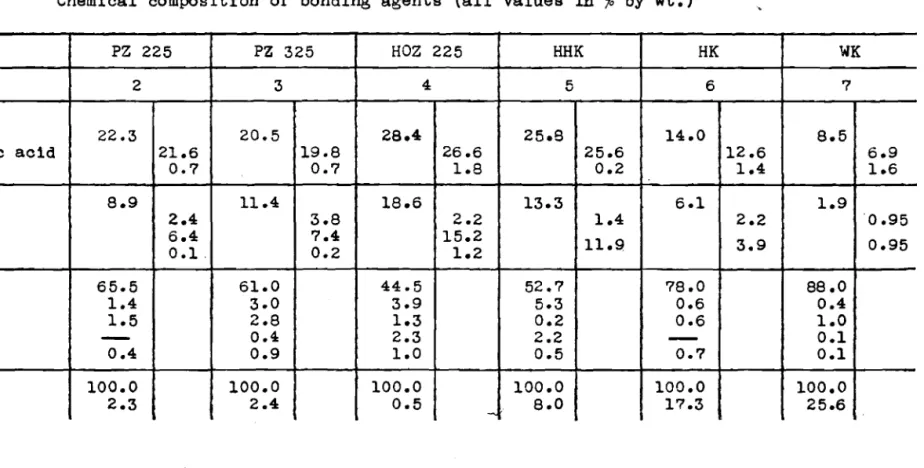

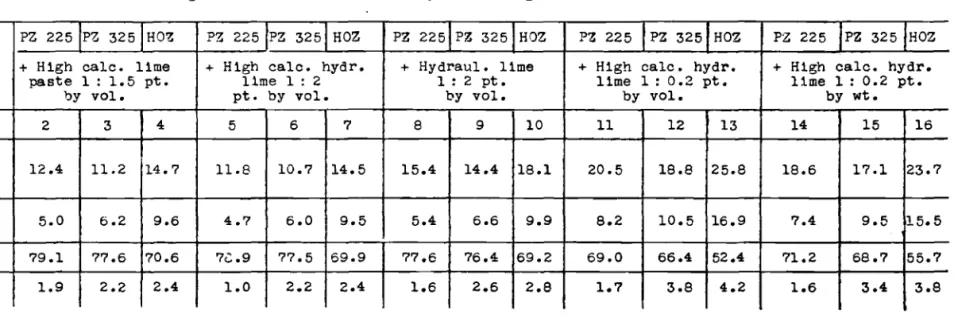

Table I gives the mean values of the results of standard tests for the building limes employed, and Table II for the cements.

For the chemical composition* of the bonding agents see

Table III, and for the calculated chemical compositions of the mix-tures of bonding agents see Table IlIa. The chemical investigation of the cements was carried out according to the analytical procedure for standard cements, with a special test for loss on ignition in the case of blast furnace cement. The limes were analyzed by the standard procedure for bUilding limes.

*

The chemical analyses were carried out by Dr. rer. nat. F. Baronetzky of the Institut fur Bauforschung.

-6-All results are calculated for substance free of ignition

loss. They are given in percent, rounded off to 0.1%.

The st r-ength s of the bonding a.gents were also determined on

prisms cured at a temperature of +5°C. The valueR obtained are

included in Tables I and II in brackets.

The 31aine specific areas and the unit weights pure were also

determined. The values obtained were as follows:

Blaine values Unit t'Jeights pure

cm2/gm

kg/dm3

High calcium hydrated lime WH 10830 2.44

Hydraulic lime WK 9600 2.47

Semi-hydraulic lime HK 7860 2.57

Pressure hydrated lime HHK 5120 2.70

Portland cement Z 225 PZ 2725 3.07

Portland cement Z 325 PZH 4105 3.01

Blast furnace cement Z 225 H03 3910 2.97

From these ーイ・ャゥセゥョ。イケ invGstigations the following results were

obtained:

All the bonding agents investigated satisfied the standard requirements involved, except that there was a slight residue of three limes on screen 0.6 DIN 1171 and the high calcium hydrated

lime exceeded the 7% permissible CO2 content.

The hydraulic lime WK corresponds in strength practically to

the semi-hydraulic lime HK. Unfortunately no hydraulic lime with a

28-day compressive strength between 10 and 20 kg/cm2 was commercially

available at the time of the tests.

The effect of the curing temperature on the 28-day compressive strength of the standard mortars, i.e., the ratio

cッュᆪᆪセウウゥカ・ ウエイ・ョセエィ cured at +5°C • 100

Compressive strength cured at +20crC was found for the individual agents as follows:

Hydraulic lime 14

·

100 := 54%26

Semi-hydraulic lime 15 • 100

=

63%24

Pr'e s sur-e hydrated lime _80

·

100 :::: 49%162

-7-Portland cement Z 325

セN

449 100=

74%Blast furnace cement 160. 100

=

56%287

The order of sensitivity of the bonding agents to lower tem-perature, based on the 28-day compressive strength, 1s therefore:

Pressure hydrated lime Hydraulic lime

Blast furnace cement Semi-hydraulic lime Portland cenent Z 325 Portland cement Z 225

(Cf. also Fig. 1)

3.2 Results of エィセ ウuprQセュ・ョエ。イケ ーイ・ャゥセゥョ。イケ tests on the bondin£ agent mixtures

3.2.1 Volumetric constancy of bonding qgent mt.,xB!res according t.Q DIN 1060 lrevised versionl

All the mixtures of compositions shown in Table V (without sand) were constant as to volume when subjected to the time test. In the rapid test, to be sure, all mixtures with the hydraulic lime, and the hydraulic ャゥセ・ alone, showed surface cracks on the cakes. 3.2.2 Hardening of bond ing agel1t .mixtures when ...tested 。」」ッイ、セョァ to

DIN 1164

In Table IV and Fig. 2 all the hardening times of the bonding agents and their mixtures according to Table V (without sand) are

compared. The results are as follows:

セゥエィ the portland cement Z 225 and blast furnace cement Z 225 the addition of high calcium lime postponed the termination of

hardening. The beginning and end of hardening remained p ract Lcal.Ly

the same for portland cement Z 225 and portland cement plus high calcium ャゥセ・ hydrate in the mixture ratio of 1 : 2, and for blast furnace cement and blast furnace cement plus 20% high calcium lime hydrate.

In all other mixtures with portland cement Z 225 and blast

furnace cement the addition of limes results in an earlier beginning and end of hardening.

-8-The portland cement Z 325 related to the addition of every type of lime by a postponement of the beginning end of hardening. In the case of portland cement Z 325 plus high calcium lime hydrate

in the ratio I : 2 these times were more than doubled. However,

even here the hardening times remained Within the permissible limits. 3.3 Executiqq and results of ュセャョ エ・ウエセ an masonry ュqイエ。セウ

3.3.1 Preparation& composition and properties of fresh masonry mortars

The mixture ratios of the test mortars were in accordance with DIN 1053, Table III, in parts by volume, converted into parts by weight on the basis of the following table of; weights per litre of

the mortar components. In carrying out the tests, measurements

were always made by weight for the sake of accuracy.

The weights per litre of the bonding agents loose poured in the 5-litre vessel were:

High calcium lime paste WT High calcium hydrated lime WH Hydraulic lime WK

Semi-hydraulic lime HK Pressure hydrated lime HHK Portland cement Z 225 PZ Portland cement Z 325 PZH

Blast furnace cement Z 225 HOZ

1.33 kg/litre 0.50 kg/litre 0.56 kg/litre 0.70 kg/litre 0.88 kg/litre 1.12 kg/lit re 1.10 kg/litre 1.04 kg/litre

The high calcium lime paste had a water content between 104 and 123% relative to the dry substance.

The grain compositions and weights per litre of the sands of the two extreme grains were:

Sand Coarse Fine Coarse Grain component in

%

by wt. 0/0.2 by grain group0.211 1/3 mm mm mm 20 30 50 40 45 15with 3% by wt. moisture reI. to dry substance kg/litre loose 1.65 1.62 1.15 1.12 Symbol for sand g f gf

-9-Table V gives the compositions of the fresh masonry mortars in parts by volume and by weight, the slump values, the numbers of strokes in the Powers apparatus, the plasticity indices and the fresh unit weights of all the mortars.

In mortar series 35 to 40 the high calcium lime hydrate was added in quantities of both 20% by weight (symbol G) and 20% by

volume (symbol R). The series with 20% by weight are denoted

35 a to 40 a. They were cured at +20oC only and tested only at the age of 28 days.

The mortar for 18 prisms measuring 4 • 4 • 16 cm was mixed

in a small laboratory mixer. The water was measured out so that

the masonry mortar would have proper trowelling properties. Consistency measurements

The consistency of the fresh masonry mortars was measured (a) with the flow-table according to Fig. 10 DIN 1164; (b) with the small Powers 。セー。イ。エオウ (Fig. 3);

(c) wi th the "cube deforming" apparatus according to the specifications of the Marquette Cement ManUfacturing Company (Fig. 4).

It is necessary to keep in mind the various principles of operation of these devices for measuring the consistency.

In the first two devices the work of deformation is performed by jolting, in the cube ap?aratus it is done by squeezing. On the jolting table a truncated cone of mortar is deformed freely into a mortar cake by being given 15 standardized jolts, the diameter of the cake characterizes the consistency as the extent of slump. In the Powers auparatus a truncated cone of mortar 1s forcibly

deformed 1nto a cylinder. The number of strokes of the jolting

table required to accomplish this 1s regarded as a measure of the

consistency. In the cube apparatus a square slab of mortar 4 • 4 •

2 inches 1s deformed under a certain load into a rhombus. The size

of the resulting acute apex angle of the rhombus is a measure of extent of the deformat1on, which 1s taken from a エ。セャ・ as the "plastic1ty index".

-

-10-Since !t could be assumed that water expelled from the mortar as well as grains of sand getting into the hinges of the cube

a ppa r'at.u s woul d change its friction, the small "lOoden pestle from

the flow-table according to DIN 1164 was dropped 15 times from a

height of 5 cm on the plate of the cube apparatus after the usual

determination of the plasticity index, and then the determination was repeated.

The entire results of the consistency measurements are given

in Table V and Fig. 5.

3.3.2 Determination of the unit weights and strengths of the

hardened masonry mortars

The 4 • 4 • 16 em prisms prepared according to DIN 1164 were

first cured 24 to 96 hours, depending on the progress of hardening

in the mould in moisture saturated air at either +20 or +5°C, in

which they then remained until the 7th day after the mould had been

removed. They were then kept until the time of testing either in

the air-conditioned room at +20oC at 65% relative humidity or at

+5°C in the room atmosphere.

Fig. 6 gives the entire test results (unit weights, flexural strengths and compressive strengths) for the different curing

conditions and the testing times provided for (28, 90 and 360 days). For the sake of clarity and easier comprehension the compressive

ウエイ・ョセエィウ of the masonry mortars, except those prcuared with coarse

sand of Sセ inherent moisutre content, are compared granhically in

Fig. 6 to 9.

4. Evaluation ッUMャ`セョ t・ウセᄃ r・ウセャセウ op m。セッョイケ Mortars

4.1 Water 」ッセエ・ョエ of fresh ュッイエ。イセ

The parts by volume of mixing water reouired according to

Table V for proper trowelling consistency qre about equal within

the separate groups of bonding agents or mixtures of agents and can be divided into three ranges wh Lch are divisible in turn into

sub-classes according to the grain compos!t i on of the sand. Table VII

P'

-11-If the water contents of the fresh mortars are calculated on the basis of the weight of the dry substance (bonding agent + sand), they are found to be approximately equal, with the exception of the mortars made with high calcium lime paste.

Table VIII shows this in order of increasing water content. The unlisted individual values of the first 6 groups in Table VIII

vary:-between 12.2 and 14.3% by wt. in mortars from coarse sand (average 13.0%); between 15.1 and 16.6% by wt. in mortars from fine sand

(a ve rage 15. 7%) • The marked difference of these values from those of group 7 (cement + high calcium lime paste) is noteworthy.

4.2 InterDretation of the results of consistency measurements on fresh masonry mortars

Fig. 5 ShOTf-1S that the consistencies of the always "trowel1ab1e" masonry mortars vary within certain limits, namely,

between 13 and 17 em on the DIN 1164 flow-table; between 30 and 13 strokes in the Powers apparatus

(with one exception); between plast ici ty indice s 15 and 40 in the II deformed

cube" apparatus.

Generally speaking the individual results from the three methods run in parallel directions, but in two of the methods they are to some extent also in opposite directions.

However, if we compare the mean values of the results of the three measuring methods for the individual groups of 「ッョ、ゥョセ agents, leaving out obvious non-conforming examples, then Fig. 10 is obtained. Here, with one exception, there is good parallelity between the

results from the Ildeformed cube" method and the Powers instrument, whereas the slump measurement on the flow table shows quite a

different sequence of masonry mortars.

However, since even slight changes in the amount of added water decisively influence the consistency for all three methods in the

F'

-12-soft mortar range (much more decisively, for example, than a change in the kind of bonding agent), it 1s doubtful whether these tradi-tional measuring methods do in fact characterize the workability and malleability of the mortars.

In seeking a testing method which would reveal the nature of the workability and do more justice to it, we were assisted by the

discovery, from Fig. 5, that the difference of the plasticity

index for the usual determination and after 15 strokes (cf' , 580.3.3.1) was not constant over all series of mortars, but was subject to

variations, and that moreover these differences, within the scope of our tests, did not depend either on the mixing ratio of the mortar, the grain composition of the sand or even on the amount of

water added, but ウッャ・ャセ on the kind of bondipg 。セ・ョエ or mixture of

bonding 。セ・セL which, of course, is precisely what is required in

such measurements.

The differences of plasticity index are plotted in Fig. 11.

ャセ・ interpret these differences to mean that in the easily workable

mortars in the main the whole work of deformation in the cube apparatus if performed by squeezing alone, whereas for the less workable mortars some additional deformation is produced by bumping

after the squeezing. The differences of plasticity index in Fig. 11

thus give the magnitude of this additional deformation. Control

tests with nure bonding agents, the results of which are also

plotted in Fig. 11, showed that this new method is applicable even

to pure bonding agents without the addition of sand, the knovm

differences of plasticity index, 1.e., the additional deformations, being smsller, but nevertheless still clearly expressed.

As far as キ・N。イ・⦅セキ。イ・ this is the first time 。セ・エィッelィ。ウ

been ウオセァ・ウエ・、セQィゥ」ィセケ・イュゥエウ characterization of the workab11ity

。ョセセ。ャャ・セ「セャセエケ of a mortar ゥuセ⦅ way that is largely independent

of the ウッヲエョ・セセN

4.3 aウウ・セA}Nウュエ of the unit weights セアヲ the masonry mortars in the

fresh and in エdセ。イ、・ョ・、 state

In table IX the mean unit we Lgnt s of the fresh masonry mortars

2·

,

,..

-13-a」」ッイ、ゥョセ to Table IX the lowest unit weights of the fresh

mortars occurred as a result of adding high calcium lime paste to

the cement mortars, while the h Lgrie st ones result from a smaller

addition of high calcium hydrated lime to the cement mortars. The addition of high calcium lime paste appears to produce a

mar-lced loosening of the mortar (cf. also Sec. 4.4.1).

From Table VI we may also note that:

The unit weights of the mortars decrease up to the 28th day. The extent of the decrease 1s greater in the mortars from fine

sand than in those from coarse, and for curing at +20oC than at +5°C.

After the 28th day some of the unit weights continue to decrease, while others increase again.

The follOWing masonry mortars show a tendency to increase in unit weight after the 28th day.

Mortg.rs from:

1. hydraulic lime;

2. portland cements Z 225 and Z 325;

3. portland cements + 20% by vol. high calcium hydrated lime;

4. portland cements + hydraulic lime;

5. cements + high calcium hydrated lime 1

6. cements + high calcium lime paste.

The following mortars show a tendency to decrease in unit weight after the 28th day.

Mortars from:

7. semi-hydraulic 11me;

8. pressure hydrated lime;

9. blast furnace cement + 20% by vol. high calcium hydrated

lime;

10. blast furnace cement + hydraulic lime.

It cannot yet be decided whether these different unit weight variations are associated with the usual scatters of the individual samples or are due to dl fferences in water binding and water

- - -

-

-14-4.4 Detorminatlpn, of. strengt:.hs, of masonry mortars

The familiar parallelism is found between the compressive and

flexural strengths of the masonry mortars. The interpretation of

the results in Table VI can therefore be undertaken on the basis of compressive strength only.

4.4.1 cッューイ・セゥカ・ strengths of the masonry mortars as a func!1Qn

of the kind of 「ッョ、ャョセ agent or mixture of bonding agents According to Fig. 6 to g, apart from a few blast furnace cement examples, three groups of masonry mortars with respect to compressive strength can be distinguished.

Table X gives these three groups and their limiting strengths on the basis of the 28-day compressive strength.

This grouping continues to apply even for the gO-day compressive

strengths. At the age of 360 days, however, mortar groups B and C

overlap, but not groups A and B. This is noteworthy.

The mortars from pressure hydrated lime occupy a special post t Lon, When cured at +20oC they fall under group B, but at +5°C under

group A. However, When we consider the high standard compressive

strength of 162 kg/em::! (cf. Table I) of the pressure hydrated lime used here, it is certain that a masonry mortar from an ordinary pressure hydrated lime (standard compressive strength セ 50 kg/em2) can only be classified as a mortar of group A even at +20oC curing.

This has been done in Table X. This was confirmed by the results

of the tests on mortars for free-standing chimneys whLch were mentioned at the beginning.

In contradiction to DIN 1053, the masonry mortars of cement plus high calcium lime paste, according to the results obtained here, also belong to the group with lower strength values. At the same time, compared wi th the stronger mortars from cement and high calcium h:{drated lime, for equal dry mix ratio, only the water con-tent in the mortar from cement plus lime paste is somewhat higher.

Its lower stretlgth should be attributed not solely to this, but much

more decisively to the considerably smaller fresh unit weight (cf. Table IX). Th.l!§...,_J.hn F!:S1dl·_t1.2!L9..lャセャァィ HGセセjsャャIAAャNャlセQHセ __t?ast8 ・vセ、・セGQエャ[ケ

reeults in 9 」ッョrエセqイアィャョ loOscn1nQ of the fresh mortar セィゥ」ィ

-15-increases the workabilitL but decreases the strength (cf. Sec. 4.3). From Fig. 6 to 9 the following also appears noteworthy:

The mortars with portland cement Z 325, despite the higher cement standard strength, appear to have higher strengths than the masonry mortar with portland cement Z 225 only in two cases, namely, on addition of hydraulic lime and on addition of RPセ by wt. high calcium hydrated lime.

In order to determine the effect that different limes added to the cement and different quantities thereof have on the compreRsive strengths of masonry mortars, the proportional values of the

compressive strengths of the lime-cement or cement-lime mortars to the strengths of the corresponding cement mortars were calculated and are represented in Fig. 12 to 15.

Fig. 12 to 15 show that for the effect of additions of lime on the compressive strengths of the individual groups of bonding agent mixtures there are certain ranges of proportions the upper boundaries of which are exceeded (in some cases quite considerably)

only by mortars made with blast furnace cement. These ranges of

proportions are practically identical in all of Fig. 12 to 15, which relate of course to two different sands and two different

curing conditions. That is to say, the change of the sand and the curing temperature do not alter the distribution of the ranges. Table XI shows the ranges and proportional values.

Referring the proportional values according to Fig. 12 to 15 for portland cement Z 325 and blast furnace cement Z 225 to the corresponding values for portland cement Z 225, in order to show the different ways in which the cements respond relatively to the different additions of limes, we get the second degree proportional values of Fig. 16 to 19.

Fig.

19

to 19 show:(la) That portland cement Z 325 responds at all ages to an addition of hydrated cernent on the average about as potland cement

Z 225 does. The proportional values for the mortars from both

sands and for both curing temperatures lie be twe en 80 and 130% with maximum values at the age of 90 days.

-16-(lb) Portland cement Z 325 gives higher strength proportions

than portland cement Z 225 for additions of hydraulic lime, namely: 110 to 160% for 20 0 curing

130 to 180% for 50 curing.

The maximum values are again obtained at the age of 90 days.

(2) Blast furnace cement Z 225 behaves differently, especially

in its dependence on curing temperature:

(a) At 20 0 curing all limes have about the same effect; but

the strength proportional values depend on age, i.e., with increasing age they are

(b)

90 to 130,% after 28 days

120 to 200'1[, after 90 days

150 to 250% after 360 days.

At 5° curing different limes and different amounts of lime act differently; the strength proportions for high calcium hydrated lime (small amounts up to 20%) are 100 to 140%

for high calcium lime paste 120 to 180%

for hi zh calc lum hyd r-at e d 1 ime (larger quant 1ties) 130 to 220%

for ィケ、イセオャゥ」 lime 140 to 230%

In case (b) the largest proportional values were again obtained after 90 days.

(3) In all cases the increase in the strength proportion

values is greater for masonry mortars from fine sand than for mortars from coarse sand.

4.4.2 COffi\?ressive ウエイ・ョァエZqNNᄃセアNヲ⦅エ「セqhSNウPョイケ mor,:tars deRending on

the 」オイゥョdセ Nォョイ[I・イ。エオイセ (+20 0 or +5°C)

Fig. 20 and 21 give the compressive strengths of the masonry mortars for prolonged curing at +5°C in percent of the compressive

strengths for prolonged curing at +200C.

fセLァN 20 and 21 show

that:-for prolonged curing of the mortar prisms at +5°C the compressive strengths compared with those for +20° curine, at all age steps,

are:-increased 110 to 180% for hydraulic lime mortars;

Lnc r'ea s e d 100 to 130;,1, for semi-hyd r-aut I c 1t me mortars;

-17-Of these masonry mortars, those employing portland cement Z 225 are least susceptible to low temperatures while those with 「ャセウエ

furnace cement are the most inhibited in their strength evolution. At greater age the strengths after +20° and +5° curing become in large measure equalized. In some cases the strengths after +5° curing are greater than after +20° curing.

The effect on stabilization of the masonry mortars at +5°C corresponds to that for the standard mortar prisms except in the case of the mortars from hydraulic lime and semi-hydraulic lime

(cf' , Sec. 3.1).

4.4.3 Compressive strengths of エィ・セ。ウッョイケ mortars for カ。セゥッオウ

grain compositions of the sand and for dry and wet sand Fig. 22 and 23 show the compressive strengths of the masonry mortars from fine sand in percent of the comparison masonry mortars from coarse sand, given separately for the curing of the specimens at +20oC and at +5°C.

Fig. 22 and 23 reveal that the influence of the grain composi-tion of the sand is the same for all the masonry mortars investi-gated and at both curing temperatures, with the exception of the mortars from pressure hydrated lime. At both curing temperatures the mortars from fine sand have about 60 to 90%, generally indeed 70 to

90% of the compressive strengths of the coarse sand mortars. In

the case of the mortar f'r'on pressure hydrated lime, howeve r , these proportional figures were:

100 to 110% for +20° curing 80 to 120% for + 5° curing.

The effect of the moisture content of the sand (3% moisture content compared with 0%) is illustrated in Fig. 24.

The loosening of the sand due to its own moisture content (reduction of weight per litre, see 3.3.1) Where proportioning of the mortar components is by volume results, in 'an increase of bond-ing agent content and hence an increase of compressive strength to predominantly 110 to 170% for both curing temperatures. Again the mortar from pressure hydrated lime constitutes an exception, since the loosening due to the moisture content of the sand increases the

-18-compressive strength to 200 to 270% at +200 curing and 170 to 220% at +5° curing.

4.4.4 Estimate of strength evolution of the masonrl ュqイエセイウ with

Qョᆪᆪセゥョァ age up to one year

The stabilization of the masonry mortars up to the age of one year is represented graphically in Fig. 25. For reasons of clarity

it was impossible to plot the more than ninety test series individ-ually. Only the upper and lower strength limits have been repre-sented as well as the mean values for the groups of bonding agents or bonding agent mixtures, the four series of mortars from wet sand being especially singled out.

From the time-strength curves of Fig. 25, especially from the 90th to the 360th day, it is clear that no unusual post-hardenings occur in individual series, especially in the case of the lime

mortars, although this is often presumed to be the case. At most

there is a somehwat clearer post-hardening in the mortar from cement

and semi-hydraulic lime. In the masonry mortars from pressure

hydrated lime and those from blast furnace cement there is even a tendency for the strength to decrease.

Fig. 25 also reveals that the masonry mortars from the chosen bonding agents and bonding agent mixtures can be divided into three groups according to their compressive strengths after 28 and 90 days. These have been denoted by the letters A, Band C in Table X and

are described there more fully.

At the age of 360 days mortar groups B and C overlap, but not groups A and B, at least in the cases Where dry sand was used.

5. Answers to the questions Raised in Section 1

Q,uestion 1.1:

According to Table IV and Fig. 2, the hardening times of the pure cements are differently affected by the addition of different

building limes. Some of the times remain practically unchanged,

-19-From the practical point of view, however, only the addition of 2 parts by volume high calcium hydrated lime to portland cement Z 325 is of importance. In this case the beginning and termination of hardening are extended over more than double the time. Even so, these substantially longer hardening times remain within the

permissible limits. Q,uestion 1.2:

The measurement of the so-called "trowellable" mortar consis-tency with the bumping table according to DIN 1164, the small

Powers apparatus and the cube deforming apparatus in some cases

give results of the same tendency and in others of opposite tendency. The mean values of the results for the bondinEf agent groups investi-gated, with one exception, show good parallelism, however, between the results from the Powers apparatus and from the cube deforming apparatus, whereas the slump values obtained on the bumping table give a different sequence of mortars (cf. Fig. 10).

Since in the soft mortar range very slight changes in the amount of water added for mixing affect the consistency values for all three methods more decisively than a change in the kind of bonding agent, it must be doubted whether these methods do in fact adequately characterize the workability and malleability of the mortars.

In

the present paper a modified application of the cubedeforming apparatus was suggested by which, to the best of our know-ledge, it is possible for the first time to characterize the work-ability of mortars more or less independently of the mixing

proportion and the quantity of water added for mixing. Question 1.3:

Based on the 28-day compressive strengths of the standard mortars, the order of sensitivity to lower temperatures, beginning with the most sensitive bonding agent is:

pressure hydrated lime hydrated hydraulic lime blast furnace cement semi-hydraulic lime portland cement Z 325

-20-portland cement Z 225.

This order of sensitivities is also found in the セセウッョイケ

mortars at the 。セ・ of 28 days, with the exce?tion of the mortars

from hyaraulic lime and semi-hydraulic lime, which here show an

increased ウエイセョァエィ for +5° curing.

Among the masonry mo rt a r s , that from pressure hyr'1rated lime

is the most sensitive, followed by those from blast furnace cement

セゥエィ and without the addition of lime. Least affected by the +5°

curing are the mortars from portland cement Z 225.

At advanced age the influence of the curing temperature tends

to 0isa?pear. In some cases the curves overlap.

£,uestion 1.4:

In the masonry mortars from the chosen bondinG agents and bonding asent mixtures,coarse sand produces higher compressive

strengths than the finer sand (cf. Fig. 22 and 23). An exception

1s the masonry mortar from pressure hydrated lime, which gives practically the same compressive strength for both types of sand.

The loosenin; of the sand due to an intrinsic moisture content of 3 percent by weight increases the mortar compressive strength at both curing temperatures when the mixture is in parts by volume. The effect is particularly noticeable in the mortar from pressure hydrated lime (Fie. 4).

Q.uestJ.9n 1.Q:

The time-ctrength curves of Fig. 25 reveal no unusual post-hardeninzs or eaualizations of strengths at advanced ages of the mortars from the various bonding agents and mixtures of bonding agents, under otherwise similar conditions, not even in the lime mortars.

The masonry mortars investigated can be divided according to

their Z8-day compressive strengths into three groups セL 3 and C

(cf. tセ「ャ・ X). At the age of 360 days groups Band C overlap,

but not groups A and 0, provided dry sands have been used.

Table XI shows the effect of the additions of limes on the c ornpr-e s s I ve strengths of the mas orir'y mortars as a function of the kind of cement.

-21-The addition of high calcium lime paste reduces the strength

very sUbstantially in all mortars. With the other kinds of lime

the influence on the mortar strength depends on the kind of cement. Portland cements Z 225 and Z 325 respond to the non-hydraulic limes in about the same way as far as the strength is concerned. On the addition of hydraulic limes, however, portland cement Z 325 produces considerably greater strength values than the comparison mortar made with portland cement Z 225.

In the case of blast furnace cement the effect of additions of lime on the strength evolution depends on the temperature and the age.

Question 1.6:

In DIN 1053, Table III, the masonry mortars are divided into three groups, namely:

Group I: Mortars from lime paste, hydrated lime and

semi-hydraulic lime;

Group II: Lime cement mortars and mortars from pressure

hydrated lime;

Group III: Cement mortars (in certain cases with moderate

additions of hydrated lime).

No special strength requirements are made of Group I, according to DIN 1053, no.4, 12. Mortars according to Group II, however, must have a mean compressive strength of 25 kg/cm2

, and those of Group III a mean compressive strength of 100 kg/cm 2

•

Table X of the present paper, however shows that the following mortars do not fit properly into Group II of DIN 1053 and in general fall short of the prescribed mean compressive strength of 25 kg/cm2:

Mortars from:

1 part by vol. cement, 1.5 parts by vol. high calcium lime paste and

8 parts by vol. sand and from

1 part by vol. pressure hydrated lime and 3 parts by vol. sand These latter mortars should either be classified under Group I or, better, four groups should be set up.

T

I

-22-A suggestion for the new classification of masonry mortars 1s given in Table XII. Since according to Fig. 25 and the answer to question 5, no significant posthardenings occurred, the suggestion

in Table XII was based on the compressive strengths after 28 days and for specimen curing at +20oC.

Only some such grouping as suggested in Table XII does justice to the actual strength characteristics of masonry mortars.

Table I

Results of standard tests on bUilding limes according to DIN 1060 (revised version).

The bracketed figures are the strengths for +5° curing

Chemical compo- Grain

ccmposi-"\

I

sit i on in % tion residue in % Wt ./l1.tre Water con- Vol. sta- Flexe

I

Compr.Bon dLng agent by wt. by wt. on screen sumption bHit, under

I

str. str ,DIN 1171 water curable

C3.0 MgO CO2 kg/litre セ • 100 after days kg/em ;;/ kg/em2

0.09 0.6

a b c d e f g h 1 k 1

H1?;h calc.

lime paste 93.62 0.45 1.94

-

- --

-

-

-High calc.

hy-I

drated lime 90.50 1.79 2.76 4.18 0.01 0.465 S8.0 passed

-

セセI Hydrated

hy-I

passed* 9.5 26 draulic lime-

- 13.50 0.48 0.01 0.489 66.7 3 (4.9) (14) Semi-hydraulici

passed 11 24 lime-

-

-

7.25 0.02 0.774 54.2 2 (5.9) (15)Pressure hy- passed 41 162

drated lime

I

-

-

3.15 0.12 0 0.791 44.5 1 (23) (80) I N e:".: ITable II

Results of standard tests on the cements according to DIN 1164.

Bracketed values refer to +5° curing

Gr1nd1ng Setting Flexural strength Compressive

strength kg/cm2

fineness, Vol.

Start Fin ish kg/cm2 (days) (days)

Bonding agent screenres. on0.09

sta-bllity hr. min. hr. min.

DIN 1171 3 7 28 3 7 28 10 by wt. d e f g h i k

I

1 a b c 40 62I

186 345Portland cement 6.76 passed 4 10 5 20

-(33) (57)

I

- (144) (291 )Z 225 I I

42 53 70

I

169 247 449Portland cement 1.76 passed 2 55 4 05

(22) (40 ) (56 ) (85 ) (163)) (331)

Z 325

34 63

-I

133I

287Blast furnace 0.86 passed 5 45 7 45

-(12) (45 ) (38)

I

(160) cenerrt Z 225 I l'J...

ITable III

Chemical composition of bonding agents (all values 10

%

by wt.>Components PZ 225 PZ 325 HOZ 225 HHK HK WK

1 2 3 4 I:.v 6 7

Soluble silicic

acid + insoluble 22.3 20.5 28.4 25.6 14.0 8.5

Soluble silicic acid 21.6 19.8 26.6 25.6 12.6 6.9

Insoluble 0.7 0.7 1.8 0.2 1.4 1.6 Sesquioxides· 8.9 11.4 18.6 13.3 6.1 1.9 Fe-:fJ 3 2.4 3.8 2.2 1.4 2.2 0.95 Ala03 6.4 7.4 15.2 11.9 3.9 0.95 MnO 0.1 0.2 1.2 CaO·· 65.5 61.0 44.5 52.7 78.0 88.0 MgO 1.4 3.0 3.9 5.3 0.6 0.4 S03 1.5 2.8 1.3 0.2 0.6 1.0 CaS

-

0.4 2.3 2.2-

0.1 Residue 0.4 0.9 1.0 0.5 0.7 0.1 100.0 100.0 100.0 100.0 100.0 100.0 Sinter loss 2.3 2.4 0.5 セ 8.0 17.3 25.6• Only the sesquioxldes insoluble in Hel (1 : 1) •

•• Only the lime bound to

cas.

•

N

?'

Table IIla

Calculated chemical composition of bonding agent mixtures (all values are in %by weight).

In the high calc. lime additives only Cao and MgO are taken into account

PZ 225 PZ 325 HO?: PZ 225 PZ 325 HOZ PZ 225 PZ 325 HOZ n 225 PZ 325 HOZ PZ 225 PZ 325 HOZ

Components + High calc. lime + High calc. hydro + Hydraul. lime + High calc. hydro + H1gh calc. hydro

paste 1 : 1.5 pt. lime 1 : 2 1 : 2 pt. lime 1 : 0.2 pt. lime 1 : 0.2 pt.

by vol. pt. by vol. by vol. by vol. by wt.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Soluble silicic acid

+ insoluble s111cic 12.4 11.2 14.7 11.8 10.7 14.5 15.4 14.4 18.1 20.5 18.8 25.8 18.6 17.1 23.7 acid Sesauioy.ldes 5.0 6.2 9.6 4.7 6.0 9.5 5.4 6.6 9.9 8.2 10.5 16.9 7.4 9.5 15.5 Fe203 + {>.1203 + MnO CaO + MgO 79.1 77.6 70.6 7C:.9 77.5 69.9 77.6 76.4 69.2 69.0 66.4 52.4 71.2 68.7 55.7 SJ3 + CaS + residue 1.9 2.2 2.4 1.0 2.2 2.4 1.6 2.6 2.8 1.7 3.8 4.2 1.6 3.4 3.8 I N

cr

-27-Table )J[

Results of tests of bonding agents and mixtures for hardening

Setting

Bonding agent or mixture Start Finish

hr. min. hr. min.

-1 2 3 4 5

-Portland cement Z 225 3 15 5 50

+ high calc. lime paste 2 25 6 50

+ high calc. hydro lime 1 : 2 3 20 5 35

+ hydraul. lime 2 25 4 10

+ high calc. hydraul. lime 1 : 0.2 2 50 4 30

-Portland cement Z 325 2 55 4 05

+ high calc. lime paste 3 50 6 10

+ high calc. hydro lime 1 : 2 6 20 8 20

+ hydraul. lime 3 15 5 45

+ high calc. hydraul. lime 1 : 0.2 3 30 4 25

-Blast furnace cement Z 225 5 15 7 45

+ high calc. lime paste 4 25 8 15

+ high calc. hydro lime 1

.

.

2 4 00 5 00+ hydraul. lime 3 05 4 15

+ high calc. hydraul. 1 ime 1 : 0.2 5 25 7 45

Table V

Composition and properties of fresh mortars

セN - .---.--- - - - セMMMMLMMN⦅⦅M⦅⦅イ⦅MMM⦅⦅⦅⦅イMM⦅⦅⦅N

M1J1:1np" pr-opo r-tton s tn pt. セケ vol.

,I

GセGMGイM "htl !"'')r'- ' to til{ wt. Slump No. of Pj e et t c t t y uセャエ

't 1 エイGセvM t.ar' Po r-t l nn d 311lst! H!1;h High イAセケセABGN Seml- Pr-e e e.l Coa r-s e s3.nd DIN Powers IndexrcubeW •

q::: ..

セ PI_d. roup ce nc nt r,.lr_j

calc , calc. Ih y-tr-auI hyj- hydro ,cf f l " .ins 1164 stroke deI or-ntng jWthen._.-fJeSrn'l- DIN 11 bv d III ᄋMゥBGゥセ、 " ' ) r"'8h

\"8 tl イイGャG|」・AQjセ y r", (lie r-auL, lime ",t ,.; jcen a t.e r- era e opa r'atue k I J

on oセLS R_セZZZ SRセQ c em • pGQセエX lime I LLme w.セ ,ry :jry g dm

セセMMM「MMM c: d e tZ--fo; - --,-- ,-h---1"---;---·"k- 1 - -m n

--t-o- -

p q r Sセ 4: - - " - ' I WKr si. セ セ 14.0 25 25.1/30.4 2.18/2.22 1 J セ 2 WKl [ i B.68 1,52 14.5 21 25.1/29,8 2.13 3 H J < r : 7%7 i i セ 13,4 37 15,0,117.8 2,24 , 1 3 0 92 4 HKt I 6.94 i t3i 14,1 25 17,3/20,1 2,18 5 PZ+WTr i セ i i iiLoZB[セPURI 12.7 22 ,17.8120,6 2.17 1.5 l) a11, MセZGoMMKMMKMMMKLMMMMMMMQヲMMMMMMi 6 PZ+WTrf 1 セ I iR.O i Iセi 13.7 13 ,29.6/31. 9 2,15 7 PZ+WTrI i i

セセI 13,3 21 23.8/25,1 2.14/2,12 セG PZH+WTr 1 - - ' セ セャI ' i セ , QLRZGゥゥセRPRQ 15.5 15 41,3/42.7 2.14 9 PZH+WTr 1. 82/0, 83 I ! 8 1,84 6 7 3 4 1/42 9 2 !セ 1.67.'2,67 1) l , 1 1 , . ,07 10 HZ+WT ! 8 1.3B 8 2 1'320 2 I-_+ r_---l 1 セii I 'i2":7 1.33/2.302) 14. 14 9, I , .15 11 RZ+WTr 1.92/0. 94 ih

、ゥエセI 15,6 13 33,2/36,0 2.12 12 pzKwセセ ! !fa セ 14,5 22 27.1/30.4 2.21 13 PZ+WH(f 1 O.セY セQit*

14.7 17 31.セSTN 5 2,22 14 PZ+WH! I I I tT6 I セ 14.2 20 24,3/30," 2,16 15 PZH+WHr ! 2 I セ I セ 15.3 15 37,4142,4 2.18 I - - 1 ---j - I セセKwhャ __ II i 0.91 ,tfsf*

14,5 20 31,4138.6 2.18/2,14 17 HZ+WHr I' 2 ! 1 2 \ ! セ 13,9 15 37,4141.4 2,IB 1 - - ' , 18 HZ+WHl 0,96tk

tE

17,2 18 31.7/35.8 2.18/2,18 Z+ 8 .h.!! 2/ 19 P WKr 1 3- IT;8 1.76 14.0 16 2B. 33,5 2,22 20 PZ+WKl 1.0 セ セ 14,4 25 24,9/29,8 2.16 21 PZH+WKr 2 Ifo fbセ 14,0 22 29.9/33, B 2.25 I - - 1 - - ヲMMMMエMMK]NBMiヲMMKNMMMKMMイNJMKMMMQMMMQMMMMKMMMセ 22 ZH+WKf I 1,02iD

m

14,9 18 29.11134.2 2,17 23 HZ+WKr 2tA

f'fo- 14.0 22 29:3/33.5 2.28/2,25 1 - - • ' 24 RZ+WKf 1.08h

t* 14,9 24 18.2/23,2 2,19 25 HHKr s:-h- セ 14,9 20 25,1/34,7 2,セORL 22 セ HHKrt Imil

セ 14.1 23 lB.0{25.7 RNセ 27 IffiKf i Uセ 63t*

15.8 25 19,セRWLS 2.19 I NIf

(1) Converted to dry substance (2) Total water content

(3) The second value gives the plasticity index after bumping 15 times

(4) The second values gives the change in unit weight after scraping off the prism after two hours, if there has been a change

28 PZr i 4 QJ.! 14,8 24 19,4;'33,2 2,23

.

5.9 0,88 29 PZ,r 1 ::DT セ 15,7 22 22,9/38,0 2,28 4,0 0,68 30 pzr セ,

セ 15,8 18 20,9/32,8 2,14 1 10 31 PZHr ,,

セ 15,5 22 23,4;'32,1 2,22 I - - 1 6.0 0.90 PZH! I i,

h..l! 20,3/29,0 32 5.9 1,04 15,0 25 2,18 4 セ 25 22,0/31,1 2,25 33 HZr 6.35 0.95 15,7 1,

セ I 24 27, 8{38, 7 2,21/2,la 34 HZr 6,23 1,12 18,3 35 PZ+WZr/ R 4 .Q....!! 14.8 30 23,1,/33,1 2,24 1 セ 5.9 0,85 PZ+WZr/R 0.09,

セ 15,8 23 28.3/35,6 2,17 36 "5,"7B I,OT 3T PZH+WZr/ R,

I '!.2.!!. 15,1 28 28.3/35.2 2,28 - 1 £...! 6.0 0, so 0,09 4 .L...!Q. 38 PZH+WZr/R 59 I 09 13.8 26 22.0/29,9 2, H/2, 22 HZ+WZr/ R 4 I セ 14,2 29 29.1/41,1 2,28 39 £...! 6.35 0,92 1U I 40 HZ+WZr/R 0,1 4 .L..!! 16.3 18 28,1,/39,2 2,18 "i"":T3" 1.12 35. PZ+WZr/G 4 .L..Q.!. 14,8 22 32, T/39, 6" 2,22 I セ S,9 0,90 36. pz+wzr/G 0,2 4 .!d. 17,3 13 37,4/45,5 Z,18 "5""7"8 1 12 3T. PZH+WZr/ G 4 セ 30,4/36,7 2.t..!! 6.0 0.94 14,4 15 2,23 I - - 1 0,2 4 !.d! 38. PZH+Wzr/G セ 1 12 14,9 19 26,5/33,5 2,18/2,18 39. HZ+WZr/G,

h.Q..Q. 15,0 21 35,1,/41,0 2L.!! "6""35 0,98 Z,24 1 4aa JU.+wzr/o 0,2 8,234 uu1,13 15,1 27 25, 9{35, 4 2,20{2,18 -J (Continued) Table V I N ID I

-30-Table VI

Unit we1ghts and strengths of mortar prisms (mean values

from 3 measurements each). The upper values relate in

> each case to +20o-cur1ng, the lower to +5°-cur1ng

- - - - _..._

-V'llt IoJtS 0('m"r't,:\t'0; セLNN[N 、セ} セャヲャ^BョGNj I ,;tr-.nrth ,"\t ᄋョGヲャイイN・セセ IUP <'t.r .... ngth

t,,"'IT'tar Ahhrcv\IT ...,j mGLLᄋエNセ "

---- " ' " _..セ k

ゥセ /c:,.,'},,

"'g""' af -trv s In k,;/cm" :It 'JI"C' of dave

AZセG」ZGィ At C\i;." "r d'\ys so r- 1Lセウ 」ZAセLLQVョセエエHャQQ .r',-.,'Jr'

ᄋLMュセG

.-";"

f--- "- ----c'I II 1'1',セ 7- 11 'lD ;If'll 2/\ 90 JfiO セセ⦅N⦅MM セMセMM MMBMMセM . _ - - - f - - - - -セ M a h , h I k 1 In n - - -_._-- - ---_._._'- - - t - - - -2,22 2,01 6,0 8.2 8.8 7,6 13 22 1 WKg 2 00 2.02 2,05 5 2 8 3 15 8 9 17 36 2 WKf 2,13 1,90 1,91 1.91 5,5 6.9 7.5 6,1 11 17 1 91 1 92 1 94 6 1 6 2 7 5 6.5 16 28 1 2.03 2.02 2,02 6,3 8,0 8,2 9.5 19 23 3 HKg 2,24 2 07 2 05 2 05 6 3 9 9 10 6 10 0 19 28 4 HKf 2, 16 1,91 1,90 1,92 5, I 6,0 6,3 6,5 12 16 1,99 1 94 1 96 4,8 6 4 8 7 8 5 14 19 5 PZ+WTg 2, 17 1,95 1,95 1.97 8.3 - 8,6 33 32 42 2 00 1 96 1 98 7 4 13 3 • 29 38 52 6 PZ+WTgf 2,15 1.92 1.91 1,95 14 17 55 50 73 1,98 1,94 1,96 14 21 25 49 60 80 7 PZ+WTf 2,12 1,87 1,88 1,90 8.0 7.4 7,1 26 28 32 1 92 1 90 1 94 8 1 9 5 10 1 24 32 35 8 PZH+WTg 2,14 1,92 1.92 1,95 8,9 9.1 10.6 28 26 37 1 95 1 97 1 99 9 0 11 3 1J 6 26 29 45 9 PZH+WTf 2,07 1,83 1,84 1,88 6,6 7,0 8,5 22 22 26 1 87 1 87 1 89 6 7 8 3 9 5 20 28 10 HZ+WTg 2,15 1,91 1.93 1,95 6,2 7,3 7,2 25 26 31 1,96 1,95 1,96 6,9 20 25 25 II HZ+WTf 2,12 . 1,86 1,87 1,91 5,6 5,9 6,2 22 22 23 I 90 1 88 1 91 5 9 6 6 6 6 17 12 PZ+WHg 2,21 2,02 2,02 2,05 19 23 30 81 63 110 2 05 2 04 2 07 17 22 34 58 68 114 1'3 PZ+WHgf 2,22 2.03 2, OJ 26 29 48 87 90 147 2.05 2,04 2,08 21 27 42 81 95 129 PZ+WHf 2,16 1,95 1,96 1.98 16 18 23 49 54 75 14 1,96 2 00 13 19 24 44 52 79 15 PZH+WHg 2.18 1,99 2,02 2.03 16 2! 27 53 65 101 2,02 2,01 1-3 20 45 55 86 16 PZH+WHf 2.14 1,9. 1,93 1.95 16 21 25 45 52 75 1,96 1,97 2,01 11 18 23 39 49 77 17 HOZ+WHg 2, 18 セL 01 2,06 2,06 16 18 20 52 64 83 2 07 P 19 • 17 40 .? RO II 1.97 1,96 1,98 14 13 14 41 52 71 18 HOZ+WHf 2,16 2. 00 2 00 1 99 12 16 15 30 50 62 19 PZ+WKg 2.22 2.01 2,05 2,09 26 31 41 89 92 162 2,08 2,08 2,11 23 40 52 85 108 175 20 PZ+WKf 2,16 1,95 1,95 2-,00" 21 25 33 64 63 119 1 97 1 96 2 01 18 29 36 54 70 126 21 PZH+WKg 2,25 2.06 2,07 2.09 35 35 46 lIO 119 171 2,10 2,12 2,12 25 29 45 99 124 188 22 PZH+WKf 2,17 1,97 2,00 2,00 27 27 40 79 91 135 2 01 セPS 19 25 38 67 92 132 23 HZ+WKg 2.25 2,10 2.09 2,07 21 24 28 76 102 129 2,11 2"10 19 28 30 61 87 103 24 IlZ+WKf 2.19 2,01 1,97 1,98 21 17 15 64 77 96 2 05 2 01 2 01 16 25 26 48 71 86 25 HHKg 2,22 2.08 2.07 2.07 14 14 11.1 51 55 51 2 08 2 08 7 1 9 0 6 6 26 29 27 26 IlIlKgf 2,26 2.13 2,08 2,07 .22 21 22 105 128 135 2 11 2 11 Mセセ _ 12 14 11 45 59 58 27 IlIlKf 2.19 2,00 2,00 1,98 13 7,2 7.4 53 61 53 2,01 7.7 9,6 6.6 25 34 23(Continued) Table VI -31-28 PZg 2,23 2.07 2.09 2.09 44 58 59 184 227 246 2 12 2 11 2 13 40 78 165 216 291 29 PZef 2.28 2,13 2.14 2.12 63 78 76 290 303 331 2 16 2 17· 2 17 53 71 102 275 333 380 30 PU 2.14 1.96 1.99 2.01 41 43 57 145 160 195 2 02 2 05 2 06 28 54 71 126 194 242 31 PZHg 2,22 2,09 2,07 2,11 50 49 58 183 192 223 2,08 2,11 2.10 40 46 55 133 177 218 32 PZHf 2.16 2.00 2.00 2,03 38 40 51 144 150 200 2 03 2 05 2 07 35 38 115 145 191 33 HZg 2.25 2.12 2.09 2,09 30 32 28 150 147 115 2,11 2.13 2.11 20 21 29 83 99 112 34 HU 2.19 2,03 1,99 1.97 27 24 22 115 99 75 2,04 2,04 2,03 20 21 25 86 86 91 35 PZ+WZg/R 2,24' 2.11 2,12 2,14 48 60 66 219 249 288 2,12 2,15 2,15 39 52 72 178 229 300 36 PZ+WZf/1\ 2,17 2,01 2.00 2.02 44 46 67 164 160 21..8 2 06 2 07. 2 07 30 54 69 145 191 252 37 PZH+WZg/R 2,26 2.13 2.14 2.14 49 58 59 202 230 265 2 16 2 16 2 17 45 42 54 173 188 260 38 PZH+WZf/R 1II 2,22 2.082 07 2.062 09 2,08 4233 4636 6048 153123 159189 226211 39 HZ+WZg/R 2.26 2,14 2.13 2.11 36 43 43 162 198 203 2.14 2.12 24 27 35 97 124 159 40 HZ+WZf/R 2,18 2,03 2.01 2,01 34 36 33 126 143 135 2 07 2 06 2 05 21 23 31 77 109 128 35& PZ+WZg/G 2,22 2.08 - - 52- - 205- - -38a PZ+WZf/G 2.18 1,95 - - 37- - - 125- - -37a PZH+WZg/G 2,23 2.07 - - 57- - 238- - -38. PZH+WZf/G 2,16 1,98 - 44 - - 162 - -- -39. HZ+WZg/G 2.24 2.09 - - 29- - - 148- - -40. HZ+WZf/G 2,18 1,99 - - 24- - - 113- -

-Table VII

Water content of fresh mortar in parts by wt. referred to the principal bonding agent

- - - - I - •

Rane;e Kind of bonding agent

LMMMMMM⦅NセMMセ⦅MMMM

Water content of the fresh masonry mortars in parts by wt. referred to the principal bonding

agent for mortar from

Range 3

I _..

-Limes Cements

Cements + 20% by vol. high calc. hydro lime

Cements + 20% by wt. high calc. hydro lime

Cements + hy1raulic ャゥセ・

Cements + hydraulic hydrated lime 1 : 2

Cements + high calculated lime paste

0.97 1.01 1.98 2.10 2.18 ..

_-Fine sand -4 Gセ 0.90 1.18 eNI r'J I 1.19 1.22-I

! 2.352.39 I ii

2.56,

-33-Water content of fresh mortars in

%

byvrt , d r'y substance

-. __ ..,,- .... --'Water content of fresh

I

mortars in%

by wt. ofI

,

dry substance in themortars from3 2

1

I

Coarse sand Fine sand--_.

__..-- -LセBM -_._-Mセセ ..-MMLセ ..-..-...-

セM .---i

,

---,--- --

⦅N⦅MセN⦅MMM⦅N⦅MKMMMMMMMMM1. Cemen ts + 20% by vol. G[lセィ

I

calc. hyd ra ted 11:710

!

12.4 15.5MRMNM」M」Mイョセョセ[Z

20%

「[MGMセセセM

hi'!,h-f- .±

calc. hydrated 11:-:16 ; 12.8 15.6 3.」・セセZセセy、イ。オZエセMセセセャセセ

__c]MGMセ[セ[M

_

1'-5-.-5---l I -4. CementsKMMM]MセZセ]エ

15.6 5. Limes : 13.1 16.0 - - - } I 6. CAments + high c a l c . !t

_ _ hydrated ャゥセZRMセセN_+

13.7 --1----=_5_._9 _7. Cements +. high calc. ャゥセ・

I

-34-Table IX

Mean values of unlt weights of masonry mortars when fresh

.

Unlt weights In kg/dm3

Klnd of bonding agent of mason ry mortars

when wet, from

Coarse sand Flne sand

-1 2 3

-

--Cements + hiiSh calc. lime

paste 2.15 2.10

-Cements + high calc. hydrated

lime 1 : 2 2.20 2.15

-Hydraulic lime 2.22 2.13

---Seml-hyd raullc lime 2.24 2.16

Cements 2.24 2.16

Cements + 20% by wt. high

calc. hydrated lime 2.23 2.17

Cements + hydraulic lime 2.24 2.17

-

.

-Pr-e s sur-e hydrated lime 2.24 2.19

-Cements + 20% by vol. high

t。「ャ[・Lセ

New group classification of masonry mortars and their limiting compressive strengths at age of 28 days

Limiting compressive strength at 28 days kg/cm2

'I

-4 3of sand and curing temperatu re MMMᄋイMMMMMMMMNセMMMMᄋM

-

E

Kind GイセセdャャN⦅

イャッセエ。イNセセューセセセセ

1ッZセZZNセセ

__セセセセ⦅

I • 1 2 MMMMMNMMMMMMセMMMNMNMセMセMMセMMNMセMMNセセNMMセ t-A1 pt. hydr-auL, hydrated lime 3 pt s , sand

1 pt. semi-hydraulic lime, 3 pts. sand

1 pt. pressure hydrated lime, 3 pts.

sand Ii

1 pt. cement, 1.5 pt. high calc. lime paste, 8 pts. sand

Coarse sand +200 Fine sand +200 Coarse sand +50 Fine sand +

.

セッ.) 7 to 33 6 to 26 9 to 29 6 to 24 ·of MMMMセMM⦅ᄋLMMMMMᄋMMᄋLMᄋᄋMMMMMMMiセᄋM MMMMMMMセNMMMMA.

I

1 pt. cement, 2 pts. high calc. hydrated lime, 8 pts. sand9

I

I " 1 pt. cement, 2 pts. ィケ、セSuャN lime, 8 pt s , sand _ _ . _ ._ _. . d. Coarse sand +200 Fine sand +200 Coarse sand +5° Fine sand +5° 52 to 110 41 to 79 4:0 to 99 30 to 67 I CoNY'

C 1 pt. 」・セ・ョエL 4 pts. sand (where applicable, up to 20% by wt. hydrated lime) Coarse sand +200 Fine sand +200 Coa.rse sand +5° Fine sand +5° 150 to 219 115 to 164 83 to 178 66 to 145Table XI

Influence of additions of 11me on the compressive strengths of masonry mortars

• 100

Mセ⦅N

--=1=---.

L1mitln; proportional values*-_.

to cement cッイdQ_NAZNセᆪN_NQNセRNエオイセョァエAlァjN⦅エNqセ⦅MjAAYNセセセイ キャセNィNNNQQュセl」セョエ

Compressive strength of the mortar with cement Kind of 11me added

.- NMMセMMMMMMMMMMMMMM

1 2

- - - . - - - . • - . f-_.

100 and 130% (180%) High calc. lime paste

High calc. hydrated lime Hy".J raulic lime

High calc. hy".Jrated lime only up to RPセ by wt. 10 and 30 and 40 and 30% 50% (100:,0 80% (130%) VJI O'l I

*

The figures in brackets are the top limits for the mortars with blast furnace cementTable

XII

Suggestion for a new classification of masonry mortars in DIN 1053

•

VJ -J I 75 20 5 30 2 B A- - - r

For clarity group designation according to Table X1 pt. by vol. hydraul. hydrated lime, 3 pts. by vol. sand

1 pt. by vol. semi-hydraul. lime, 3 pts. by vol. sand

1 pt. by vol. pressure ィケ、セエ・、

lime, 3 pts. by vol. sand 1 pt. by vol. cement, 1.5 pt. by vol. high calc. lime paste,

8 pts. by vol. sand

I I --- , I I

1 pt. by vol. cement, 2 pts. by vol. high calc. hydrated lime,

8 pts. by vol. sand

1 pt. by vol. cement, 2 pts. by vol. hydraul. lime, 8 pts. by

vol. sand I I - ---I. . . . " . . . . -I - 1 -I 1

II

III

New mortar group Suggested compressive strength Mortar compositionI

kg/cm2 _ _ _ _ Min. _, Mean---r

I '

_3.----L-'__:-__

1_

5_ _1 pt. by vol. high calc. lime INo str. requirements

paste, 3.5 pt. by vol. sand

1 pt. by vol. high calc.

hydrated lime, 3 pts. by vol. sand

-38-o SOO kg/crrI HeXUrdl Sfr. CornpresSIV J-,.. GQPPMセセ _. n+eO"CCur;"'fj セ セ +SOCCurinJ V) 300 - - - . .セ

•

'" " " ., 200..

L -セ Q.. C 0 セQャhjセiセ

Q R !l 80 o 20 10 !cgpI Fig. 1Standard strengths of bonding agents at age of 28 days セM nEnd ofウ・エィセ セ --- -_. セ N ⦅ M M iMMNMMMMセM -r1 SI"rtor se.!f;n'J --Fig. 2

Beginning and end of setting of bonding agent mixtures

WT = High calc. lime paste

'tJH = High calcium hydrated lime

WK ::: Hydraulic hydrated lime

HK

-

Semi-hydraul ic lime HHK ::: Pressure hydrated limefャァセ :3

-40-3iiセ 67891011 12131/115161718 19;(12122232'1 252627 282930313233J11 3S36J7J8J9/10 35J6JTJ8J91/Q HK Cemenf+ Cement» Cemeat» HHK Cemenf Cemenf+ a a a a a a

WeiBku{'':li:ig Wei8kulkhyrfr. Wusser/rrrik ,20141/.-% 20Gew.-%

3/u.rnp OINT1611 __u. PldSf,cily de(,um"J (!uf,.. Wei8lru!khydraf

P..we.rs sヲBッOH・セ ----fl/J!fJt'"edy 、エANセイLNLN、 t!<4te- - dffer 15"£u."'P$

Fig. 5

Results of consistency measurements by different methods

WelBkalkteig - High calc. lime paste WeiBkalkhydr. - High calc. hydrated lime Wasserkalk - Hydraulic lime

-41-v

I

8

r-- On"'''7j <:Lie e-

----

ondJny "-1€-nf rn/A' u r e s - - - in arciLje-ofJ6Qdays n" " • 90 " I

. .

N 28·

c_ -f--- MMMMMMMセ III "flJJl11

セ

11

I

WKHKIf.'If PZ HOZ PZasJl5HOZ PZas 326 HOZ, FU25 326 l'.tlZS326HOZPZ125 .J25 HOZ as 326m

'--..---' '-y---J

l'forl4r9'oupI セ 1Il

Fig. 6

Compressive strengths of mortars from coarse sand (I) after curing at +200

c

v

I ...i5WIf., ..NNNLセ

1:1

セaッョセェョj d,ent lI"nclinj 0.10.,.,1rniKfu/"es

naf ""'1e 01JtID day.

B' •

.

SO·

I .

. .

/118·

.i1.i1

セ

1111

.... HK' PZ HOr PZm Jl5HOZ PZl25 J1S HOZ 1'1"Jl5HOZ flr125Jl5Iff1lI"/llSJlS IffIl

Fig. 7

Compressive strengths of mortars from fine sand (II) after curing at +20o

c

WelBkalkteig - High calc. lime paste WelBka1khydr. - High calc. hydrated lime

-42-o on d; n7mIHel --/Jdnd'''9 BYセョヲ n-Jh!UN'5- ___ セ セK <r«

. .

orJM、セウ 90.

I.

.

.

28.

1---- ---N⦅セ セMM _._-- イMMセ - ..セ-セQ

JilI1

セi セ

111I

I

niclJlgtprtiffJtII'HKHHK P. HOZ PZ225325HOZ PZ225325NQZ PZ225325HOZ PZ225325HOZ PZ225J25/flU

225 325 225 '-v-' '----v--' I'1irkrセGN⦅i If Dl +wャゥャAャエZエイャセ +/Mtil!lt:trllrlryrir. 7:2 ir Fig. 8 KセOォ +セXォQQOォャエケイャイ。ヲ 7:tJ,2 PI,byv.f. /V6 .by,,,fe, Dl

Compressive strengths of mortars from coarse sand after curing at +5°C 225 325 225 '-y---J ' - - . - - ' QGヲゥヲヲQQQセ ,/'''''fcd If J1I o _ i o n d l n j Of -' Bondin, .1",1 rna-!

[JAI a'i;-arJii)day5

11 •

. .

90.

I .

.

.

28.

---Jl.6l

t

セ

.1111

I

セ

nidfI!JfPfiiff WK HKHHK 'ZHOZ PZ225 32SHOZ PZ225325 HQZ PZZ25325HOZ PZ225325HOZ I'b25325HOZFig. 9

Compressive strengths of mortars from fine sand (III) after curing at +5°C

We1Bkalkteig - High calc. lime paste We1Bkalkhydr. - High calc. hydrated l1me Wasserkalk - Hydraulic lime

Mean values of consistency measure-ments by the individual methods

I tl>-セ I セ セ .

-

セ セ M • セセ\Aャセセセ セ セセLセ ... セ Fig. 11 セ セ セセセセセセセ

セセセセセセ <Ii ilIt セセセセセセセ

セセセセセセ i i :I

- !'IIs""'y,."",Idt"'S 1\ M]MMセセ ..,enT-5wi!:'-"l 1\

' :./1".

i i ,|セ

: I I i ! ...\

セ :\1\

:\

\

:\

\[\/

1'-. \ i'\.\ i"-.

• 1\ 1'. ;-"'1 ' i LセI't

MセヲQL1\

-,

<,'\.

,,'\

...,

\. 7 . I I'i

..."

Ii .. セ,

セ セ ,.. .... ':i: o..

i:;' Ii セ セ セ 2 12 7' '" " ." セ 10 '2 .,t. セ 8 セ a:: <,. 6 ()Differences of plasticity indices at various applications of cube deforming apparatus

(post-deformation, new suggestion)

.... ;l:: セ l i セセセャZセセセ セセセセセッjZャセセBMャ セセ Fig. 10 15 3S

"'0

QセX セ セSP セ 15,5 em. セ セQTP セ セ :r"'5

\/).s

:r '" 20 "':I " セ セRU '\iWeiBkalkteig - High calc. lime paste

WeiBkalkhydrat - High calc. hydrated lime Wasserkalk - Hydraulic lime

Effect of various lime additives on masonry mortars from coarse

sand after 200 - c u r i n g

I

セ

セ

I nAt a.1e of 3fi(Jda.ys

n· •

.

90.

I .

. .

l8.

,

11J1

I'Z2IS _ HfIZ nzzs _ HtIZ Ft_JISHOZ PZZZS 3Z5 HfIZ PZm 3Z5h,

80

KLNNNLセ + ....Oセ +iIlI:I:nrlvIk KQiKエGセ 7:Q.Z

1:3 Ph· ,.lIol tis.kv ..,1,

l1tItfary ....p' i irr

Fig. 13

Effect of various lime additives on masonry mortars from fine

sand after 20°-curing

,

a:

180 k JoI IMPt mS_'6tJ

セoセ セGmセQᆬo セ 0 セ o 0 。セ E 120 'M ..p o m!=1 ..d : セ 1/Xl セZiN エャoセ 0=

H".04

'M JoI e 0 セ idセNN」ャVP ]セ " tI eo [Zセ[wj ilia k 10toセ:.91/120

Ptod !D S =;-00.,.., 0,.0 t1 KBBセQZTQ JlIdyエiセエ 1'6.6.",I.. ir Fig. 12 Jr Kセ Kセセ +1tIIsIIrlIafk 1:3n.At o'ja of'3fi(J da vs

. I . ,. II go .. .