Science Arts & Métiers (SAM)

is an open access repository that collects the work of Arts et Métiers Institute of

Technology researchers and makes it freely available over the web where possible.

This is an author-deposited version published in:

https://sam.ensam.eu

Handle ID: .

http://hdl.handle.net/10985/18175

To cite this version :

Bin JIA, Alexis RUSINEK, Raphaël PESCI, Slim BAHI, Richard BERNIER - Thermo-viscoplastic

behavior of 304 austenitic stainless steel at various strain rates and temperatures: Testing,

modeling and validation International Journal of Mechanical Sciences Vol. 170, p.105356

-2020

Any correspondence concerning this service should be sent to the repository

Administrator :

archiveouverte@ensam.eu

Thermo-viscoplastic

behavior

of

304

austenitic

stainless

steel

at

various

strain

rates

and

temperatures:

Testing,

modeling

and

validation

B.

Jia

a,b,∗,

A.

Rusinek

c,d,e,

R.

Pesci

b,

S.

Bahi

c,

R.

Bernier

ca ENSAM-Arts et Métiers ParisTech, Laboratory of Design, Manufacturing and Control (LCFC), Metz 57070, France

b ENSAM-Arts et Métiers ParisTech, Laboratory of Microstructure Studies and Mechanics of Materials (LEM3), UMR CNRS 7239, Metz 57078, France c Lorraine University, UFR MIM, Laboratory of Microstructure Studies and Mechanics of Materials (LEM3), UMR CNRS 7239, Metz 57078, France d Institute of Fundamental Technological Research, Ul. Pawinskiego 5B, Warsaw 02-106, Poland

e Chair of Excellence, Departamento de Ingeniería Mecánica, UC3M (Carlos III University, Madrid) Avda. de la Universidad 30, Leganés, Madrid 28911, Spain

a b s t r a c t

Thispaperpresentsasystematicstudyofthethermo-viscoplasticbehaviorofa304austeniticstainlesssteel(ASS). Theexperimentswereconductedovera widerangeofstrainrates(10−3 s−1 to3270s−1 )andtemperatures

(-163°Cto172°C),forwhichthedeformationbehaviorof304ASSbecomesmorecomplexduetothe strain-inducedmartensitictransformation(SIMT)effect.Dynamictestsatlow/elevatedtemperatureswereconducted usingtheHopkinsontechniquecoupledwithacoolingdevice/heatingfurnace,andtemperaturedistribution withinthespecimenwasverifiedtobeuniform.Experimentalresultsshowedthatthestrainhardeningrateof 304ASSwasstronglyaffectedbySIMTeffect.Forquasi-statictests(10− 3 s− 1 to1s− 1 )atlowtemperatures (-163°Cto-20°C),thestress-strainrelationsexhibitedanS-shapeandasecondstrainhardeningphenomenon. Thestrainratesensitivityandtemperaturesensitivityof304ASSwerealsodifferentfrommetallicmaterials deformedbydislocationglide.Severalunexpectedphenomenaincludingthenegativestrainratesensitivityand thechangingtemperaturesensitivityfromquasi-statictodynamictestswereobserved.Basedonexperimental results,anextensionoftheRusinek-Klepaczko(RK)modelconsideringSIMTeffectwasusedtosimulatethe deformationbehaviorof304ASS:itpredictedflowstresscurvesof304ASSabove-60°Ccorrectly.Inaddition,to validatetheextendedRKmodelandtheidentifiedmodelparameters,numericalsimulationsofballisticimpact testsof304ASSplatesatvarioustemperatureswerecarriedout,showingagoodagreementwithexperiments.

1. Introduction

As a representative of transformation induced plasticity (TRIP) steels[1],304ASShasauniquecombinationofhighstrengthandhigh ductility[2].ItsbeneficialmechanicalpropertiescomefromtheSIMT effect,which meansthatuponplasticdeformationprocesstheinitial austenitephase (𝛾)transforms intothe stablemartensite phase (𝛼′); thus,bothimprovedworkhardeningrateandsignificantlyenhanced ductilitycanbeachieved.304ASSiswidelyusedinmanyengineering areasrangingfromliquefiednaturalgasstorageatcryogenic tempera-tures[3,4]tocrash-resistantstructuresinautomotiveindustryatroom temperature[5,6] andnuclearfacilitiesatelevatedtemperatures[7]. Therefore,much workhasbeendonetoinvestigate thedeformation behaviorof304ASSundervariousstrainratesandtemperatures.

The effect of temperature on the deformation behavior of 304 ASSisdifferentfromthecommonlyusedalloyswiththedeformation mechanismof dislocationglide.Asshown in Fig.1, attemperatures

lowerthanMd ,thetemperaturebelowwhichmartensitic transforma-tion occursautomaticallyor can betriggered byplasticdeformation [5,6],stress-strainrelationsof304ASSexhibitanS-shapeandasecond hardeningphenomenon.Thisiscausedbythemartensitic transforma-tion effect. At temperaturesabove Md , the deformation mechanism of 304 ASSchanges intodislocationglide [5]. Withincreasing tem-perature, dislocationannihilation due tothe crossslip andclimbof dislocationsisaccelerated[8];thusthestrengthof304ASSdecreases without the second hardeningphenomenon. Byun etal. [9] studied thequasi-statictensionbehaviorof304ASSattemperaturesbetween −150°Cand450°C.Itwasobservedthatboththeyieldstressandthe ultimate tensile strength decreased with increasing temperature T0, andtheoptimalductilitypeakedat20°C.Attemperatureslowerthan 20°C, a second hardeningphenomenon accompanied by martensitic transformation was observed. Hamada et al. [10] investigated the quasi-staticdeformationbehaviorof201and201Lausteniticstainless steels at temperatures ranging from −80°C to 200°C and obtained similarresults:theflowstressincreaseswithdecreasingtemperature. Zheng andYu [11] studiedthe quasi-statictension behaviorof 304 ASSat temperaturesbetween −253°Cand20°Candfoundthatboth theflowstressandthestrainhardeningrateincreasedwithdecreasing

Fig.1. SchematicillustrationofthedeformationmechanismofTRIPsteelsatdifferenttemperatures:stressassistedplasticity(𝑀𝑠−𝑀𝑠𝜎),strain-inducedplasticity

(𝑀𝜎

𝑠−𝑀𝑑),anddislocationglideplasticity(>Md)[12].

temperature. In addition, due to the thermally induced martensitic transformationbeforetests,theyield stressesat −253°Cand−196°C weresignificantlyhigherthanfortheothertemperatures.

Theeffectofstrainrateonthedeformationbehaviorof304ASScan beexplainedintwostrainregimes:attheinitialstageofdeformation, theconstitutivebehaviorof304ASSisdominatedbydislocationslip. Theflowstressincreaseswithincreasingstrainrateasthetimeavailable foradislocationtowaitinfrontofanobstaclefortheadditional ther-malenergyisreduced[8,13].However,whenitcomestolargestrains, thestrengtheningeffectoriginatedfromSIMTisinhibitedbyadiabatic heating,andthecorrespondingstrainhardeningratedecreases. Consid-eringtheeffectsofstrainrateonbothdislocationslipandSIMT,either positive[14,15]ornegative[3,16]strainratesensitivityatlargestrains wasobserved.Lichtenfeldetal.[17] investigatedthetensionbehavior of304Lstainlesssteelundervariousstrainrates(10−4s−1to4×102 s−1)atroomtemperature.Theyieldstressincreasedcontinuouslywith increasingstrainrate.However,theultimatestrengthdeclinedfirstin quasi-staticstrainrates(10−4s−1to10−2s−1)andthenbegantoincrease indynamicstrainrates(10−1s−1to4×102s−1).Asimilarphenomenon wasobservedbyIshikawaandTanimura[18] in304Nstainlesssteel.

Fromtheliteraturereview, thedeformationbehaviorof 304ASS hasbeen investigatedmassively.Previous studiesmainlyfocused on quasi-staticbehavioratvarioustemperaturesordynamicbehaviorat roomtemperature.Althoughthecombinedeffectsoftemperatureand dynamicloadingonmechanicalproperties of304ASSarefrequently encounteredsuchasliquefiednaturalgasstorage(−163°C)andsheet metalforming(20°Cto300°C),thecorrespondingdeformationbehavior isnotclearlyunderstood.Inaddition,attemperaturesaboveMd ,the deformationbehaviorof 304ASSissimilartothatof thecommonly usedsteels.However,attemperatureslowerthanMd ,thedeformation behaviorof304ASSbecomescomplexduetotheSIMTeffect.Hence,a deformationbehaviorstudyof304ASSespeciallyfocusingon temper-aturesbelowMd (140°Cforthestudiedmaterial)canbeinteresting.

In this paper, the compression behavior of 304 ASS has been studiedoverawiderangeofstrainratesandtemperatures.Inindustrial applications,strainrates can reach2000s−1witha commonregime lyingaround10−3–10s−1[19].Consideringthestrainratelimitations

oftheadoptedSHPBtechniqueandtheflowstresslevelofthestudied 304 ASS,fourquasi-staticstrain rates(10−3 s−1, 10−2 s−1, 10−1 s−1 and1s−1)andthreedynamicstrainrates(1550s−1,2370s−1,3270 s−1)wereselected.Forthetestingtemperature,muchworkconcerning deformation behavior of 304 ASSat room or hightemperature can be found, butstudiesat lowertemperatureis rare.Inthiswork, six temperaturescoveringlow temperature(−163°C,−60°Cand−20°C), room temperature (20°C) and temperatures respectively below Md (88°C)andslightlyhigherthanMd (172°C)wereconsidered.

First,self-designedheatingfurnaceandcoolingdevicearecoupled to theconventional SHPB device fordynamic compression tests not only at low butalsoat elevatedtemperatures. Theset-up reliability is verified by both experiments and numerical simulations. Then, compressiontestsof304ASShavebeenconductedandtheeffectsof temperatureandstrainrateonthedeformationbehaviorof 304ASS arediscussedin detail. Anextension of theRusinek–Klepaczko(RK) constitutive model [20,21] considering martensitic transformationis chosen to describe the temperature and strain rate-dependent con-stitutive behavior. Finally, toverify theprediction capability of the extendedRKmodel,numericalsimulationsofballisticimpacttestsof 304ASShavebeencarriedoutandcomparedtoexperiments.

2. Materialbehaviorandset-updescription

2.1. Materialandspecimens

Thematerialconsideredhereinisacommercial304stainlesssteel produced by Thyssenkrupp Materials, available in annealed plates (dimensions: 1000×100×12 mm3). According to the manufacturer’s specification,thechemicalcompositionofthesteelisgiveninTable1.

Table1

Chemicalcompositionofthe304ASSgivenbythesupplier(wt%).

Material C Cr Mn N Ni Co Cu Fe

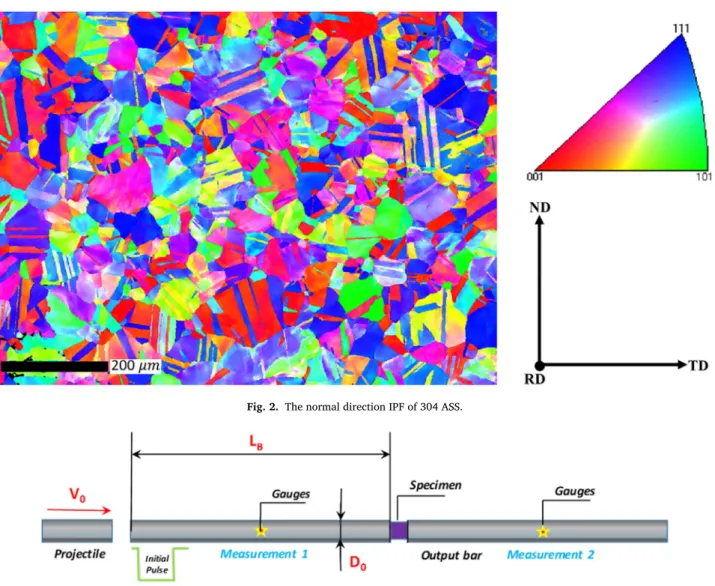

Fig.2. ThenormaldirectionIPFof304ASS.

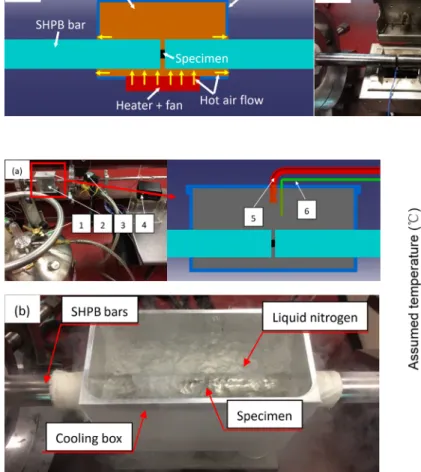

Fig.3.SchematicdiagramoftheconventionalSHPBset-up.

Themicrostructureofthe304 ASSwas characterizedbyelectron backscatterdiffraction (EBSD) technique. Byapplying a step sizeof 1𝜇mandconsideringamisorientationangleof5°,thenormaldirection inversepolefigure(IPF)isshowninFig.2.Itisseenthatthe304ASS consistsof100%austenitephasewithanaveragegrainsizeof28𝜇m.

Thespecimensusedforcompressiontestsarecylinders3mmhigh and6mmindiameter.Asreportedin[22],aheighttodiameterratioof s0=0.5helpstoreducethefrictionandtheinertiaeffects.Thespecimens weremachinedfromtheas-receivedplatealongtherollingdirection usingwireelectricaldischargemachining(WEDM)technique.Toavoid bucklingand toensure a uniform stress state inside thespecimens, the specimen end faces were coated with lubricant. To ensure the reliabilityof theexperimental results,three testswereperformedfor eachtemperatureandstrainratecombination.Theaveragecurvefor eachconditionisdepictedasthereferenceinthiswork.

2.2. Quasi-staticanddynamiccompressiontests

Quasi-static tests at room temperature were conducted using a Zwick/Roell200 kNuniversal testing machine. Fortests atlow and hightemperatures,acoolingdeviceoraheatingfurnacewasused.

Tostudythedynamicbehaviorof304ASS,compressiontestswith averagestrainrates around103 s−1 andinitialtemperaturesvarying between −163°Cand172°Cwere carriedout using an SHPBset-up. TheSHPBdevice, Fig.3,consistsof twolongelasticbars(length of LB = 1500mmanddiameterofD0 = 20mm),a compression

speci-mensandwichedbetween themandaprojectile.Whentheprojectile impacts the inputbar withan initial velocity V0, an incident wave

𝜀I = 𝜌C0V0/2Eis induced with a celerity 𝐶0= √

𝐸∕𝜌 (E and 𝜌 are YoungmodulusanddensityoftheSHPBbars,respectively).Duetothe cross-section differenceand the mechanical impedance between the barsandthespecimen,partoftheincidentwaveisreflectedbackas 𝜀R (t)andtheresttransfersintothesecondbaras𝜀T (t).Usingthethree

waves measurement, the average stress-strainrelationsof the tested materialmaybedetermined.Acompletedescriptionofthestresswave analysistodefinematerialbehaviormaybefoundin[23].

For dynamic tests at elevated temperatures, a heating furnace coupledtotheconventionalSHPBset-upisadopted.Anillustrationof thefurnaceisshowninFig.4.Duringtheheatingprocess,thespecimen togetherwithpartoftheincidentandtransmitterbarsareheated.Two thermocouplesareused tomonitorthetemperatureof thespecimen and the furnace environment, respectively; the latter can provide feedbacktothetemperaturecontrollertoadjusttheheatingrate.The maximumtestingtemperaturebytheheatingfurnaceiscloseto250°C. Concerning dynamic tests at low temperatures, a cooling device basedonpulsedcryogenicgasmethodhasbeendeveloped,Fig.5(a). The coldnitrogengas flows froma liquidnitrogentank through an aluminumpipeintothecoolingbox.Thetemperatureinsidethe cool-ingboxis monitoredbyathermocoupleconnectedtoa temperature controller.Oncetheenvironmentaltemperaturereachesthesetvalue, thetemperaturecontrollercutsoff thepowerofthepumptostopthe

Fig.4. Heatingfurnaceforhightemperature tests:(a)aschematicillustrationand(b)the completedevice.

Fig.5.Coolingdeviceforlowtemperaturetests:(a)between−90°Cand−20°C and(b)−163°C.1)liquidnitrogentank,2)coolingbox,3)pumpfornitrogen gasflow,4)temperaturecontroller,5)pipeforthenitrogengasflow,6) ther-mocouple.

nitrogengas flow. Bythis method, thetemperature varies precisely from −90°C to −20°C. In addition, to decrease strongly the initial temperature,thecoolingboxisfilledwithliquidnitrogendirectly.By thismethod,aminimumtemperatureof−163°Ccanbereached.

Since the heatingfurnace and cooling device for high/low tem-peraturetestsarehome-developed,theirreliabilityshouldbechecked before testing.Hence, the temperatureevolution of theheating fur-nace/coolingdevicehasbeenmeasuredexperimentallyandispresented inthenextsection.Inaddition,thetemperaturedistributioninsidethe specimenwasfurtherestimatedbyfiniteelementmethod(FEM)based onthermalheattransferapproach.

3. Calibrationandheattransfermodelingoftheheating furnace/coolingdevice

Thetemperatureevolutionofthespecimenandtheenvironmentis measuredexperimentally,andtheresultisshowninFig.6.Bysetting theenvironmentaltemperaturesoftheheatingfurnace/coolingdevice to be 200°C, 100°C, −25°C, −68°C and −163°C, the corresponding temperatures of the specimen are 172°C, 88°C, −20°C, −60°C and −163°C.ThewaitingtimeTw forthespecimentemperaturetobestable changes depending on the initial temperature T0. It increases from

Tw =270sat−163°CcontinuouslytoTw =1820sat172°C.Bychanging theenvironmentaltemperatureoftheheatingfurnace/coolingdevice between −163°C and 200°C, the corresponding temperature in the specimenvariesfrom−163°Cto172°C.

To analyze the temperature distribution in the heating fur-nace/coolingboxmoreprecisely,numericalsimulationsusingCOMSOL

Fig.6. Temperatureevolutioninthespecimenwiththeenvironmental temper-aturevariesbetween−163°Cand200°C.

Multiphysics havebeenconducted.Thethermaltransferis described bythegeneralizedtransientheatequation,Eq.1.

𝜌.𝐶𝑝 (𝑇).𝜕𝑇𝜕𝑡 −∇.(𝑘(𝑇).∇𝑇)=0 (1)

Thethermal conductivityk(T)andthespecificheatCp (T) of304 ASSmay be foundin [24]. Theboundaryconditions aredefined in Eq.(2)andFig.7.

- Naturalconvectiveheatfluxqc onthefreesurfacesoftheheating furnace/coolingdeviceandtheSHPBbars.

- Forced convective heat flux qf through the free surfaces of the specimenandtheSHPBbarsbyhotair,coldnitrogengasorliquid nitrogen.

- Thermalcontactheatfluxqint betweeninterfacesofthespecimen andtheSHPBbars.

- Hotairinflowandoutflowwithcertaintemperaturesandvelocities. ⎧ ⎪ ⎨ ⎪ ⎩ 𝑞𝑐 =−ℎ𝑐 (𝑇−𝑇0 ) 𝑖𝑛𝜕Ω𝑐 𝑞𝑓 =−ℎ𝑓 (𝑇−𝑇0 ) 𝑖𝑛𝜕Ω𝑓 𝑞𝑖𝑛𝑡 =ℎ𝑖𝑛𝑡 (𝑇−𝑇0 ) 𝑖𝑛𝜕Ω𝑖𝑛𝑡 (2) wherehc =10W/(m2•K)andh

int =105W/(m2•K)arethenaturalheat convectionandthelayerconductancecoefficient,respectively.Valuesof hc andhint maybefoundin[25].Theforcedheatconvectioncoefficient hf isequalto818W/(m2⋅K)whencoolingdownthespecimenbyliquid nitrogenand109W/(m2⋅K)whennitrogengasorhotairisused.Values ofhf wereobtainedbyfittingnumericalresultstotheexperimentaldata. A comparisonof temperatureevolution betweenexperiments and numericalsimulationsisshowninFig.6.Itisclearthatagood agree-mentisobtainedforallthefivetemperatures.Therefore,thenumerical

Fig.7. BoundaryconditionsfortemperaturedistributionanalysisusingCOMSOLMultiphysics:(a)lowtemperatureand(b)elevatedtemperature.

simulationscanpredictthetemperatureevolutionanddistributionof theheatingfurnace/coolingdevicecorrectly.

Basedonthenumericalresults,thetemperatureevolutionoffour positionsshowninFig.8(a)wasrecorded;theresultsarethenplotted inFig.8(b).ItisseenthattemperaturesinpointsAandBarealways the same, indicating a uniform temperature distribution within the specimen.Incomparison,temperaturesin points C andD arelower duetotheheatexchangebetweentheSHPBbarsandtheenvironment. Thetemperaturedifferencebetweenthefourpointsincreaseswhenthe testingtemperaturedeviatesobviouslyfromroomtemperature,anda strongtemperaturegradientalongtheSHPBbarsisobservedforT0= −163°Cand200°C.

AccordingtoFig.8(b),thetemperaturesinthefourpositionsare stableaftera waitingtime of 2000s.At Tw =2000s, thetemperature distributionof thespecimenandtheenvironmentisshowninFig.9. Fortestsatlowtemperatures,asshowninFig.9(a),(b)and(c),astrong temperaturegradientformsalongtheSHPBbars,butthetemperature distributionwithinthespecimenisuniformwithamaximum fluctua-tionof0.05°C.Fortestsatelevatedtemperatures,asshowninFig.9(d) and(e), atemperature gradientis observed from thebottom tothe topof theheatingfurnace,butthetemperaturewithin thespecimen remainsuniformwithafluctuationof1.2°C.

4. Experimentalresultsanddiscussion

4.1. Forceequilibriumstatewithinthespecimen

Thetypicalwavesignalsfromonetestat1564s−1and172°Care showninFig.10(a).Inordertoobtainanaccuratedeformationbehavior descriptionusingtheSHPBtechnique,forceequilibriumstatewithinthe specimenisnecessary.Hence,aparameterproposedbyRavichandran andSubhash,R(t),isusedtoevaluatetheforceequilibriumcondition. 𝑅(𝑡)=|||| | Δ𝐹(𝑡) 𝐹𝑎𝑣𝑔 (𝑡) || || |=2 || ||𝐹𝐹11((𝑡𝑡))+−𝐹𝐹22((𝑡𝑡)) || || (3)

whereF1(t)andF2(t)arethetwoforcesactingontheendfacesofthe specimen,respectively.TheyarecalculatedasF1(t)=EA(𝜀I (t)+𝜀R (t)) and F2(t) = EA𝜀T (t), whereE and A are Young’smodulus and the

cross-sectionalareaoftheSHPBbars,respectively.ΔF(t)andFavg (t)are respectivelythedifferenceandtheaverageofthetwoforces.Aforce equilibriumstateisachievedwhenR(t)isclosetozero.

BasedontheexperimentalresultsinFig.10(a),thevariationoftrue stress,strainrateandforceequilibriumcoefficientwithtruestrainis cal-culatedandshowninFig.10(b).ItcanbeseenthatR(t)isalwayslower than0.1,exceptafluctuationatatruestrainof0.02.Therefore,force

Fig.8. (a)Positionsoftemperaturemeasurementand(b)temperatureevolutionofthefourpositions.

equilibriumstateisachievedfromtheverybeginningofthetestand maintainsuptothemaximumstrain.Theverifieddynamicforce equi-libriumconditionensuresthattheexperimentallymeasuredstress-strain relationsgiveanaccuratedeformationbehaviordescriptionof304ASS. 4.2. Truestress-truestrainrelationsof304ASS

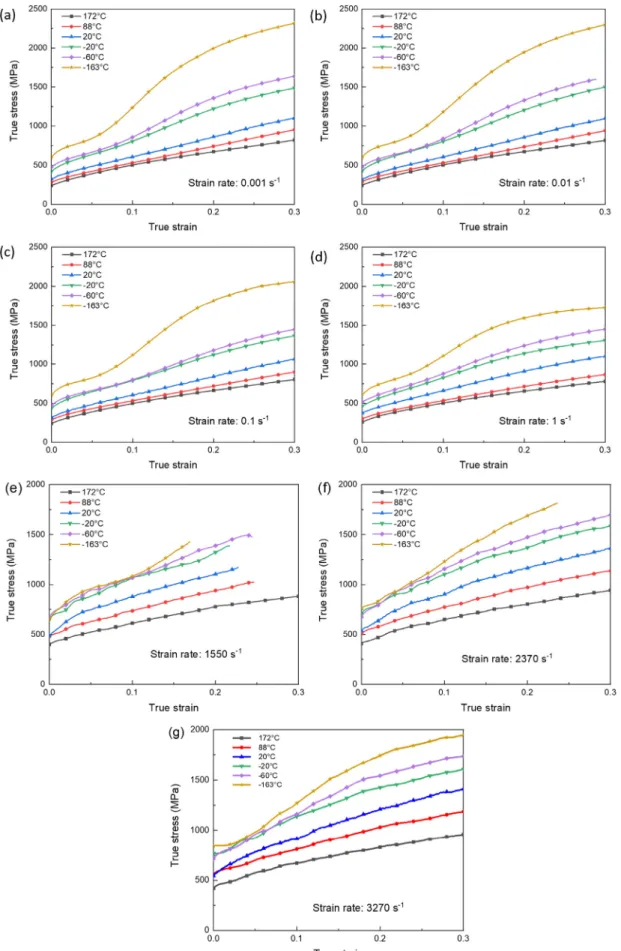

The true stress-true strain curves of 304 ASS at temperatures between−163°Cand172°Candstrainratesfrom10−3s−1to3270s−1 areshowninFig.11.Itisseenthatforallthetestedstrainratesand temperatures, theflow stress increases continuously with increasing strainbutthestrainhardeningratesdiffer.Inquasi-statictests(10−3s−1 to1s−1)conductedat172°C,thestrainhardeningratedecreasesslowly withincreasingstrain;asthetestingtemperaturedecreasesto88°C,the flowstressincreasesalmostlinearly withaconstantstrainhardening rate; with further decrease of testing temperature, the stress-strain curves exhibitan S-shape and a second hardeningphenomenon. As discussedintheintroductionsection,thisphenomenonisalsoobserved byseveralotherauthors[14,17,26,27]inTRIPsteelsandisattributed tothe SIMTeffect. Fortemperatures belowMd , which is 140°Cfor the304 ASS, martensitic transformation can be triggered by plastic deformation. A mixture of martensite and austenitephases is much harder than pure austenite phase. Therefore, the strain hardening

rate is enhanced. At 172°C, a temperature above Md , the deforma-tion mechanism changesinto dislocationglide: thestrain hardening rate is controlled by a competition between dislocation generation, accumulation andannihilation [8]. As is pointedout by theunified constitutivemodelproposedbyLinetal.[8],thedislocationsgenerate andaccumulatequicklyatsmallstrains,andthentheincreasingrateof dislocationdensitydecreasesgraduallyatlargestrains.Therefore,small strainhardeningrateatlargestrainsisobserved.Concerningdynamic tests(1550s−1to3270s−1)atvarioustestingtemperatures,theresults areshowninFig.11(e),(f)and(g).Itisseenthatthesecondhardening phenomenonisnotobviousanymoreasmartensitictransformationis stronglyinhibitedbytheadiabaticheatingeffect.

4.3. Strainratesensitivityof304ASS

Thevariationsofflowstresswithstrainrateasafunctionoftesting temperaturefortruestrainsof0.05and0.2areplottedinFig.12(a)and (b),respectively.Theyrepresentrespectivelythedeformationbehavior of pure austenite phase and a mixture of austenite andmartensite phases.

AsshowninFig.12(a),thevariationofflowstresswithstrainrate atatruestrainof0.05isconsistentwithmetallicmaterialsdeformed bydislocationglide:theflowstressfirstremainsconstantinquasi-static

Fig.9. Temperaturedistributioninthe heat-ingfurnace/coolingdevicewiththespecimen temperaturesstableat:(a)−163°C,(b)−60°C, (c)−20°C,(d)88°Cand(e)172°C.

tests(10−3 s−1 to1s−1) andthenincreasescontinuouslyin dynamic tests (1550 s−1 to 3270 s−1).A phenomenonshould be noticed: in dynamicstrainrateregime,thestrainratesensitivityiscoupledwith temperature.Theflowstressincreasesmoreslowlyatlowtemperatures than that at high temperatures. For thermo-viscoplastic behavior modeling,anitemdescribingthecouplingrelationshipbetweenstrain rateandtemperaturesuchastheArrheniusequationisneeded.

Theevolutionofflowstresswithstrainrateatatruestrainof0.2is showninFig.12(b).Inquasi-staticstrainrates,thestrainratesensitivity isdifferentfromthatatthetruestrainof0.05.Fortemperaturesbelow −20°C,theflowstressdecreaseswithincreasingstrainrate,indicating a negative strain rate sensitivity. Inparticular, at −163°C,the flow stressinquasi-statictestsisevenhigherthanthatunderdynamictests. Fortemperaturesabove20°C,theflowstressdoesnotchangeobviously

Fig.10. Atypicalcompressiontestat1564s− 1 and172°C:(a)thewavesignalsand(b)thetruestress,strainrateandforceequilibriumcoefficientvstruestrain curves.

withincreasingstrain rate.Indynamic strainrates,apositive strain ratesensitivitysimilar tothat atthetrue strainof 0.05isobserved. Butthestrainratesensitivityismorepronouncedatlowtemperatures insteadofthepreviouslyobservedhightemperatures.

4.4. Temperaturesensitivityof304ASS

Fig.13showstheevolutionofflowstresswithtemperatureat differ-entstrainratesandtwostrains.AsshowninFig.13(a),theflowstress decreaseswithincreasingtemperature.Thedecreasingtendenciesare around1.40MPa/°Cand1.74MPa/°Cforquasi-staticanddynamic strainrates,respectively.However,from−60°Cto−163°C,thedynamic flowstressincreasesbymerely20MPa:thestrongtemperature sensi-tivitydisappears.AsimilarphenomenonhasbeenobservedinHSLA-65 steelbyNemat-NasserandGuo[28] whenthecompressionbehavior wasstudiedover awiderangeof strainratesandtemperatures. Ac-cordingtothethermallyactivateddislocationmotiontheory[29],the totalflowstresscanbedividedintotwoitemscalledtheinternalstress 𝜎𝜇andtheeffectivestress𝜎∗.Thetwopartsdescriberespectivelythe

strainhardeningeffectandthethermalactivationprocess,Fig.14.𝜎𝜇is

independentofstrainrateandkeepsalmostconstantatdifferent temper-atures,while𝜎∗isstronglyaffectedbytheeffectsofstrainrateand tem-perature.Duringquasi-static(10−3s−1to1s−1)testsatvarious temper-atures,𝜎∗firstremainsconstantandthenincreasessignificantlyat tem-peratureslowerthan0.1Tm (Tm referstothemeltingtemperatureof al-loysandis1300°Cfor304ASS).Hence,from−60°C(0.13Tm )to−163°C (0.06Tm ),theflowstressincreaseswithdecreasingtemperature.When thestrainratechangesfromquasi-statictodynamic(1550s−1to3270 s−1),𝜎∗increasescontinuouslybutthestressdifferencebetweenvarious temperaturesbecomessmaller.Therefore,thepreviousobservedstrong temperaturesensitivityalmostvanishesindynamictests.

Fig. 13(b) shows the evolution of flow stress with temperature at a true strain of 0.2. Undertheeffects of strain rateon both the transformation process and the dislocation motion, the flow stress decreaseswithincreasingtemperaturebutthedecreasingtendenciesin quasi-staticanddynamictests aredifferent:theflowstressdecreases fasterintheformerconditionthaninthelatter.

5. Thermo-viscoplasticbehaviormodelingof304ASS

Motivatedbyscientific andengineeringdemands, alargenumber ofconstitutivemodelshavebeenproposedtodescribethedeformation behaviorof materials. Basically, they can be dividedinto two cate-gories:thephenomenologicalandthephysicalbasedmodels.Thefirst

categorydescribesflowstressofmaterialsaccordingtoempirical obser-vationsanddoesnothaveanyphysicalbackground,e.g.,Johnson-Cook model [31], Khan–Huang model [32], Fields–Backofen model [33], Molinari–Ravichandranmodel[34],Voce–Kocksmodel[35],Arrhenius equation[36]andtheirvariants[37–40].Anothergroupofconstitutive models are builtaccording to deformation mechanism of materials, suchasZerilliandArmstrongmodel[41], Rusinek–Klepaczkomodel [20],Voyiadjis–Almasri model[42] andBodner–Partommodel[43]. Inaddition,artificialneuralnetworkmodelsareincreasinglyusedin areasofconstitutivebehaviorpredictionastheyprovideacompletely differentapproachtomaterialsmodelingthanthetraditionalstatistical or numericalmethods[44]. Adetaileddescriptionofdifferent kinds ofconstitutivemodelswiththeiradvantagesanddisadvantagescanbe foundin[45].

According to the deformation behavior analysis of 304 ASS in Section 4, a coupling effect of strain rate and temperature exists. Moreover,thedeformationbehaviorisstronglyaffectedbymartensitic transformation.Therefore,aconstitutivemodeltakingthetwoeffects intoconsiderationisneededforaccuratedeformationbehavior model-ing.Inthissection,anextensionoftheoriginalRKmodelconsidering martensitic transformation[21] is used todescribe thedeformation behaviorof304ASS.

Atypicaltruestress-truestraincurveof304ASSat−20°Cand10−3 s−1isshowninFig.15.Thecurveisdividedintotwoparts:withinatrue strainof0.08,nomartensitictransformationoccursduringthe deforma-tionprocess;forlargerstrains,thedeformationmechanismchangesinto acompetitionbetweendislocationslipandmartensitictransformation. Thetruestress-truestraincurvewithoutphasetransformationcanbe extendedbythesamestrainhardeningrate.Theextendedcurveis as-sumedastheflowstressof304ASSwithoutmartensitictransformation andcanbedescribedbytheoriginalRKmodel.Thedifferencebetween therealandtheextendedstress-straincurveissupposedtobecaused by martensitic transformation.The corresponding flowstress can be describedbyanextendeditemcoupledtotheoriginalRKmodel.

Theitemdefiningmartensitictransformationisbasedonthe prob-ability thattheaustenitephase will transforminto martensitephase undercertainconditions.No accuratephase fractionmeasurementis needed todefine the modelparameters. Various martensite fraction measurement techniquescan beused buteach ofthemhasthe limi-tationsanditisprettydifficulttoobtainaccurateproportionsofeach phase:

- Metallographicobservationisconvenientbuttheresultsarestrongly affectedbysamplesurfacepreparationtechniques.

Fig.11. Truestress-truestrainrelationsof304ASSasafunctionoftemperatureatstrainratesof:(a)10− 3 s− 1 ,(b)10− 2 s− 1 ,(c)10− 1 s− 1 ,(d)1s− 1 ,(e)1550s− 1 ,(f) 2370s− 1 and(g)3270s− 1 .

Fig.12. Variationofflowstresswithstrainrateasafunctionoftemperaturefortruestrainsof:(a)0.05and(b)0.2.

Fig.13. Variationofflowstresswithtemperatureasafunctionofstrainratefortruestrainsof:(a)0.05and(b)0.2.

Fig.14. Decompositionofthetotalflowstressintotheinternalstress𝜎𝜇and

theeffectivestress𝜎∗ usingthethermallyactivateddislocationmotiontheory

Fig.16. ComparisonofflowstresscurvesbetweenexperimentsandRKmodelfor(a)10− 3 s− 1 ,(b)10− 2 s− 1 ,(c)10− 1 s− 1 ,(d)1s− 1 ,(e)1550s− 1 ,(f)2370s− 1 and (g)3270s− 1 .

- ForEBSD,thesevereplastic deformationmakestheindexingrate decreasealot,sothemeasurementresultsarerepresentativeonly undersmallstrains.

- ThedetectionareaofXRDislimitedtothesamplesurface. - Magnetic permeability measurement is also used to calculate

martensitefractionbuttheinversemagnetostriction phenomenon cannotbeavoided.

Withoutmartensitefractionmeasurement,theerrorcausedby inac-curatemeasurementmethodscanbelargelyavoided.

5.1. TheextendedR-Kconstitutiveequation

Inspiredbythethermally-activateddislocationmotiontheory[29], theoriginalformoftheRKmodelisgivenasasumoftwocomponents: theinternalstress𝜎𝜇(𝜀𝑝 ,̇𝜀𝑝,𝑇)andtheeffectivestress𝜎∗(̇𝜀𝑝,𝑇),Fig.14. Theformercomponentisinducedbylong-rangebarrierstodislocation motionandisindependentofdeformationconditions.Incontrast,the lattercomponentiscausedbyshort-rangebarrierstodislocationmotion such asthe interactions of dislocationsand crystaldefects, andcan beovercomebythermalactivationprocess[13].Thetwocomponents aremultipliedby a parameterE(T)/E0 torepresent thetemperature dependenceofYoung’smodulus.

̄𝜎(𝜀𝑝 ,̇𝜀𝑝 ,𝑇)=𝐸(𝑇) 𝐸0 [( 𝜀𝑝 ,̇𝜀𝑝 ,𝑇)+𝜎∗ ( ̇𝜀𝑝 ,𝑇)] (4)

AstrainhardeningequationsimilartotheSwiftlawisusedto de-scribetheinternalstress𝜎𝜇(𝜀𝑝 ,̇𝜀𝑝 ,𝑇).

𝜎𝜇

(

𝜀𝑝 ,̇𝜀𝑝,𝑇)=𝐵(̇𝜀𝑝,𝑇)(𝜀0+𝜀𝑝 )𝑛 (̇𝜀 𝑝,𝑇 )

(5) where𝜀0 referstothevaluecorresponding totheyieldpointduring quasi-statictests.

Theeffectivestress𝜎∗(̇𝜀𝑝 ,𝑇)definestheflowstressinducedby ther-malactivationprocessusinganArrheniusequation:

𝜎∗(̇𝜀𝑝,𝑇)=𝜎∗ 0 ⟨ 1−𝐷1 ( 𝑇 𝑇𝑚 ) loglog (̇𝜀 max ̇𝜀𝑝 )⟩𝑚 ∗ (6) where𝜎∗

0istheeffectivestressat0K,D1andm

∗arematerialconstants. Todefinethestresscomponentcausedbymartensitic transforma-tion,athirditem𝜎𝑇 𝑟 (𝜀𝑝 ,̇𝜀𝑝 ,𝑇)iscoupledtotheoriginalR-Kmodel.

̄𝜎(𝜀𝑝 ,̇𝜀𝑝 ,𝑇)=𝐸(𝑇) 𝐸0 [ 𝜎𝜇 ( 𝜀𝑝 ,̇𝜀𝑝 ,𝑇)+𝜎∗ ( ̇𝜀𝑝 ,𝑇)]+𝜎𝑇 𝑟 ( 𝜀𝑝 ,̇𝜀𝑝 ,𝑇) (7) 𝜎𝑇 𝑟 ( 𝜀𝑝 ,̇𝜀𝑝,𝑇)=𝜎0𝛼𝑓 ( 𝜀𝑝 ,̇𝜀𝑝 )𝑔(𝑇) (8) where𝜎𝛼

0 referstothemaximumstressincreasecausedbymartensitic transformation.Thevalueshouldbe obtainedbymechanicaltests at thelowesttemperatureofinterest.

𝑓(𝜀𝑝 ,̇𝜀𝑝 )isaphenomenologicalfunctiontodescribetheeffectsof strainrateandstrainontheprobabilityofmartensitictransformation. Itisgivenas

𝑓(𝜀𝑝 , ̇𝜀𝑝)=[1−𝑒𝑥𝑝(−ℎ(̇𝜀𝑝 )𝜀𝑝 )]𝜉 (9) ℎ(̇𝜀𝑝 )=𝜆0exp

(

−𝜆 ̇𝜀𝑝) (10)

where𝜉 isaconstantthatdefinesthestrainvalueforwhichthe austen-itephasestartstotransformintomartensitephase.Thevaluecanbe determinedaccordingtotheinterruptincreaseinstrainhardeningrate ofstress-straincurves.ℎ(̇𝜀𝑝 )isafunctionthatdescribesthestrainrate dependentmartensitictransformation.𝜆0and𝜆 aretwoshapefitting pa-rameters.Adetaileddescriptionconcerningthefittingresultsofphase transformationusingℎ(̇𝜀𝑝 )canbefoundin[21].

Todefinetheeffectoftemperatureonthetransformationprocess,a temperaturefunctiong(T)isproposed:

𝑔(𝑇)=1− ( 𝑇−𝑀 𝑆 𝑀𝐷 −𝑀𝑆 )𝑛 (11)

Fig.17. ThedescriptionerroroftheextendedR-Kmodelinpredictionofthe experimentaldata.

whereMS refers tothetemperaturebelowwhich theGibbsfree en-ergybetweenaustenitephaseandmartensitephaseishighenoughfor martensitictransformationtooccurspontaneously.MD isthe temper-atureabovewhichmartensitictransformationdoesnotoccuranymore andthedeformationmechanismchangesintotwinningordislocation slip.nrepresentsthestrainratesensitivityofthetransformation pro-cess.

ThedeterminationofextendedRKmodelparametersisdividedinto twosteps:firstofall,theextendedcurvesof304ASSunderdifferent strainratesandtemperaturesareregardedasthestress-strainrelations withoutmartensitictransformationandarethendefinedbytheoriginal RK model. A detailed description of the fitting procedures can be foundin[30].Afterthat,thestresscomponentcausedbymartensitic transformation is defined by the third item𝜎Tr of theextended RK

model. Inbothsteps, aleastsquaremethod isusedtominimize the errorbetweenthecalculateddataandtheexperimentalresults.

ThetotalnumberofmaterialconstantsoftheextendedRKmodel is12including4parameterstodefinemartensitictransformation.The fittedmaterialparametersoftheoriginalR-Kmodelandtheextended itemareshowninTables2and3,respectively.

5.2. Comparisonbetweenexperimentalandpredictedflowstressof304 ASS

A comparison between experiments and predicted stress-strain curvesaswellasthecorrespondingpredictionerrorsareshowninFigs. 16 and17, respectively.Thepredictionerror Δis usedtoassessthe fittingresultsandisdefinedas

Δ = 1 𝑁 ∑𝑁 𝑖 =1 || || | 𝜎𝑖 𝑒𝑥𝑝 −𝜎𝑖 𝑝𝑟𝑒 𝜎𝑖 𝑒𝑥𝑝 × 100%||||| (12)

ItisseenfromFigs.16 and17 thatagoodagreementisachieved for testing temperatures between −60°C and 172°C. The prediction errors are respectively 7.6% and4.9% for quasi-static anddynamic tests. According to J.A.Rodríguez-Martínez et al. [46], an obvious temperatureincreasestillexistsinquasi-statictestsofTRIPsteels,and it affects martensitic transformation significantly. However, in this study,thequasi-statictestsareconsideredasisothermal.Therefore,the predictedresultsforquasi-statictestsarenotasgoodasthedynamic ones.Inaddition,duetotheunexpectedlowstrainratesensitivityof 304 ASSat−163°C,Fig.13, thepredictedflowstressis significantly higher than theexperimental ones with anaverage error of 21.2%.

Table2

ThefittedparametersoftheoriginalRKmodelfor304ASSwithoutmartensitictransformation.

E0 (GPa) Tm (K) 𝜃∗ (-) 𝜎∗0 (MPa) D1 (-) m∗ (-) B 0 (MPa) v (-) n0 (-) D2 (-) 𝜀 0 (-) 210 1700 0.9 658 0.58 1.84 1693 0.41 0.39 − 0.19 0.023

Fig.18. ComparisonofstrainratesensitivitybetweenexperimentsandtheextendedRKmodelattruestrainsof(a)0.05and(b)0.2.

Table3

Thefittedparametersoftheextendeditemdescribingthe marten-sitictransformation.

𝜎0 (MPa) MD (K) MS (K) 𝜆 (-) 𝜆0 (-) 𝜉 (-) 𝜂 (-) 1026 413 20 0.60 21.17 10.76 0.82

ThisismainlybecauseintheextendedRKmodel,aphenomenological insteadofphysicalfunctionisusedtodescribethemartensitic transfor-mationprocess.Thefunctionworkswellwithinalimitedtemperature regime. Compared to sophisticated physical models [47–49], the phenomenological approach simplifies the finite element (FE) code implementationprocessandhelpstoreducethecomputationaltime. However,forabettermartensitictransformationbehaviordescription, afurtherimprovementoftheextendedRKmodelisneeded.

Tocomparetheexperimentaldatawiththepredictedonesindetail, theevolutionofflowstresswithstrainratefortwostrains0.05and 0.2areshowninFig.18.ItisclearinFig.18(a)thattheextendedRK modelgivesasatisfactorypredictionofstrainratesensitivityatvarious temperatures, except −163°C. In dynamic strain rates, the coupling relationshipbetweenstrainrateandtemperatureisalsocaptured:the materialshowshigherstrainratesensitivityatelevatedtemperatures.In Fig.18(b),thenegativestrainratesensitivityinquasi-staticstrainrates isnotpredictedcorrectly.Asexplainedbefore,thisisbecausein quasi-statictests,theexperimentallyobservedtemperatureriseisnottaken intoconsiderationwhenperformingconstitutivebehaviormodeling.

Concerning predictions of temperature sensitivity, a comparison betweenexperimentsandtheextendedRKmodelisshowninFig.19. Itisclearthatthemodeldefinesthetemperaturesensitivityaccurately between −60°Cand172°C.InFig.19(b),thedecreased temperature sensitivitywithincreasingstrainrateisalsocaptured.Onthewhole, theextendedR-Kmodelpredictsthedeformationbehaviorof304ASS correctlyfortestingtemperaturesT0≧−60°C.

6. ValidationoftheextendedRKmodel

Theutilityofaconstitutivemodelliesinnot onlyitscapacity of fitting experimentally obtained results but alsoits abilityto predict

deformationbehaviorbeyondthetestingconditions. Toevaluatethe extendedRKmodelandthepreviouslydefinedmodelparameters, nu-mericalsimulationsof304ASSplatesimpactedbyaconicalprojectile atdifferenttemperatureshavebeencarriedout.

6.1. Numericalmodeldescription

The numericalsimulationswereperformed basedon theballistic impactresults of304ASSreportedbyJiaetal.[24].During experi-ments,304ASSthinplateswereimpactedbyaconicalprojectileunder sub-ordnance velocitiesrangingfrom80 m/sto180 m/sandinitial temperaturesbetween−60°Cand200°C.Eachplateisasquarewitha sidelengthof130mmandathicknessof1.5mm.Theconicalprojectile isacylinderwithadiameterof12.8mmandaheightof25mm.Atthe topoftheprojectile,aconicalnosewithanangleof72° ismachined.A detaileddescriptionoftheballisticimpactset-up,theconicalprojectile andthecoolingdevice/heatingfurnaceforlow/elevatedtemperature testscanbefoundin[24].

A3Dfull-sizefiniteelement(FE)modelconsistingoftheprojectile andthetargethasbeenbuiltusingsoftwareABAQUS/Explicit,Fig.20. Thegeometryanddimensionsofthetargetareexactlythesameasthe experimentalones.Thetargetissetasadeformablebody,andthe con-stitutivebehaviorischaracterizedbythepreviouslydefinedextended RKmodel.Toreducecalculationtime,theprojectileisregardedasa rigidbodywithaconstantmassof29g.Thefouredgesofthetargetare fixedandnodisplacementisallowed.Theconicalprojectileisplaced perpendicular to the target with a predefined velocity. For contact betweentheprojectileandthetarget,penaltymethodwithafriction coefficientof0.1isadopted,avaluefrequentlyusedfordrysteel-steel contact [50]. The perforation process is assumed as adiabatic, no heattransferbetweenthetargetandtheprojectileorthesurrounding environmentistakenintoconsideration.

Accordingtoameshconvergencestudy,theoptimalmeshdensity distributioninthetargetisshowninFig.21.Thecentralpartofthe tar-getisbuiltwith107380C3D8Relements(8-nodelinearbrick,reduced integrationelement)withaninitialelementsizeof0.2mm.ALE adap-tivemeshingisusedtomaintainahighmeshqualitythroughout the analysis.Intheexteriorarea,wherenoprojectile/targetimpactoccurs,

Fig.19. ComparisonoftemperaturesensitivitybetweenexperimentsandtheextendedRKmodelattruestrainsof:(a)0.05and(b)0.2.

Fig.20. Thefiniteelementmodelofballisticimpacttests.

Table4

Failurestrainsof304ASSplatefordifferenttesting tem-peratures.

Initial temperature ( °C) − 60 − 20 20 200 Failure strain, 𝜀 f 0.49 0.55 0.6 0.67

C3D8Relementswithaninitialelementsizeof1.5mmareadopted.In thewholetarget,fiveelementsacrossthethicknessdirectionareused. Thismeshdensityisrecommendedbyseveralauthorswhenmodeling ballisticimpactbehaviorofthinmetallicstructures[50,51].

Tobeabletocapturethefractureprocess,afailurecriterionwith element deletion is necessary. According to the work of Kpenyigba etal.[51],aconstantfailurestrainforeachprojectileshapeisableto producenumericalresultsinagoodagreementwithexperiments.Inthis work,aconstantfailurestrainisassumedforeachtestingtemperature. Accordingtoanoptimizationofballisticcurves,thefailurestrainsfor differenttestingtemperatureswereestimated,Table4.

Fig.22. Comparisonofballisticcurvesbetweenexperimentsandnumericalsimulations:(a)−60°C,(b)−20°C,(c)20°Cand(d)200°C.

6.2. Numericalresultsintermsofballisticcurvesandfracturepatterns TheexperimentalresultsintermsofballisticcurvesVR -V0are pre-sentedinFig.22.Thecurvesarethenfittedtotheequationproposed byRechtandIpson[52],Eq.(13).InEq.(13),theresidualvelocityof theprojectileVR iscalculatedasafunctionoftheinitialvelocityV0, theballisticlimitvelocityVbl andafittingparameter𝛼.

𝑉𝑅 =(𝑉0𝛼−𝑉𝑏𝑙 𝛼

)1∕𝛼 (13)

Acomparisonbetweentheexperimentalandthenumericalballistic curves is shown in Fig. 22. A good agreement is observed for all thefourtemperatures. Withtheincreasingtesting temperature from −60°Cto−20°C,20°Cand200°C,thepredictedballisticlimitvelocities decreasegraduallyfrom108m/sto106m/s,100m/sand87m/s.The predictionerrorsofVbl forthefourtemperaturesarerespectively4.9%, 2.9%,4.2%and6.5%.Inaddition,theevolutiontendencyofVR with V0 isalsocapturedcorrectlybynumericalsimulations.Underallthe fourtemperatures,the VR -V0 curves show aparabolic shape.Fitting thenumericalVR -V0curvesintoEq.16,thefittedvaluesofparameter

𝛼 fordifferent temperaturesareshownin Table5. Itis seenthat in bothexperimentsandnumericalsimulations,valuesof𝛼 increasewith increasingtesting temperature,indicatinga deterioratedballistic im-pactresistanceandalowerballisticlimitvelocityathightemperatures. Therefore,theevolutionsofVbl and𝛼 areconsistentwitheachother.

Table5

Parameter𝛼 underdifferenttestingtemperaturesinbothexperimentsand numericalsimulations.

Initial temperature ( °C) − 60 − 20 20 200 Values of 𝛼 using experimental V R - V 0 2.285 2.239 2.713 2.766 Values of 𝛼 using numerical V R - V 0 2.028 2.005 2.712 2.660

ForacompletevalidationoftheextendedRKmodel,thepredicted failure mode is compared to the experimental ones, Fig. 23. It is seen thatpetalling resulting fromradialnecking duringthepiercing process isobserved, thesameasexperiments. Plasticdeformationis onlyobservedinpetalsoftheperforatedspecimens,especiallyonthe fracturesurfacewherethematerialexperiencedthelargestdeformation untilfailure;plastic deformationin theotherparts ofthespecimens isprettylimited,withamaximumvalueof1.1%fordifferenttesting temperatures.

Thenumberofpetalsvariesunderdifferenttestingtemperatures.A comparisonofthenumberofpetalsbetweenexperimentsandnumerical results isshown inTable 6. Duringnumerical simulations,thevalue decreasescontinuouslyfrom6at−60°Cto4at200°C.Inexperiments, asimilartendencyisobservedbutthecorrespondingvaluesare com-parativelysmaller.Inanycase,tohaveabetterunderstandingofthe

Fig.23. Comparisonoffracturepatternbetweenexperimentsandnumericalsimulations:(a)−60°C,(b)−20°C,(c)20°Cand(d)200°C.

Table6

Experimentalandnumericalnumberofpetalsasafunctionoftesting tem-peratureatV0 =110m/s.

Initial temperature ( °C) − 60 − 20 20 200 Number of petals in experiments 5 4 3 3 Number of petals in numerical simulations 6 5 4 4

failuremode,afurtherstudyonthefailurebehaviorof304ASSasa functionofstrainrate,temperatureandstressstateisnecessary.

7. Conclusionsandremarks

Thethermo-viscoplasticbehaviorof304ASShasbeensystematically studiedoverawiderangeofstrainrates(10−3 s−1 to3270s−1)and

temperatures(−163°Cto172°C).Dynamictestsatlow/elevated tem-peratureswereconductedusingtheHopkinsontechniquecoupledwith specificallydesignedcoolingdevice/heatingfurnace,andreliabilityof thetechnique wasverified bythermal simulations.The deformation behaviorof 304ASSwasanalyzedin termsofstrainhardeningrate, strainratesensitivityandtemperaturesensitivity.Basedon experimen-talresults,anextensionoftheRKmodelconsideringSIMTeffectwas usedtodescribetheconstitutivebehaviorof304ASS.Thecorrectness of the extended RK model was further verified through numerical simulationsof ballistic impact tests at various testing temperatures. Severalnoteworthyconclusionsaredrawn:

1 Withthedevelopedcoolingdevice/heatingfurnace,dynamictests attemperaturesrangingfrom−163°Cto172°Ccan beconducted usingtheHopkinsontechnique.Accordingtothenumericalresults, thetemperature distributionwithin the compressionspecimen is uniformwithamaximumfluctuationof1.2°C.

2 Thedeformationbehaviorof 304ASSis dominatedbya compe-tition between dislocation glide and martensitic transformation. Bothstrainrateandtemperaturehavesignificanteffectsonthetwo mechanisms.Hence,thedeformationbehaviorof304ASS,mainly representedbythestrainhardeningrate,strainratesensitivityand temperaturesensitivity,isdifferentfrommetallicalloyscommonly deformedbydislocationslip.Severalunexpectedphenomenasuch astheS-shapedstress-straincurves,thenegativestrainrate sensi-tivityandthechangingtemperaturesensitivityfromquasi-staticto dynamicstrainrates,areobserved.

3 From−60°Cto−163°Candunderdynamic strainrates,the tem-peraturesensitivityof304ASSwaslowerthanthatfortheother temperatures. According to the thermally activated dislocation motiontheory,thisismainlycausedbythecomparativelysmaller effectivestress𝜎∗increasefrom−60°Cto−163°C.

4 The extended RK model was used to describe the constitutive behaviorof304ASSwithanadditionalitemlinkedtomartensitic transformation.Themodelpredictedtheflowstresscurvesof304 ASSabove−60°Ccorrectlywiththeseveralunexpectedphenomena beingcaptured.Thepredictionerrorsforquasi-staticanddynamic testswere7.6%and4.9%,respectively.

5 The utility of the extended RK model was further evaluated by numericalsimulationsofballisticimpacttestsatvarious tempera-turesbetween−60°Cand200°C.Thenumericalresultsintermsof ballisticcurves werecompared toexperiments:both theballistic limitvelocitiesVbl andtheballistic curves VR -V0 werepredicted accurately. In addition, the failure process was also captured: boththefailurepatternandthenumberof petalsunderdifferent temperatureswerepredictedcorrectly.

Authorstatement

TheideaandstructureofthearticlewereproposedbyAlexisRusinek andRaphaëlPesci.Theset-updesignandexperimentswereconducted byBinJia,RichardBernierandSlimBahi.BinJia,AlexisRusinekand Slim Bahi performed constitutive behavior modeling and numerical simulationsofballisticimpactbehavior.Thepaperwritingwasmainly donebyBinJiawithsuggestionsandmodificationsfromAlexisRusinek andRaphaëlPesci.Allauthorsreadandapprovedthefinalmanuscript.

DeclarationofCompetingInterest

Theauthorsdeclaredthattheyhavenoconflictsofinterestinthis work.Wedeclarethatwedonothaveanycommercialorassociative interestthat represents a conflictof interestin connectionwith the worksubmitted.

Acknowledgements

PartofthisworkwasfinanciallysupportedbytheChinaScholarship CouncilunderGrant201606220056.

References

[1] Fischer FD, Sun Q-P, Tanaka K. Transformation-induced plasticity (TRIP). Appl Mech Rev 1996;49:317–64. https://doi.org/10.1115/1.3101930 .

[2] Zackay VF , Parker ER , Fahr D , Busch R . The enhancement of ductility in high--strength steels. ASM Trans Quart 1967;60:252–9 .

[3] Park WS, Yoo SW, Kim MH, Lee JM. Strain-rate effects on the mechanical behavior of the AISI 300 series of austenitic stainless steel under cryogenic environments. Mater Des 2010;31:3630–40. https://doi.org/10.1016/j.matdes.2010.02.041 .

[4] Kumar S, Kwon H-T, Choi K-H, Hyun Cho J, Lim W, Moon I. Current status and future projections of LNG demand and supplies: a global prospective. Energy Policy 2011;39:4097–104. https://doi.org/10.1016/j.enpol.2011.03.067 .

[5] Curtze S, Kuokkala V-T, Hokka M, Peura P. Deformation behavior of TRIP and DP steels in tension at different temperatures over a wide range of strain rates. Mater Sci Eng A 2009;507:124–31. https://doi.org/10.1016/j.msea.2008.11.050 .

[6] Rodríguez-Martínez JA, Rusinek A, Pesci R. Experimental survey on the behaviour of AISI 304 steel sheets subjected to perforation. Thin-Wall Struct 2010;48:966–78.

https://doi.org/10.1016/j.tws.2010.07.005 .

[7] Lee W-S, Lin C-F, Chen T-H, Luo W-Z. High temperature deformation and frac- ture behaviour of 316 L stainless steel under high strain rate loading. J Nucl Mater 2012;420:226–34. https://doi.org/10.1016/j.jnucmat.2011.10.005 .

[8] Lin YC, Dong W-Y, Zhou M, Wen D-X, Chen D-D. A unified consti- tutive model based on dislocation density for an Al-Zn-Mg-Cu alloy at time-variant hot deformation conditions. Mater Sci Eng A 2018;718:165–72.

https://doi.org/10.1016/j.msea.2018.01.109 .

[9] Byun TS, Hashimoto N, Farrell K. Temperature dependence of strain hardening and plastic instability behaviors in austenitic stainless steels. Acta Mater 2004;52:3889– 99. https://doi.org/10.1016/j.actamat.2004.05.003 .

[10] Hamada AS, Karjalainen LP, Misra RDK, Talonen J. Contribution of deformation mechanisms to strength and ductility in two Cr–Mn grade austenitic stainless steels. Mater Sci Eng A 2013;559:336–44. https://doi.org/10.1016/j.msea.2012.08.108 .

[11] Zheng C, Yu W. Effect of low-temperature on mechanical behavior for an AISI 304 austenitic stainless steel. Mater Sci Eng A 2018;710:359–65.

https://doi.org/10.1016/j.msea.2017.11.003 .

[12] Krizan D . TRIP steels: advanced high strength multiphase steels for automotive ap- plications. Proc Int Conf 2006:659–68 on “COM-MATTECH ”, Trnava, Slovakia .

[13] Lin YC, Yang H, He D-G, Chen J. A physically-based model consider- ing dislocation–solute atom dynamic interactions for a nickel-based su- peralloy at intermediate temperatures. Mater Des 2019;183:108122.

https://doi.org/10.1016/j.matdes.2019.108122 .

[14] Talonen J, Hänninen H, Nenonen P, Pape G. Effect of strain rate on the strain-induced 𝛾 → 𝛼′ -martensite transformation and mechanical prop- erties of austenitic stainless steels. Metall Mat Trans A 2005;36:421–32.

https://doi.org/10.1007/s11661-005-0313-y .

[15] Lee W-S, Lin C-F. Impact properties and microstructure evolu- tion of 304 L stainless steel. Mater Sci Eng A 2001;308:124–35.

https://doi.org/10.1016/S0921-5093(00)02024-4 .

[16] Park WS, Chun MS, Han MS, Kim MH, Lee JM. Comparative study on mechani- cal behavior of low temperature application materials for ships and offshore struc- tures: part I —Experimental investigations. Mater Sci Eng A 2011;528:5790–803.

https://doi.org/10.1016/j.msea.2011.04.032 .

[17] Lichtenfeld JA, Van Tyne CJ, Mataya MC. Effect of strain rate on stress-strain behav- ior of alloy 309 and 304 L austenitic stainless steel. Metall Mat Trans A 2006;37:147– 61. https://doi.org/10.1007/s11661-006-0160-5 .

[18] Ishikawa K, Tanimura S. Strain rate sensitivity of flow stress at low temperatures in 304n stainless steel. Int J Plastic 1992;8:.. 947–58

https://doi.org/10.1016/0749-6419(92)90044-D .

[19] Gür C., Pan J. Handbook of thermal process modelling of steels. 2009. CRC Press: Boca Raton, FL; n.d.

[20] Rusinek A, Klepaczko JR. Shear testing of a sheet steel at wide range of strain rates and a constitutive relation with strain-rate and tem- perature dependence of the flow stress. Int J Plastic 2001;17:87–115.

https://doi.org/10.1016/S0749-6419(00)00020-6 .

[21] Rodríguez-Martínez JA, Rusinek A, Klepaczko JR, P ęcherski RB. Extension of R–K constitutive relation to phase transformation phenomena. Mater Des 2009;30:2513– 20. https://doi.org/10.1016/j.matdes.2008.09.043 .

[22] Malinowski JZ, Klepaczko JR. A unified analytic and numerical approach to speci- men behaviour in the Split-Hopkinson pressure bar. Int J Mech Sci 1986;28:381–91.

https://doi.org/10.1016/0020-7403(86)90057-3 .

[23] Xu Z, Ding X, Zhang W, Huang F. A novel method in dynamic shear testing of bulk materials using the traditional SHPB technique. Int J Impact Eng 2017;101:90–104.

https://doi.org/10.1016/j.ijimpeng.2016.11.012 .

[24] Jia B., Rusinek A., Bahi S., Bernier R., Pesci R., Bendarma A. Perforation behavior of 304 stainless steel plates at various temperatures. J Dyn Behav Mater2019:1–16.

https://doi.org/10.1007/s40870-019-00208-9 .

[25] COMSOL A. COMSOL Multiphysics Reference Manual: Version 3.5. Stockholm; 2008. [26] Murr LE, Staudhammer KP, Hecker SS. Effects of strain state and strain rate on deformation-induced transformation in 304 stainless steel: part II. Microstructural study. MTA 1982;13:627–35. https://doi.org/10.1007/BF02644428 .

[27] Hecker SS, Stout MG, Staudhammer KP, Smith JL. Effects of strain state and strain rate on deformation-induced transformation in 304 stainless steel: part I. Magnetic measurements and mechanical behavior. MTA 1982;13:619–26.

https://doi.org/10.1007/BF02644427 .

[28] Nemat-Nasser S., Guo W.-.G. Mechanics of materials 2005;37:379–405.

https://doi.org/10.1016/j.mechmat.2003.08.017 .

[29] Kocks UF , Argon AS , Ashby MF . Thermodynamics and kinetics of slip. Argonne Na- tional Laboratory; 1973 .

[30] Klepaczko JR, Rusinek A, Rodríguez-Martínez JA, P ęcherski RB, Arias A. Mod- elling of thermo-viscoplastic behaviour of DH-36 and Weldox 460-E struc- tural steels at wide ranges of strain rates and temperatures, comparison of constitutive relations for impact problems. Mech Mater 2009;41:599–621.

https://doi.org/10.1016/j.mechmat.2008.11.004 .

[31] Johnson G.R. A constitutive model and data for materials subjected to large strains, high strain rates, and high temperatures. Proc 7th Inf Sympo Ballistics 1983:541– 547.

[32] Khan AS, Huang S. Experimental and theoretical study of mechanical behavior of 1100 aluminum in the strain rate range 10 − 5 − 104s − 1. Int J Plastic 1992;8:397– 424. https://doi.org/10.1016/0749-6419(92)90057-J .

[33] Fields D , Backofen W . Determination of strain hardening characteristics by torsion testing. Proc ASTM 1957;57:1259–72 .

[34] Molinari A, Ravichandran G. Constitutive modeling of high-strain-rate deformation in metals based on the evolution of an effective microstructural length. Mech Mater 2005;37:737–52. https://doi.org/10.1016/j.mechmat.2004.07.005 .

[35] VOCE E . The relationship between stress and strain for homogeneous deformation. J Inst Metals 1948;74:537–62 .

[36] Zener C, Hollomon JH. Effect of strain rate upon plastic flow of steel. J Appl Phys 1944;15:22–32. https://doi.org/10.1063/1.1707363 .

[37] Khan AS, Zhang H, Takacs L. Mechanical response and modeling of fully compacted nanocrystalline iron and copper. Int J Plastic 2000;16:1459–76.

https://doi.org/10.1016/S0749-6419(00)00023-1 .

[38] Khan AS, Sung Suh Y, Kazmi R. Quasi-static and dynamic loading responses and constitutive modeling of titanium alloys. Int J Plastic 2004;20:2233–48.

https://doi.org/10.1016/j.ijplas.2003.06.005 .

[39] Khan AS, Suh YS, Chen X, Takacs L, Zhang H. Nanocrystalline aluminum and iron: mechanical behavior at quasi-static and high strain rates, and constitutive modeling. Int J Plastic 2006;22:195–209. https://doi.org/10.1016/j.ijplas.2004.07.008 .

[40] Farrokh B, Khan AS. Grain size, strain rate, and temperature dependence of flow stress in ultra-fine grained and nanocrystalline Cu and Al: syn- thesis, experiment, and constitutive modeling. Int J Plastic 2009;25:715–32.

https://doi.org/10.1016/j.ijplas.2008.08.001 .

[41] Zerilli FJ , Armstrong RW . Dislocation-mechanics-based constitutive relations for ma- terial dynamics calculations. J Appl Phys 1987;61:1816–25 .

[42] Voyiadjis GZ, Almasri AH. A physically based constitutive model for fcc metals with applications to dynamic hardness. Mech Mater 2008;40:549–63.

https://doi.org/10.1016/j.mechmat.2007.11.008 .

[43] Bodner SR, Partom Y. Constitutive equations for elastic-viscoplastic strain-hardening materials. J Appl Mech 1975;42:385–9. https://doi.org/10.1115/1.3423586 .

[44] Lin YC, Zhang J, Zhong J. Application of neural networks to predict the elevated temperature flow behavior of a low alloy steel. Comp Mater Sci 2008;43:752–8.

https://doi.org/10.1016/j.commatsci.2008.01.039 .

[45] Lin YC, Chen X-M. A critical review of experimental results and constitutive de- scriptions for metals and alloys in hot working. Mater Des 2011;32:1733–59.

https://doi.org/10.1016/j.matdes.2010.11.048 .

[46] Rodríguez-Martínez JA, Pesci R, Rusinek A. Experimental study on the marten- sitic transformation in AISI 304 steel sheets subjected to tension under wide ranges of strain rate at room temperature. Mater Sci Eng A 2011;528:5974–82.

https://doi.org/10.1016/j.msea.2011.04.030 .

[47] Olson GB, Cohen M. Kinetics of strain-induced martensitic nucleation. MTA 1975;6:791. https://doi.org/10.1007/BF02672301 .

[48] Stringfellow RG, Parks DM, Olson GB. A constitutive model for transfor- mation plasticity accompanying strain-induced martensitic transformations in metastable austenitic steels. Acta Metallurgica et Materialia 1992;40:1703–16.

https://doi.org/10.1016/0956-7151(92)90114-T .

[49] Iwamoto T, Tsuta T, Tomita Y. Investigation on deformation mode de- pendence of strain-induced martensitic transformation in trip steels and modelling of transformation kinetics. Int J Mech Sci 1998;40:173–82.

https://doi.org/10.1016/S0020-7403(97)00047-7 .

[50] Rodríguez-Martínez JA, Rusinek A, Pesci R, Zaera R. Experimental and numerical analysis of the martensitic transformation in AISI 304 steel sheets subjected to perfo- ration by conical and hemispherical projectiles. Int J Solids Struct 2013;50:339–51.

https://doi.org/10.1016/j.ijsolstr.2012.09.019 .

[51] Kpenyigba KM, Jankowiak T, Rusinek A, Pesci R. Influence of projectile shape on dy- namic behavior of steel sheet subjected to impact and perforation. Thin-Wall Struct 2013;65:93–104. https://doi.org/10.1016/j.tws.2013.01.003 .

[52] Recht RF, Ipson TW. Ballistic perforation dynamics. J Appl Mech 1963;30:384–90.