To cite this version : Nguyen, Anh Son and Musiani, Marco and

Orazem, Mark E. and Pébère, Nadine and Tribollet, Bernard and

Vivier, Vincent

Impedance analysis of the distributed resistivity of

coatings in dry and wet conditions

. (2015) Electrochimica Acta, vol.

179. pp. 452-459. ISSN 0013-4686

To link to this article : doi:

10.1016/j.electacta.2015.02.109

URL : http://dx.doi.org/10.1016/j.electacta.2015.02.109

O

pen

A

rchive

T

OULOUSE

A

rchive

O

uverte (

OATAO

)

OATAO is an open access repository that collects the work of Toulouse researchers and

makes it freely available over the web where possible.

This is an author-deposited version published in :

http://oatao.univ-toulouse.fr/

Eprints ID : 14432

Any correspondance concerning this service should be sent to the repository

administrator:

staff-oatao@listes-diff.inp-toulouse.fr

Impedance

analysis

of

the

distributed

resistivity

of

coatings

in

dry

and

wet

conditions

Anh

Son

Nguyen

a,

Marco

Musiani

b,

Mark

E.

Orazem

c,

Nadine

Pébère

a,*

,

Bernard

Tribollet

d,

Vincent

Vivier

daUniversitédeToulouse,CIRIMAT,UPS/INPT/CNRS,ENSIACET,31030Toulousecedex4,France bIstitutoperl'EnergeticaeleInterfasi,CNR,CorsoStatiUniti4,35127Padova,Italy cDepartmentofChemicalEngineering,UniversityofFlorida,Gainesville,Florida32611,USA dLISECNRS,UniversitéPierreetMarieCurie,75252,Pariscedex05,France

Keywords: aluminiumalloy corrosionprotection constantphaseelement(CPE) Youngimpedancepermittivity wateruptake

ABSTRACT

Acommercialcoating(epoxy-polyaminoamidewaterbornepaint)depositedona2024aluminiumalloy wascharacterizedbyimpedancemeasurements,firstindryconditionsandthenasafunctionofthe immersiontimeinNaClsolutions(wetconditions).Thebehaviourofthedrycoatingwasclosetothatof anidealcapacitorandcouldbeaccuratelymodelledwiththepower-lawmodelcorresponding toa constantphaseelement(CPE)behaviour.UponimmersioninNaClsolutions,thebehaviourofthewet coatingbecameprogressivelylessideal,i.e.fartherfromacapacitivebehaviour.Thisresultprovided supporttothehypothesisthataninhomogeneousuptakeoftheelectrolytesolutionwasthecauseofthe oftenobservednon-idealresponsesofwetcoatings.TheexperimentalEISdatarecordedforimmersion timesupto504hourswerecomparedwithmodelsassumingeitherapower-laworanexponential variationofthecoatingresistivityalongitsthickness,respectivelyimplyingaphaseangleindependentof frequencyorslightlydependentonit.

1.Introduction

Intworecentpapers[1,2]ourgrouphasproposedthattheCPE behaviourobservedintheimpedanceofmetal/coating/electrolyte systemswastheresultofpower-lawdependencesofthecoating resistivity(

r

)andpermittivity(e

)alongtheirthickness.Inturn,theresistivity and permittivity variations were attributed to an inhomogeneousuptake ofelectrolytic solutionintothecoating, stronger in proximity of the coating/electrolyte interface and progressively weakeralong the coatingthickness asthe metal/ coatinginterfacewasapproached.Accordingly,localresistivityand permittivitywerecalculatedasafunctionofthelocalelectrolyte volumefraction,usingeffective-mediumformulascorresponding toparallelcombinationsofcoatingmaterialandelectrolyte.The proposedmodel,henceforthcalled“power-lawmodel”,tookinto accountboththroughpores,directlyconnectingthemetal/coating and coating/electrolyte interfaces via low-resistivity paths, and pores less deepthan thecoating thickness.In relatedprevious work [3,4], it had been shown that the variation of the local

permittivity,byafactorof10to100atmost,hadanegligibleeffect, andsotheCPEbehaviourcouldbeentirelyascribedtoapower-law resistivity profile. The power-law model was used to analyse experimentaldataobtainedwithhybridsol–gelcoatingsdeposited ontoa2024aluminiumalloyandexposedtoelectrolyticsolutions

[1].Itwasshownthataninaccurateknowledgeoftheresistivityof thecoatingmaterial

rc

didnotaffectthequalityoftheagreement between model and experimental data, nor the values of the regressedparameters,aslongasrc

waslarge[2].Instead,thelack ofanaccurateknowledgeoftheresistivityoftheelectrolyte(rw

) within the coating pores, which could not be assumed to be identicaltothatofthebulkelectrolyte,preventedthecalculation ofaccuratewateruptakevaluesfromtheresistivityprofiles[2].Astrongimplicitassumptionunderlyingtheuseofthe power-law model, previously developed [3,4] and applied tofilms of variouschemicalnatures[5,6],intheanalysisoftheimpedanceof anti-corrosion coatings was that the non-ideally capacitive behaviourwastheresultoftheuptakeoftheelectrolyticsolution, not of a pre-existing variation of resistivity along the film thickness. Heterogeneities in the pristine coating morphology, e.g.somenano-scaleporosity,werenotexcluded.However,aslong asthecoatingwasnotexposedtoasolution,theair-filledpores hadnoeffectontheconductivity.Onlytheingressofanelectrolytic *Correspondingauthor.Tel.:+33534323423;fax:+33534323499.

E-mailaddress:Nadine.Pebere@ensiacet.fr(N.Pébère).

solutioncouldproduceconductivedomainsandrevealastructural inhomogeneity, as well as induce the formation of additional defectsortheincreaseoftheirsize.Theprimaryaimofthiswork hasbeentestingthishypothesisbymeasuringtheimpedanceof thesamecoatingunderdryandwetconditions,i.e.inthemetal/ coating/metal configuration, and then in the commonly used metal/coating/electrolyteconfiguration,thelatter forincreasing immersiontimes.Thecoatingchosentoperformtheexperiments wasatwo-componentwater-basedanticorrosiveprimer contain-ingseveralpigments,knowntoprovideaneffectiveanti-corrosion protection to the 2024 aluminium alloy [7]. The dry coating properties (

e

c andrc

) were first determined by impedancespectroscopy. Then, the impedance evolution upon immersion ofcoatedsamplesin either0.5Mor 0.05MNaClsolutions was followed.

Thereisnoaprioriphysicalreasonwhytheelectrolyticsolution uptakemustleadtoaresistivityprofileaccuratelydescribedbya powerlaw,which would cause a strictlyconstant phase angle. Therefore, an exponential variation of the coating permittivity alongitsthicknesswasconsideredasapossiblealternative,whena CPE did not account for the observed behaviour. Such an exponentialdependenceresultsinthewell-knownYoung imped-ance [8] characterized bya phase angle slightly dependent on frequency[9].

The present study is part of a wider program aimed at developing and characterizing chromate-free coatings for 2024aluminiumalloy. Studiesonthesame epoxy-polyaminoa-midewaterbornepaint,withoutchromates,areinprogressand investigations on coatings containing environmentally friendly inhibitorsareplanned.

2.Experimental

The coating samplesused and theimpedance measurement protocolarepresentedinthissection.

2.1.Thecoatingsamples

Thecoatingwasatwo-componentwater-basedpaintusedas an anticorrosive primer. The base was a polyaminoamide (Versamid1 type) andthe hardenerwasa bisphenolA epoxy polymer. The coatings were manufactured by Mapaero SAS. Differentpigmentswereaddedtotheorganicmatrix:titanium oxide (12wt.%), talc (11wt.%), silica (1wt.%) and strontium chromate(16wt.%).Theratioofthepigmentvolume concentra-tion(PVC)tocriticalpigmentvolumeconcentration(CPVC)was equalto0.61.The CPVCis thepigmentconcentrationatwhich thereisjustenoughbinderinthedrycoatingtocompletelyfillall thevoidsbetweenthepigmentparticles[10,11].ThePVCtoCPVC

ratioisanimportantparameterwhichcontrolsthefilmbarrier properties.

Thecoatingsweredepositedontoa2024T3aluminiumalloy (henceforth called “AA2024”) currently used in the aerospace industry. The chemical composition in weight percent of the alloywas:Cu:4.90; Mg:1.31;Mn:0.56;Si:0.08;Fe:0.26;Zn: 0.10; Ti: 0.01 and Al to balance. The specimens consisted of 125mm80mm1.6mmplatesmachinedfromarolledplate. Before painting, the samples were degreased at 60 C (pH=9) for15min,rinsedtwicewithdistilledwater,thenetchedin an acid bath at 52 C for 10min, and rinsed again with distilled water.Theliquidpaintswereappliedbyairsprayingandcured at roomtemperature. Thecoatings were 20–21

m

mthick. 2.2.ElectrochemicalimpedancemeasurementsForthedrycoating,atwo-electrodeconfigurationwasused. A cylindrical Plexiglass tube was fixed on top of the coated sample,exposingasurfaceareaof5.94cm2.Thewellwas

filled with mercury (1cm height) and the electric contact was done with a copper wire. Impedance measurements were performedwitha Solartron1255FrequencyResponse Analyzer connectedwitha1296DielectricInterface.Impedancediagrams wereobtainedatadcpotentialof0Voverafrequencyrangeof 1Hz to105Hz with 10points per decade and using a 100mV

peak-to-peak sinusoidalvoltage.

Fortheimpedancemeasurementsintheconventionalmetal/ coating/electrolyte configuration,a classical three-electrodecell was usedinwhich thecoated specimenservedastheworking electrode. A cylindrical Plexiglas tube was fixed on top of the coatedsample,exposingasurfaceareaof24cm2,and

filledwith either 0.5M or 0.05M NaCl solutions. A saturated calomel electrode and a large platinum sheet were used as reference andcounterelectrode,respectively.Theelectrochemicalcellwas opentoairandwas keptatroomtemperaturewithanaverage valueof17 Cwhichmayhaveundergonefluctuationsby!2 C. Electrochemicalimpedancemeasurementswerecarriedoutusing aBiologicVSPapparatus.Theimpedancediagramswereobtained, forexposuretimesrangingfrom2to504h,underpotentiostatic conditions,atthecorrosionpotential,overa frequencyrangeof 65kHzto1Hzwith8pointsperdecade,usinga30mV peak-to-peaksinusoidalvoltageperturbation.Toconfirmconsistencywith theKramers–Kronig relations,themeasurement modelanalysis describedbyAgarwaletal.[12–14]wasused.Alldatawerefound to satisfy the Kramers–Kronig relations. A relatively good reproducibilityof theresultswas observedinthepresentwork andtheresultsshownforasinglecoatingweretypicalofother nominally identical coatings. Nevertheless,as observed by Tait

[15],variabilityisobservedforindustrialcoatings.Theconcepts

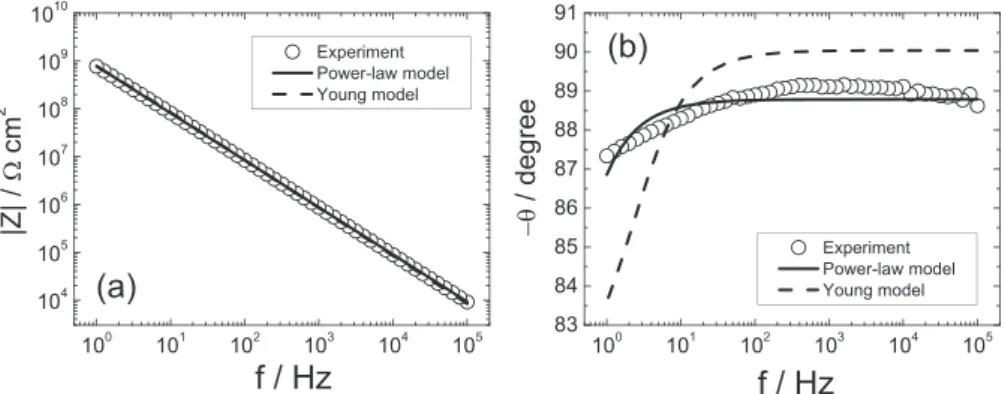

Fig.1.Theimpedancemodulus(a)andphaseangle(b)obtainedforthedrycoating(21mmthick)asfunctionsoffrequency.Theexperimentaldata(o)arecomparedwiththe regressionresults:power-lawmodel,Eq.(2)(solidline)andYoungmodel,Eq.(5)(dashedline).

developedinthepresentworkmaybeusedtofacilitatearefined statisticalanalysisofcoatings.

The impedance data analysis was performed using a non-commercial softwaredeveloped at the LISECNRS, Paris,which allowsthecomparisonoftheexperimentaldiagramswiththose calculated using a combination of passivecircuitelements and analyticalexpressions.

3.ResultsandDiscussion

3.1.Analysisoftheimpedancedataforthedrycoating

The experimental impedance diagram (Bode coordinates) obtainedforthedrycoatingis presentedinFig.1.Thediagram is characterized by a single time constant attributed to the dielectricpropertiesofthecoating,andisveryclosetoanideal capacitivebehaviour.Iftheexperimentaldataobtainedinthe1– 105Hz frequency range are analysed in terms of a parallel combination ofcoating resistance(Rc)and capacitance(Cc), the

bestfittedRcandCcvaluesare1.11010

V

cm2and1.910"10Fcm"2,andthecoatingpermittivity,calculatedas

e

c¼Ccde

0A (1)is

e

c=4.5. However,theseCcande

cvalues arenotfullyreliable.Indeed,inspectionofthephaseangle(

u

)plotshowsthatu

was lower than 90, the value expected for an ideally capacitive response, and varied slightly, between 87 and 89 in a wide frequencyrange.Therefore,todeterminethesephysicalquantities, thepower-lawmodel,knowntocorrespondtoaCPEbehaviour, wasregressedtotheimpedancedata,usingthefollowingformula[3] Zð

v

Þ¼gdr

ð1"aÞ d ðr

"1 c þjve

ce

0Þa (2)where

r

disthecoatingresistivityatthecoating/solutioninterface and gisanumericalcoefficientthathasavalueverycloseto1 whena

is close to 1 [3]. The best-fitted curve, shown as a continuous linein Fig.1, provides a good agreementbetween model and data. The expanded phase angle scale in Fig. 1b emphasizes the minor discrepancy. The regression procedure providednumericalvaluesoftheadjustableparametersa

,e

c,rc

and

r

d,reportedinTable1.Fig.1balsoshowsthatapplicationofa Young model, described in a subsequent section, yielded an inadequatefittothedata.Theresistivityprofileinthedrycoating,showninFig.2,was calculatedaccordingto[3]

r

r

d ¼r

dr

c þ 1"r

dr

c !j

g " #"1 (3) usingtherc

andr

dvaluesinTable1andthepower-lawexponentg

calculatedfromtheCPEexponenta

[3]asg

¼ 11"

a

(4)InEq.(3),

j

¼x=d

isthedimensionlesspositionalongthecoating thickness,measuredfromthemetal/coatinginterface.InFig.2,it canbeseenthat,throughoutmostofthecoatingthickness,theresistivityhasaconstantvalueof1.01013

V

cm,henceforthusedas

rc

value,i.e.asresistivityofthedrycoatingmaterial.Inathin layerofthecoating,ca.1m

mthick,nexttothecoating/mercury interface,theresistivitydecreasesapproximatelybyafactorof10. Thisdecreasecouldbeduetoavariationofthecoatingproperties initsoutermostpartortosomepenetrationof mercuryin the defects and irregularities of the coating surface which were observedbySEM.Thefittedresistivityvalueof thedrycoating,rc

=1.01013V

cm, wasmuch higherthanthat assumedin our[1,2]andotherstudies[16],

rc

=21011V

cm,andwellabovethethresholdvalueatwhichitsincorrectestimatebecomes unimpor-tant[2].Thecoatingcapacity,calculatedaccordingtoEq.(1),was 2.010"10Fcm"2, 5.3% larger than the value obtained by

modelling the coating with a Rc//Cc parallel combination, and

the dielectric constant was 4.9, slightly larger than the value obtainedbyaRc//Ccparallelcombination.Table2summarizesthe

resistance,capacityandpermittivityvaluesobtainedbyanalysing theimpedanceresponseofthedrycoatingintermsofanRc//Cc

parallelcombination orwiththepower-lawmodel.Inthelatter case,thecoatingresistanceisgivenbythereallowfrequencylimit oftheimpedance[3].Thesimilarvaluesobtainedwiththetwo methodsshowthat thedry coatingbehaves almostasan ideal capacitor.

3.2.Evolutionofthecoatingbehaviouruponimmersioninthe electrolyte

Fig.3showsthevariationofthecorrosionpotential(Ecorr)of

coatedsamplesasafunctionoftheimmersiontimeineither0.5M or0.05MNaClsolution,between2and504h.Atimmersiontimes shorterthan2h,Ecorrundergoesrapid,uncontrolledvariationsand

cannotbeaccuratelymeasuredduetothehighresistivityofthe coating,i.e.duetotheabsenceofadirectcontactbetweenmetal and electrolyte penetratedthrough the coating. After 2h, Ecorr

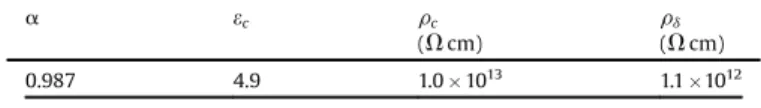

Table1

Best-fittedvaluesoftheadjustableparametersinEq.(2)obtainedbyregressingthe power-lawmodeltoexperimentaldataforthedrycoating.

a ec rc

(Vcm)

rd

(Vcm)

0.987 4.9 1.01013 1.11012

Fig.2.ResistivityasafunctionofdistancecalculatedaccordingtoEq.(3)forthedry coating.

Table2

Resistance,capacityandpermittivityvaluesobtainedbyanalysingtheimpedance responseofthedrycoatingintermsofRc//Ccparallelcombinationorwiththe

power-lawmodel. a Rc (Vcm2) Zf(0)a (Vcm2) Cc (Fcm"2) ec Rc//Cc 1 1.11010 – 1.910"10 4.5 Power-lawmodel 0.987 – 2.01010 2.010"10 4.9 aZ f(0)iscalculatedas:Zfð0Þ¼gdr ðg"1Þ=g d r 1=g 0 withg¼1þ2:88g"2:375 andg givenbyEq.(4).

becamemeasurable,andalmostidenticalforbothNaClsolutions. From2to20h,Ecorrprogressivelyshiftedtowardspositivevalues

(by ca. 0.1V, from its initial value). Then, after remaining essentiallyconstant from 20 to80h, Ecorrslowly declineduntil

theendofthetest,toreachasignificantlylowervalueinthemore concentratedNaClsolution.ThebehaviourshowninFig.3maybe rationalizedas follows: (i) Atthe beginning of immersion, the coatingisfreefromthroughporesthatwouldallowanimmediate contactbetween metaland electrolytic solution. (ii),thewater penetratesfastintothecoatingand a metal/solutioncontact is establishedafterca.2h,butNa+andCl–ionsdonotdiffuseatthe

samerate[17–23];therefore,theionscontentatthemetal/coating interfaceisduetostrontiumchromateincorporatedinthecoating. (iii)From2to24h,Ecorrincreasesduetotheoxidizingeffectof

chromates.(iv)Around24h,significantamountsofNa+orCl"ions

starttoreachthemetalandEcorrstopsincreasingbecausetheCl–

ionsinterferewiththepassivatingactionofchromates.(v)From 80h onwards, Ecorr undergoes a progressive decrease, more

pronouncedin themoreconcentrated NaClsolution.Theeffect of NaCl concentration on Ecorr becomes stronger at longer

immersiontimes,whenlargerquantitiesofCl–ionshavereached

themetal/coatinginterface.Independent measurementscarried outwithbareAA2024samplesshowedwell-definedstableEcorr

valuessoonafterexposure;after2himmersion,Ecorrwas"0.63V/

SCEand "0.52V/SCE in0.5Mand 0.05MNaCl,respectively, in qualitativeagreementwiththeEcorrdifferencesobservedinFig.3,

forlongimmersiontimes.TheEcorrvaluesaresignificantlymore

positiveforcoatedsamples,afterlongimmersion,thanforbare ones.

The impedance of the coated sample was measured after variousimmersiontimes,from2to504h,in0.5Mand0.05MNaCl solutions.ThecompleteBodeplotsarepresentedanddiscussedin thefollowingsection.Wefocushereontheevolutionofthephase angle, measured in the high frequency range (100Hz–65kHz), withtheimmersion time, shownin Fig.4a, for the0.5MNaCl solution.Twofactsareevident:(i)

u

isnotrigorouslyconstantbut becomesslightlysmallerfordecreasingfrequency,i.e.astrictCPE behaviour is not observed; (ii) theu

vs. frequency curves are progressivelydisplacedtowardsloweru

valuesastheimmersion time increases. Point (i) is discussed in the following section.Fig.4bpresentsaplotof

u

,measuredatanarbitraryfrequencyof 1kHz,asafunctionoftheimmersiontime(logarithmicscale).The phaseanglerelevanttothedrycoatingisindicatedonthefigure.It canbeseenthatthephaseanglemonotonicallydecreasesfrom89 to78 upon prolongingtheimmersion,withonlyminor differ-encesbetweenthe two NaClsolutions. Thedecrease ofu

withincreasingimmersiontimesprovesthattheprogressivedeparture fromaquasi-ideallycapacitiveresponseiscausedbytheingressof theelectrolyticsolutioninthecoating,inducingadistributionof itspropertiesalongitsthickness.

3.3.Analysisoftheimpedancedataforthewetcoating

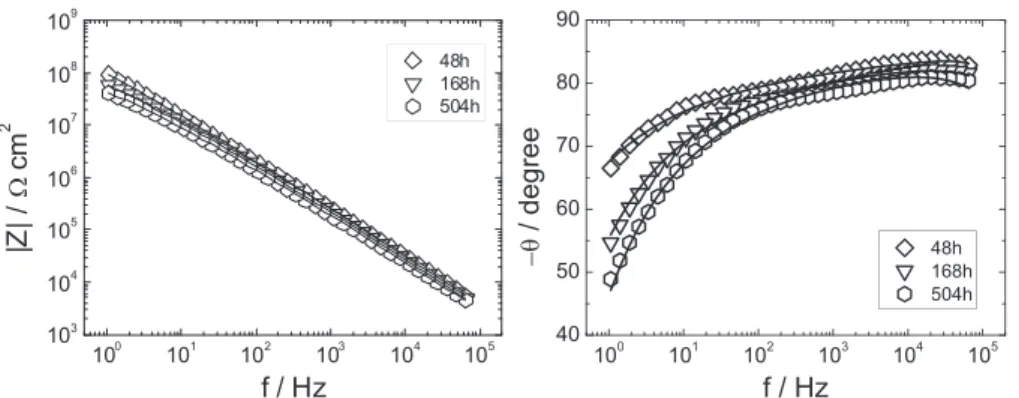

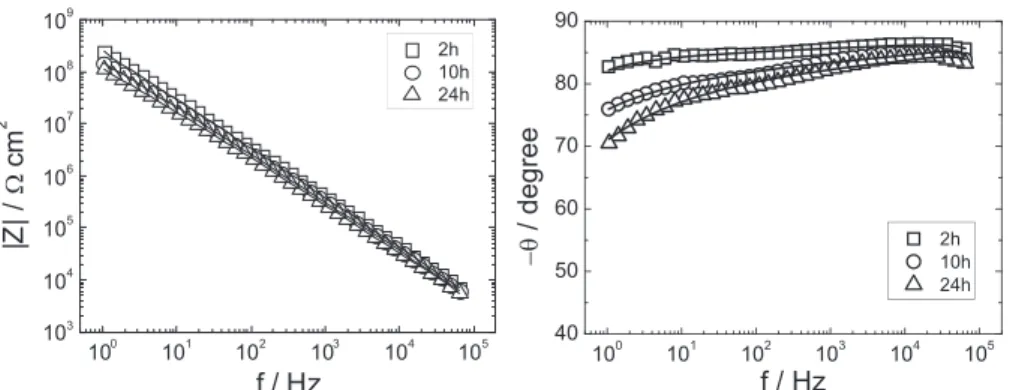

Inthissection,impedanceplotsarepresentedanddiscussed, starting fromthe longerimmersion times ('48h). Taking into account that the impedance diagrams undergo progressive, monotonicvariations,asanticipatedintheprevioussection,the data obtained at immersion times of 2 to 24h, are then analysedbyadoptingamodelthatcombinesthefeaturesofthe drycoatingandthoseofthewetcoatingafterlong immersion.

Fig. 5 presents the impedance diagrams (Bode coordinates) obtainedwiththecoatedsamplesfor immersion timesvarying from48to504h.Asmentionedabove,norealCPEbehaviouris observedandthereforetheanalysisoftheexperimentaldatawith the power-law model cannot yield a satisfactory agreement. Therefore,thedatawerecomparedwiththeYoungimpedance[8], whichmaybewritten

Z¼"

l

jve

we

0ln 1þjve

we

0r

0e"d=l 1þjve

we

0r

0 ! (5) and is knowntocorrespondtoan exponentialvariation of the coatingresistivityalongitsthickness,i.e.:Fig.3.Corrosionpotential(Ecorr)asafunctionofimmersiontimeforthecoated

AA2024samplesintwoNaClsolutions(concentrationsareindicatedonthefigure).

Fig.4. Phaseangle(highfrequencyrange)oftheimpedancefortheAA2024coated sampleina0.5MNaClsolution(a)andphaseanglevaluesmeasuredat1kHzas functionsofimmersiontimefortwoNaClsolutions(concentrationsareindicated onthefigure)(b).

r

ðxÞ¼r

0expð"x

l

Þ (6)In both Eqs. (5) and (6),

e

wandr0

respectively denote thepermittivityofthecoatingunder“wetconditions”andthecoating resistivityatthemetal/coatinginterface,whichmaybeequalor notto

e

candrc

,respectively,andtheparameterl

indicateshowsharply the resistivity changes with position (a larger

l

correspondstoasmootherresistivityprofile).

ByregressingEq.(5)totheexperimentaldata,thevaluesofthe adjustableparameters

l

,e

w,r0

wereobtained.TheyarereportedinTable3,togetherwith

r

dvaluescalculatedas:r

d¼r

0expð"d

l

Þ (7)The goodquality ofthe agreementbetweendataand model is shown by Fig. 5, where the best fitted curves are drawn as continuouslines.InspectionofTable3showsthat(i)

l

remains fairlyconstant,around1.5 10"4cm;(ii)thepermittivityofthewetcoating(

e

w)isabouttwicelargerthanthatofthedrycoatingfor 48h of immersion, and increases when the immersion is prolonged; (iii) at 48h immersion time,

r0

is close to, but somewhatlowerthanrc

,thenitprogressivelydecreases;(iv)ther

dvaluesareca.6ordersofmagnitudelowerthanther0

values,at eachimmersiontime.Fig. 6 presents the impedance diagrams (Bode coordinates) obtainedwiththecoatedsamples forimmersion timesvarying from2to24h.Takingintoaccounttheresistivityprofileofthedry coating (Fig. 2), as well as the fitted

r0

andr

dvalues at 48h immersion time and later (Table 3), it is hypothesizedthat for shortertimes(2–24h)thecoatingconsistsoftworegions:aninner region,nexttothemetal/coatinginterface,wheretheresistivityis thatofthedrycoating,andanouterregionwheretheresistivity varies exponentially with x. The permittivity is assumed tobe identical in both inner and outer layers, and independent of position.Thishypothesisimplieswatertobeuniformlydistributed along thecoatingthicknessandtheionstobenot.Assuminga uniformwaterdistributionisprobablyjustaroughapproximation.However, it has been shown that a moderate dependence of permittivityonpositionhasnegligibleeffectsonimpedance[3].

Two-layermodelswerealreadyconsideredbyseveralauthors

[20,24–26].Inthepresentstudy,theinner/outerlayerdistinction existsfromthepointofviewofresistivitybecauseNa+andCl–ions

aresupposedtobepresentintheouterlayerbutnotintheinner layer. Due to their penetration, the inner layer progressively disappears.Themodelforintermediateimmersiontimes(2–24h), is sketched in Fig. 7. Since the resistivity at x(d (where d represents the thickness of the inner part of the coating) is assumedidenticalto

rc

(i.e.1.01013V

cm),theimpedanceofthesystemisgivenby Z¼d

r

c ð1þjve

we

0r

cÞ"l

jve

we

0ln 1þjve

we

0r

ce"ðd"dÞ=l 1þjve

we

0r

c ! (8) wherethefirstandsecondtermsontherighthandsidearethe impedancesoftheinnerandouterlayersrespectively,connected inseries.By regressing Eq. (8) to the experimental data, the values reportedinTable4wereobtainedfortheadjustableparameters

l

,e

w,d.Thesametablealsoreportsr

dvalues,calculatedaccordingtoEq.(7).Thenumberofadjustableparametersisthesameasforthe longerimmersiontimes(Eq.(5)),sincetheresistivityatx=dneeds nottobeadjusted.Thegoodqualityoftheagreementbetweendata andmodelsketchedinFig.7isshownbyFig.6,wherethebest fittedcurvesareshownascontinuouslines.It istonotethat if Eq.(5)wereusedtoregressthe2–24himpedancedatainsteadof Eq.(8)thebestfittedvalueof

r0

wouldbemuchhigherthanrc

, whichhasnophysicalmeaning.Inspectionof Table 4 shows the following trends.(i) The

l

valuesincreasewithimmersiontimeandaresmallerthan,butof thesameorderas,thosemeasuredatimmersiontimes'48h.(ii) Thepermittivityofthecoating

e

wafter2himmersionisalreadysignificantlylargerthanthatofthedrycoating;thenitincreases slightlywithimmersiontime.(iii)Thethicknessoftheinner,more resistive part of the coating, decreases as immersion time increases,andbecomes almostcompletelynegligible at24h(it mustbepointedoutthattheexperimentaldataobtainedat24h immersion time may be equally well fitted with both short-immersionandlong-immersionmodels);(iv)

r

dvaluesundergo minorvariationswhentheimmersiontimeincreases.Thereisa substantial continuity in the variation of the parameters that appearinbothTables3and4,i.e.l

,e

wandr

d,withtheimmersiontime.

Fig.8 showsthe dependence of thecoating permittivity on immersiontime. The observedtrendsaresimilarfor both NaCl concentrations. However, in agreement with previous authors

[17,23],Fig.8showsthatpermittivityishigherin0.05Mthanin 0.5MNaCl.Thisresultmaysuggestthatwateruptakeishigherin Fig.5. ImpedanceresponseinBodeformatfortheAA2024coatedsampleobtainedafter48,168and504himmersionin0.5MNaClsolution(asindicatedonthefigure).The solidlinesarethebestfittedcurvescalculatedaccordingtoEq.(5).

Table3

Dependenceofthefittedparametersontheimmersiontimeina0.5MNaClsolution (longimmersiontimes–resistivityprofilesdescribedbytheYoungmodel).

Time (h) l (cm) ew r0 (Vcm) rda (Vcm) 48 1.4 10"4 10.6 7.1 1012 2.5 106 168 1.5 10"4 11.5 1.31012 1.3106 504 1.5 10"4 12.2 5.71011 5.7105 aCalculatedaccordingtoEq.(7).

the less concentrated NaCl solution, but may also reflect the decrease in the permittivity of NaCl solution with increasing concentration[27–29].Thewaterpartialvolume,estimatedfrom permittivity values,by using a linear combination formula [1],

wouldincreasefromca.4.5%at2htoca.9.7%at504h.Suchawater uptakewouldprobablycauseswellingofthecoating,butthiseffect wasneglected.

ThefittedparametersinTables3and4wereusedtocalculate the resistivity profiles shown in Fig. 9a. The resistivity was calculatedaccordingto 0<x(d

r

ðxÞ¼r

c d<x<dr

ðxÞ¼r

cexp "ðx"dÞl

! 8 < : (9)for immersion timesof 2 to24h, and accordingtoEq. (6),for immersiontimesof48to504h.Fig.9bshowsacomparisonofthe resistivityprofiles forthe twoNaCl concentrations,after 2and Fig.6. ImpedanceresponseinBodeformatfortheAA2024coatedsampleobtainedafter2,10and24himmersionin0.5MNaClsolution(asindicatedonthefigure).Thesolid linesarethebestfittedcurvescalculatedaccordingtoEq.(8).

Fig.7.Schematicrepresentationofthetwo-layermodel.Thecoatingisassumedto consistofaninnerlayerwithuniformresistivityr=rcandanouterlayerwithan

exponentialdependenceofresistivityonposition.

Table4

Dependenceofthefittedparametersontheimmersiontimeina0.5MNaClsolution (shortimmersiontimes: Innerregionwhere theresistivityis thatof thedry coating+outerregiondescribedbytheYoungmodel).

Time (h) l (cm) ew d (mm) rda (Vcm) 2 0.910"4 8.3 8.3 4.6106 10 1.2 10"4 9.5 3.0 4.3 106 24 1.4 10"4 10.2 0.6 3.4 106 aCalculatedaccordingtoEq.(7).

Fig.8.ThewetcoatingpermittivityasafunctionofimmersiontimeintheNaCl solutionsindicatedonthefigure.

Fig. 9.Coatingresistivity profiles inferred fromthe impedance analysis as a function ofposition: (a)withimmersion timein a0.5M NaCl solutionasa parameter;and(b)comparisonofthecoatingresistivityprofilesinthetwoNaCl concentrationsat2hand504hofimmersion.

504h. Minor differencesare observedand both sets of profiles suggestthesamephysicalphenomena:

-As described in Section 3.1, the dry coating has essentially homogeneouspropertiesalong itsthickness,withamoderate variation of resistivityonly in theoutermost, ca. 1

m

mthick layer. Therefore, its impedance is close to that of an ideal capacitor, although the power-law model accounts for the observedbehaviourmoreeffectively.-Uponimmersionintheelectrolyte,thecoatingstartstouptake waterand,moreslowly,ions.Itsresistivityintheregioncloseto thecoating/solutioninterfacesignificantlydropsinashorttime. Thesolutionuptakeoverridestheinitiallyexistingpower-law profileoftheresistivity,andcausesthedevelopmentofamuch morepronouncedexponentialprofile(sixordersofmagnitude insteadofone).Theevolutionoftheimpedanceresponse(e.g.,

Fig. 4b) reveals the increasing spatial heterogeneity of the coatingproperties.

-Alreadyafter2h,thecoatingpermittivitybecomesmuchhigher than thatof thedrycoating, suggestingthat wateruptake is extensiveoverthewholecoatingthickness,inagreementwith thefactthat,atsuchimmersiontime,Ecorrbecomesmeasurable.

However,duringthefirst24h,aninnerlayerofthecoating,as resistiveasthedrycoating,coexistswithanouterlayerwitha lower,position-dependentresistivity,becausethethicknessof thelayeraffectedbyNa+andCl–penetrationisnotaslargeasthe

wholecoatingthickness.Then,between24and48htheNa+and

Cl–ionsreachthemetal/coatinginterfaceandthethicknessof

theinnerlayerbecomeszero.Inthesameperiodoftime,the corrosionpotentialstopsincreasingandstartstomoveslowlyin thenegativedirection. Penetrationofionsisfaster whenthe coatingisexposedtothemoreconcentratedNaClsolution,as observed in Fig. 9b: for the same time, d is largerand the resistivityishigherwhenNaClconcentrationislower. -Atimmersiontimes'48h,afurtherwateruptakeisindicatedby

the minor increase in permittivity, and a more marked ion penetration by the continuous decrease of resistivity, at all positionsandnotablyatthemetal/coatinginterface.

-Evenafter504himmersion

r0

iscloseto1012V

cm2,avalueapttoensuregoodcorrosionprotection.

TheevolutionofbothimpedanceandEcorrwithimmersiontime

provides a coherentpicture of the phenomena occurringupon penetrationofwaterandionsintothecoatingmaterial.Sincethis pictureisnotthesameasthatproposedinourpreviouspapers

[1,2],somedifferencesdeserveacomment.

Thereare major differences in experimental systems,which haveastrongimpactontheresults.Thecoatingsstudiedin[1]and

[2]didnotcontainanypigment,whiletheonesdescribedinthe present paper are heavily loaded with inorganic fillers and pigments.Thesechemicalsmarkedlyenhancethecoating imped-ance. Due to the better barrier properties of the pigmented coatings, the analysis of their impedance does not require consideringafiniteresistanceof throughpores, inparallelwith thecoatingimpedance,atvariancewith[1,2].Sincethethicknesses andthecapacitiesofthedifferentcoatingsareofthesameorder, the response of thepigmented coatings is dominated by their capacityoveramuchlargerfrequencyrange,wheretheanalysisof thefrequencydependenceofthephaseangleallowsrecognizing evenaminordeparturefromastrictCPEbehaviour.This,inturn, allowstheassessmentofrelativemeritsofmodelsbasedoneither power-laworexponentialdependencesoftheresistivityonthe position along the coating thickness. However, power-law and exponential

r

(x)-xdependencesmustbeconsideredonlyassimple mathematical descriptions of physical situations which, in practice,maybemanifoldandmorecomplicated.Both Ecorr and impedance data in this work suggest that

penetrationofwaterandionsoccursondifferenttimescales.The formerprocessisfasterandaffectspermittivitymorestronglythan resistivity; the latter is slower and affects almost exclusively resistivity. Sucha decoupling of the effects of water and ionic penetrationdoesnotallowthecalculationoflocalresistivityand permittivity,using similareffectivemedium formulas,basedon thelocalpartialvolumeofsolutionwithinthecoating,asproposed in[1],andinpreviousworkbyothers[16].Inthemodelproposed in[1],theresistivityprofilewastheresultofavariation,alongthex axis,ofthepartialvolumeofasolutioncontainingionsata(not known)concentrationindependentofx.Inthepresentpaper,the resistivityprofileisdiscussedastheresultofaposition-dependent concentrationofionsinthewaterpresentwithinthecoatingata partial volume assumed independent of x. Again, the physical situationmayinvolvedistributionofboth waterpartialvolume (within thecoating) and ion concentrations(within thewater) alongthethickness.

4.Conclusions

The impedance of pigmented coatings deposited onto AA2024wasstudiedunderdryandwetconditions.Intheformer configuration,theoutercoatingsurfacewasputincontactwith mercury, in the latter with NaCl solutions. The dry coating behaviourwasclosetothatof acapacitorand didnotreveala significantdependence ofthecoatingresistivityontheposition alongitsthickness,exceptforsomevariationintheoutermost,ca. 1

m

m thick layer. The behaviour of wet coatings progressively departedfromthequasi-ideallycapacitiveresponse,provingthat penetration of water and ions caused the development of a resistivityprofilemuchmoremarkedthanthatobservedwiththe dry coatings. The frequency dependence of the phase angle suggestedtheresistivity-positiondependencetobeclosertoan exponential than to a power-law relationship. Impedance and corrosionpotentialvs.immersiontimedataconvergedtosuggest thatwaterpenetrationoccurredonashortertimescalethanionic penetration.Theresistivityprofilewasthereforeascribedmainly toagradientofthelocalionconcentrationinthewaterpenetrated withinthecoating.Acknowledgments

The authorsgratefully acknowledge thecompany MAPAERO (Pamiers,France)forthepreparationofthecoatedsamplesand moreparticularlyPaulineCôteandPierre-JeanLathièreforfruitful discussiononcoatingtechnologies.ThePhDthesisofNguyenAnh Sonispreparedintheframeworkoftheassociatedinternational laboratory“FunctionalCompositeMaterials(FOCOMAT)”between FranceandVietnam.

References

[1]S.Amand,M.Musiani,M.Orazem,N.Pébère,B.Tribollet,V.Vivier, Constant-Phase-ElementBehaviorCausedbyInhomogeneousWaterUptakein Anti-CorrosionCoatings,Electrochim.Acta87(2013)693–700.

[2]M.Musiani,M.Orazem,N.Pébère,B.Tribollet,V.Vivier,Determinationof ResistivityProfilesinAnti-CorrosionCoatingsfromConstant-Phase-Element Parameters,Prog.Org.Coat.77(2014)2076–2083.

[3]B.Hirschorn, M.E.Orazem,B. Tribollet, V.Vivier, I. Frateur,M.Musiani, Constant-Phase-Element Behavior Caused by Resistivity Distributions in Films:1.Theory,J.Electrochem.Soc.157(2010)C452–C457.

[4]M.Musiani,M.Orazem,N.Pébère,B.Tribollet,V.Vivier, Constant-Phase-Element Behavior Caused by Coupled Resistivity and Permittivity DistributionsinFilms,J.Electrochem.Soc.158(2011)C424–C428. [5]B.Hirschorn, M.E.Orazem,B. Tribollet, V.Vivier, I. Frateur,M.Musiani,

Constant-Phase-Element Behavior Caused by Resistivity Distributions in Films:2.Applications,J.Electrochem.Soc.157(2010)C458–C463. [6]M.E.Orazem,I.Frateur,B.Tribollet,V.Vivier,S.Marcelin,N.Pébère,A.L.Bunge,

Constant-Phase-Element(CPE)ImpedanceResponse,J.Electrochem.Soc.160 (2013)C215–C225.

[7]C.LePen,C.Lacabanne,N.Pébère,Characterisationofwater-basedcoatings byelectrochemicalimpedancespectroscopy,Prog.Org.Coat.46(2003) 77–83.

[8]L.Young,Anodicoxidefilms,AcademicPress,NewYork,1961.

[9]C.A.Schiller,W. Strunz,Theevaluationofexperimentaldielectricdataof barriercoatingsbymeansofdifferentmodels,Electrochim.Acta46(2001) 3619–3625.

[10]W.K.Asbeck,M.V.Loo,Criticalpigmentvolumerelationships,Industrialand EngineeringChemistry41(7)(1949)1470–1475.

[11]G.P.Bierwagen,CPVC(criticalpigmentvolumeconcentration)calculations,J. PaintTechnol.44(1972)46–55.

[12]P. Agarwal, M.E. Orazem, L.H. García-Rubio, Measurement Models for ElectrochemicalImpedanceSpectroscopy:1.DemonstrationofApplicability, J.Electrochem.Soc.139(1992)1917–1927.

[13]P.Agarwal,OscarD.Crisalle,M.E.Orazem,L.H.García-Rubio,Applicationof Measurement Models to Electrochemical Impedance Spectroscopy: 2. Determination of the Stochastic Contribution to the Error Structure, J. Electrochem.Soc.142(1995)4149–4158.

[14]P. Agarwal,M.E. Orazem,L.H. García-Rubio,Applicationof Measurement Models to Electrochemical Impedance Spectroscopy: 3. Evaluation of Consistencywith the Kramers–KronigRelations, J. Electrochem.Soc.142 (1995)4159–4168.

[15]W.S. Tait, Using electrochemical measurements to estimatecoating and polymerdurability,J.Coat.Technol.75(2003)45–50.

[16]B.R. Stafford,Electrochemical impedance spectroscopyresponseof water uptakeinorganiccoatingsbyfiniteelementmethods,Electrochim.Acta52 (2006)1339–1348.

[17]H.Leidheiser Jr.,D.J. Mills,W.Bilder, Thepermeabilityofpolybutadiene coatingtoions,waterandoxygen,in:M.W.Kendig,H.LeidheiserJr.(Eds.), Corrosionprotection by organiccoatings, Vol.87-2, TheElectrochemical SocietyInc.,Pennington,1987,pp.23–36.

[18]J.R.Scully,Electrochemicalimpedanceoforganic-coatedsteel:correlationof impedanceparameterswithlong-termcoatingdeterioration,J.Electrochem. Soc.136(1989)979–989.

[19]B.N.Popov,M.A.Alwahaibi, R.E.White,Usingelectrochemicalimpedance spectroscopyasatoolfororganiccoatingsolutesaturationmonitoring,J. Electrochem.Soc.140(1993)947–951.

[20]V.B.Miškovic-Stankovic,D.M.Dražic,M.J.Teodorovic,Electrolytepenetration throughepoxycoatingselectrodepositedonsteel,Corros.Sci.37(1995) 241–252.

[21]V.B. Miškovic-Stankovic, D.M. Dražic, Z. Ka9carevic-Popovic, The sorption characteristicsofepoxycoatingselectrodepositedonsteelduringexposureto differentcorrosiveagents,Corros.Sci38(1996)1513–1523.

[22]J.M.Hu,J.Q.Zhang,C.N.Cao,Determinationofwateruptakeanddiffusionof Cl– ion in epoxy primer on aluminum alloys in NaCl solution by

electrochemicalimpedancespectroscopy,Prog.Org.Coat.46(2003)273–279. [23]Q.Zhou,Y.Wang,ComparisonofclearcoatingdegradationinNaClsolution

andpurewater,Prog.Org.Coat.76(2013)1674–1682.

[24]U. Rammelt, G. Reinhard, Application of electrochemical impedance spectroscopy(EIS)forcharacterizingthecorrosion-protectiveperformance oforganiccoatingsonmetals,Prog.Org.Coat.21(1992)205–226. [25]B.R.Hinderliter,S.G.Croll,D.E.Tallman,Q.Su,G.P.Bierwagen,Interpretationof

EISdatafromacceleratedexposureofcoatedmetalsbasedonmodelingof coatingphysicalproperties,Electrochim.Acta51(2006)4505–4515. [26]G.Bouvet,D.D.Nguyen,S.Mallarino,S.Touzain,Analysisofthenon-ideal

capacitivebehaviourforhighimpedanceorganiccoatings,Prog.Org.Coat.77 (2014)2045–2053.

[27]W.Ellison,A.Balana,G.Delbos,K.Lamkaouchi,L.Eymard,C.Guillou,C.Prigent, Newpermittivitymeasurementsofseawater,RadioSci.33(1998)639–648. [28]X.Yang,K.Huang,Theempiricalformulaforcalculatingthecomplexeffective

permittivityofanaqueouselectrolytesolutionatmicrowavefrequency,IEEE Trans.Geosci.RemoteSens.43(2003)315–320.

[29]A.Peyman,C.Gabriel,E.H.Grant,Complexpermittivityofsodiumchloride solutionsatmicrowavefrequencies,Bioelectromagnetics28(2007)264–274.