Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Internal Report (National Research Council of Canada. Institute for Research in Construction), 1991-10

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=7b150425-b65a-4afb-ade6-3dd5e382963f https://publications-cnrc.canada.ca/fra/voir/objet/?id=7b150425-b65a-4afb-ade6-3dd5e382963f

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20358985

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Results of ISO surface flammability tests (ISO/CD 5658: Part I) conducted at the National Research Council of Canada

National Research Conseil national

11

Council Canada de recherches Canadanu. 615 institute for lnstitut de

Oc: tuber.. Research in recherche en

Construction construction

Results of IS0 Surface Flammability Tests

(ISO/CD 5658.. Pad 1) Conducted

d

the

~ational

Research council of Canada

by M.A Sultan and R.C. Monette CISTI/ICTST Y D P #,,, am+ Q n r ,.*. , .,.,-, N R C / C N R C

I n t e r n a l r e p o r t

Internal Report No. 615 Date of issue: October 1991

~ ~ t e r n a l r e p o r t ( I n s t i t u t e f

J-ANAL\<SE

This is an internal report of the lnstitute for Research in Construction. Although not intended for general distribution, it may be cited as a reference in other publications

Results of I S 0 Surface Flammability Tests (ISOICD 5658: Part 1)

Conducted a t the National Research Council of Canada

M.A. Sultan and R.C. Monette ABSTRACT

The IMO flame spread test apparatus was utilized to gain knowledge on the flammability behaviour of six combustible building materials when tested in accordance with the ISOICD 5658: Part 1 draft proposal. A brief description of the test apparatus, specimens and materials, as well as a summary of tests results, are provided. Detailed test results in accordance with the draft proposal data format are also included.

INTRODUCTION

The flame spread apparatus developed by the International Maritime Organization ( N O ) was commissioned at the National Fire Laboratory

(NFL)

of the National Research Council of Canada (NRCC) in 1983 and it was used in the IMO inter-laboratory flame spread tests on ship materials. In 1988, the IMO adopted a new flame spread test method, Resolution A 564 (14)' " fire test procedures for surface flammability of bulkhead and deck finish materials" which utilizes the IMO flame spread apparatus.In 1990, the American Society for Testing and Materials (ASTM) adopted two new flame spread test standards: one test for building materials designated ASTM E 1321-90 (LIFT methcd)2 "a standard test method for determining material ignition and flame spread properties" and one test for ship materials, similar to the IMO Resolution A 564 (14), designated ASTM E 1317-903 "standard test method for flammability of marine surface finishes".

Currently, the International Standards Organization (ISO) is considering both the IMO and the LIlT test methods for develovine two new standard tests for flame svread: one test has been proposed as the "ISOICD 56% Part 1 Fire Tests

-

Reaction toire

-

Surface Spread of Flame of Building Products-

Vertical Specimenw4. It is equivalent to the IMO test method, Resolution A 564 (14)1, 1988. The other test has been proposed as the "ISOICD 5658 Part 2 - Fire Tests-

Reaction to Fire-

Lateral Ignition and Flame Spread of Building Products"5. It is also equivalent to ASTM E 1321-90.The purpose of this repon is to present the results of the I S 0 inter-laboratory tests conducted at the NFL in accordance with the ISOICD 5658 Part 14 proposed method. The results of the inter-laboratory tests conducted in accordance with the ISOICD 5658 Part 25

proposed method will be presented in another report. APPARATUS DESCRIPTION

Fig.1 shows a vhotomavh of the test avvaratus. which com~rises two sevarate assemblies: the radia;~-~an$l kPpon assembiy'and the specimen kppon assembly. The

two assemblies are joined together in a manner which allows adjustments in the relative position of the radiant panel to the specimen to be made easily so as to yield a specific radiant distribution along the centre line of the s~ecimen. The angle between the s~ecimen

The radiant panel assembly consists of a gas-fired radiant panel, an air and fuel gas supply, air and fuel (natural gas) flow meter, fuel control valves, pressure reducer, safety controls and the radiant panel support frame. A gas-fued radiant panel consists of a radiating surface of porous refractory tiles mounted at the front of a stainless steel plenum chamber to provide a uniform radiating surface with dimensions of 480 mm by 280 mm. To increase the combustion efficiency, an Inconel 600 wire grid is mounted approximately

12 mm in front of the tile surface.

The specimen holder assembly consists of the specimen holder guides, stack, non- contacting pilot flame, flame front viewing rakes, radiation pyrometer, mirror, specimen holders and the specimen support frame. The non-contacting pilot flame, as shown in Figs. 2 and 3, was positioned vertically 10 mm from the surface at the hot end of the specimen for these tests.

The operating level of the radiant panel was monitored continuously during the tests by means of a wide angle radiation pyrometer.

A video camera was placed near the apparatus to allow test observations to be remotely monitored and recorded for later analysis.

SPECIMENS

Three specimens 155 mm by 800 mm were tested for each material.

Prior to insertion of the specimen into the specimen holder, the specimen was wrapped at its back and edges with a sheet of 0.2 mm thick aluminum foil to prevent the escape of pyrolysis gases at the edges and rear surface. When the specimen was inserted in the specimen holder, two 1 W mm thick non-combustible backing boards were placed at the back of the specimen and held in place by clamps. A line was marked on the specimen surface at mid-width over its full length. Observations of flame front progress along the specimen were made with reference to the points on that marked lime.

A11 specimens and backing boards were conditioned before testing at a temperature of 23+3OC and a relative humidity of 5(H5%.

CALIBRATION

The incident heat flux and pilot burner were calibrated according to the IS0 draft proposed method4. In calibrating the incident heat flux, two steps were taken. The first

was the mechanical alignment of the sample holder guide rails and the radiant panel to achieve the correct relative spacing and angle between them. The second step was the adjustment of the radiant panel fuel supply. The heat flux distribution was measured with the aid of a water-cooled flux meter. The required heat flux of 50.5 kW/m2 and

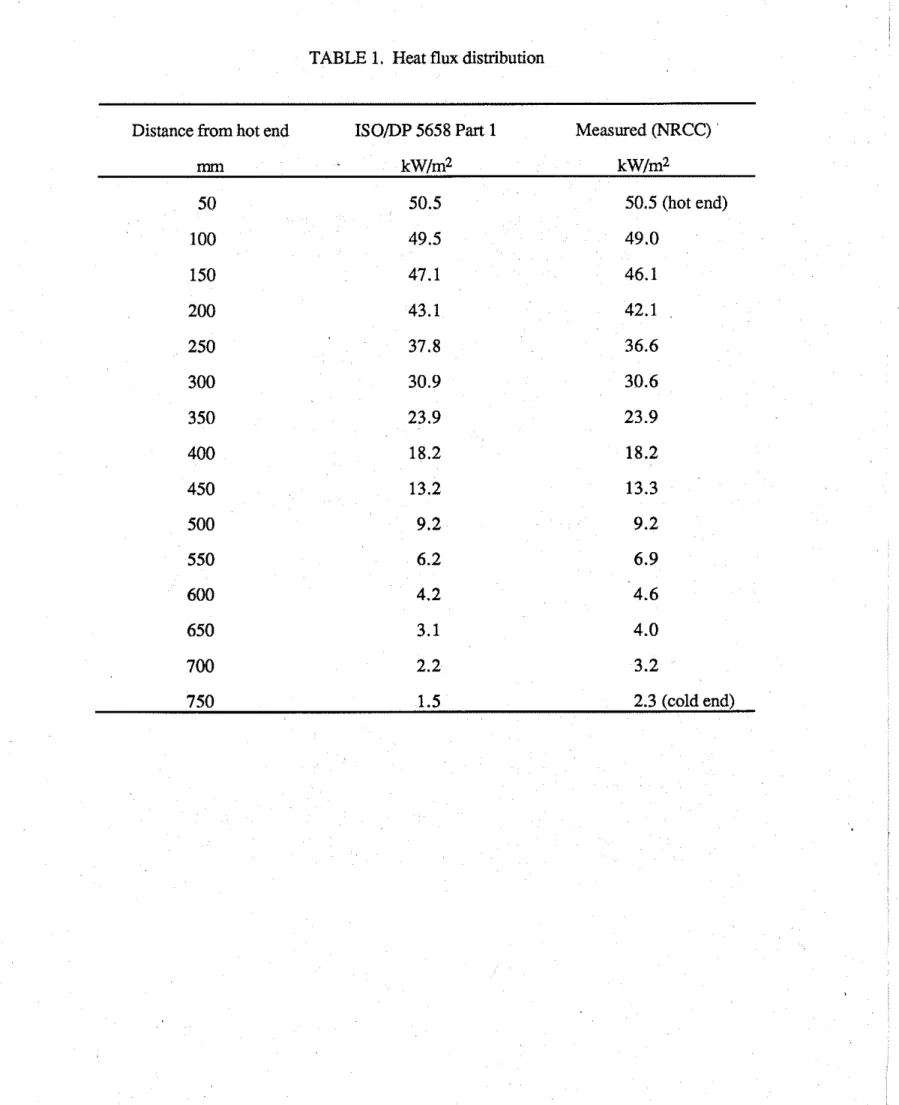

23.9 kW/m2 at the 50 mm and 350 mm points respectively was achieved. The measured heat flux levels at different points along the specimen and the corresponding values required by the I S 0 proposed method are given in Table 1 and are also shown in Fig. 4.

The pilot flame was adjusted to the required height and distance from the surface of a dummy board by means of softwood strips as described in Ref (4).

MATERIALS

Six different materials were tested in triplicate. Information on these materials is given in Table 2.

TEST METHOD

The tests were conducted in accordance with the ISOICD 5658: Part 1 proposed method4.

RESULTS

The results in full are presented in report form in Appendices A-F. Also, a summary of the test results is given in Table 3.

4 mm FR Plywood -The specimens ignited and the flame spread steadily. Falling debris was noticed when the flame front was at a distance of 300 mm to 350 mm from the hot end. For Specimens 1 , 2 and 3, the flame front extinguished at 530 mm and 249 s, 500 mm and 225 s and 470 mm and 146 s, respectively.

29 mm Cyanurate Foam with Aluminum Foil Facing

-

The specimens ignited but no flame spread was noticed.9.5 mm Paper Faced Plasterboard -The specimens ignited and the flame front proceeded slowly. For Specimens 1 , 2 and 3 respectively, the flame front extinguished at 380 mm and 144 s, 430 mm and 194 s and 410 mm and 189 s.

9 mm Birchfaced Plywood - The specimen charred and ignited and the flame front spread steadily. The flame front extinguished at 685 mm and 676 s, 715 mm and 886 s and 630 mm and 525 s for Specimens 1,2 and 3 respectively.

3 mm PMMA -The specimens ignited quickly and flame front spread steadily along the full length of all specimens. The tests were terminated at 1730 s, 1680 s and 1699 s for Specimens 1 , 2 and 3, respectively.

40 mm Expanded Polystyrene - The specimens ignited and the flame front spread slowly. Loud "pops" occurred just before and after the ignition of each specimen. The flame front extinguished at 555 mm and 895 s, 530 mm and 570 s and 500 mm and 696 s for Specimens 1 , 2 and 3, respectively.

REFERENCES

1. IMO A. 564 (14) - Revised recommendation on fire test procedures for surface flammability of bulkhead and deck finish materials, IMO, London, U.K., 1988.

2. ASTM E 1321-90 - Standard test method for determining material ignition and flame spread properties, ASTM, Philadelphia, PA, 1990.

3. ASTM E 1317-90 - Standard test method for flammability of marine surface finishes, ASTM, Philadelphia, PA, 1990.

4. ISOJCD 5658 Part 1 - Fire tests - reaction to fire - surface spread of flame of building products

-

vertical specimen, Document N 120, ISODC92/SCl/WG3, 1990.5. ISOICD 5658 Part 2

-

Fire Tests-

Reaction toFire

-

Lateral Ignition and Flame Spread of Building Products, ISO/TC92ISCl/WG3, Document N 156, March 1991.TABLE

1.Heat

flux distributionDistance from hot end ISO/DP 5658 Part 1 Measured (NRCC)

mm kW/m2 kW/m2

50 50.5 50.5 (hot end)

100 49.5 49.0

150 47.1 46.1

TABLE 2. Materials

Material # Description 1 4 mm

FR

Plywood 2 29 mm Cyanurate Foam3 9.5 mm Paper Faced Plasterboard 4 9 mm Birchfaced Plywood

5 3 mm PMMA

6 40 mm Expanded Polystyrene

TABLE 3. Summary of test results

Material # Average heat for Average Critical flux at sustained burning extinguishment

W / m 2 ) (kW/m2)

1 1.42 8.67

2 0.00 0.00

3 2.29 17.3

APPENDIX A

ROUND ROBIN FLAME SPREAD TEST TEST RESULT

Country/Laboratory: Canada/NRCC Date of measuring : 89-09-13 Ambiant Temperature (Oc) :

-

22SPECIMEN Name: 4

nun.

fr plywood Numbers:-

1BACKING PLATE Density (kg/m3)

:a

,

Thickness (mm):s

FUEL TYPE Radian Panel: Natural gas,

Pilot: Acetylene gas Application of pilot flame to the specimen: RemoteFLAME SPREAD DATA

Remarks

Time of ignition (s) 2 5

Flame Spread Distance (mm) Time (s)

50 2 6

250 28 Debris falling at 300 nun.

300 3 1 at 438 secs.

400 89 Debris falling at 350 nun.

450 142 at 272 secs.

Maximum Flame spread distance(mrn):a Critical irradiance (kw/mz) : 7

Duration of the test (s)

:%-

ROUND ROBIN FLAME SPREAD TEST TEST RESULT

Councry/;aboratory: Canada/NRCC Dace of measuring : 89-09-13 Ambiant Temperature (Oc) :

-

22SPECIMEN Name: 4 mm. fr plywood Numbers: 2

-

BACKING PLATE Density (kg/m3)

:=

,

Thickness (mm) :-

12 FUEL TYPE Radian Panel: Natural gas,

Pilot: Acetylene gas Application of pilot flame to the specimen: RemoteFLAME SPREAD DATA

Tine of ignition (s) 18

Flame Spread Discance (r.r.) Time ( s )

5 0 19 Remarks 250 32 Debris falling at 150 mm. 300 40 at 155 secs. - 350 - 62 400 95 Debris falling at 200 mm. 450 151 at 165 secs. 550 Debris falling at 300 mm. 600 at 200 secs. 700 750

Maximum Flame spread distance(mm)

:2

Critical irradiance (kwh2) : 8Duration of the test (s) :

-

225'-ROUND ROBIN FLAME SPREAD TEST TEST RESULT

Country/Laboratory: Canada/NRCC Date of measuring : 89-09-13 Ambiant Temperature (Oc) :

-

22SPECIMEN Name: 4 mm. fr plywood Numbers: - 3

BACKING PLATE ~ensity (kg/m3)

:z

,

Thickness (mm) :-

12 FUEL TYPE Radian Panel: Natural gas,

Pilot: Acetylene gas Application of pilot flame to the specimen: RemoteFLAME SPREAD DATA

Time of ignition (s) 23

Flame Spread Distance (mm) Time (s)

50 2 4 Remarks 200 2 6 250 27 Debris falling at 100 mm. 300 47 at 140 secs. 400 100 Debris falling at 150

mm.

450 146 at 149 secs. 700 750Maximum Flame spread distance(mm): 470 Critical irradiance (kw/m2) : 11

-

Duration of the test (s) : 180-APPENDIX B

ROUND ROBIN FLAME SPREAD TEST TEST RESULT

Country/Laboratory: Canada/NRCC Date of measuring : 90-01-12

Ambiant Temperature (Oc)

:a

Numbers:1

SPECIMEN Name:ISO cvanurate foam with aluminiumfoil facinq

BACKING PLATE ~ensity (kg/m3) :-7.2Q

,

Thickness (mm):x

FUEL TYPE Radian Panel: Natural sas,

Pilot: Acetvlene aas Application of pilot flame to the specimen: ImwinsinqFLAME SPREAD DATA

Remarks

Time of isnition (sf 0

Flame Swread Distance (mm) Time (s

50 :he sample burn from its

100 center to the top at 25mm.

150 but no flame spread.

200

250 Aluminium puff up from

- 300 foam up to 400mm.

Maximum Flame spread distance(mm)

:A

Critical irradiance (kw/m2):4

Duration of the test (s) :-&QQ

ROUND ROBIN FLAME SPREAD TEST TEST RESULT

Country/Laboratory: Canada/NRCC Date of measuring : 90-01-12

Ambiant Temperature (Oc) :% Numbers :_2

SPECIMEN Name:ISO cvanurate foam with aluminium foil facinq

BACKING PLATE Density (kg/m3)

:m

,

Thickness (mm):a

FUEL TYPE Radian Panel: Natural aas

,

Pilot: Acetvleneass

Application of pilot flame to the specimen: Imainainq FLAME SPREAD DATA

Remarks

Time of ianition (s) 0

Flame Saread Distance (mm) Time (s)

50 The sample burn from its

100 center to the top at 25mm.

150 but no flame spread.

200

250 Aluminium puff up from

300 foam up to 400mm.

350

Maximum Flame spread distance(mm) :J Critical irradiance (kw/m2)

:A

Duration of the test (s) :-@JQROUND ROBIN FLAME SPREAD TEST TEST RESULT

Country/Laboratory: Canada/NRCC Date of measuring : 90-01-12

Ambiant Temperature (Oc)

:x

Numbers:A

SPECIMEN Name:ISO cvanurate foam with aluminiumfoil facinq

BACKING PLATE ~ensity (kg/m3)

: m

,

Thickness (mm):x

FUEL TYPE Radian Panel: Natural sas

,

Pilot: Acetvlene sas Application of pilot flame to the specimen: Im~insingFLAME SPREAD DATA

Remarks

Time of isnition (s) 0

Flame Soread Distance

(mm)

Time (s)50 The sample burn from its

100 center to the top at 25mm.

150 but no flame spread.

200

250 Aluminium puff up from

300 foam up to 400mm.

700 750

Maximum Flame spread distance(mm):> Critical irradiance (kw/m2) : 4 Duration of the test (s) :-@,.Q

ROUND ROBIN FLAME SPREAD TEST TEST RESULT Country/Laboratory: Canada/NRCC Date of measuring : 89-12-14 Ambiant Temperature ('c)

:a

APPENDIX CSPECIMEN Name: 9.5 mm PVC faced lasterb board Numbers:J BACKING PLATE ~ensity (kg/m3)

:m

,

Thickness (mm):A

FUEL TYPE Radian Panel: Natural aas,

Pilot: Acetvlene aas Application of pilot flame to the specimen: RemoteFLAME SPREAD DATA

Remarks Time of iqnition (s) 4 0

Flame S ~ r e a d Distance (mm) Time (s)

5 0 4 0

100 41 Flame appear in the top

150 42 left corner at 18 secs.

Maximum Flame spread distance(mm):a Critical irradiance (kw/m2)

:a

Duration of the test ( s ):a

ROUND ROBIN FLAME SPREAD TEST TEST RESULT

Country/Laboratory: Canada/NRCC Date of measuring : 89-12-14 Ambiant Temperature (Oc)

:A

SPECIMEN Name: 9.5 mm ~ a o e r faced plasterboard Numbers:l BACKING PLATE Density (kg/m3) :-

,

Thickness (mm):a

FUEL TYPE Radian Panel: Natural Gas,

Pilot: Acetvlene aas Application of pilot flame to the specimen: RemoteFLAME SPREAD DATA

Time of iunition (s) 3 7 Flame Spread Distance (mm) Time (sL

50 3 7

Remarks

Maximum Flame spread d i s t a n c e ( m m ) : S Critical irradiance (kw/m2) : 14.9

Duration of the test (s)

:a

ROUND ROBIN FLAME SPREAD TEST TEST RESULT

Country/Laboratory: Canada/NRCC Date of measuring : 89-12-14 Ambiant Temperature (Oc)

:a

SPECIMEN Name: 9.5

mm

paper faced,~lasterboard Numbers:A BACKING PLATE Density (kg/m3):m

,

Thickness (mm): s

FUEL TYPE Radian Panel: Natural qas

,

Pilot: Acetylene aaq Application of pilot flame to the specimen: RemoteFLAME SPREAD DATA

Time of iqnition (s) 3 5

Flame Spread Distance (mm) Time (s)

50 35

Remarks

Maximum Flame spread distance(mm):a Critical irradiance (kw/m2)

:

1

7

.

0

Duration of the test ( s ):a

APPENDIX D

ROUND ROBIN FLAME SPREAD TEST TEST RESULT

Country/Laboratory: Canada/NRCC Date of measuring : 89-11-07 Ambiant Temperature (Oc) :

-

21SPECIMEN Name: 9 mm. Birch plywood Numbers:

-

1BACKING PLATE

ensi it^

(kg/m3):=

,

Thickness (mrn) :-

12FUEL TYPE ~ a d i a n Panel: Natural gas

,

Pilot: Acetylene gas Application of pilot flame to the specimen: RemoteFLAME SPREAD DATA

Remarks

Tine of ignition (s) 2 3

Flame Spread Distance (mn) Time ( s )

5 0 2 3

200 27 Debris falling at 200 mm.

250 32 at 510 secs.

Maximum Flame spread distance(mm) : 685 Critical irradiance (kw/m2) : 3.2 -

Duration of the test (s)

:zp

ROUND ROBIN FLAME SPREAD TEST TEST RESULT

Ambiant Temperature (Oc) : 21

SPECIMEN Name: 9 mm. Birch plywood Numbers: - 2

BACKING PLATE

ensi it^

(kg/m3) :=,

Thickness(mm)

:-

12 FUEL TYPE Radian Panel: Natural gas,

Pilot: Acetylene gas Application of pilot flame to the specimen: RemoteFLAME SPREAD DATA

Remarks Time of ignition (s) 3 2

Flame Spread Distance (mm) Time (s)

50 3 2

250 38 Debris falling at 250 mrn.

Maximum Flame spread distance(mm): 715 Critical irradiance (kwh2) : 2.6 -

Duration of the test (s)

:a-

ROUND ROBIN FLAME SPREAD TEST TEST RESULT

Councry/Laboracory: Canada/NRCC Dace of measuring : 89-11-07 Ambiant Temperature (Oc) :

-

2 1SPECIMEN Name: 9 mm. Birch plywood Numbers: - 3

BACKING PLATE

ensi it^

(kg/m3):=

,

Thickness (nun) :-

12 FUEL TYPE Radian Panel: Natural gas,

Pilot: Acetylene gas Application of pilot flame to the specimen: RemoteFLAME SPREAD DATA

Remarks Time of ignition (s) 26"

Flame Spread Distance (mm) Time (s)

5 0 2 6

200 28 Debris falling at 200 mm.

250 36 at 600 secs.

750

Maximum Flame spread distance(mm): 630 Critical irradiance (kw/m2) : 3.8

-

Duration of the test (s)

:x-

ISO/TC92/SCl/WG3

El

APPENDIXE

ROUND ROBIN FLAME SPREAD TEST TEST RESULT

Country/Laboratory: Canada/NRCC Date of measuring : 90-04-10 Ambiant Temperature (Oc)

:a

SPECIMEN Name: 3 mm PMMA Numbers:l

BACKING PLATE ~ensity (kg/m3) :-

,

Thickness(mm)

:x

FUEL TYPE Radian Panel: Natural sas

,

Pilot: Acetvlene uas Application of pilot flame to the specimen:^FLAME SPREAD DATA

Time of iunition ( s ) 3 2

Flame Soread Distance(rnm) Time (s)

50 3 2 Remarks 300 70 Dripping at 150 secs. 350 96 Dripping at 150 secs. 400 134 450 195 700 1316 750 1730

Maximum Flame spread distance(mm):750 Critical irradiance (kw/m2)

:

2

.

3

Duration of the test (s) : 1730

POUND ROBIN FLAME SPREAD TEST TEST RESULT

Country/Laboratory: Canada/NRCC Date of measuring : 90-04-10 Ambiant Temperature (Oc)

:a

SPECIMEN Name: 3 mm PMMA Nurnbers:J

BACKING PLATE

ensi it^

(kg/m3):720

,

Thickness (mm):a

FUEL TYPE Radian Panel: Natural oas

,

Pilot: Acetvlene aas Application of pilot flame to the specimen: RemoteFLAME SPREAD DATA

Time of isnition (s) 31

Flame Swread Distance (mm) Time (s)

50 32

Remarks

100 35

150 38 Melting and dripping

Maximum Flame spread distance(mm)

:a

Critical irradiance (kw/m2) :2.3

Duration of the test(s): 1680

ROUKD ROBIN FLAME SPREAD TEST TEST RESULT

Country/Laboratory: Canada/NRCC Date of measuring : 90-04-10 Ambiant Temperature (Oc)

:a

SPECIMEN Name: 3 mm PMMA Numbers:A

BACKING PLATE Density (kg/m3) :J.&3

,

Thickness (mm):X

FUEL TYPE Radian Panel: Natural aas

,

Pilot: Acetvlene sas Application of pilot flame to the specimen: RemoteFLAME SPREAD DATA

Remarks

Time of icrnition(s) 34

Flame S ~ r e a d Distance (mm) Time (s)

50 3 5

750 1699

Maximum Flame spread distanCe (mm) :-

Critical irradiance (kw/m2) :2.3

Duration of the test (s) :-

APPENDM F ROUND ROBIN FLAME SPREAD TEST

TEST RESULT Country/Laboratory: Canada/NRCC Date of measuring : 90-06-05 Ambiant Temperature (Oc) :

-

26SPECIMEN Name: 40 mm expended polystyrene Numbers: - 1 BACKING PLATE Density (kg/m3)

:a

,

Thickness (mm) : - 12 FUEL TYPE Radian Panel: Natural gas,

Pilot: Acetylene gas Application of pilot flame to the specimen: RemoteFLAME SPREAD DATA

Time of ignition ( s ) 165 Flame Spread Distance (mm) Time (s)

50 165

Remarks

200 165 Loud explosion from sam-

250 165 ple.0nce before ignition

300 165 once after ignition.

350 190

400 240 Majority of burning oc-

450 455 curs in molting plastic

500 660 pool collecting in spe-

550 895 cimen holder.

Maximum Flame spread distance(mm)

:=

Critical irradiance (kw/m2) : 6.5Duration of the test (s) :*-

ROUND ROBIN FLAME SPREAD TEST TEST RESULT

Country/Laboratory: Canada/NRCC Date of measuring : 90-06-05

Ambiant Temperature (Oc)

:z

SPECIMEN Name: 40 mm expended polystyrene Numbers:

-

2 BACKING PLATEensi it^

(kg/m3):x

,

Thickness (mrn) : 12 FUEL TYPE Radian Panel: Natural gas,

Pilot: Acetylene gas Application of pilot flame to the specimen: RemoteFLAME SPREAD DATA

Remarks

Time of ignition (s) 173

Flame Spread Distance (mm) Time ( s )

50 173

200 173 Loud explosion from sam-

-

250 173 ple.0nce before ignition

300 174 once after ignition.

400 305 Majority of burning oc-

450 356 curs in molting plastic

500 570 pool collecting in spe-

550 cimen holder.

650 700 750

Maximum Flame spread distance(mm):a Critical irradiance (kw/m2) : 7.5

Duration of the test (s)

:=-

ROUND ROBIN FLAME SPREAD TEST TEST RESULT

Country/Laboratory: Canada/NRCC Date of measuring : 90-06-05

Ambiant Temperature (Oc) :

-

2 6SPECIMEN Name: 40 mm expended polystyrene Numbers:

-

3BACKING PLATE Density (kg/m3) : 7 2 0

,

Thickness(mm)

:s

FUEL TYPE Radian Panel: Natural gas

,

Pilot: Acetylene gas Application of pilot flame to the specimen: RemoteFLAME SPREAD DATA

Remarks Time of igni~ion (s) 1 9 4

Flame Spread Distance (mm) Time (s)

50 1 9 4

1 9 5 Loud explosion from sam-

2 5 0 1 9 6 ple.0nce before ignition

3 0 0 1 9 8 once after ignition.

4 0 0 2 7 8 Majority of burning oc-

4 5 0 3 7 3 curs in molting plastic

5 0 0 6 9 6 pool collecting in spe-

5 5 0 cimen holder.

600 650

7 5 0

Maximum Flame spread distance(mm):a Critical irradiance (kw/m2) : 9.0

Duration of the test (s) :*-