Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Internal Report (National Research Council of Canada. Division of Building Research), 1960-07-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=a4c0fb75-c80e-4ce2-bc6a-6e384d9589fa https://publications-cnrc.canada.ca/fra/voir/objet/?id=a4c0fb75-c80e-4ce2-bc6a-6e384d9589fa

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20338192

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Air infiltration, surface temperature and condensation studies on two aluminum windows

NATIONAL RESEARCH COUNCIL CANADA

DIVISION OF BUILDING RESEARCH

AIR INFILTRATION, SURFACE TEMPERATURE9AND

CONDENSATION STUDIES ON TWO ALUMINUM WINDOWS by

E&S& Nowak and A&Go Wilson

Internal Report

No& 199

of the

Division of Building Research

OTTAWA July 1960

PREFACE

The Division is privileged to receive the co-operation of manufacturers in studying and reporting upon the performance of proprietary bUilding components when the information to be

gained is being sought for research purposes. A study of the

performance of window units is being carried out which of necessity

involves the examination of a variety of window designs. The

manufacturer in the case now reported offered samples of particular

ゥョエ・イ・ウセ since they had been designed to provide somewhat more

resistance to heat flow through the metal frames than is customary. These studies are continuing.

The authors are both mechanical engineers,

Mr.

Wilsonbeing Head of the Building Services Section of the Division;

Mr.

Nowak, formerly a Research Officer of that section is atpresent taking post-graduate studies at IUrdue University in the United States.

Ottawa

I II III

IV

V TABLE OF CONTENTSDesc+iption of Windows and Test Installation Air Infiltration Tests

Temperature Measurements Condensation Tests

Summary and Conclusions

Page 1 2 3 10 11

AIR infiltrationセ SURFACE teセセeratureセand

CONDENSATION STUDIES ON TWO ALUMINUM WINDOWS

by

This report covers laboratory measurements of

temperaturep condensation and air infiltration on manufactureris

demonstration samples of an aluminum double double-hung window and an aluminum casement window intended for residential or

commercial bUildingsc The frames of both consisted of two

aluminum sections separated by a wood spacer to eliminate

continuous metal paths from inside to outsideo The sash of the

casement window was Similarly 」ッョウエイオ」エ・、セ but with a

hard-board spacer. Special consideration is given to the adequacy

of these "thermal breaksll in terms of metal and glass surface エ・ュー・イ。エオイ・ウセ

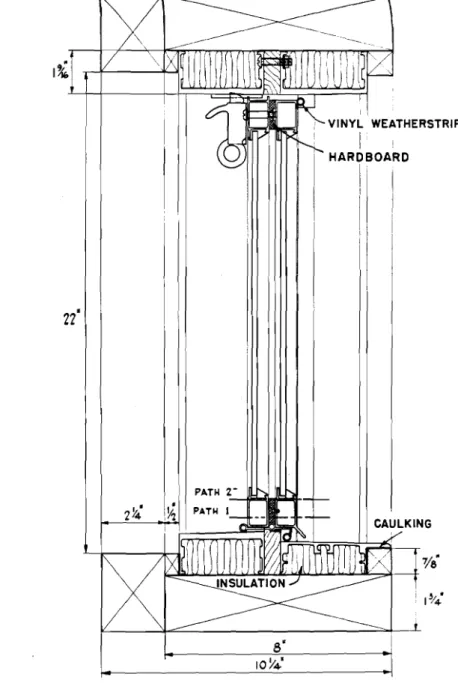

I. DESCRIPTION OF WINDOWS AND TEST INSTALLATION

The details of the two windows used in this study are given

in Figs. 1 and 2. The window frames of both consisted of two

aluminum sections separated by a 9/16=in. thick wood spacer.

The casement sash of the casement window consisted of two aluminum

sections separated by a QOTセゥョN thick hard=board spacer. The

spacers served as "thermal breaks"o

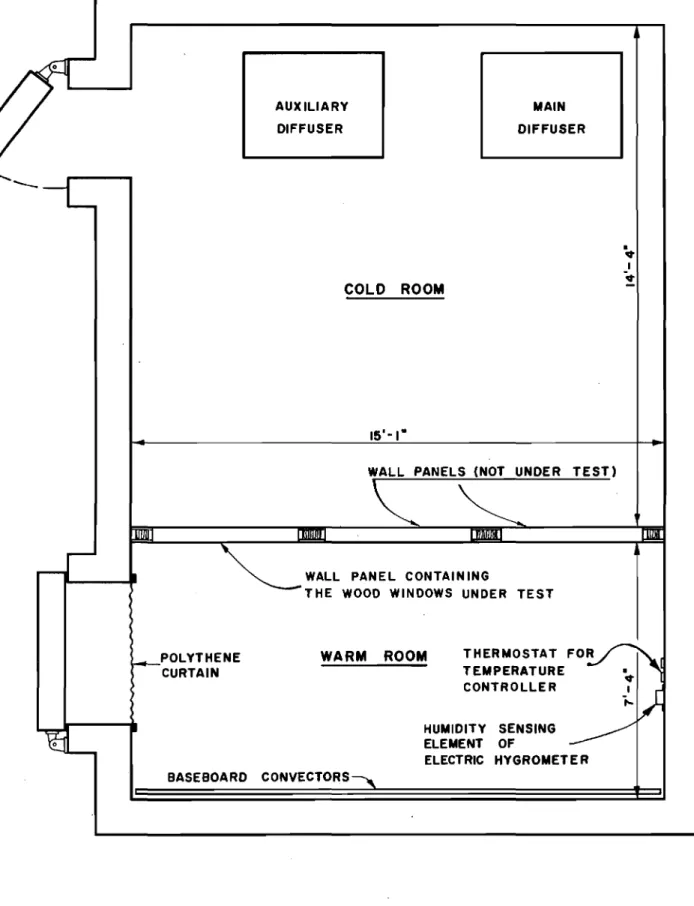

During all of the tests the windows were contained in a

Tセ by8=ft. insulated wood-frame wall panel installed in the

Building Services cold room. Details of the wall panel are

given in Fig.

3.

The details at the head and sills of the twowindows as installed in the wall panel are given in Figse 1 and 2,

Figure

4

shows the wall panel with respect to the testequipment in the, cold room. The wall panel formed part of

the partition which divided the cold room into large and small

compartments. In this report the large and small compartments

are termed cold room and warm room9 respectively< During the

temperature measurement and condensation tests9 temperature

and humidity conditions intended to simulate those found Lnsi.de

and outside of buildings were provided in the warm and cold イッッュウセ

respectively. .

The necessary cooling in the cold room was provided by

evaporation coils and the electric reheat elements. Air was circulated over the cOils and the reheaters by a fano . The air temperature variation at any point in the cold room did not

exceed ±Oc25 F degrees The ヲャッッイセエッM」・ゥャゥョァ air temperature

gradient did not exceed 1 degree, These conditions were ュ。ゥョセ

tained by the use of a modulating temperature controller which

regulated the electrical input into the reheaters with the refrigeration system operating continuouslyo

The cold room air moved in a downward direction over

the outer surfaces of the two windowsc The air velocity was

not uniform and was approximately 6 and

4

mph over the outersurfaces of the double 、ッオ「ャ・セィオョァ and casement キゥョ、ッキセ イ・ウー・」エゥカ・ャケセ

The warm room was heated by the gravity baseboard

convectors located approximately

9

ino from the floor o Theelectrical input to the convectors was regulated by a

temperature controller o The air temperature at a level of

Tセ ft from the floor in the centre of the warm room was ュ。ゥョセ

tained at 700F to within

±

1 degreeoA humidifying and a dehumidifying system operated by an electric hygrometer of the contact meter type maintained

the desired relative humidities in the room o Wet and dry

bulb temperatures were observed to within *0025 F degrees with an aspirating psychrometer at a point in the room near the

thermostat locationo The humidities9 determined from the

observations of wet and dry bulb temperatures9 were maintained

within

±

1 per cent oII AIR INFILTRATION TESTS

These tests were carried out to determine the over=all

air leakage characteristics of the two windows. The procedure

followed was to seal one side of the window into an air=tight compartment and either introduce or withdraw air at a rate such as to maintain a given pressure difference across the window o

The air conditions on both sides of the window were maintained

at approximately 72°F and 50 per cent relative humidity0

A calibrated variable area flowmeter measured the air

flow to or from the compartment to within 0.13 cfme The

pressure difference across the window was measured with a Betz micromanometer having a sensitivity of 0 0001 ino of water o

The air flow to or from the compartment was in excess of the air flow through the window by the amount of extraneous

セ 3 =

results reported here have been corrected for this. In

addition the results obtained under test conditions have been converted to air flow rates which would occur with air at a

standard density of 00075 pcf and an air temperature of 70oFo

The conversions obtained by test9 are based on the flow equations

for the window 0

The air leakage characteristics for the two windows are

given in Figo 5. The differences between the air flows obtained

with inside pressure greater than outside and the air flows obtained with inside pressure less than outside were small and

in most cases were within the limits of error. In view of エィゥウセ

a best line was drawn through the test results.

The air infiltration rates for the double double-hung and casement windows at a pressure difference equivalent to the dynamic head of a 25,-mph wind (0.301 ina of water) are 1.2

and 0 06 cfm per foot of sash 」イ。」ォセイ・ウー・」エゥカ・ャケN The Aluminum

Window Manufacturers Association in their specifications suggest a maximum air infiltration rate for double double-hung and

casement windows of 0.5 afm per foot of sash crack at a pressure difference corresponding to a 25-mph wind.

III TEMPERATURE MEASUREMENTS

The temperatures of the interior and exterior window

surfaces were measured at various inside-outside air temperature

differences. All of the temperatures were measured with B.S. NoD

30 gauge thermocouples in conjunction with a sensitive electronic indicator.

A vertical string of thermocouples installed in the centre of the warm room measured the variation in air temperature from

the ceiling to the flooro A second string of thermocouples

measured the variation in air temperature in the cold room o

The thermocouples used in the measurement of air temperatures were unshielded.

The interior and exterior aluminum surfaces were ゥョセ

strumented with thermocouples as shown in Figa 6(a)0 The twisted

soldered part formed the thermojunction and approximately ャセ

ina of the lead Wires were embedded in horizontal shallow slotsc

ilie thermocouples were held in direct contact with the aluminum surfaces by an adhesiveo

The interior and exterior glass surfaces were instrumented

wi th butrt-wel de d thermocouples shown in Fig. 6,(b). These

4

-a bl-ack pl-astic t-ape -and -att-ached to the exterior gl-ass

surfaces with cellulose tape. Cellulose tape was used because

of its better adherence at low temperatures.

During the first series of cold room tests the de-humidification system was operated continuously to minimize

surface condensation. The warm room relative humidity was

lowered from approximately 50 to 10 per cent in the course

of this test. There was no condensation on the interior

aluminum and glass surfaces during these temperature ュ・。ウオイ・セ

ments, although it occurred on the aluminum surfaces between the panes and on the inside surface of the outer pane at

the first cold room temperature of 20oP,

Tables 1 and 2 give the results of the temperature

measurements. lli.ere are appreciable differences between

the inside surface temperatures of the aluminum at the top

and bottom of the windows. These differences are particularly

notable for the frame of the double double-hung window and the sash of the casement window.

There was no significant variation in inside or outside air temperature over the height of the windows and the surface-to-surface thermal conductances of the components of both the frames and sash were the same at top and bottom. hッキ・カ・セ

there are other factors affecting the inside surface temperatures that might contribute to the differences observed between

top and bottom surfaces. One of these is relative resistance

to heat exchange at inside and outside surfaces which depends on the amount of exposed surface and the "film coefficientlt

,

this in turn depends on the orientation of the surfaces, their emissivities and the air velocity.

A second factor that would be expected to affect the inside surface temperature is lateral heat exchange between

the frame or sash and the surrounding construction. This

will depend on the thermal properties of the surrounding 」ッョセ

struction and on the location, relative to this construction9

of the thermal break in the frame or sash. In double windows

a peculiar lateral heat exchange condition is created if the frames or sash are exposed to the air space where convective action may lead to substantially lower air temperatures at

the bottom than at the top. Previous studies on a double wood

window 2 ft high with a 3/4-in. air space showed air temperature

differences between the top and bottom of the air space of 18v

27 and 43°P at cold room temperatures of 20, 0 and -30op. This

indicates that the lateral heat exchange between the sash or frame and the air space may be different at the bottom than at the top.

5

-TABLE 1

TEMPERATURE MEASUREMENTS ON CASEMENT WINDOW

THERMOCOUPLE LOCATION TEMPERATURE (OF)

Cold Room 38 20 0 -30

Interior Aluminum Surfaces

Window frame at centre of head 59 52 46 38

Window frame at mid height 58 52 44 34

Window frame at centre of sill 57 49 41 30

Centre of sash at top 56 48 4-1 30

Centre of sash at bottom 52 41 30 14

Exterior Aluminum Surfaces

Window frame at centre of head 42 26 9 -17

Window frame at mid height 42 25 8 -19

Glass Surfaces

Inside surface of inner pane at centre 60 53 47 39

Outside surface of outer pane at centre 43 27 11 -14

Warm Room Air Temperature

Distance from the floor (in. )

94

-

70 70 72 74-

70 70 71 54-

70 70 71 35-

69 68 69 15-

67 65 65 7-

66 64 626

-TABLE 2

TEMPERATURE MEASUREMENTS ON DOUBLE

DOUBLE-HUNG WINDOW

THERMOCOUPLE LOCATION TEMPERATURE (OF)

Cold Room

38

20

0

-30

Interior Aluminum Surfaces

Window frame at head

62

58

54

47

Window frame at mid height

59

53

46

36

Window frame at sill

53

43

32

17

Exterior Aluminum Surfaces

Window frame at head

43

29

14

-14

Glass Surfaces

Inside of inner panes at centre

60

54

48

40

Outside of outer panes at centre

41

25

8

-19

Warm Room Air Temperature Distance from the floor (in. )

94

-

70

70

72

74

-

70

70

71

54

-

70

70

71

35

-

69

68

69

15

-

67

65

65

.•7

-

66

64

62

7

-Attempts are sometimes made to predict inside surface

temperatures on the basis of simple heat flow theory. These

calculations ignore lateral heat exchange. Thus a comparison

of measured surface temperature and calculated temperatures may give some indication of the extent to which lateral heat exchange has affected surface temperatures.

Table

3

gives the results of such calculations, aswell as measured values of the inside surface temperatures for

purposes of comparison. It was assumed that the exposed surfaces

of the aluminum were at a uniform temperature and that the

surfaces of the aluminum in contact with the thermal breaks

were isothermal and at the same temperature. In these

cal-culations account was taken of the amount of'inside and ッオエセ

side exposed surface by increasing the appropriate film

coefficient in proportion to the ratio of exposed surface area to the cross-sectional area of the thermal break.

Inside film coefficients of 0.74, 0.37 and 0.91 Btu

per (sq ft) (hr)

(OF)

were taken for horizontal, downward andupward heat flow, respectively, with one exception. This was

for the horizontal surface of the sill of the casement window where the value of 0.74 for a vertical surface was used? since

the sill was swept by air moving down the vertical glass

sur-face.

An

outside film coefficient of3.3

was assumed basedon a surface emissivity of 0.05 and a wind velocity of

7t

mphQConductivities of 0.8 and 1.4 Btu per (hr) (sg ft)

(OF

per in,)were assumed for the wood and masonite spacers, respectivelyo All of these coefficients are based on data in the 1958 ASHAE

Guide. The conductivity of aluminum is about 1400 and for purpose

of calculation its thermal resistance is negligible. Both

windows were located at levels where the air temperature was

approximately 70°F and this value was used in the calculations0

The calculated surface temperatures at the head and sill for the frames of both windows given in Table 3 are in remarkable agreement with measured values, both as to absolute temperature and differences between top and bottom? even though lateral heat exchange between the frames and the air space was

ignored. It might be expected that the effect of lateral

heat exchange on the surface temperatures of the casement frame would be slight since it is not closely associated with the air

space. However, an appreciable area of the frame of the double

hung window is exposed directly to the window air space. Furthermore, more of the inside frame is exposed to the air space at the bottom than at the top, due to the position of the thermal break relative to the saSh, which would accentuate

TABLE 3

PREnICTED SURFACE tセセeratures BASED ON UNIFORM SURFACE tetィセeratures

I

DOUBLE DOUBLE-HUNG WINDOW CASEMENT WINDOW CASEMENT SASHFRAME

FRAME

loUTSIDE

tスセmj_ehaM TTcasured values Predicted Values Measured Values Predicted Values Measured Predicted

TURE of Temperature of Tempera tu re of Temperature of Temperature Values Values

(OF) at"the at the at the at the at the at the

Mid Mid Mid Mid

Top Ht Bot Top Ht Bot Top Ht Bot Top Ht Bot Top Bot Top Bot

38 62 59 53 59 50 53 59

58-

57 58 57 57 56 52 50 4920 58 53 43 53 39 43 52 52 49 51 49 50 48 41 38 38

0 54 46 32 46 27 32 46 44 41 44 41 42 41 30 25 25

-30 47 36 17 35 10 15 38 34 30 32 29 30 30 14 6 5

TABLE 4

PREDICTED SURFACE TEMPERATURES BASED- ON- ONE DIMENSIONAL HEAT FLOW

CASEMENT SASH bUTSIDE TEMPERATURE (OF)

Predicted Temperatures (OF) Measured Temperatures (OF) for Path 1 at the

Path 1 Path 2 Top Bottom

38 59 47 56 52

i

20 52 34 48 41 0 45I

20 41 30 -30 5 2 30 14 IセMM

I

r-·-" " J9

-The good agreement obtained for calculated and measured values of frame temperatures was perhaps partly fortuitous. Comparison of calculated and measured surface temperatures for the casement sash indicates very poor agreement, both

in absolute values and temperature differences. Calculated

values are much lower and temperature differences between top

and bottom less than were measured. The reasons for this are

not apparent. For example9 the conductivity of thermal break

would have to be approximately 0.25, instead of 1.4 as assumed, to provide reasonable agreement with the average of temperatures

measured top and bottomo One possible factor is the thermal

connection between sash and frame through the hinges at the

bottom and the latch at the topo However, this would not explain

the differences in measured surface temperatures at top and

bottom. It seems probable that lateral heat exchange to the

air space is more important in this connection than is suggested by the results of the calculations for the frame of the double

double-hung window.

Another method which is commonly employed in the calculation of surface temperature assumes one-dimensional

heat flow through the various paths, that ゥウセョッ heat flow

between adjacent paths. Thus surface temperatures can be

calculated for each of the paths. It is evident from Figs o

1 and 2 that the paths of heat flow through the head and sill

of the frames of the two windows are highly complex. Therefore

no attempt was made to calculate surface temperatures for the

various paths through the frames of the two windows. On the

other hand there are two distinct paths of heat flow through

the sections of the casement sash. Table 4 gives the calculated

values of temperature for the two paths, along with the values of temperature which were measured at the top and bottom of the

casement sasho

In actual fact there is heat flow between the adjacent

paths and, since aluminum has a high thermal conductance, the

inside surface temperature of the sash will be essentially uniform. It would be expected that this uniform temperature would be

closer to the temperature predicted for path 2 than for path ャセ .

but this is not the case,

The foregoing comparison of calculated and measured surface temperatures indicates the need for a more thorough study of

the thermal performance of metal window sash and frames, ゥョ」ッイセ

porating thermal breakso The studies should be designed so that

the relative effects of the various factors influencing the surface

temperatures can be determined" In this connection electrical

models using conducting paper or other suitable membrane material might have some application, particularly in studying the ゥューッイエセ

10

-IV CONDENSATION TESTS

It was stated previously, in connection with the

temperatures given in Tables 1 and 2, that there were appreciable variations in surface temperatures from top to bottom of the

frames of both windows. As a result of these variations, 」ッョセ

densation will first occur·on the lower portions of the windowso For example, based on measured surface temperatures condensation will occur on the sill of the double double-hung window at an

inside relative humidity of 24 per cent and on the head at an

inside relative humidity of 57 per cent with an outside temperature

of OOF.

The factors affecting window surface temperatures have

already been discussedo Ideally the resistance of the frame or

sash to heat flow should be such that the frame or sash surface temperatures are not less than the inside surface temperatures

of the glass o In the case of the test windows, glass temperatures

were only measured at the mid height. However, it can be seen

from Tables land 2 that the glass temperature exceeded the temperature at the mid height of the frames by about two and

five degrees at outside temperatures of 38 and セSPッfN Therefore

condensation will occur on the frames at slightly lower relative

humidities than on the glass. For example, at an outside

temperature of OOF condensation will appear on the frame of the double doub le- hung wi.ndow up to the mid height at a humidity of 42 per cent while it will appear on the glass up to the mid height at a humidity of 45 per cent,

In the case of the casement, sash temperatures were only

measured at the top and bottom. However, if as an approximation

the averages of the values of temperatures that were measured at the top and bottom are taken as the temperature at the mid height of the sash it becomes evident from Table 1 that the temperatures. at the mid height of the sash were probably substantially lower

than the glass temperature. For example, at an outside temperature

of OOF the temperature at the mid height of the sash is about

eleven degrees lower than the glass temperature at the same levele Therefore condensation may appear on the sash up to the mid

height at an inside humidity as low as 29 per cent while it will only occur on the glass up to the mid height at an inside humidity of

44 per cent.

This was generally borne out by observations of the extent of condensation on the interior surfaces of the double double-hung and casement windows under different sets of warm

room セ cold room conditions. Observations were made with one

level of relative humidity in the warm room at cold room

11

-room at cold -room temperatures of 0 and -20oF. The lower values

of relative humidity were chosen so as to just cause condensation to form on the interior window surfaces.

Tables 5 and 6 give the test conditions and extent of

condensation on the interior surfaces of the two windows.

Con-densation on the glass surfaces always appeared first at the

bottom and occurred in uniform bands. Condensation always

occurred on the frame of the double hung window and on the sash of the casement window before appearing on the corresponding glass

surfaces. However, it appeared on the glass surface of the

casement window before it appeared on the frame. Temperature

measurements indicated that glass and frame temperatures of the casement window were approximately equal at mid height during the condensation tests"

Figures

7

and 8 are photographs which show the extentof condensation on the inside surfaces of the outer panes of

the double double hung and casement windowso It is evident that

a considerable amount of frost had accumulated on the outer panes of the double double-hung window during the course of the

con-densation tests.

On

the other handg there was littleff anyfrost accumulation on the outer pane of the casement window. Measurements of air pressure differences across the

partition (Figo 4) indicated that the casement window was located

at a level where inflow of air from the cold room to the warm room occurred while the double double-hung window was in a region

where outflow of air from the warm to the cold room occurredo

The pressure differences were set up as a result of the differences

in density of the cold room and warm room air. The flow of air

from the warm room to the air space of the double double-hung

window had a ィオュゥセゥョァ effect on the spaceg while the flow of

air from the cold room to the air space of the casement window had a dehumidifying effect on the space.

The direction of air flow in an actual installation will depend on the location of the window with respect to the building

neutral zone (ioeo the level at which inside pressure equals ッオGエセ

12

-TABLE 5

CONDENSATION ON INTERIOR SURFACES OF DOUBLE DOUBLE-HUNG WINDOW

COLD ROOM HUMIDITY IN EXTENT OF CONDENSATION

J

TEMPERATURE WARM ROOM

(OF) dRH Dew pt (OF) Frame Inside Surface

1°

of Inner Panes

_.

20 46 48.5 Moisture on l-h- inoc:

sill

0 30 37.5 Ice on sill 2 in.

0 380 5 44.5 Moisture on sill Bottom half

and extending

!

way up sides-20 20 27.5 Frost on sill

--20 30 37.5 Ice and frost on Bottom half

sill, moisture

extending

!

way13

-TABLE 6

CONDENSATION ON INTERIOR SURFACES OF CASEMENT WINDOW

COLD ROOM

TEMPERATURE WARJ:.'I ROOK EXTElT':r Oiil JOlTJJEITSA'I'ICil"

(OF)

;bI-lli

Dew Pt (OF) Frame Sash Inside Surfaceof Inner Pane

20

46

48.5

none All over ャセM ino0

30

37.5

none Bottom 2 inahalf

0

3805

44.5

none All over Bottom half-20

20

27.5

none Frost on Iino

"2

bottom half

-20

30

37.5

Ice Ice and Bottom halfon frost on

sill bottom of

14

-v

SUMMARY AND CONCLUSION1) The air infiltration rates for the double double-hung

and casement windows were 10 2 and 0,6 cfm per foot of sash crack,

respectivelY1 at a pressure difference eqUivalent to the velocity

head of a 25-mph wind. This can be compared to the maximum

allowable air infiltration rate for these types of windows of 00 5

cfm per foot of sash crack given in the Specificiation of the Aluminum Window Manufacturers Association.

2) There were substantial vertical variations in the

surface temperatures of the frame of the double double hung window

and the sash of the casement window. There were smaller vertical

variations in the surface temperatures of the frame of the casement

window. It is not clear to what extent the frame and sash

tempera-ture variations were due to differences in the amount of inside and outside exposed surface area as compared to lateral heat exchange with surrounding construction, particularly the window air spaceo A more comprehensive study of the relative effects of lateral heat exchange, the ratio of inside and outside exposed areas and the location of the thermal breaks is suggested.

3) As a criterion of the thermal performance for metal frames or sash it is suggested that the inside surface temperature of

the metal should at no point be lower than the minimum surface temperature of the inner pane.

4) The 9Jl6-in. wood spacer as used in the frames of both windows resulted in inside frame surface temperatures equal to

or slightly lower than the corresponding glass surface temperatures0

In terms of the criterion suggested in Noo3 above, 'the "thermal

breaklt provided by the 9/16-in. wood spacer might be regarded as

borderline0 The 1/4-in. hard-board spacer in the sash of the

casement window resulted in inside sash surface temperatures

substantially less than the corresponding glass surface temperatures and might therefore be regarded as inadequate as a "thermal break"o

In view of these results it would appear that many of the "thermal

breaklt arrangements presently being used in'metal windows are

HEAD SILL 8'I,' WEATHERSTRIP I III '" "

.

.," I I VINYL⦅Nセ

t--" ·1 Z'4' I'l' .• • I ·-I.I_----_=---..::!....- ..-{•

ICAL! (llIC... I. HORIZONTAL SECTION o VERTICAL SECTION FIGURE I7/8"

セ セ MセMMMMMMMMMMMMMセセセZMMMMMMMMMMMMMMMセ

IJ/

iI I

I I jMセ

セMM

A.-"-___ '

I-<L-.J ....do- セ!

'0/ - セ セ I :

"'t

!

(.i Il I I I+

セ

I.

• I I I I 1 I ! I I I/

!

1 : I I I I JI-_--LJ- NlMjMMMェセ!

1 N⦅j⦅ャ「セセ[Zj[[[[[ャ[エZZ]]]]]]]]]]]]]]]]]V[ャ[[[[[[[ャ[[[[[[[ャ[[[[[[[j[[[Ql⦅ャMMMj I I I I I I1/----:---,

iセ 22' I , VINYL WEATHERSTRIP I HARDBOARD Ii !I

I i 8' IOY4'FIGURE

2

DETAILS

OF THE

CASEMENT

WINDOW

SECTION A-A 2". 8" FRAMING---<-t

Iii' PLYWOOD

'14' MASONITE----!F-"'l 2 INCH "FIBRE GLAS"

BATT INSULATION.

r-f>

A I ! I IV

...

セ»>

19" '..

.;;: CD..,

; . ' , .'. セ..

I .... Gl .. ..'..: '. : '. .' 23-1/4' "....J::...

...

:::\1

- ,".セZZZ セ .::' .::\:.... 49- 3/4' セaWALL PANEL WITH MASONITE REMOVED

FIGURE 3

AUXILIARY DIFFUSER COLD ROOM MAIN DIFFUSER •

•

I..

lt1

-•

;--POLYTHENE CURTAINWALL PANELS (NOT UNDER TEST)

セセ

WARM ROOM THERMOSTAT foセゥG|A

TEMPERATURE • CONTROLLER セI HUMIDITY SENSING セ ELEMENT OF »-> ELECTRIC HYGROMET E R BASEBOARD CONVECTORS,

FIGURE 4

PLAN OF COLD ROOM

4-DOUBLE DOUBLE HUNG WINDOW CASEMENT WINDOW LEGEND 0-0

.-.

0·2 0-4 0-6o-s

1-0 1-2 1-4 1-6r-a

2-0 AIR INFILTRATION RATE C_F.M_ PER FOOT OF SASH PERIMETERen セ o c 0-300 z セ en en o 0:: o <X 0-200 セ o z セ 0:: セ u, u, 0-100 c セ 0:: セ en en セ 0:: Q. u, o 0-400 z

i

0 - 5 00 __MNNセMMNセ

- -NLNNMセMMMイMMMMイMMMMイMMNNNNNMMNNL

0:: セ t-<X セFIGURE

5

AIR

INFILTRATION

CHARACTERISTICS

FOR THE CASEMENT AND DOUBLE

(COPPER) (CONSTANTAN) I It セ 8" 2·

FIGURE 6A

SURFACE THERMOCOUPLE FOR

.ALUM

INUM

FRAME

(COPPER) (CONSTANTAN) I I---

1-FIGURE 6 B

SURFACE THERMOCOUPLE FOR INNER AND

OUTER PANE

FIGURE 1 FROST ACCUMULATION ON INSIDE SURFACE OF THE OUTER PANE