Publisher’s version / Version de l'éditeur:

Solplan Review, 150, pp. 1-2, 2010-02-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Effect of wall energy retrofit on drying capability

Maref, W.; Armstrong, M. M.; Rousseau, M. Z.; Nicholls, M.; Lei, W.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC: https://nrc-publications.canada.ca/eng/view/object/?id=1db6cc94-0a86-4611-85ae-46312499ee6a https://publications-cnrc.canada.ca/fra/voir/objet/?id=1db6cc94-0a86-4611-85ae-46312499ee6a

http://www.nrc-cnrc.gc.ca/irc

Effe c t of w a ll e ne rgy re t rofit on drying c a pa bilit y

N R C C - 5 3 5 9 0

M a r e f , W . ; A r m s t r o n g , M . ; R o u s s e a u , M . Z . ; N i c h o l l s , M . ; L e i , W .

F e b r u a r y 2 0 1 0

A version of this document is published in / Une version de ce document se trouve dans: Solplan Review, (150), pp. 1-2, February 01, 2010

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d'auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d'identifier la source de l'information et, dans certains cas, d'interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

Effect of wall energy retrofits on drying capability

By Dr. Wahid MarefIn an article in Solplan in 2007, NRC-IRC reported on its new Ventilation and Wall Research House. This current article reports on research recently completed using the wall facility part of the house. The research examined the effect of two energy retrofit strategies on wall wetting and drying.

Test walls

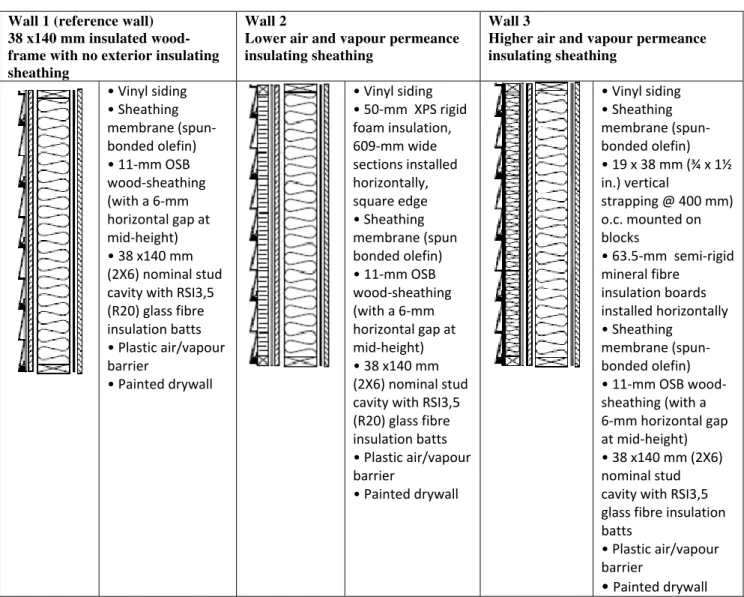

Three wall specimens were installed side-by-side into test bays. Wall 1 was the reference wall with nominal batt RSI of 3.5 (R20). Wall 2 was upgraded by installing 50 mm XPS rigid foam insulation to provide a wall nominal RSI of 5.25 (R30). Wall 3 was upgraded by RSI 1.76 (R10) by adding 63.5 mm semi-rigid mineral insulation boards installed horizontally (Table 1).

Table 1 Description of base wall and test walls Wall 1 (reference wall)

38 x140 mm insulated wood-frame with no exterior insulatin sheathing

g

Wall 2

Lower air and vapour permeance insulating sheathing

Wall 3

Higher air and vapour permeance insulating sheathing • Vinyl siding • Sheathing membrane (spun‐ bonded olefin) • 11‐mm OSB wood‐sheathing (with a 6‐mm horizontal gap at mid‐height) • 38 x140 mm (2X6) nominal stud cavity with RSI3,5 (R20) glass fibre insulation batts • Plastic air/vapour barrier • Painted drywall • Vinyl siding • 50‐mm XPS rigid foam insulation, 609‐mm wide sections installed horizontally, square edge • Sheathing membrane (spun bonded olefin) • 11‐mm OSB wood‐sheathing (with a 6‐mm horizontal gap at mid‐height) • 38 x140 mm (2X6) nominal stud cavity with RSI3,5 (R20) glass fibre insulation batts • Plastic air/vapour barrier • Painted drywall • Vinyl siding • Sheathing membrane (spun‐ bonded olefin) • 19 x 38 mm (¾ x 1½ in.) vertical strapping @ 400 mm) o.c. mounted on blocks • 63.5‐mm semi‐rigid mineral fibre insulation boards installed horizontally • Sheathing membrane (spun‐ bonded olefin) • 11‐mm OSB wood‐ sheathing (with a 6‐mm horizontal gap at mid‐height) • 38 x140 mm (2X6) nominal stud cavity with RSI3,5 glass fibre insulation batts • Plastic air/vapour barrier • Painted drywall

Test Conditions

The wall specimens were exposed to natural weather conditions on the exterior side, while temperature, relative humidity, and pressure conditions on the interior side were varied. The two retrofitted specimens (Walls 2 and 3) were challenged with high indoor relative

humidity and air pressure levels while construction deficiencies providing a path for air leakage were introduced. The reference test wall (Wall 1) was constructed with no controlled air leakage path.

Data were collected to examine the hygrothermal response of the test specimens at critical locations within the test assembly, over the Fall 2007 and Winter and Spring 2008. The performance of the two retrofitted test specimens was compared to that of the reference wall.

Results

The results showed that adding some thermal insulation to the exterior of an insulated stud cavity can contribute to reducing the duration of the potential for interstitial condensation, but

condensation can still take place during the coldest period of winter in a climate such as Ottawa. The study showed that necessary conditions for condensation are: cold exterior temperatures resulting in an interstitial surface temperature below the dew point of room air, an air leakage path through the wall assemblies, air pressure indoor higher than outdoor (air exfiltration drive) and indoor moisture load.

It was found that the air and vapour permeance properties of the insulation material positioned on the exterior of the stud cavity had some effect on the moisture transport and distribution across the wall assemblies. The XPS foam exhibited lower vapour and air permeance than the mineral fibre insulation and this difference in properties can explain the lower rate of moisture transmission through the XPS foam. Higher vapour pressure or absolute humidity differences were observed across layers with low air and vapour permeance.

For “reversed” moisture flow (summer conditions), the wall assembly with XPS exterior insulating sheathing exhibited a lower vapour permeance than the one with semi-rigid mineral fibre, reducing the rate of migration of exterior moisture inward towards the stud cavity materials.

Both wall assemblies with external thermal insulation experienced short-term wintertime

condensation wetting in the stud cavity when air exfiltration was present during sufficiently cold weather conditions; however, both wall assemblies dried out without any apparent stains or damage to the stud cavity materials.

The two assemblies with exterior insulation were less prone to interstitial condensation than similar walls without such exterior thermal insulation. The study showed that the addition of an exterior insulating sheathing raised the temperature of the stud cavity materials and could maintain them above the dew point of interior air, thus reducing the likelihood and duration of

interstitial condensation, within limits. When the outdoor climate got very cold, the benefit of the insulating sheathings on reducing the condensation potential was reduced.

Both retrofitted wall systems managed moisture appropriately but through different mechanisms in winter and summer, thereby showing the benefits of retrofitting wall systems with these exterior insulations.

For more information about the research, the wall test facility and partnership opportunities, visit the website http://www.nrc-cnrc.gc.ca/irc, or contact Dr. Wahid Maref (Wahid.maref@nrc-cnrc.gc.ca).

Dr. Wahid Maref is a Senior Research Officer in NRC-IRC’s Building Envelope and Structure program.